Professional Documents

Culture Documents

ETS12-01-02 - 12-24KV Limiting Fuse Link For Swicthgear

Uploaded by

Terex14253Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ETS12-01-02 - 12-24KV Limiting Fuse Link For Swicthgear

Uploaded by

Terex14253Copyright:

Available Formats

Ergon Energy Corporation Limited

Technical Specification for 12kV

and 24kV Powder Filled Current

Limiting Fuse Links for Use in

Switchgear (In Air)

ETS12-01-02

Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

Contents

1. Purpose and Scope...................................................................................................... 1

2. References .................................................................................................................... 1

2.1 Applicable Standards .......................................................................................... 1

3. Drawings ....................................................................................................................... 1

3.1 Drawings by the Purchaser ................................................................................. 1

4. Service Conditions....................................................................................................... 1

5. Design and Construction ............................................................................................ 2

5.1 Requirements...................................................................................................... 2

5.2 Ratings ................................................................................................................ 2

5.3 Fuse-link Applications ......................................................................................... 2

5.4 Fuse-Link Dimension .......................................................................................... 3

5.5 Striker ................................................................................................................. 3

6. Performance and Testing ............................................................................................ 3

6.1 Testing ................................................................................................................ 3

7. Risk Assessment ......................................................................................................... 3

8. Quality Assurance........................................................................................................ 4

9. Samples ........................................................................................................................ 4

9.1 Production Samples ............................................................................................ 4

10. Packaging and Marking ............................................................................................... 4

10.1 General ............................................................................................................... 4

10.2 Marking ............................................................................................................... 4

11. Service Performance ................................................................................................... 4

12. Reliability ...................................................................................................................... 5

12.1 Service Life ......................................................................................................... 5

12.2 Evidence in Support of Reliability........................................................................ 5

13. Training ......................................................................................................................... 5

14. Environmental Considerations ................................................................................... 5

15. Information to be Provided ......................................................................................... 5

i Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

15.1 Specific Technical Requirements ........................................................................ 5

15.2 Checklist of Supporting Documentation .............................................................. 5

15.3 Documentation to be Supplied During the Course of the Contract...................... 5

16. Appendix A.1 – Items List ........................................................................................... 6

17. Appendix A.1 – Items List (cont)................................................................................. 7

18. Attachment 1 – Technical Details ............................................................................... 8

19. Attachment 2 – Technical Document Checklist ........................................................ 9

ii Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

1. Purpose and Scope

This specification sets out the technical requirements for 12kV and 24kV powder filled fuses

suitable for use in switchgear in air. The fuses are primarily used for the protection of

distribution transformers.

A list of items covered by this specification is given in the Appendix A.1.

2. References

2.1 Applicable Standards

The fuses shall be designed, manufactured and tested in accordance with the relevant

parts of the following standards and all amendments issued from time to time except where

varied by this specification.

Should inconsistencies be identified between standards and/or this specification, the

Supplier shall immediately refer such inconsistencies to the Corporation for resolution.

STANDARD TITLE

AS1033.2 High voltage fuses (for rated voltages exceeding 1000V)

Part 2 – Current-limiting (Powder-filled) type

IEC 60282-1 High-voltage fuses- Part 1: Current-limiting fuses

AS/NZS ISO: 9001 Quality Management Systems – model for quality assurance in

design, development, production, installation and servicing

3. Drawings

3.1 Drawings by the Purchaser

No drawings are included in this specification

4. Service Conditions

The switchgear using the fuses to be purchased under this specification will be exposed to

the following environmental conditions:

Ambient Temperatures 45o summer day time

-5o winter night time

Solar Radiation Level 1100 watts per square metre with high ultraviolet

content

Precipitation Tropical summer storms with gust wind speeds

above 160km/h, and an annual rainfall in excess of

1500 mm

Humidity Extended periods of relative humidity in excess of

90% R.H.

Page 1 of 10 Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

Atmospheric Classifications Areas of coastal salt spray and/or industrial pollution

with equivalent salt deposit densities in the range 2.0

- 3.0 g/m2.

The fuses will be used in sealed epoxy resin fuse enclosures, having varying degrees of

external ventilation depending on the switchgear type. .

5. Design and Construction

Design and construction performance parameters are detailed in this section.

5.1 Requirements

The fuse-links shall have the following ratings and comply with the Australian Standard

AS1033.2 or an equivalent international standard. The fuse-links shall be used primarily for

protection of delta connected three phase distribution transformer.

5.2 Ratings

Rated voltage 12kV 24kV

Rated Current Refer Table Below

Rated breaking current 40kA(minimum) 20KA (minimum)

Rated frequency 50Hz

Fuse classification Full Range

Rated insulation level of fuse-holder 95kV BIL 125kV BIL

Full range fuses are specified above but fuses of other classification will be considered.

5.3 Fuse-link Applications

The HV fuse sizes currently used by the Purchaser for the protection of distribution

transformers are listed below.

Transformer three Fuse Rating(A) Fuse Rating(A) Typical Fuse

phase kVA for 12kV for 24kV Rating for LV.

Transformers Transformers

100 10 125

200 20 200 per circuit

315 25 16 200 per circuit

500 40 20 200 per circuit

750 50 & 63 200 per circuit

1000 80 40

The fuse links offered shall be capable of withstanding magnetising inrush currents up to 12

times the transformer rated full load current for 0.1 seconds and 25 times the transformer

rated full load current for 0.01 seconds and discriminate with the secondary fuse links

specified.

Page 2 of 10 Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

The fuse links shall be capable of withstanding 125% of the transformer rated full load

current continuously and periodic over-loads up to 150% of the transformer rated full load

current.

The fuse links shall be able to clear a phase to neutral fault on the secondary terminals of

the transformer in less than 1.5 seconds, in order to limit damage to the transformer in the

event of such fault. (The impedance voltage of the transformer at the rated current may be

assumed as 4%)

The current- time characteristics of the fuses offered shall be included in the tender.

Fuse links shall be suitable for mounting in any orientation.

5.4 Fuse-Link Dimension

Fuse-links shall have dimensions in accordance with Reference I1 and I2 of Figure D1,

Appendix D of AS1033.2 respectively for rated voltages 12kV and 24kV.

Drawings showing the critical dimensions of the fuse links offered shall be

submitted with the tender.

5.5 Striker

The fuse-links shall be fitted with a striker for indication purposes and to initiate three phase

tripping of the circuit being protected. The mechanical characteristics of the striker shall be

in accordance with the medium duty type in Table 6.3 of AS1003.2. The energy rating of

the striker shall be 1J±0.5J.

6. Performance and Testing

6.1 Testing

Test certificates of the type tests specified in the Section 4 of AS1033.2 shall be provided

with the tender. The routine and batch test certificates shall be submitted with each

delivery.

The test certificate for the time current characteristics provided with the tender shall include

the minimum melting time characteristics and the total clearing time characteristics. A table

of (current -time) data defining the above curves shall also be included with the tender in

(MS Office) Excel format.

Current limiting data showing the extent of current limiting should be included.

The testing shall have been carried out by a nationally accredited testing authority.

7. Risk Assessment

There is no requirement for manufacturer provided safety risk assessments for the items

covered in this specification.

Page 3 of 10 Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

8. Quality Assurance

It is the Purchaser’s policy to procure goods, equipment and services from sources that

demonstrate the ability to supply quality products.

Tenderers are required to submit documentary evidence that the design and manufacture

of the fuses offered is in accordance with AS/NZS/ISO 9001.

This documentation shall include the Capability Statement associated with the Quality

System Certification

9. Samples

9.1 Production Samples

When requested, production samples of each item shall be submitted with the offer.

10. Packaging and Marking

10.1 General

Tenderer's attention is specifically drawn to the requirements of the Logistic Specification

with regard to the packaging, marking and delivery of palletised goods.

10.2 Marking

Markings shall be provided on the fuse-links in accordance with Clause 6.9.3 of AS 1033.2

The following information shall be legibly and indelibly marked on BOTH sides of the

carton:

a) Manufacturer’s name and sequential unit identification number

b) Ergon Energy’s Purchase Order number

c) Ergon Energy's Item Identification Number

d) Rated voltage and current of fuse links

e) Gross mass of carton and contents

f) Handling or lifting instructions where applicable

11. Service Performance

Potential first time Suppliers to the Purchaser shall state:

1. The period of service achieved by items offered within Australian service conditions;

2. Australian electricity supply authorities who have a service history of the items

offered;

3. Contact names and phone numbers of relevant employees of those supply

authorities who can verify the service performance claimed.

Page 4 of 10 Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

12. Reliability

12.1 Service Life

Comments on the reliability and performance of the items offered, for a service life of 35

years under the specified system and environmental conditions, shall be submitted with the

offer.

12.2 Evidence in Support of Reliability

Such comments shall include evidence in support of the reliability and performance claimed

including information of Failure Mode and Effect Analysis.

13. Training

Training material in the form of drawings, instructions and/or audio visuals shall be provided

for the items accepted under the offer. This material shall include but is not limited to the

following topics:

Handling

Storage

Application guide

Installation

Maintenance

Environmental performance

Electrical performance

Mechanical performance

Disposal

14. Environmental Considerations

Suppliers are required to comment on the environmental soundness of the design and the

materials used in the manufacture of the items offered. In particular, comments should

address such issues as recyclability and disposal at end of service life and also disposal of

packaging material.

15. Information to be Provided

15.1 Specific Technical Requirements

Attachment 1 is a schedule of the technical details that suppliers are required to complete

and return with their offer.

15.2 Checklist of Supporting Documentation

Attachment 2 details a checklist of supporting technical documentation which is required to

be submitted wit the tender.

15.3 Documentation to be Supplied During the Course of the Contract

Test certificates as required in Clause 6.

Page 5 of 10 Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

16. Appendix A.1 – Items List

Item No IINo Description

1 0620613 FUSE LINK, 12 kV, HRC, Air Insulated, 10 Amp, Barrel 292mm Lg 50.8mm

Dia plus End Caps 34mm Lg 45mm Dia, with Striker Pin, to DIN Standard

43625, Full Range Fuse. For Use in Hazemayer MD4, ABB Safelink and Areva

SBX Ring Main Units

2 0620648 FUSE LINK, 12 kV, HRC, Air Insulated, 20 Amp, Barrel 292mm Lg 50.8mm

Dia plus End Caps 34mm Lg 45mm Dia, with Striker Pin, to DIN Standard

43625, Full Range Fuse. For Use in Hazemayer MD4, ABB Safelink and Areva

SBX Ring Main Units

3 2404922 FUSE LINK, 12 kV, HRC, Air Insulated, 25 Amp, Barrel 292mm Lg 50.8mm

Dia to DIN Standard 43625, Full Range Fuse. For Use in Hazemayer MD4,

ABB Safelink, Krone Kesio and Areva SBX Ring Main Units

4 0621008 FUSE LINK, 12 kV, HRC, Air Insulated, 40 amp, Barrel 292mm Lg 76.2mm Dia

plus End Caps 34mm Lg 45mm Dia, with Striker Pin, to DIN Standard 43625,

Full Range Fuse. For Use in Hazemayer MD4, ABB Safelink and Areva SBX

Ring Main Units

5 0621016 FUSE LINK, 12 kV, HRC, Air Insulated, 80 Amp, Barrel 292mm Lg 76.2mm

Dia plus End Caps 34mm Lg 45mm Dia, with Striker Pin, to DIN Standard

43625, Full Range Fuse. For Use in Hazemayer MD4, ABB Safelink and Areva

SBX Ring Main Units

6 2400616 FUSE LINK, 12 kV, HRC, Air Insulated, 31.5 Amp, Barrel 292mm Lg 50.8mm

Dia to DIN Standard 43625, Full Range Fuse. For Use in Hazemayer MD4,

ABB Safelink, Krone Kesio and Areva SBX Ring Main Units

7 2404926 FUSE LINK, 12 kV, HRC, Air Insulated, 50 Amp, Barrel 292mm Lg 76.2mm

Dia plus End Caps 34mm Lg 45mm Dia, with Striker Pin, to DIN Standard

43625, Full Range Fuse. For Use in Hazemayer MD4, ABB Safelink and Areva

SBX Ring Main Units

8 2406261 FUSE LINK, 12 kV, HRC, Air Insulated, 63 Amp, Barrel 292mm Lg 50.8mm

Dia to DIN Standard 43625, Full Range Fuse. For Use in Hazemayer MD4,

ABB Safelink, Krone Kesio and Areva SBX Ring Main Units

9 2400629 FUSE LINK, 12kv HRC, Air Insulated 125 Amp Ring Main Unit DIN Type Air

Insulated Barrel 359mm Lg 76.2mm Dia with End Caps 44mm Lg 76.2mm Dia

with Striker Pin to DIN Standard 43625 Full Range Fuse.

Table continued on next page.

Page 6 of 10 Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

17. Appendix A.1 – Items List (cont)

Item No IINo Description

10 2404923 FUSE LINK, 12kv HRC, Air Insulated 40 Amp Ring Main Unit DIN Type Air

Insulated Barrel 565mm Lg 76.2mm Dia including End Caps 44mm Lg

76.2mm Dia with Striker Pin to DIN Standard 43625 Full Range Fuse.

11 2424919 FUSE LINK, 24 kV, HRC, Air Insulated 16 Amp, Barrel 442mm Lg 50.8mm Dia

plus End Caps 34mm Lg 45mm Dia, with Striker Pin to DIN Standard 43625.

Full Range Fuse For use in F&G, Schneider RM6 and Ormazabal

12 0621113 FUSE LINK, 24 kV, HRC, Air Insulated 20 Amp, Barrel 442mm Lg 50.8mm Dia

plus End Caps 34mm Lg 45mm Dia, with Striker Pin to DIN Standard 43625.

Full Range Fuse For use in F&G, Schneider RM6 and Ormazabal

13 2404138 FUSE LINK, 24 kV, HRC, Air Insulated, 63 Amp, Barrel 442mm Lg 50.8mm

Dia, plus End Caps 33mm Lg 45mm Dia, with Striker Pin to DIN Standard

43625, Full Range Fuse. For use in F&G, Schneider RM6 and Ormazabal

14 2404139 FUSE LINK, 24 kv HRC, Air Insulated 40 Amp Ring Main Unit DIN Type Air

Insulated Barrel 442mm Lg 50.8mm Dia plus End Caps 33mm Lg 45mm Dia

with Striker Pin to DIN Standard 43625 Full Range Fuse, For use in F&G,

Schneider RM6 and Ormazabal.

Page 7 of 10 Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

18. Attachment 1 – Technical Details

The supplier shall complete this schedule for each item offered and shall guarantee the

particulars as set out:

Tender Item Number IINo

Name of Manufacturer

Address of Manufacturer

Place of Manufacturer

Manufacturer’s Catalogue Number

and Drawing Numbers

Material of Fuse

Weight of Each Fuse (kg)

Weight per Crate (kg)

Time-Current Characteristics of Fuse Attached? YES/NO

Cut-off current Characteristics of Fuse Attached? YES/NO

I2 t Characteristics Attached? YES/NO

Dimensional details of the fuse Attached? YES/NO

Prospective Breaking Current (kA)

Breaking Capacity (kA)

Minimum Breaking Current (A)

Power dissipation at rated current (W)

Energy rating of the striker pin (J)

Details of Fuse End caps:

End cap Material

Type of Plating

Thickness of plating (micron)

SIGNATURE OF TENDERER: ___________________________________________

DATE ___________________

Page 8 of 10 Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

19. Attachment 2 – Technical Document Checklist

CLAUSE PARTICULAR RESPONSE

Clause 5.3 Fuse-link Applications Response

1 The current-time characteristics of the

fuse-links offered shall be submitted with

the tender.

Clause 5.4 Fuse-link Dimensions Response

1 Drawings showing the critical dimensions

of the fuse links offered shall be submitted

with the tender.

Clause 6.0 Performance and Testing Response

6.1 Test certificates of the type tests specified

in the Section 4 of AS1033.2 shall be

provided with the tender.

Clause 8.0 Quality Assurance Response

8 Tenderers are required to submit

documentary evidence that the design

and manufacture of the fuses offered is in

accordance with AS/NZS/ISO 9001.

Clause 9.0 Samples Response

9.1 When will samples be available, if

required?

Clause 11. Service History Response

1 The period of service achieved by items

offered within Australian service

conditions

2 Australian electricity supply authorities

who have a service history of the items

offered

3 Contact names and phone numbers of

relevant employees of those supply

authorities who can verify the service

performance claimed

Clause 12 Reliability Response

12.1 Comments on the reliability and

performance of the items offered, for a

service life of 35 years under the specified

system and environmental conditions,

shall be submitted with the offer.

12.2 Evidence in support of the reliability and

performance claimed including

information of Failure Mode and Effect

Analysis.

Clause 13 Training Response

Page 9 of 10 Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

Technical Specification for 12kV and 24kV Powder

Filled Current Limiting Fuse Links for Use in Switchgear

(In Air)

CLAUSE PARTICULAR RESPONSE

1 Comment on the availability of training

materials

Clause 14 Environmental Considerations Response

1 Suppliers are required to comment on the

environmental soundness of the design

and the materials used in the manufacture

of the items offered. In particular,

comments should address such issues as

recyclability and disposal at end of service

life and also disposal of packaging

material.

Note: All requested supporting documentation is to be attached to this Attachment 2.

NAME OF TENDERER:

ADDRESS OF TENDERER:

SIGNATURE: FOR AND ON BEHALF OF TENDERER

DATE: ______________________

Page 10 of 10 Specification ETS12-01-02 Ver 3

Ergon Energy Corporation Limited ABN 50 087 646 062

You might also like

- Payroll Management SystemDocument56 pagesPayroll Management SystemSagar Malusare84% (64)

- PGCIL GIS Specification - Rev 4 (June-14)Document74 pagesPGCIL GIS Specification - Rev 4 (June-14)Travis Wood100% (1)

- Technical Submittal - 3 WAY & 4 WAY - RMUDocument149 pagesTechnical Submittal - 3 WAY & 4 WAY - RMUفارس معتوقNo ratings yet

- 01 Technical Specification For 160MVA 220 132 33KV Power TransformerDocument88 pages01 Technical Specification For 160MVA 220 132 33KV Power Transformerk. harikarasudhan33% (3)

- 16 Samss 510Document11 pages16 Samss 510HatemS.MashaGbehNo ratings yet

- D5 5 HandbookDocument38 pagesD5 5 HandbooklcandoNo ratings yet

- DBS3900 Product Description (V200 - 01)Document60 pagesDBS3900 Product Description (V200 - 01)Elaine Tan-DiazNo ratings yet

- Tender Documentation For Construction Projects - An Overview PDFDocument16 pagesTender Documentation For Construction Projects - An Overview PDFHaziqah AisyahNo ratings yet

- ETS12-01-03 - Limiting Fuse Link For Oil SwitchgearDocument12 pagesETS12-01-03 - Limiting Fuse Link For Oil SwitchgearTerex14253No ratings yet

- ETS12-01-01 - 12-24KV FuseLink HolderDocument12 pagesETS12-01-01 - 12-24KV FuseLink HolderTerex14253No ratings yet

- ETS12-01-04 - 12-24KV Current Limiting Fuse For OH ApplicationsDocument12 pagesETS12-01-04 - 12-24KV Current Limiting Fuse For OH ApplicationsTerex14253No ratings yet

- ETS12-02-01 - LV Fuse LinksDocument29 pagesETS12-02-01 - LV Fuse LinksTerex14253No ratings yet

- Technical Specification For 12kV, 24kV and 36kV Drop-Out DisconnectorDocument18 pagesTechnical Specification For 12kV, 24kV and 36kV Drop-Out DisconnectorAurelio AleixoNo ratings yet

- Spec For Tender - 12kV Vacuum ContactorDocument5 pagesSpec For Tender - 12kV Vacuum ContactortafseerahmedNo ratings yet

- Power Flex 7000 Specification GuideDocument40 pagesPower Flex 7000 Specification Guideoadipphone7031No ratings yet

- Technical Specification: Section-Series Reactor (400 KV CLASS)Document15 pagesTechnical Specification: Section-Series Reactor (400 KV CLASS)byjuvcNo ratings yet

- NPS/001/009 - Technical Specification For 11kV, 20kV and 33kV Pole Mounted Auto-Reclose Circuit BreakersDocument31 pagesNPS/001/009 - Technical Specification For 11kV, 20kV and 33kV Pole Mounted Auto-Reclose Circuit BreakerskotiniNo ratings yet

- Technical Specification For 11kV, 20kV and 33kV Pole Mounted Auto-Reclose Circuit Breakers NPS001 - 009Document29 pagesTechnical Specification For 11kV, 20kV and 33kV Pole Mounted Auto-Reclose Circuit Breakers NPS001 - 009Indika Withanage100% (1)

- 216kV Surge Arrester Technical SpecificationDocument16 pages216kV Surge Arrester Technical SpecificationSolar PowerNo ratings yet

- BLDC SPEC - 0021 - 2005 (Rev.2) PDFDocument18 pagesBLDC SPEC - 0021 - 2005 (Rev.2) PDFdivisional electrical enggNo ratings yet

- Tender Specs ROSOV CH 7 BDocument17 pagesTender Specs ROSOV CH 7 BShakeel AhmedNo ratings yet

- MR Mk30 Regulador TensionDocument269 pagesMR Mk30 Regulador TensionAnonymous 10zKm4n93No ratings yet

- Materials System SpecificationDocument14 pagesMaterials System SpecificationAnandan ramachandranNo ratings yet

- Save Energy and Benefit Nation with Efficient TransformersDocument48 pagesSave Energy and Benefit Nation with Efficient Transformerssepta ibnuNo ratings yet

- Technical SpecificationDocument23 pagesTechnical Specificationc katsanos100% (1)

- Draft Spec No. ETI-PSI-14Document13 pagesDraft Spec No. ETI-PSI-14vishnu kumar VyasNo ratings yet

- Technical Specification For Composite Line Post Insulators: Ergon Energy Corporation LimitedDocument25 pagesTechnical Specification For Composite Line Post Insulators: Ergon Energy Corporation LimitedardiwilagagunNo ratings yet

- Technical Specification For 33 KV Control and Relay Panels Against Tn-2527. 1.0 ScopeDocument43 pagesTechnical Specification For 33 KV Control and Relay Panels Against Tn-2527. 1.0 ScopeHossam AlzubairyNo ratings yet

- D-26 محولات توزيع 11 ك.فDocument19 pagesD-26 محولات توزيع 11 ك.فAhmed Al-BaghdadiNo ratings yet

- 16 Samss 507 PDFDocument27 pages16 Samss 507 PDFnadeemNo ratings yet

- S7-200 Technical SpecificationsDocument78 pagesS7-200 Technical SpecificationsLong TrầnNo ratings yet

- Specification For Tender AIS 17,5 KV Vacuum CBDocument8 pagesSpecification For Tender AIS 17,5 KV Vacuum CBNguyen ngoc thongNo ratings yet

- 16 Samss 519Document10 pages16 Samss 519hisham.yousefNo ratings yet

- Rev1 of Spec For 25 Kva PDFDocument24 pagesRev1 of Spec For 25 Kva PDFAshwinee KumarNo ratings yet

- MSEDCL - 11KV VCB SpecsDocument37 pagesMSEDCL - 11KV VCB Specsabhi6784No ratings yet

- 02.power Transformer-160 &63mvaDocument138 pages02.power Transformer-160 &63mvaraj_stuff006100% (1)

- 16 Samss 514Document17 pages16 Samss 514HatemS.MashaGbehNo ratings yet

- 01 Power TransformerDocument23 pages01 Power TransformerKec M&BD0% (1)

- 5522A Specs RevVDocument18 pages5522A Specs RevVbismarck bismarckNo ratings yet

- Specification For Distribution TransformersDocument18 pagesSpecification For Distribution TransformersDanish MohammedNo ratings yet

- HV and LV CablesDocument11 pagesHV and LV Cablessarsan nedumkuzhi maniNo ratings yet

- Lot 1 - 3 SpecsDocument82 pagesLot 1 - 3 SpecsEdwin Cob GuriNo ratings yet

- Instruction Manual: 5COR469100 - BR25AT - REV00Document8 pagesInstruction Manual: 5COR469100 - BR25AT - REV00Javier SalaNo ratings yet

- Solcon USA HRVS DN MV 10 13pt8kV Spec Guide 2011Document10 pagesSolcon USA HRVS DN MV 10 13pt8kV Spec Guide 2011harmlesdragonNo ratings yet

- S-AAA-SWG-MVLV-LA (Rev.0-2015)Document7 pagesS-AAA-SWG-MVLV-LA (Rev.0-2015)Paulson GloryNo ratings yet

- 65 Bedded MCH-mongar-Technical Specification - Electrical and LV SystemDocument53 pages65 Bedded MCH-mongar-Technical Specification - Electrical and LV SystemJigme TenzinNo ratings yet

- 0.6 - 1 KV MICA-XLPE-LSHF CAT A MC Rev.02Document19 pages0.6 - 1 KV MICA-XLPE-LSHF CAT A MC Rev.02Supakanit LimsowanNo ratings yet

- E05 33 11 LV Distribution Power Cables v5Document77 pagesE05 33 11 LV Distribution Power Cables v5Anorld WalkerNo ratings yet

- SECTION 16060 Grounding and Bonding Rev 0Document22 pagesSECTION 16060 Grounding and Bonding Rev 0Ahmed HashimNo ratings yet

- Technical Specification VCB PanelDocument14 pagesTechnical Specification VCB PanelDarshit VyasNo ratings yet

- 33kV & 22kV GIS Specifications PDFDocument15 pages33kV & 22kV GIS Specifications PDFAlauddin khanNo ratings yet

- La WbsebDocument11 pagesLa WbsebPritamNo ratings yet

- ETS 0071 Am 1Document17 pagesETS 0071 Am 1AnthonyNo ratings yet

- LIGHTNING ARRESTORS - Rev 2Document11 pagesLIGHTNING ARRESTORS - Rev 2kajale.shrikantNo ratings yet

- 3931295f en 5522A Ext Specs WDocument19 pages3931295f en 5522A Ext Specs WKazi AlimNo ratings yet

- Materials System Specification: Saudi Aramco Desktop StandardsDocument13 pagesMaterials System Specification: Saudi Aramco Desktop StandardsEagle Spirit100% (1)

- 11 KV Capacitor BankDocument26 pages11 KV Capacitor BankPrabhat SinghNo ratings yet

- 1212.01 15kV GRD WYE-Padmount & Overhead Distribution TransformersDocument18 pages1212.01 15kV GRD WYE-Padmount & Overhead Distribution TransformerskrisNo ratings yet

- AC Combiner Box Specification 400vac)Document7 pagesAC Combiner Box Specification 400vac)emilNo ratings yet

- 400kV CB - MSETCLDocument33 pages400kV CB - MSETCLVenkatNo ratings yet

- Design Example Report: Title Specification Application Author Document Number Date RevisionDocument34 pagesDesign Example Report: Title Specification Application Author Document Number Date Revisionzuffflor_925748656No ratings yet

- 33 KV Potential TransformerDocument14 pages33 KV Potential TransformerTamal DuttaNo ratings yet

- Technical Specification 11kV Covered Conductor and AccessoriesDocument28 pagesTechnical Specification 11kV Covered Conductor and AccessoriesAshish bhattNo ratings yet

- DLC01 - Vol 3 Specs 2 LVABC Construction ManualDocument43 pagesDLC01 - Vol 3 Specs 2 LVABC Construction ManualTerex14253No ratings yet

- Section Four - Medium Voltage Tr-Xlpe Cables: Explanatory Information 2-13Document56 pagesSection Four - Medium Voltage Tr-Xlpe Cables: Explanatory Information 2-13Terex14253No ratings yet

- Compression Fittings Technical SpecDocument12 pagesCompression Fittings Technical SpecTerex14253No ratings yet

- DLC01 - Vol 3 Specs 1 MV and LV Specficiations - ConsDocument24 pagesDLC01 - Vol 3 Specs 1 MV and LV Specficiations - ConsTerex14253No ratings yet

- ACSR Metric PDFDocument13 pagesACSR Metric PDFArinze AdibeNo ratings yet

- All Aluminum Alloy 6201-T81 Conductors (AAAC)Document12 pagesAll Aluminum Alloy 6201-T81 Conductors (AAAC)Terex14253No ratings yet

- Specificationmonopoles Overhead Double Circuit LineDocument28 pagesSpecificationmonopoles Overhead Double Circuit LineHosam AlzubairyNo ratings yet

- Technical Specification For Suspension and Suspension Angle ClampsDocument10 pagesTechnical Specification For Suspension and Suspension Angle ClampsTerex14253No ratings yet

- Overhead Sub Transmission Construction Manual Earthing Overhead Sub TransmissionDocument10 pagesOverhead Sub Transmission Construction Manual Earthing Overhead Sub TransmissionTerex14253No ratings yet

- Rajesh Sharma Automatic Meter Reading For Sub Stations and Consumer MetersDocument30 pagesRajesh Sharma Automatic Meter Reading For Sub Stations and Consumer MetersAayush ManhasNo ratings yet

- TSDOS BOLD Transmission Line Considerations FINAL 7 28 16 PDFDocument13 pagesTSDOS BOLD Transmission Line Considerations FINAL 7 28 16 PDFizlajnNo ratings yet

- Document - in Project New 11kv Feeder From Rarawai Eflcomfjwp Contentuploads201507mr 117 2015 TenderreDocument13 pagesDocument - in Project New 11kv Feeder From Rarawai Eflcomfjwp Contentuploads201507mr 117 2015 TenderreTerex14253No ratings yet

- Technical Specification For Non-Tension (Bolted) ConnectorsDocument20 pagesTechnical Specification For Non-Tension (Bolted) ConnectorssulemankhalidNo ratings yet

- Technical Specification For Helical Fittings For Overhead Power LinesDocument14 pagesTechnical Specification For Helical Fittings For Overhead Power LinesTerex14253No ratings yet

- ETS01-07-01 - Specs LV ABC & XLPE Cable Equipment & FittingsDocument61 pagesETS01-07-01 - Specs LV ABC & XLPE Cable Equipment & FittingsTerex14253No ratings yet

- 6ContrA31-Section VI-PS-lines Technical Spec - DistributionDocument30 pages6ContrA31-Section VI-PS-lines Technical Spec - DistributionTerex14253No ratings yet

- Construction of 11kv Dedicated Feeder of 11kv Dedicated Feeder For Power SupplyDocument76 pagesConstruction of 11kv Dedicated Feeder of 11kv Dedicated Feeder For Power SupplyTerex14253No ratings yet

- Guides For: Electric Cooperative Development and Rural Electrifi CationDocument37 pagesGuides For: Electric Cooperative Development and Rural Electrifi CationTerex14253No ratings yet

- Development of A Grid-Based Rural ElectrDocument10 pagesDevelopment of A Grid-Based Rural ElectrTerex14253No ratings yet

- Bazian Steel Factory Earthing CalculationDocument29 pagesBazian Steel Factory Earthing Calculationsahli medNo ratings yet

- STNW3369 Distribution Line Design UGDocument62 pagesSTNW3369 Distribution Line Design UGlampardbkNo ratings yet

- Guideline For Adoption of CMEN Earthing System: Purpose and ScopeDocument14 pagesGuideline For Adoption of CMEN Earthing System: Purpose and ScopeTerex14253No ratings yet

- JTS02-02-01 - Pad Mounted Distribution TransformerSpecDocument47 pagesJTS02-02-01 - Pad Mounted Distribution TransformerSpecTerex14253No ratings yet

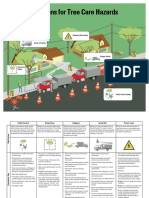

- Solutions For Tree Care HazardsDocument2 pagesSolutions For Tree Care HazardsTerex14253No ratings yet

- OHTL CatalogDocument46 pagesOHTL CatalogXabi AlonsoNo ratings yet

- General Purpose ISO ContainersDocument15 pagesGeneral Purpose ISO ContainersMIRCEA1305No ratings yet

- ITSD Document StandardDocument77 pagesITSD Document StandardhenrykylawNo ratings yet

- Final Industry Book of Knowledge v1.2Document39 pagesFinal Industry Book of Knowledge v1.2Vandana BaitNo ratings yet

- Astm F3001-14 (2021)Document6 pagesAstm F3001-14 (2021)SiavashNo ratings yet

- Euro Ncap Application of Star Ratings v13Document8 pagesEuro Ncap Application of Star Ratings v13borislavNo ratings yet

- 01ML0030 ES-08009 - C - Especificação de MPDocument2 pages01ML0030 ES-08009 - C - Especificação de MPRafah1212No ratings yet

- CBC BulldozerDocument57 pagesCBC BulldozerJohn JamesNo ratings yet

- MM - 1.1 DumpDocument16 pagesMM - 1.1 Dumptrip100% (1)

- ITP For Structure Steel Erection WorksDocument13 pagesITP For Structure Steel Erection WorksShewale PravinNo ratings yet

- Project Document Control: Instruction F2.5Document4 pagesProject Document Control: Instruction F2.5sj_scribdNo ratings yet

- Ceramic Tile Installation MaterialsDocument15 pagesCeramic Tile Installation MaterialsIm ChinithNo ratings yet

- GeM Bidding 4954071Document18 pagesGeM Bidding 4954071UMESH PATILNo ratings yet

- Method Statement For Conduit Installation - Cast in Situ of PVC / Gi / Ms Conduit Pipe For Electrical WorksDocument6 pagesMethod Statement For Conduit Installation - Cast in Situ of PVC / Gi / Ms Conduit Pipe For Electrical WorksRahul BharadwajNo ratings yet

- MDTS 262rev 02 04.11.2020Document6 pagesMDTS 262rev 02 04.11.2020Abhey DograNo ratings yet

- SPP DOC 200 - 209 QUIZ - NO ANSWERDocument15 pagesSPP DOC 200 - 209 QUIZ - NO ANSWERTatiana 21No ratings yet

- SCC PDFDocument16 pagesSCC PDFSaptarshi ChatterjeeNo ratings yet

- Bazil (22381027) Srs AtmDocument29 pagesBazil (22381027) Srs AtmBazilNo ratings yet

- Civil Engr - IshaqDocument3 pagesCivil Engr - IshaqKhalil KhattakNo ratings yet

- Srs ATMDocument17 pagesSrs ATMsaitejaNo ratings yet

- ACTED Rehabilitation of Health Center SchoolsDocument86 pagesACTED Rehabilitation of Health Center Schoolsعلي جودهNo ratings yet

- Piping Stress Analysis Specification for PTTEP Arthit Field DevelopmentDocument23 pagesPiping Stress Analysis Specification for PTTEP Arthit Field Developmentsamprof4vw83% (6)

- UCS503 Process ModelsDocument29 pagesUCS503 Process Modelsmichal1991No ratings yet

- Cubicles & Toilet Partition Systems: Product CatalogDocument15 pagesCubicles & Toilet Partition Systems: Product CatalogheshamNo ratings yet

- Supplier Quality Manual PDFDocument59 pagesSupplier Quality Manual PDFMos CraciunNo ratings yet

- PPCoN 2169-2000Document113 pagesPPCoN 2169-2000Minh Hong PhamNo ratings yet

- L1-CHE-INF-009 VRIOGS Retirement FAQSDocument4 pagesL1-CHE-INF-009 VRIOGS Retirement FAQSCK TangNo ratings yet