Professional Documents

Culture Documents

Tubacex-Prakash 10650T1 Qap

Uploaded by

rabiprasad.iispl.comletedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tubacex-Prakash 10650T1 Qap

Uploaded by

rabiprasad.iispl.comletedCopyright:

Available Formats

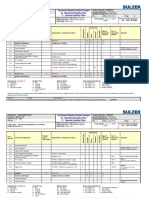

Quality Assurance Plan For Seamless U-Tubes

Tubacex Prakash India Pvt. Ltd.

131/1,Umbergaon-Sanjan Road,Umbergan.Gujarat.India-396 171 Document No. Rev. date Rev. No. Page No.

D/QCD/002 01.09.2015 0 01 of 02

ITP No. TPIPL /QAP/1549/0018 Rev- 00 Date: 26.03.2020

CUSTOMER NAME. M/s. E BACHILLER B.S.A.

PO No. 658150 DTD: 27.02.2020

SOC No. 1201549

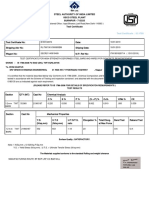

PRODUCT SPECIFICATION: ASME SEC. II PART-A (ED.2017) SA 789 ,SA 1016.

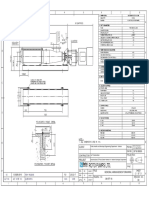

CUSTOMER DOCUMENT: U Tube Drawing- Provided by client, Material Purchase specification_SA-789 UNS S31803

PRODUCT DETAILS: COLD FINISHED SEAMLESS AUSTINETIC-FERRITIC STAINLESS STEEL U-TUBES GRADE: UNS S31803 SIZE: 19.05 MM OD X 2.11 & 2.41 MM (MW)THK X 6096 MM LEG LENGTH, QTY - 356 +10 NOS.

QUANTUM OF FORMAT OF SCOPE OF INSPECTION

SR NO. COMPONENTS CHARACTERISTICS CLASS TYPE OF CHECK REFERANCE DOCUMENT ACCEPTANCE NORMS REMARKS

CHECK RECORD TPIPL TPI/CUSTOMER

RAW MATERIAL As per ASTM A 276 /SA 789

1.1 Identification of Raw material Major Visual 100% SA 789 RMTC P R/R

IDENTIFICATION / UNS S31803

2.0 IN PROCESS INSPECTION

Heat treatment

Solution Annealing at 1040 0C SA 789/SA 1016 / UNS SA 789/SA 1016 / UNS Heat Treatment

2.1 (IN STRAIGHT TUBES Major Heat Treatment 100% P R/R

followed by water Quenching S31803 S31803 Record & Chart

CONDITION)

Eddy Current test

(IN STRAIGHT TUBES

2.2 Internal flaws Major Visual 100% As per E 309 / SA1016 As per E 309 / SA1016 Test Record P R/R

CONDITION PRIOR TO U

BEND)

As per SA 789/ SA 1016 / As per SA 789/ SA 1016 /

a) Product Analysis Major Chem. AS PER SPEC. Test Record P R/R

UNS S31803 UNS S31803

As per SA 789/ SA 1016 / As per SA 789/ SA 1016 / A

b) Tensile Testing Major Mech. AS PER SPEC. Test Record P R/R

A 370 / UNS S31803 370 / UNS S31803

Chemical, Mechanical &

Metallurgical Test on Tubes As per SA 789/ SA 1016 / As per SA 789/ SA 1016 / A

2.3 c) Hardness Testing Major Mech. AS PER SPEC. Test Record P R/R

(In straight tubes prior to U- A 370 / UNS S31803 370 / UNS S31803

Bend)

As per SA 789/ SA 1016 / As per SA 789/ SA 1016 / A

d) Flattening Test Major Mech. AS PER SPEC. Test Record P R/R

A 370 370

As per SA 789/ SA 1016 / As per SA 789/ SA 1016 / A

e) Flaring Test Major Mech. AS PER SPEC. Test Record P R/R

A 370 370

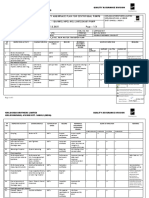

Quality Assurance Plan For Seamless U-Tubes

Tubacex Prakash India Pvt. Ltd. Document No. Rev. date Rev. No. Page No.

131/1,Umbergaon-Sanjan Road,Umbergan.Gujarat.India-396 171

D/QCD/002 01.09.2015 0 02 of 02

ITP No. TPIPL /QAP/1549/0018 Rev- 00 Date: 26.03.2020

QUANTUM OF FORMAT OF SCOPE OF INSPECTION

SR NO. COMPONENTS CHARACTERISTICS CLASS TYPE OF CHECK REFERANCE DOCUMENT ACCEPTANCE NORMS REMARKS

CHECK RECORD

TPIPL TPI/CUSTOMER

Mock up test for Check As per ASME SEC. VIII Div-

As per ASME SEC. VIII Div-1

Thinning, Flattening at U bend 1 / TEMA RCB 2.31 of

2.4 U-Bending Major Measurement 100% / TEMA RCB 2.31 of section - Mock up test report P W Ref .Note 1 & 2

portion for inner most 3 radius section -5 / PO MATERIAL

5 / PO MATERIAL SPEC

after stress relieving SPEC

U bend Annealing for all Stress relieving at 1020°C at U

As per TEMA RCB 2.3.1 of As per TEMA RCB 2.3.1 of

U_TUBES bend portion +300 mm Heat Treatment soaking temperature shall be

2.5 Major Stress Relieving 100% section -5 / PO MATERIAL section -5 / PO MATERIAL P R/R

(Electric Resistance Heat Straight from Tangent line Record 30-40 seconds

SPEC SPEC

Treated) followed by Forced air cooling

Pickling & Passivation Pickling & Passivation

2.6 Surface Condition Major Visual 100% As per A 380 As per A 380 P R/R

for U bend tubes. report

3.0 FINAL INSPECTION

Hydrostatic testing for U As per SA 789/SA1016 / As per SA 789/SA1016 / PO At 1000 PSI for 5 sec holding

3.1 Pressure, Time, Leakage Major Visual 100% Test Record P 10% W

tubes PO MATERIAL SPEC MATERIAL SPEC time.

OD,Thickness at straight OD & Thk tolerance as per

Visual & Dimensional

portion, Leg Length, Radius, Visual & As per SA 789/SA1016 / As per SA 789/SA1016 / PO spec ,

3.2 Inspection Major 100% Inspection Record P 10% W

Straightness, Surface condition Measurement PO MATERIAL SPEC MATERIAL SPEC Leg.LENGTH: +3 MM, - 0MM,

(U bend tubes)

& Identification mark on tubes. Bend Radius: ±1.5mm,

Liquid Penetranrt Test for all

ASME Sec-VIII Div-1 ASME Sec-VIII Div-1

radius (At U bend portion

3.3 Surface defect Major Visual 10% Appendix 8 / PO Appendix 8 / PO MATERIAL Test Record P R/R After stress relieving only.

+300 mm straight from

MATERIAL SPEC SPEC

Tangent line)

Seaworthy packed in wooden

3.4 Packing & Dispatch Major Visual 100% SA 789 / SA1016 SA 789 / SA1016 / Packing Record P -

cases with end caps

Review &

Certification & Verification of all TCs for Endorsement of

3.5 Major Visual 100% SA 1016 / PO SA 1016 / PO P R/R

Documentation completion Documents, MTC

(As per EN 10204 3.1)

Legends: P- Perform by, W- Witness, V- Verify, A- Approval, PO- Purchase Order,TDC -Technical delivery condition, R/R-Record Review, TPIPL- TUBACEX PRAKASH INDIA PVT. LTD.

NOTE:

1 one tube from inner most three radius shall be hardness tested before and after heat treatment, minimum 5 points, 3 in the external diameter of the bent part and 2 in the straight part.

2 Flattening shall be 10 % for R ≤5D i.e. for innermost 3 radiuses, for rest radius flattening shall be 6% max.

Supriya Yadav J. ENPARAJ

Quality Engineer AGM (QA/QC)

Prepared By(TPIPL QA) Reviewed By (TPIPL QA) Approved By(Client)

You might also like

- ITEM: Carbon Steel Seamless PipesDocument3 pagesITEM: Carbon Steel Seamless Pipesmanoj thakkarNo ratings yet

- Itp TTRK PDFDocument5 pagesItp TTRK PDFrahmath nawazNo ratings yet

- Inspection and Test Plan For Cement Mortar Lining of Steel Pipes, Fittings, Bends and Welded JointsDocument5 pagesInspection and Test Plan For Cement Mortar Lining of Steel Pipes, Fittings, Bends and Welded Jointsrahmath nawazNo ratings yet

- AEPCOM-QAP-3281-58548 Rev 1Document3 pagesAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARINo ratings yet

- Fire QAPDocument2 pagesFire QAPSuryadev singhNo ratings yet

- QAP For MS Pipes RevisedDocument3 pagesQAP For MS Pipes RevisedAnuj PandeyNo ratings yet

- MPS Sa-789 S31803 Rev0Document2 pagesMPS Sa-789 S31803 Rev0rabiprasad.iispl.comletedNo ratings yet

- Data Book de BombaDocument7 pagesData Book de BombaSharon Botiny100% (1)

- WM65AJN200Document4 pagesWM65AJN200Shasin SolankiNo ratings yet

- 02 I Test PlanDocument1 page02 I Test Planrahmath nawazNo ratings yet

- Inspection Checklist: S.No Components Class Type of Check Quantum of CheckDocument8 pagesInspection Checklist: S.No Components Class Type of Check Quantum of CheckCheeragNo ratings yet

- Quality Assurance Plan FastnersDocument1 pageQuality Assurance Plan FastnersSuKHjiT SiNGhNo ratings yet

- Public Health and Municipal Engineering Department - NelloreDocument3 pagesPublic Health and Municipal Engineering Department - Nellorejuliyet strucNo ratings yet

- Agirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestDocument6 pagesAgirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestRJS TUTORIALNo ratings yet

- Quality Assurance Plan For MV Switchgear (Type - Unigear/Leangear Cubicle With " Vd4/Vind - Breaker")Document3 pagesQuality Assurance Plan For MV Switchgear (Type - Unigear/Leangear Cubicle With " Vd4/Vind - Breaker")sriram.5230No ratings yet

- 65X M L - 211224 - 180120 - Converted - by - AbcdpdfDocument1 page65X M L - 211224 - 180120 - Converted - by - AbcdpdfVidhyarthi Photocopy KhargoneNo ratings yet

- Original: Pt. Asiatrust Technovima QualitiDocument3 pagesOriginal: Pt. Asiatrust Technovima QualitiMarvel IsmeNo ratings yet

- Oil SampleDocument7 pagesOil SampleMohamed AskarNo ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- Masdar Technical Supplies: Inspection and Test PlanDocument1 pageMasdar Technical Supplies: Inspection and Test PlanmaqboolNo ratings yet

- QAP For Pipes For Hydrant and Sprinkler SystemDocument3 pagesQAP For Pipes For Hydrant and Sprinkler SystemCaspian DattaNo ratings yet

- BTG 11.12.22-11.18.22 T-1 PDFDocument1 pageBTG 11.12.22-11.18.22 T-1 PDFKimberly DayoNo ratings yet

- 11.tec-Saukem-Loi003-I01-006 V1 R4Document23 pages11.tec-Saukem-Loi003-I01-006 V1 R4Purushothaman SeenuNo ratings yet

- Desmet Ballestra India PVT LTD: Inspection Test PlanDocument2 pagesDesmet Ballestra India PVT LTD: Inspection Test Plansameer patilNo ratings yet

- QAP - Rev - 0Document4 pagesQAP - Rev - 0Ravindra YogiNo ratings yet

- QAP HMEL 7480000754 L08722A501-SignedDocument3 pagesQAP HMEL 7480000754 L08722A501-SignedSuyog GawandeNo ratings yet

- MQAP - Long Rod InsulatorDocument8 pagesMQAP - Long Rod InsulatorRajitha BoppaNo ratings yet

- Doc-20231030-Wa0009 231031 151223Document3 pagesDoc-20231030-Wa0009 231031 151223Erwanto SENo ratings yet

- Gtes LT HSRP QapDocument5 pagesGtes LT HSRP Qapshashank shahNo ratings yet

- NTPC DPTDocument495 pagesNTPC DPTKuppan Srinivasan100% (1)

- Itp Atwts PDFDocument3 pagesItp Atwts PDFrahmath nawazNo ratings yet

- Test Certificate 16mmDocument1 pageTest Certificate 16mmSabyasachi Bangal100% (2)

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- Sample FET To ISO 15848-1 PDFDocument4 pagesSample FET To ISO 15848-1 PDFVivi Oktavianti100% (1)

- Bleeding Line Mbe 6 WTRDocument8 pagesBleeding Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- With Strainer, Piston QapDocument1 pageWith Strainer, Piston QapajmainNo ratings yet

- Screen & Conveyorgad, Data Sheet & Qap - SP-1326Document14 pagesScreen & Conveyorgad, Data Sheet & Qap - SP-1326ankit singlaNo ratings yet

- Material Test Report: 600# W.N RF 3 SCH 80 H5292Document2 pagesMaterial Test Report: 600# W.N RF 3 SCH 80 H5292Gabriel De La FuenteNo ratings yet

- Secpl RW QapDocument1 pageSecpl RW QapmaheshpanditNo ratings yet

- Direction Qualite: NAWCPF-MSBI-NCPF-000-QC-PRO-91509Document9 pagesDirection Qualite: NAWCPF-MSBI-NCPF-000-QC-PRO-91509Zouhair BenmabroukNo ratings yet

- 01 - A - I Test PlanDocument1 page01 - A - I Test Planrahmath nawazNo ratings yet

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- Inspection and Test PlanDocument3 pagesInspection and Test Planrahmath nawazNo ratings yet

- Itp RJM PDFDocument3 pagesItp RJM PDFrahmath nawazNo ratings yet

- QAP Check ListDocument1 pageQAP Check Listbed passNo ratings yet

- PQR PDFDocument2 pagesPQR PDFNjoku ChijiokeNo ratings yet

- Ione 7a60 NM PR 2100 - RaDocument3 pagesIone 7a60 NM PR 2100 - RayarubNo ratings yet

- Int-Aim-231887 PT 06-15-23Document2 pagesInt-Aim-231887 PT 06-15-23Joshua ClaytonNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- QAP (WO No. 58 & 59) PDFDocument3 pagesQAP (WO No. 58 & 59) PDFKailasNo ratings yet

- ItpDocument2 pagesItpVinay YadavNo ratings yet

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- Test Certificate 12mmDocument1 pageTest Certificate 12mmSabyasachi Bangal67% (9)

- Shuqaiq Phase-3 Water Transmission SystemDocument5 pagesShuqaiq Phase-3 Water Transmission Systemrahmath nawazNo ratings yet

- QAP - ITP - Steel Girder ApproachDocument21 pagesQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- GS Peb QapDocument4 pagesGS Peb Qapshailendr12No ratings yet

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Lethal Dose TableDocument1 pageLethal Dose TableRochie DiezNo ratings yet

- Fleet Management 101 Training Part 1:: Presenters Gary Hatfield, Mercury Associates William Gookin, Mercury AssociatesDocument22 pagesFleet Management 101 Training Part 1:: Presenters Gary Hatfield, Mercury Associates William Gookin, Mercury AssociatesAdolphe Hotereshi100% (1)

- Cutlist Cistern TankDocument10 pagesCutlist Cistern TankAilyn O. DungogNo ratings yet

- Deguzman Vs ComelecDocument3 pagesDeguzman Vs ComelecEsnani MaiNo ratings yet

- PNAPDocument79 pagesPNAPYu chung yinNo ratings yet

- Gears DifferentialDocument13 pagesGears Differentialpulkitymcaust_112907100% (1)

- Okuma CL302L Parts List & ManualDocument3 pagesOkuma CL302L Parts List & Manualcoolestkiwi100% (1)

- UCLA-Career Preparation ToolkitDocument61 pagesUCLA-Career Preparation ToolkitCaelulalaNo ratings yet

- Turkish Verbs - Basics O'f Turkish Grammar IDocument27 pagesTurkish Verbs - Basics O'f Turkish Grammar IAzza BakhtiNo ratings yet

- SAP On ASE Development UpdateDocument16 pagesSAP On ASE Development Updatebetoy castroNo ratings yet

- Ms. Louise Lim Mr. Ivan Cyrus DaldeDocument27 pagesMs. Louise Lim Mr. Ivan Cyrus DaldeJazlyn Andria JarafaNo ratings yet

- Laboratory Activity 1CDocument4 pagesLaboratory Activity 1CAini HasshimNo ratings yet

- 05 N141 31673Document21 pages05 N141 31673priya thakurNo ratings yet

- Sand Cone Test ResultsDocument71 pagesSand Cone Test ResultsGayan Indunil JayasundaraNo ratings yet

- Application Icx Sales ManagerDocument5 pagesApplication Icx Sales ManagerPersy LópezNo ratings yet

- XDM-100 IOM SDH A00 4-5 enDocument334 pagesXDM-100 IOM SDH A00 4-5 endilipgulatiNo ratings yet

- VISTA LAND AND LIFESCAPES INC FinalDocument9 pagesVISTA LAND AND LIFESCAPES INC Finalmarie crisNo ratings yet

- CostcoDocument12 pagesCostcoThảo Nguyên PhạmNo ratings yet

- Forward Planning DocumentDocument24 pagesForward Planning Documentapi-396981495No ratings yet

- Cost ActivityDocument6 pagesCost ActivityDeepak PahujaNo ratings yet

- Seven Keys To Church GrowthDocument4 pagesSeven Keys To Church GrowthJob0% (1)

- Psychology - Masters in Psychology Entrance Examination Book (Power Within Psychology, Amit Panwar) (Z-Library)Document414 pagesPsychology - Masters in Psychology Entrance Examination Book (Power Within Psychology, Amit Panwar) (Z-Library)Suraj100% (12)

- ATP Parts Guide-B3Z Mechanical Seal PumpDocument1 pageATP Parts Guide-B3Z Mechanical Seal PumpRony FloresNo ratings yet

- 1 MergedDocument81 pages1 MergedCHEN XIAN YANG MoeNo ratings yet

- Harper's Illustrated Biochemistry - Hormonal Control in Signal TransductionDocument18 pagesHarper's Illustrated Biochemistry - Hormonal Control in Signal TransductionDr Sanjeeb Kumar Dey BaidyaNo ratings yet

- 2010 ATRA Technical SeminarDocument35 pages2010 ATRA Technical Seminartambache69100% (1)

- Eligibility Conditions: Advertisement For Regular Commission in Pakistan Army Through 136 Pma Long CourseDocument5 pagesEligibility Conditions: Advertisement For Regular Commission in Pakistan Army Through 136 Pma Long CourseHusnain IshtiaqNo ratings yet

- Europe MapDocument13 pagesEurope MapNguyên ĐỗNo ratings yet

- Spark RPG Colour PDFDocument209 pagesSpark RPG Colour PDFMatthew Jackson100% (1)

- Giki Students Hand Book 08Document75 pagesGiki Students Hand Book 08Jawad Rasheed Sheikh100% (1)