Professional Documents

Culture Documents

Screen & Conveyorgad, Data Sheet & Qap - SP-1326

Uploaded by

ankit singlaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Screen & Conveyorgad, Data Sheet & Qap - SP-1326

Uploaded by

ankit singlaCopyright:

Available Formats

GAD, DATA SHEET & QAP OF MECHANICAL SCREEN, MANUAL SCREEN & CONVEYOR

Project: 4MLD SBR BASED SEWAGE TREATMENT PLANT AT SANGUR ZONE-II

Client: PUNJAB WATER SUPPLY & SEWERAGE BOARD.

Contractor: SHAPOORJI PALLONJI AND CO. PVT. LTD., MUMBAI-KIPL(JV)

MANUFACTURER: JASH ENGINEERING LIMITED

Submission Status: FOR APPROVAL Issue Status:

Rev. Date of Submission: Prepared By: AN

0 25.01.19 Reviewed By: SN/CB

DWG./Doc. No: SP-1326/PWSSB/SANG/4MLD/M/DOC-01/00 Approved By: DB

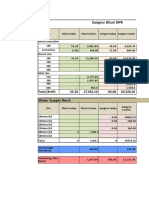

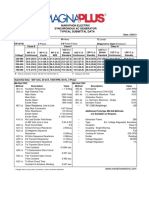

BILL OF MATERIAL

DESCRIPTION : BOM OF CONTROL PANEL FOR FINE BAR SCREEN OPERATED BY HYDRAULIC CYLINDER.

CLIENT : M/s. PUNJAB WATER SUPPLY & SEWERAGE BOARD SOS-MK2- 2237

PROJECT : SBR BASED SEWAGE TREATMENT PLANT 4 MLD AT SANGRUR ZONE-II

DWG. NO. : JE/SM/ELEX/ZA/STD-01,13.10.14 R4

QTY : 01 SCREENMAT + 1 CONVEYOR

01 NO. FOR 4 MLD AT SANGRUR ZONE-II

COMPONENT DESCRIPTION QTY. MAKE

NAME

Q1 On Off Switch 3 Pole, 415 Volts AC 50Hz 16 Amp. Main Isolator 1 No. Salzer

0F1-0F3 HRC Fuse Unit NS type with 2 Amps Fuse 3 Nos. Schneider / Siemens

R,Y,B Red,Yellow,Blue,22.5mm Dia. Crystal LED Lamp, 230 V AC 3 Nos. Teknic / Siemens

US 1 & 2 220V AC 24V DC ( PU-1Z ) 1 Nos Autonix

TR Transformer 400-415-440 / 110V/230V 300 VA 1 No VT/Eq.

F1,F4 Motor protection circuit breaker with 1NO + 1NC contacts(2.5 to 4.0 A) 2 No. Schneider / Siemens

F2 MCB DP 4A 1 No. Schneider / Siemens

F3,F5,F6 MCB DP 2A 3 Nos. Schneider / Siemens

K1,K9 Contactor 9 Amp With 1 NO+1 NC Contact & 110 V AC Coil, 2 Nos. Schneider / Siemens

K1,K9 Add On Block 3 NO + 1 NC 1 No. Schneider / Siemens

K4,K5,K6,K7,K8, Plug In Relay with Base 2C/O 110V AC 5 Nos. Schneider / Siemens

K2,K3 On-off Operational Timer 110V AC, 1 Sec-60 Min. 2 Nos EAPL

K10 OFF Delay Timer230V A 1Sec~ 30 Min. 1 No. EAPL

S1,S3 Mushroom Head Emergency Stop Red Stay Put Type With 1 NO +1 NC Contact 2 Nos Teknic / Siemens

S2,S4 Selector Switch Actuator 3 Way, Centre Off Stay Put Type With 2 NO Contacts. 2 Nos Teknic / Siemens

H1,H6 Pilot Lamp Holder 22.5mm Dia, Green With 110 V AC Crystal LED Lamp. 2 Nos Teknic / Siemens

H2-H5,H7 Pilot Lamp Holder 22.5mm Dia, Red With 110 V AC Crystal LED Lamp. 5 Nos. Teknic / Siemens

TB1-TB4 Screw on Terminals10 sq. mm 4 Nos. Phoenix / UK Series

TB6-TB8,TB24- Screw on Terminals 4 sq. mm 6 Nos Phoenix / UK Series

TB26

TB5 Screw on Earth Terminals 4 sq. mm (Green) 4 Nos Phoenix / UK Series

TB9-TB23, TB27- Screw on Terminals 2.5 Sq. mm 28 Nos Phoenix / UK Series

TB39

DATE : 24.01.2018 FOR JASH ENGINEERING LTD.

QUALITY ASSURANCE PLAN FOR JASH “BELT CONVEYOR”

MANUFACTURER CLIENT PUNJAB WATER SUPPLY & SEWERAGE BOARD

: JASH ENGINEERING LIMITED UNIT-II CONTRACTOR M/S SHAPOORJI PALLONJI AND CO. KIPL (JV)

Survey no. 74 Gram Bardari Nr Sanwer

Road,Tehsil Sanwer Indore (M.P.) SBR BASED SEWAGE TREATMENT PLANT AT SANGRUR ZONE-

PROJECT II (4 MLD)

INDIA

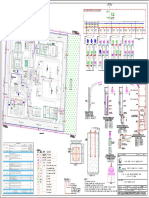

G.A. DRG. NO. JE/SC/GAC/BC/482– 00-R2

QAP NO. & DTD. JEL/QAP/BC/’MK2-2237-R2 DTD. 16/01/2019

Sr. Component & Reference Acceptance SCOPE

Characteristics Quantum of Check Format record

No. Operation Document norm JASH CLIENT / TPI

(1) MATERIAL TESTS:

Test Certificate /

a) Electric Motor Physical One per Lot Supplier Test Review Review

Certificate

Test Certificate /

Approved G.A. Approved G.A.

b) Gear Box Physical One per Lot Supplier Test Review Review

Drawing Drawing

Certificate

Test Certificate /

c) Belt (Rubber Belt) Physical Properties One per Lot Supplier Test Review Review

Certificate

(2) SHOP TESTS :

Approved G.A. Approved G.A. JASH Inspection

a) Dimensional Check Measurement 100% Perform Witness

Drawing Drawing Report

Smooth

Operation Test Performance / Operation JASH Inspection

b) Physical 100% Interference Perform Witness

(Dry Run) test Report

free movement

NOTE: -

1) We do not undertake additional testing other than above stated tests.

2) TPI – Third party Inspection Agency.

Clients Comments if Any:

Prepared By: JASH Engineering Ltd. Approved By:

QUALITY ASSURANCE PLAN FOR JASH “MANUAL SCREEN “

MANUFACTURER : JASH ENGINEERING LIMITED UNIT-II CLIENT PUNJAB WATER SUPPLY & SEWERAGE BOARD

Survey no. 74 Gram Bardari Nr Sanwer

Road,Tehsil Sanwer Indore (M.P.) CONTRACTOR M/S SHAPOORJI PALLONJI AND CO.- KIPL (JV)

INDIA SBR BASED SEWAGE TREATMENT PLANT AT SANGRUR

PROJECT ZONE-II (4 MLD)

G.A. DRG. NO. JE/SM/M/GAC/655-00 – R2

QAP NO. & DTD. JEL/QAP/MS/’MK2- 2237 -R2 DTD. 16/01/2019

Sr. Component & Reference SCOPE

Characteristics Quantum of Check Acceptance norm Format record

No. Operation Document JASH CLIENT / TPI

(1) MATERIAL TESTS:

a) Bottom Plate Chemical Composition Approved G.A. Approved G.A. Test Certificate Review / Perform Review

One per Lot

Drawing Drawing

b) Screen Bars Chemical Composition Test Certificate Review / Perform Review

(2) SHOP TESTS :

Approved G.A. Approved G.A. JASH Inspection

a) Dimensional Check Dimensional 100% Perform Witness

Drawing Drawing Report

NOTE : -

1. We do not undertake additional testing other than above stated tests.

2. TPI – Third party Inspection Agency.

3. PMI shall be carried out for SS parts test.

Clients Comments if Any:

Prepared By : JASH Engineering Ltd. Approved By :

QUALITY ASSURANCE PLAN FOR JASH “SCREENMAT” FINE BAR SCREEN

MANUFACTURER : JASH ENGINEERING LIMITED UNIT-II CLIENT PUNJAB WATER SUPPLY & SEWERAGE BOARD

Survey no. 74 Gram Bardari Nr Sanwer

Road,Tehsil Sanwer Indore (M.P.) CONTRACTOR M/S SHAPOORJI PALLONJI AND CO. KIPL (JV)

INDIA SBR BASED SEWAGE TREATMENT PLANT AT SANGRUR

PROJECT

ZONE-II (4 MLD)

REF. DRG. NO. JE/SM/GAC/ZA/741-00 – R2

QAP NO. & DTD. JEL/QAP/SCREENMAT/MK2-2237-R2 DTD. 16/01/2019

Component & Reference Quantum of SCOPE

Sr. No. Characteristics Acceptance norm Format record

Operation Document Check JASH CLIENT / TPI

1) MATERIAL TESTS:

a) Side Rails Chemical Composition One per Lot Test Certificate Perform / Review Review

b) Screen Bars Chemical Composition One per Lot Test Certificate Perform / Review Review

c) Moving & Fixed Shaft Chemical Composition Approved G.A. One per Lot Approved G.A. Test Certificate Perform / Review Review

Drawing Drawing

Manufacturer

d) Electric Motor Physical 100 % Review Review

Test Certificate

Manufacturer

e) Electric Control Panel Physical 100 % Review Review

Test Certificate

2) SHOP TESTS :

Approved G.A. JASH Inspection

a) Dimensional Check Measurement G.A. Drawing 100.00% Perform Witness

Drawing Report

Operation Test With

Performance / Smooth Interference JASH Inspection

b) Control Panel (Dry Run) Physical 100% Perform Witness

Operation test free movement Report

at horizontally position

NOTE: -

1) We do not undertake additional testing other than above stated tests.

2) TPI – Third party Inspection Agency.

Clients Comments if Any:

Prepared By: JASH Engineering Ltd. Approved By:

You might also like

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- PRESSURE SWITCH DATA SHEET R1 - ApprovedDocument7 pagesPRESSURE SWITCH DATA SHEET R1 - ApprovedArvnd VckyNo ratings yet

- SP - DS LSDocument5 pagesSP - DS LSsakhr fahdNo ratings yet

- IPS-MBD20031-In-512 - Data Sheet of Rotameter - ADocument3 pagesIPS-MBD20031-In-512 - Data Sheet of Rotameter - ANikhil KarkeraNo ratings yet

- Test ReportDocument6 pagesTest ReportAmir ShahzadNo ratings yet

- CT Site Test Report SummaryDocument6 pagesCT Site Test Report SummaryNaveed100% (1)

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- Transformers (Level-1 & 2)Document45 pagesTransformers (Level-1 & 2)SAGARNo ratings yet

- N2 - Rev ADocument13 pagesN2 - Rev AChirag ShahNo ratings yet

- UBL DEB-E-6-M2-DS-MS3-001-G DataSheet Mechanical Steam Separator Rev.A IFRDocument5 pagesUBL DEB-E-6-M2-DS-MS3-001-G DataSheet Mechanical Steam Separator Rev.A IFRAndi Candra IrawanNo ratings yet

- 0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2Document6 pages0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2fathan fathullahNo ratings yet

- QASCO CommissioningTest ReportDocument13 pagesQASCO CommissioningTest ReportstglNo ratings yet

- Level Gauge Data SheetDocument4 pagesLevel Gauge Data SheetJKKNo ratings yet

- AK2 - RevADocument13 pagesAK2 - RevAChirag ShahNo ratings yet

- COM-PW-MR03-0008-001-04-JS1227-ITT - Starter Panel GA DrawingDocument4 pagesCOM-PW-MR03-0008-001-04-JS1227-ITT - Starter Panel GA DrawingMohammed BrashdiNo ratings yet

- Generator Transformer - Technical Parameters Rev. GDocument19 pagesGenerator Transformer - Technical Parameters Rev. GMinh Tien DangNo ratings yet

- ABB T 001 - SHT 0001Document5 pagesABB T 001 - SHT 0001Arun dasNo ratings yet

- WO 33-4 Shastri Bridge Panel Cost R0 25.09.2021 - FINALDocument27 pagesWO 33-4 Shastri Bridge Panel Cost R0 25.09.2021 - FINALJayashree GopalakrishnanNo ratings yet

- R2 - RevADocument12 pagesR2 - RevAChirag ShahNo ratings yet

- Submittal #1 EquipmentDocument57 pagesSubmittal #1 EquipmentFERDINADNo ratings yet

- Ph12-3a-10-22-P007 - Rev - A - 40mva Oltc Ac and DC ChecksDocument5 pagesPh12-3a-10-22-P007 - Rev - A - 40mva Oltc Ac and DC Checksaravindhana1a1No ratings yet

- MR For Pipeline Bulk Materials, Rev.ADocument31 pagesMR For Pipeline Bulk Materials, Rev.ASandeepNBabuNo ratings yet

- PO SR - No.8, HEL REPORT 120004Document4 pagesPO SR - No.8, HEL REPORT 120004Agni DuttaNo ratings yet

- Sheath Test FormatDocument5 pagesSheath Test FormatAhmed FaragNo ratings yet

- Test Report - Cable 111Document2 pagesTest Report - Cable 111vivek juthaniNo ratings yet

- Data Sheet For Gate Valve: TitleDocument2 pagesData Sheet For Gate Valve: TitlechintanNo ratings yet

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- Index: Sheet 1 of 29 REV 01Document26 pagesIndex: Sheet 1 of 29 REV 01Ayush ChoudharyNo ratings yet

- IN-QD-5531-21005-AIS-001-R1 Circuit Breaker Inspection Report-GulDocument13 pagesIN-QD-5531-21005-AIS-001-R1 Circuit Breaker Inspection Report-GulSikandar MasoodNo ratings yet

- Specification For Limit SwitchesDocument2 pagesSpecification For Limit SwitchesHarish GundaNo ratings yet

- Pressure Transmitter SpecificationDocument4 pagesPressure Transmitter Specificationsakhr fahdNo ratings yet

- Magnetic Flowmeter FT 103Document3 pagesMagnetic Flowmeter FT 103riswan nugrahaNo ratings yet

- CCM 2.5MVATX QASCO CommissioningTest Report.Document13 pagesCCM 2.5MVATX QASCO CommissioningTest Report.Ginger TurnerNo ratings yet

- Transformer Test ReportDocument46 pagesTransformer Test ReportAkshay GatkalNo ratings yet

- PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaDocument13 pagesPT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaJan Richardo GultomNo ratings yet

- Instrumentation Tubes Quality Assurance ProgramDocument1 pageInstrumentation Tubes Quality Assurance ProgramPrathamesh OmtechNo ratings yet

- Duqm Project EPC 2 - Utilities and Offsites Data SheetDocument9 pagesDuqm Project EPC 2 - Utilities and Offsites Data SheetsudhirguduruNo ratings yet

- PH Analyzer Data SheetDocument4 pagesPH Analyzer Data SheetRabah AmidiNo ratings yet

- 02 - FEWA-EL-SWGR-TD-0112, Rev 1, 2016Document24 pages02 - FEWA-EL-SWGR-TD-0112, Rev 1, 2016MuraryspottyNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Differential Pressure SwitchDocument3 pagesDifferential Pressure SwitchJKKNo ratings yet

- Differential Pressure Transmitter (Smart)Document6 pagesDifferential Pressure Transmitter (Smart)JKKNo ratings yet

- Analyzer Data SheetDocument3 pagesAnalyzer Data Sheetsokrat sebtiNo ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Camy Plants: Shell Long Seam Back-Chip D.P. Test ReportDocument5 pagesCamy Plants: Shell Long Seam Back-Chip D.P. Test Reportnarendra vermaNo ratings yet

- Cable Schedule For Thermal Cycle Rev3 03012017Document53 pagesCable Schedule For Thermal Cycle Rev3 03012017Mahadevan MahalingamNo ratings yet

- PT Amman Mineral Nusa Tenggara Batu Hijau Project SpecificationDocument6 pagesPT Amman Mineral Nusa Tenggara Batu Hijau Project Specificationelia nugraha adiNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- Pressure Differential Transmitter Datasheet for LNG Terminal ProjectDocument3 pagesPressure Differential Transmitter Datasheet for LNG Terminal ProjectsswahyudiNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- CCL 1Document1 pageCCL 1prabu cNo ratings yet

- C2C Manual Valve Data SheetDocument13 pagesC2C Manual Valve Data Sheetpraveen kumar vengadasamyNo ratings yet

- D 1 1Document956 pagesD 1 1karthi82887No ratings yet

- WQT RecordDocument6 pagesWQT RecordGururaj P KundapurNo ratings yet

- Megger Test FormDocument1 pageMegger Test FormJHON CHRISTOPHER CENTINONo ratings yet

- AMBPL Busduct SpecsDocument5 pagesAMBPL Busduct SpecsPrasadNo ratings yet

- Duqm Refinery Project EPC Package OneDocument22 pagesDuqm Refinery Project EPC Package OnePrashant KumarNo ratings yet

- Jul 2017Document2 pagesJul 2017ankit singlaNo ratings yet

- Jul 2017Document1 pageJul 2017ankit singlaNo ratings yet

- 04 - 10 - 2017-DPR-Sangrur Dhuri ProjectDocument199 pages04 - 10 - 2017-DPR-Sangrur Dhuri Projectankit singlaNo ratings yet

- June 2017 ContributionDocument1 pageJune 2017 Contributionankit singlaNo ratings yet

- 014 - Apr'21Document3 pages014 - Apr'21ankit singlaNo ratings yet

- Gate Design and ComponentsDocument7 pagesGate Design and Componentsankit singlaNo ratings yet

- Rotork Valve Ad, Data Sheet & Qap of - Mld-M-Doc-14 - R0Document13 pagesRotork Valve Ad, Data Sheet & Qap of - Mld-M-Doc-14 - R0ankit singlaNo ratings yet

- Power Cable Schedule and Sizing CalculationDocument3 pagesPower Cable Schedule and Sizing Calculationankit singlaNo ratings yet

- Water treatment plant equipment layoutDocument1 pageWater treatment plant equipment layoutankit singlaNo ratings yet

- WhatsAppDocument1 pageWhatsAppankit singlaNo ratings yet

- 100 KVA DG 12 MLD MPS Zone IIDocument12 pages100 KVA DG 12 MLD MPS Zone IIankit singlaNo ratings yet

- Protection PresentationDocument15 pagesProtection PresentationAlmiqdad AldeekNo ratings yet

- DN 6724Document2 pagesDN 6724venvettyNo ratings yet

- Automatic Headlight SwitcherDocument2 pagesAutomatic Headlight SwitcherRekhaPadmanabhanNo ratings yet

- 12ax7 Comparison of Current Made TubesDocument5 pages12ax7 Comparison of Current Made TubesTom DorseyNo ratings yet

- Cod.380S.A: Instruction ManualDocument24 pagesCod.380S.A: Instruction Manualalphons3No ratings yet

- Voltamp Transformers OfferDocument11 pagesVoltamp Transformers OfferAmit JainNo ratings yet

- Metra Hit: 22S/M, 23S, 24S, 25S, 26S/M/MILDocument60 pagesMetra Hit: 22S/M, 23S, 24S, 25S, 26S/M/MIL04hngNo ratings yet

- Emech Exp-1Document13 pagesEmech Exp-1ATCNo ratings yet

- Caja de Conexion Metálica Wet Location - Hangzhou - Ul - E483162 - 2022.08Document16 pagesCaja de Conexion Metálica Wet Location - Hangzhou - Ul - E483162 - 2022.08andres20tjNo ratings yet

- Hydraulic Excavator PC200-8 PC200LC-8 PC220-8 PC220LC-8: 90 Diagrams and DrawingsDocument5 pagesHydraulic Excavator PC200-8 PC200LC-8 PC220-8 PC220LC-8: 90 Diagrams and Drawingsari100% (3)

- Marathon Electric Synchronous Ac Generator Typical Submittal DataDocument2 pagesMarathon Electric Synchronous Ac Generator Typical Submittal Datamarkigldmm918No ratings yet

- Wiring Diagram Selection: Y004.868/003/en Issue 1.16 Page 1/5Document5 pagesWiring Diagram Selection: Y004.868/003/en Issue 1.16 Page 1/5Medjahdi RafikNo ratings yet

- Technical Service Manual Dishwasher Parts FunctionsDocument37 pagesTechnical Service Manual Dishwasher Parts FunctionstrutleptNo ratings yet

- Cable Sizing Calculations Front SheetDocument6 pagesCable Sizing Calculations Front SheetcvijeshNo ratings yet

- DC Motor 2 Marks QuestionsDocument3 pagesDC Motor 2 Marks QuestionsAbhishek100% (1)

- Teapo SZDocument2 pagesTeapo SZZainudin GhozaliNo ratings yet

- 1501 - 001 - 06 SafetyDocument35 pages1501 - 001 - 06 Safetynils_erickssonNo ratings yet

- 0 - PANASONIC Horizontal Deflection Transistor Series For TV PDFDocument11 pages0 - PANASONIC Horizontal Deflection Transistor Series For TV PDFalex3712No ratings yet

- Ansaldo Electric Drives 15/30 kW Technical SpecsDocument4 pagesAnsaldo Electric Drives 15/30 kW Technical SpecsMr.K ch50% (2)

- Evaluating Dielectric Conditionin SF6 Gas BreakersDocument18 pagesEvaluating Dielectric Conditionin SF6 Gas BreakersGabriel Zenarosa Lacsamana100% (1)

- KENR76610001 Plano Sist Electrico 420E Serie PRADocument12 pagesKENR76610001 Plano Sist Electrico 420E Serie PRAJuan Carlos Inga VasquezNo ratings yet

- ETS12-01-02 - 12-24KV Limiting Fuse Link For SwicthgearDocument13 pagesETS12-01-02 - 12-24KV Limiting Fuse Link For SwicthgearTerex14253No ratings yet

- DS GSD GSD V GSF GSF V Electronic Glass Fuses 250V MersenDocument1 pageDS GSD GSD V GSF GSF V Electronic Glass Fuses 250V MersenAdrián T.V.No ratings yet

- Lighting Op 7Document1 pageLighting Op 7dhirajsatyam98982285No ratings yet

- AVTRON LoadbankDocument2 pagesAVTRON LoadbankAris DaylagNo ratings yet

- Tinyswitch-4 Family: Energy-Efficient, Off-Line Switcher With Line Compensated Overload PowerDocument26 pagesTinyswitch-4 Family: Energy-Efficient, Off-Line Switcher With Line Compensated Overload PowerFrancisco MárcioNo ratings yet

- Specifications For MV Panels Upto 415VDocument8 pagesSpecifications For MV Panels Upto 415VNATHANNo ratings yet

- General Description Features: 2A Step Down DC To DC ConverterDocument9 pagesGeneral Description Features: 2A Step Down DC To DC ConverterEmanuel CarageaNo ratings yet

- Data Sheet TRIO-20 - 0-27 - 6 - BCD - 00379 - EN - Rev ADocument4 pagesData Sheet TRIO-20 - 0-27 - 6 - BCD - 00379 - EN - Rev Anaiad09No ratings yet

- Eaton HRG Low Voltage Design Guide Dg022019enDocument8 pagesEaton HRG Low Voltage Design Guide Dg022019ensiddhant103No ratings yet