0% found this document useful (0 votes)

712 views1 pageASTM A105 Forging Test Certificate

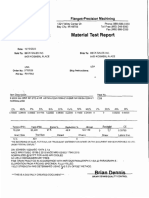

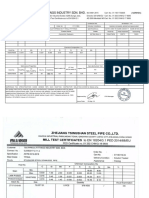

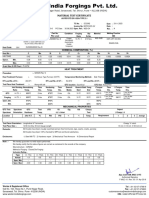

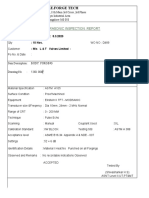

1. M.E. Forge Tech produced two open die forgings made of ASTM A105 steel for L&T Valves.

2. The forgings underwent non-destructive testing including ultrasonic and magnetic particle testing and were found to be satisfactory without defects.

3. The chemical analysis, mechanical properties, and microstructure of the forgings were tested and found to comply with specifications for material used in NACE MR0175/2015 and TDC 026 Rev. 10 applications.

Uploaded by

K.s. Raghavendra KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

712 views1 pageASTM A105 Forging Test Certificate

1. M.E. Forge Tech produced two open die forgings made of ASTM A105 steel for L&T Valves.

2. The forgings underwent non-destructive testing including ultrasonic and magnetic particle testing and were found to be satisfactory without defects.

3. The chemical analysis, mechanical properties, and microstructure of the forgings were tested and found to comply with specifications for material used in NACE MR0175/2015 and TDC 026 Rev. 10 applications.

Uploaded by

K.s. Raghavendra KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd