Professional Documents

Culture Documents

What Is %LEL / %UEL / Lower and Upper Explosive Limits For Flammable Gases and Vapors

Uploaded by

Sherwin Delfin CincoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is %LEL / %UEL / Lower and Upper Explosive Limits For Flammable Gases and Vapors

Uploaded by

Sherwin Delfin CincoCopyright:

Available Formats

What is %LEL / %UEL / PID

Lower and Upper Explosive Limits for Flammable Gases

and Vapors

Before a fire or explosion can occur, three conditions must be met simultaneously.

A fuel (ie. combustible gas) and oxygen (air) must exist in certain proportions, along with an ignition

source, such as a spark or flame. The ratio of fuel and oxygen that is required varies with each

combustible gas or vapor.

The minimum concentration of a particular combustible gas or vapor necessary to support its combustion

in air is defined as the Lower Explosive Limit (LEL) for that gas. Below this level, the mixture is too "lean"

to burn. The maximum concentration of a gas or vapor that will burn in air is defined as the Upper

Explosive Limit (UEL). Above this level, the mixture is too "rich" to burn. The range between the LEL and

UEL is known as the flammable range for that gas or vapor.

Methane - LEL: 5% by volume in Air / UEL: 17% by volume in Air

Visual example to show where on the scale % of LEL is measured

Lower and Upper Explosive Limits

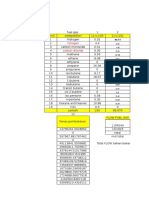

The values shown in the table below are valid only for the conditions under which they were determined

(usually room temperature and atmospheric pressure using a 2 inch tube with spark ignition). The

flammability range of most materials expands as temperature, pressure and container diameter increase.

All concentrations in percent by volume.

Gas LEL UEL

Acetone 2.6 13

Acetylene 2.5 100

Acrylonitrile 3 17

Allene 1.5 11.5

Ammonia 15 28

Benzene 1.3 7.9

1.3 Butadiene 2 12

Butane 1.8 8.4

n Butanol 1.7 12

1 Butene 1.6 10

Cis 2 Butene 1.7 9.7

Trans 2 Butene 1.7 9.7

Butyl Acetate 1.4 8

Carbon Monoxide 12.5 74

Carbonyl Sulfide 12 29

Chlorotrifluoro ethylene 8.4 38.7

Cumene 0.9 6.5

Cyanogen 6.6 32

Cyclohexane 1.3 7.8

Cyclopropane 2.4 10.4

Deuterium 4.9 75

Diborane 0.8 88

Dichlorosilane 4.1 98.8

Diethylbenzene 0.8

1.1 Difluoro 1 Chloroethane 9 14.8

1.1 Difluoroethane 5.1 17.1

1.1 Difluoro ethylene 5.5 21.3

Dimethylamine 2.8 14.4

Dimethyl Ether 3.4 27

2.2 Dimethyl propane 1.4 7.5

Ethane 3 12.4

Ethanol 3.3 19

Ethyl Acetate 2.2 11

Ethyl Benzene 1 6.7

Ethyl Chloride 3.8 15.4

Ethylene 2.7 36

Ethylene Oxide 3.6 100

Gasoline 1.2 7.1

Heptane 1.1 6.7

Hexane 1.2 7.4

Hydrogen 4 75

Hydrogen Cyanide 5.6 40

Hydrogen Sulfide 4 44

Isobutane 1.8 8.4

Isobutylene 1.8 9.6

Isopropanol 2.2

Methane 5 17

Methanol 6.7 36

Methylac etylene 1.7 11.7

Methyl Bromide 10 15

3 Methyl 1 Butene 1.5 9.1

Methyl Cellosolve 2.5 20

Methyl Chloride 7 17.4

Methyl Ethyl Ketone 1.9 10

Methyl Mercaptan 3.9 21.8

Methyl Vinyl Ether 2.6 39

Monoethy lamine 3.5 14

Monomethy lamine 4.9 20.7

Nickel Carbonyl 2

Pentane 1.4 7.8

Picoline 1.4

Propane 2.1 9.5

Propylene 2.4 11

Propylene Oxide 2.8 37

Styrene 1.1

Tetrafluoro ethylene 4 43

Tetrahydrofuran 2

Toluene 1.2 7.1

Trichloro ethylene 12 40

Trimethylamine 2 12

Turpentine 0.7

Vinyl Acetate 2.6

Vinyl Bromide 9 14

Vinyl Chloride 4 22

Vinyl Fluoride 2.6 21.7

Xylene 1.1 6.6

Gas LEL UEL

Principles of Gas Detection

One of the many requirements for entering confined spaces is the measurement for flammable gases.

Prior to entry of a confined space, the level of flammable gases must be below 10% of LEL.

The most common sensor used for measuring LEL is the Wheatstone bridge/catalytic bead/pellistor

sensor ("Wheatstone bridge").

LEL Sensors Explained

A Wheatstone bridge LEL sensor is simply a tiny electric stove with two burner elements. One element

has a catalyst (such as platinum) and one doesn't. Both elements are heated to a temperature that

normally would not support combustion.

However, the element with the catalyst "burns" gas at a low level and heats up relative to the element

without the catalyst. The hotter element has more resistance and the Wheatstone bridge measures the

difference in resistance between the two elements, which correlates to LEL.

Unfortunately, Wheatstone bridge sensors fail to an unsafe state; when they fail, they indicate safe levels

of flammable gases. Failure and/or poisoning of Wheatstone bridge LEL sensor can only be determined

through challenging Wheatstone bridge sensors with calibration gas.

LEL Sensors Limitations

Two mechanisms affect the performance of Wheatstone bridge LEL sensors and reduce their

effectiveness when applied to all but methane:

1. GASES BURN WITH DIFFERENT HEAT OUTPUTS

Some gases burn hot and some burn relatively cool. These differing physical characteristics lead to

difficulties when using LEL sensors. For example, 100% of LEL Methane (5% methane by volume)

burns with twice the heat of 100% of LEL Propane (2.0 propane by volume).

2. HEAVIER HYDROCARBON VAPORS HAVE DIFFICULTY DIFFUSING INTO LEL SENSORS

AND REDUCE THEIR OUTPUT

Some Heavier hydrocarbon vapors have difficulty diffusing through the sintered metal flame arrestor on

LEL sensors. This flame arrestor is necessary to prevent the sensor itself from starting a fire and does

not prevent gases like methane, propane and ethane from reaching the Wheatstone bridge. However,

hydrocarbons like gasoline, diesel, solvents, etc, diffuse through the flame arrestor slower so that less

vapor reaches the Wheatstone bridge and the sensor gives less output.

Why Not Use an LEL Monitor?

Many Volatile Organic Compounds (VOCs) are flammable and may be detected by the LEL or

combustible gas sensors found in virtually every multigas monitor. However, LEL sensors are not

particularly useful in measuring toxicity because they do not have enough sensitivity.

WHAT ARE SOME COMMON VOCS?

VOCs are the chemical compounds that keep industry going and include:

Fuels

Oils, °reasers, Heat Transfer Fluids

Solvents, Paints

Plastics, Resins and their precursors

and many others

VOCs are found throughout industry, from the obvious applications in the petro-chem industry to not-so-

obvious applications such as sausage manufacturing.

What is meant by PPM?

Parts per million (ppm) is a commonly used unit of concentration for small values. One part per million is

one part of solute per one million parts solvent or 10-6. Parts per million and other "parts per" notations

(e.g., parts per billion or parts per trillion) are dimensionless quantities with no units. Preferred methods

for expressing parts per million include μV/V (microvolume per volume), μL/L (microliters per liter), mg/kg

(milligram per kilogram), μmol/mol (micromole per mole), and μm/m (micrometer per meter).

The "parts per" notation is used to describe dilute solutions in chemistry and engineering, but its meaning

is ambiguous and it is not part of the SI system of measurement. The reason the system is ambiguous is

because the concentration depends on the original unit fraction that is used. For example, comparing one

milliliter of a sample to a million milliliters is different from comparing one mole to a million moles or one

gram to one million grams.

The University of Minnesota provides some other analogies that may help you visualize the scale involved

with PPM.

ONE PPM IS LIKE:

one inch in 16 miles

one second in 11.5 days

one minute in two years

one car in bumper-to bumper traffic from Cleveland to San Francisco

Other visualization of scale involved with PPB

ONE PPB IS LIKE:

adding a pinch of salt to a 10 ton bag of potato chips

One ppb is like one sheet in a roll of toilet paper stretching from New York to London.

LEL Sensors Measure Explosivity, Not Toxicity

LEL sensors measure percent of LEL. For example, Gasoline has an LEL of 1.4%. Therefore, 100% of

LEL is 14,000 ppm of gasoline, 10% of LEL is 1,400 ppm of gasoline and 1% of LEL is 140 ppm of

gasoline.

140 ppm of gasoline is the lowest amount of vapor that the LEL monitor can "see." Gasoline has a TWA

of 300 ppm and a STEL of 500 ppm; this does not make LEL sensors well suited for measuring gasoline

vapors because they simply don't provide adequate resolution.

LEL sensors measure explosivity, not toxicity. Many VOCs are potentially toxic at levels that are well

below their explosive levels and below the sensitivity of the LEL sensors.

AS DESCRIBED ABOVE:

One of the many requirements for entering confined spaces called is the measurement of confined

spaces for flammable gases.

Prior to entry of a confined space, the level of flammable gases must be below 10% of LEL.

The most common sensor used for measuring LEL is the Wheatstone bridge/catalytic bead/pellistor

sensor ("Wheatstone bridge").

While useful in a wide variety of applications, in some settings Wheatstone bridge LEL sensors either

don't have enough sensitivity to a particular chemical, or chemicals used in the environment can render

the Wheatstone bridge sensor inoperable.

In these types of circumstances, PIDs (photoionization detectors) can provide an alternative,

highly accurate, and poison-free means of measuring 10% of LEL for confined space entry.

What is a PID?

A Photo-Ionization Detector measures VOCs and other toxic gases in low concentrations from ppb (parts

per billion) up to 10,000 ppm (parts per million or 1% by volume).

A PID is a very sensitive broad-spectrum monitor, like a "low-level LEL monitor. A Photo-Ionization

Detector measures VOCs and other toxic gases in low concentrations from ppb (parts per billion) up to

10,000 ppm (parts per million or 1% by volume). A PID is a very sensitive broad-spectrum monitor, like a

"low-level LEL monitor.

How does a PID Work?

A Photo Ionization Detector (PID) uses an Ultraviolet (UV) light source (Photo= light) to break down

chemicals to positive and negative ions (Ionization) that can easily be counted with a Detector. Ionization

occurs when a molecule absorbs the high energy UV light, which excites the molecule and results in the

temporary loss of a negatively charged electron and the formation of positively charged ion.

The gas becomes electrically charged. In the Detector these charged particles produce a current that is

then amplified and displayed on the meter as "ppm" (parts per million) or even in "ppb" (parts per billion).

The ions quickly recombine after the electrodes in the detector to "reform" their original molecule.

PIDs are non-destructive; they do not "burn" or permanently alter the sample gas, which allows them to

be used for sample gathering.

What does a PID measure?

The largest group of compounds measured by a PID are the Organics: compounds containing Carbon (C)

atoms. These include:

Aromatics - compounds containing a benzene ring including benzene, toluene, ethyl benzene and

xylene

Ketones and Aldehydes - compounds with a C=O bond including acetone, methyl ethyl ketone

(MEK) and acetaldehyde

Amines and Amides - Carbon compounds containing nitrogen, like diethylamine

Chlorinated hydrocarbons - trichloroethylene (TCE), perchloroethylene (PERC)

Sulfur compounds - mercaptans, sulfides

Unsaturated hydrocarbons - like butadiene and isobutylene

Alcohol's- like isopropanol (IPA) and ethanol

Saturated hydrocarbons - like butane and octane. In addition to organic compounds, PIDs can be

used to measure some Inorganics. These are compounds without carbon and include:

Ammonia

Semiconductor gases: Arsine, Phosphine

Hydrogen sulfide

Nitric Oxide

Bromine and Iodine

You might also like

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)From EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)No ratings yet

- Swirling IncenDocument42 pagesSwirling Incendrop shipNo ratings yet

- InTech Focus Final Control Elements Sept2019Document33 pagesInTech Focus Final Control Elements Sept2019luciaNo ratings yet

- PFD - Nitrogen Plant UTL Plaju (Cold Box)Document1 pagePFD - Nitrogen Plant UTL Plaju (Cold Box)Julia Dwi LestariNo ratings yet

- Boiler OEE Calculation Ver1.00Document37 pagesBoiler OEE Calculation Ver1.00bkprodhNo ratings yet

- Furnace Control With The Help of TempDocument16 pagesFurnace Control With The Help of TempMukesh BhartiNo ratings yet

- MM MM MM Kpa (Psi) Kpa (Psi) MM MM MM: Steps When D /T 10Document3 pagesMM MM MM Kpa (Psi) Kpa (Psi) MM MM MM: Steps When D /T 10bibhansuNo ratings yet

- Vent Size Imp For Pressure VesselsDocument3 pagesVent Size Imp For Pressure Vesselsthomas_v501925No ratings yet

- @ 60 Degc 100 WT % H2ODocument30 pages@ 60 Degc 100 WT % H2OMildoggNo ratings yet

- Actual Pressure Head Ideal Pressure Head Velocity Head Elevation Head Actual Total Head Ideal Total HeadDocument5 pagesActual Pressure Head Ideal Pressure Head Velocity Head Elevation Head Actual Total Head Ideal Total HeadPei IngNo ratings yet

- Rect Plates: Enter Pipe Length in Inches Enter Schedule From The FollowingDocument19 pagesRect Plates: Enter Pipe Length in Inches Enter Schedule From The FollowingGanesh AdityaNo ratings yet

- 3P04 Tutorial 4 Post 2008Document8 pages3P04 Tutorial 4 Post 2008Khaled KamalNo ratings yet

- Perancangan CycloneDocument20 pagesPerancangan CycloneDavid LambertNo ratings yet

- Cooling Tower Calculations: I N P U TDocument2 pagesCooling Tower Calculations: I N P U ThuangjlNo ratings yet

- A04 Signal Cable Schedule (Field JB RIO)Document2 pagesA04 Signal Cable Schedule (Field JB RIO)Rakesh Karan SinghNo ratings yet

- ML Tank-Horizontal Tank Sizing Rev 0Document1 pageML Tank-Horizontal Tank Sizing Rev 0AJAY1381No ratings yet

- Semi Elliptical Head Volume and AreaDocument2 pagesSemi Elliptical Head Volume and AreaRNo ratings yet

- High Integrity Protection Systems (HIPS) - Making SIL Calculations EffectiveDocument4 pagesHigh Integrity Protection Systems (HIPS) - Making SIL Calculations Effective陳國政No ratings yet

- MX-20105ABC - Rev.1 (Stirrer - Agi Mix Tank D) - EnglishDocument4 pagesMX-20105ABC - Rev.1 (Stirrer - Agi Mix Tank D) - EnglishidilfitriNo ratings yet

- Heat Loss Example 4 4Document4 pagesHeat Loss Example 4 4WickyNo ratings yet

- fouling factor 중량 비체적: ft^2/Btu m^2/Kcal lb/ft kg/m lb/ft^3 kg/m^3 0.3689556791 1.4881889764 16.018732594Document27 pagesfouling factor 중량 비체적: ft^2/Btu m^2/Kcal lb/ft kg/m lb/ft^3 kg/m^3 0.3689556791 1.4881889764 16.018732594김종민No ratings yet

- Psuextension Particle Size 4mm MetricDocument8 pagesPsuextension Particle Size 4mm MetricRed RedNo ratings yet

- Absorption (FGD)Document62 pagesAbsorption (FGD)Chaidir FajariNo ratings yet

- CT Blowdown PhilosophyDocument6 pagesCT Blowdown PhilosophyzamijakaNo ratings yet

- Ecuación de AntoineDocument35 pagesEcuación de AntoineRuben PachecoNo ratings yet

- Recommended Equal Friction MethodDocument2 pagesRecommended Equal Friction MethodPhyu Mar Thein KyawNo ratings yet

- Vent Dispersion Calc - OptionalDocument4 pagesVent Dispersion Calc - OptionalPeddy Nesa0% (1)

- Equal Friction MethodDocument7 pagesEqual Friction MethodfghabboonNo ratings yet

- Ammonia Mixing in Denox ApplicationDocument5 pagesAmmonia Mixing in Denox ApplicationvedrandriNo ratings yet

- Ta 0 °C Pa 0.98 Bar Xa 9260 % Ha 2435 KJ/KG: EvaporatorDocument8 pagesTa 0 °C Pa 0.98 Bar Xa 9260 % Ha 2435 KJ/KG: EvaporatorShella Theresya PandianganNo ratings yet

- Flow ConditionerDocument6 pagesFlow ConditionerIdehen KelvinNo ratings yet

- Nox ModelDocument127 pagesNox ModelClarence AG YueNo ratings yet

- Scrcostmanualchapter7thedition 2016revisions2017Document107 pagesScrcostmanualchapter7thedition 2016revisions2017Dave KevinNo ratings yet

- Perhitungan Furnace Efesiesnsi Furnace CDU 11-F-101Document40 pagesPerhitungan Furnace Efesiesnsi Furnace CDU 11-F-101Aditya PratomoNo ratings yet

- 9 - Primary DeNOx Measures in Large Pulverized Coal and Lignite Units Practical Solutions For Existing UniDocument24 pages9 - Primary DeNOx Measures in Large Pulverized Coal and Lignite Units Practical Solutions For Existing UniStefanos GabalacNo ratings yet

- STM Dosing and Feeding Systems For Air Pollution ControlDocument42 pagesSTM Dosing and Feeding Systems For Air Pollution ControlJoseph RileyNo ratings yet

- CID FanDocument2 pagesCID FanIrfan AhmedNo ratings yet

- Equilibrium LineDocument8 pagesEquilibrium Linedhea novitaNo ratings yet

- Hs DiagramDocument32 pagesHs DiagramsubratorajNo ratings yet

- Made by Date: Top BTM Condition Condition Braced ? SS Slenderness Status Lo LeDocument12 pagesMade by Date: Top BTM Condition Condition Braced ? SS Slenderness Status Lo LeT Satheesh KumarNo ratings yet

- Product Line Sulphur enDocument4 pagesProduct Line Sulphur enprgunjalNo ratings yet

- Zfactor Spreadsheet VersionDocument35 pagesZfactor Spreadsheet VersionCHANADASNo ratings yet

- Turbine Combustion Kinetics PSR-1 : CVODE Starts at Line 100 On EXCEL SheetDocument14 pagesTurbine Combustion Kinetics PSR-1 : CVODE Starts at Line 100 On EXCEL SheetcymyNo ratings yet

- De Laval C-D NozzleDocument4 pagesDe Laval C-D NozzleAravind Pradhyumnan BalajiNo ratings yet

- Ows Piping Size2BLDocument3 pagesOws Piping Size2BLreach_arindomNo ratings yet

- 03 HRR Flame Height Burning Duration Calculations Sup1Document5 pages03 HRR Flame Height Burning Duration Calculations Sup1Haris AbdulahNo ratings yet

- Pdi EspDocument1 pagePdi EspSonratNo ratings yet

- RVK Energy LTD: Sheet 1 of 6Document6 pagesRVK Energy LTD: Sheet 1 of 6lightsonsNo ratings yet

- PFD Dme PlantDocument1 pagePFD Dme PlantSyamsul Rizal Abd ShukorNo ratings yet

- 2 - Application of NOx Emissions Control Technologies To Achieve NOx Emission Less Than 200 MgNm3 On CoalDocument15 pages2 - Application of NOx Emissions Control Technologies To Achieve NOx Emission Less Than 200 MgNm3 On CoalStefanos GabalacNo ratings yet

- Furnace Efficiency: Fuel OilDocument3 pagesFurnace Efficiency: Fuel OilMohamed Sayed AbdoNo ratings yet

- Heat Balance Computation and TFT DeterminationDocument8 pagesHeat Balance Computation and TFT DeterminationJose Renz EspaltoNo ratings yet

- Loop 1 Loop Loop Loop Loop Loop Loop Loop Loop: DMP-B01-B54814-2 DMP-B01-B54814-2Document86 pagesLoop 1 Loop Loop Loop Loop Loop Loop Loop Loop: DMP-B01-B54814-2 DMP-B01-B54814-2Rakesh Karan SinghNo ratings yet

- Oilproperties.Xls: Γ Api +131 - 5 Ρ Γ R Γ Γ ADocument3 pagesOilproperties.Xls: Γ Api +131 - 5 Ρ Γ R Γ Γ ATifano KhristiyantoNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Vent Dispersion CalcDocument9 pagesVent Dispersion CalcPeddy Nesa0% (1)

- LP - FlashDocument6 pagesLP - FlashvikramNo ratings yet

- Approved: Pöyry EnergyDocument3 pagesApproved: Pöyry Energytvpham123No ratings yet

- What Is LEL UEL PIDDocument11 pagesWhat Is LEL UEL PIDHafed HafedNo ratings yet

- What Is %LEL / %UEL /: Lower & Upper Explosive Limits For Flammable Gases & VaporsDocument11 pagesWhat Is %LEL / %UEL /: Lower & Upper Explosive Limits For Flammable Gases & Vaporskenoly123No ratings yet

- TD BI Crane Maintenance Book1Document9 pagesTD BI Crane Maintenance Book1Sherwin Delfin CincoNo ratings yet

- IMDG Part3 PDFDocument148 pagesIMDG Part3 PDFSherwin Delfin CincoNo ratings yet

- Wheel Over Position CalculationDocument3 pagesWheel Over Position CalculationSherwin Delfin CincoNo ratings yet

- Classification of Dangerous Goods: Class 1:explosivesDocument5 pagesClassification of Dangerous Goods: Class 1:explosivesSherwin Delfin CincoNo ratings yet

- SOLAS Convention Explained in SummaryDocument13 pagesSOLAS Convention Explained in SummarySherwin Delfin CincoNo ratings yet

- IMDG Part3 PDFDocument148 pagesIMDG Part3 PDFSherwin Delfin CincoNo ratings yet

- International Maritime Dangerous Goods (IMDG) Code, 2018 EditionDocument15 pagesInternational Maritime Dangerous Goods (IMDG) Code, 2018 EditionSherwin Delfin CincoNo ratings yet

- GR No. 80965 June 6, 1990Document3 pagesGR No. 80965 June 6, 1990Sherwin Delfin CincoNo ratings yet

- GyroerrorDocument4 pagesGyroerrorSherwin Delfin CincoNo ratings yet

- G.R. No. L-16587Document3 pagesG.R. No. L-16587Sherwin Delfin CincoNo ratings yet

- 123 Scra 160Document8 pages123 Scra 160Sherwin Delfin CincoNo ratings yet

- G.R. No. 129018Document1 pageG.R. No. 129018Sherwin Delfin CincoNo ratings yet

- G.R. No. L-17725Document3 pagesG.R. No. L-17725Sherwin Delfin CincoNo ratings yet

- G.R. No. 133632Document1 pageG.R. No. 133632Sherwin Delfin CincoNo ratings yet

- 183 Scra 171Document1 page183 Scra 171Sherwin Delfin CincoNo ratings yet

- Acebedo Optical Vs CADocument2 pagesAcebedo Optical Vs CASherwin Delfin CincoNo ratings yet

- G.R. No. L-30056Document5 pagesG.R. No. L-30056Sherwin Delfin CincoNo ratings yet

- GR No. 43012, Jan 16, 1936Document3 pagesGR No. 43012, Jan 16, 1936Sherwin Delfin Cinco100% (1)

- G.R. No. L-3756 June 30, 1952Document1 pageG.R. No. L-3756 June 30, 1952Sherwin Delfin Cinco100% (1)

- Canon 2.0 Villatuya vs. Tabolingcos A.C. No. 6622Document16 pagesCanon 2.0 Villatuya vs. Tabolingcos A.C. No. 6622Sherwin Delfin CincoNo ratings yet

- A.C. No. 6622 Villatiya vs. Tabolingcos DigestDocument4 pagesA.C. No. 6622 Villatiya vs. Tabolingcos DigestSherwin Delfin CincoNo ratings yet

- Farmakognosi Steroid PDFDocument14 pagesFarmakognosi Steroid PDFjulioNo ratings yet

- Angew Chem Int Ed - 2015 - Pan - Total Synthesis of Diterpenoid Steenkrotin ADocument4 pagesAngew Chem Int Ed - 2015 - Pan - Total Synthesis of Diterpenoid Steenkrotin Azhang quanNo ratings yet

- Cambridge IGCSE Chemistry Topic 10: Metals: ReactivityDocument3 pagesCambridge IGCSE Chemistry Topic 10: Metals: Reactivityasif shawNo ratings yet

- CALDURI Specifice GAZEDocument2 pagesCALDURI Specifice GAZEDan SabadusNo ratings yet

- Active Ingredients of CosmeceuticalsDocument6 pagesActive Ingredients of CosmeceuticalsRnD Roi SuryaNo ratings yet

- Isolation of R (+) - Limonene From Orange PeelDocument3 pagesIsolation of R (+) - Limonene From Orange PeelPrince Pulvera67% (3)

- Lesson 21 - How To Be A Better ParentDocument36 pagesLesson 21 - How To Be A Better ParentKamto EzenwamaduNo ratings yet

- Biotechnology - Principles and Processes: 1) Genetic EngineeringDocument11 pagesBiotechnology - Principles and Processes: 1) Genetic EngineeringRaichal P BijuNo ratings yet

- Gasifcn NptelDocument12 pagesGasifcn NptelYaaroNo ratings yet

- Zymo Research Price List 2022Document4 pagesZymo Research Price List 2022indra maulanaNo ratings yet

- Race PCR PDFDocument6 pagesRace PCR PDFmanuel1788No ratings yet

- Extraction of Banana FiberDocument2 pagesExtraction of Banana Fibermuthamil05No ratings yet

- Thermochemical Properties Estimation For Biodiesel Related MixturesDocument11 pagesThermochemical Properties Estimation For Biodiesel Related Mixturesalberth_carantónNo ratings yet

- Growing and Using Capsicums and Chillies (2014Document71 pagesGrowing and Using Capsicums and Chillies (2014AscanioNo ratings yet

- Mock Che CHKLSTDocument3 pagesMock Che CHKLSTnassorussi9No ratings yet

- Ashford Formula Spec Data SheetDocument4 pagesAshford Formula Spec Data Sheetcaleb pazNo ratings yet

- Cebu PhilippinesDocument11 pagesCebu PhilippinesShaqena ZamriNo ratings yet

- Author's Accepted Manuscript: Biocatalysis and Agricultural BiotechnologyDocument32 pagesAuthor's Accepted Manuscript: Biocatalysis and Agricultural BiotechnologyPushpendra ChauhanNo ratings yet

- Theoretical Background: (CITATION Soh19 /L 1033)Document4 pagesTheoretical Background: (CITATION Soh19 /L 1033)Kimberly McleanNo ratings yet

- ASRJC H2 Chem 2021 P1 QPDocument20 pagesASRJC H2 Chem 2021 P1 QPantesipation ฅ'ω'ฅNo ratings yet

- BSC Bed 2 Year Chemistry SyllabusDocument6 pagesBSC Bed 2 Year Chemistry Syllabuslelico724No ratings yet

- W4L1 Combustion ReactionsDocument30 pagesW4L1 Combustion ReactionsYahia MetwalliNo ratings yet

- AR Infinite SolutionDocument16 pagesAR Infinite SolutionAbhishek S AatreyaNo ratings yet

- 2023 MQP 2334 ChemistryDocument7 pages2023 MQP 2334 ChemistrySHRIRAM JOSHINo ratings yet

- CommercialDocument233 pagesCommercialDil KathayatNo ratings yet

- Prep #26 - Non-Aqueous Liquids - Starch GlyceriteDocument1 pagePrep #26 - Non-Aqueous Liquids - Starch GlyceriteKirsten Shayne ManingasNo ratings yet

- CellDocument21 pagesCellsouravNo ratings yet

- Sonali Mohapatra, Chinmaya Mishra, Sudhansu S. Behera, Hrudayanath Thatoi, 2017, Vol. 78, PP 1007-1032Document26 pagesSonali Mohapatra, Chinmaya Mishra, Sudhansu S. Behera, Hrudayanath Thatoi, 2017, Vol. 78, PP 1007-1032Charles MarlowNo ratings yet

- The Journal of Supercritical Fluids: Owen Catchpole, Teresa Moreno, Fernando Montañes, Stephen TallonDocument9 pagesThe Journal of Supercritical Fluids: Owen Catchpole, Teresa Moreno, Fernando Montañes, Stephen TallonJeni NicolaeNo ratings yet

- Tapioca As An Alternative White Board For Writing and LearningDocument15 pagesTapioca As An Alternative White Board For Writing and LearningHaizel AbdulpattaNo ratings yet

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (58)

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (588)

- Challenger: A True Story of Heroism and Disaster on the Edge of SpaceFrom EverandChallenger: A True Story of Heroism and Disaster on the Edge of SpaceNo ratings yet

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachFrom EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachRating: 3.5 out of 5 stars3.5/5 (6)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (83)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)

- Dealers of Lightning: Xerox PARC and the Dawn of the Computer AgeFrom EverandDealers of Lightning: Xerox PARC and the Dawn of the Computer AgeRating: 4 out of 5 stars4/5 (88)

- Nutrition 101: Understanding the Science and Practice of Eating WellFrom EverandNutrition 101: Understanding the Science and Practice of Eating WellRating: 4.5 out of 5 stars4.5/5 (22)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- Fallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldFrom EverandFallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldRating: 4.5 out of 5 stars4.5/5 (83)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreFrom EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreRating: 4.5 out of 5 stars4.5/5 (33)

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureFrom EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureRating: 5 out of 5 stars5/5 (125)

- Packing for Mars: The Curious Science of Life in the VoidFrom EverandPacking for Mars: The Curious Science of Life in the VoidRating: 4 out of 5 stars4/5 (1396)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- From Darwin to Derrida: Selfish Genes, Social Selves, and the Meanings of LifeFrom EverandFrom Darwin to Derrida: Selfish Genes, Social Selves, and the Meanings of LifeRating: 4 out of 5 stars4/5 (2)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4 out of 5 stars4/5 (6)

- The One-Straw Revolution: An Introduction to Natural FarmingFrom EverandThe One-Straw Revolution: An Introduction to Natural FarmingRating: 4.5 out of 5 stars4.5/5 (272)