Professional Documents

Culture Documents

Industrial Lubricants - Hardcastle Petrofer

Uploaded by

rohan kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Lubricants - Hardcastle Petrofer

Uploaded by

rohan kumarCopyright:

Available Formats

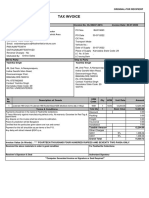

nd

10,Kitab Mahal, (2 floor),

192, Dr. D. N. Road, Fort,

Mumbai - 400 001.

India

Phone : (91) 22-2368 6617

Fax : (91) 22-2368 4644

e-mail : ho@hawcoindia.com

web : www.hawcoindia.com

Industrial

Lubricants

industrial oils and chemicals industrial oils and chemicals

HARDCASTLE has made

pioneering efforts during its long

market presence in the Indian

Metal Processing Chemicals and

lubricants Industry.

SLIDE WAY OIL:

HARDCASTLE was the first to

introduce advanced technology

products such as Polymer

Quenchant and Fire Resistant

HILUBRIC WL Series

Hydraulic Fluids to the Indian

Industry by indigenously

manufacturing and supporting

the performance through

unmatched service back-up.

HARDCASTLE is an approved HYDRAULIC OIL:

supplier to an entire spectrum of

leading industrial organizations

in the Private and Public sectors HILUBRIC AW Series

in India.

Thus, HARDCASTLE HILUBRIC HLP Series

Many products of PETROFER is an unparalleled HILUBRIC HLP-HN Series

HARDCASTLE are already combines of an Indian Company

being used by some leading AND a German Company both

industries on an exclusive basis. having served their respective

An Introduction ………… On the other hand, from its origin industries for over half a century.

in Central Europe, PETROFER They have come together to

Welcome to Hardcastle Petrofer has developed a worldwide complement each other's

network of associates and expertise and serve the Indian

Private Ltd. (HARDCASTLE

PETROFER), a joint Venture distributors to ensure that the industry with their combined

GEAR OIL:

between the Jatias of needs of its international strength. THE OBJECTIVE : TO

HARDCASTLE group and the customers are met completely. EXCEED THE HIGHLY

world renowned Petrofer SPECIALISED EXPECTATIONS HILUBRIC GR Series

Germany. PETROFER's commitment to

quality assurance and the

OF VARIED CUSTOMER

NEEDS.

HILUBRIC GR SYN HC Series

environment is reflected in it's

accreditation to the DIN EN ISO The products of HARDCASTLE

9001, QS 9000, VDA 6.1 and PETROFER, play a vital role in a

DIN EN ISO 14001 standards. wide variety of industrial

applications such as Heat

PETROFER's range of Industrial Treatment, Metal Working,

Lubricants are approved by Cleaning, Wire Drawing, HEAT TRANSFER OIL

various OEM's such as Bosch Corrosion Prevention, Fluid

Rexroth, Buhler Druckguss AG, Power, Steel Rolling, Off-Shore

Deckel - Maho Gildemeister, Drilling, Mining, etc. In addition, HILUBRIC TT - 1

Engel Austria GmbH, Muller - highly specialised products are

About the Partners…..

Weingarten AG, Liebherr developed for a wide range of HILUBRIC SYN TT Series

Verzahntechnik GmbH, Nagel customised applications.

Maschinen/Werkzeugfabrik

GmbH etc. HARDCASTLE PETROFER's

Indian manufacturing facility is

About us……

The excellence of PETROFER's located at Sarigam (near Vapi),

product range is the result of the Gujarat. You can always depend SPINDLE OIL:

Company's philosophy of on HARDCASTLE PETROFER's

continuous improvement and the team of qualified and

dedication of its personnel at its experienced chemists and

development centre in engineers, who will work with you HILUBRIC N Series

Hildesheim, Germany. to find the optimum solution to

your needs.

INTRODUCTION

SLIDE WAY OIL

HILUBRIC WL Series

Product description: Specifications :

The HILUBRIC WL Series of Slide way Oils are HILUBRIC WL slide way oils qualify to DIN 51517

formulated from High quality base oil and unique quality standard.

combination of additives. These Slide way oils are

stick-slip free & have high capacity to absorb the

pressure. These features avoid the boundary

lubrication conditions as much as possible for the best

possible accurate functioning of Machine Tool Slide Application :

ways.

The HILUBRIC WL Series of slide way oils are

The HILUBRIC WL Series of slide way oils have high most suitable for horizontal slide ways of

level of ageing resistance, excellent corrosion machine tools, ball screws, linear guides,

protection as well as very good oxidation resistance. translating screws as well as headstocks.

These slide way oils have very good compatibility with

Hardcastle Petrofer make soluble cutting oils.

These products have very good lubricity resulting in

“High quality Lubricant means improved productivity of machines and equipments & hence better profitability of a Business " effective wear protection under continuous loading

conditions. These slide way oils are Zinc free and have

excellent water separation characteristics.

Today, it is more important than Lubricants for Industry: Detergent products quickly

ever to maintain the value of that means careful absorb water and continue to

expensive assets. Modern selection of raw materials; ensure great corrosion

plant requires the optimum in continuous product monitoring; protection for your expensive

lubrication or power- extensive experience across equipment. HILUBRIC WL Series

transmitting media. The the whole field of tribological

selection of the right viscosity engineering. All this assures When selection of the

and the correct level of you that our products will be of lubricating / hydraulic medium,

additives are of utmost the highest quality. most suitable for a special Kinematic Viscosity

importance in preventing the purpose is being made, our Specific Gravity Flash point (°C)

ISO VG Product Name (mm²/s @ 40°C)

damage and destruction of At the concept stage of our Technical Services Department @ 30°C ASTM D 92

ASTM D 445

expensive equipment. lubricants for industry, special will gladly give advice at any

attention has been given to a time.

We have been dedicated for product being compatible with 46 HILUBRIC WL 46 46 0.877 220

years to the field of special common sealing elements and We monitor application

purpose lubricants, hydraulic materials and beyond that, to properties of lubricants, on

fluids and transmission oils and having demulsifying properties. request, within the framework 68 HILUBRIC WL 68 68 0.880 220

have a wealth of practical of our Customer Services in

experience. There are, Diffused water-miscible our laboratories.

therefore, special purpose oils coolant/lubricants (emulsions 100 HILUBRIC WL 100 100 0.884 230

of various viscosity classes and or solutions) can therefore This brochure is intended to

levels of performance available easily be removed by drawing give a general view of our

today for most industrial off. Any dangerous, mixed standard programme in the field 150 HILUBRIC WL 150 150 0.885 240

lubrication problems. Suitable friction that causes wear is of Industrial Lubrication.

lubricants have been made thus avoided.

available through our Research We can supply you with greases 220 HILUBRIC WL 220 220 0.892 250

and Development departments and other special purpose

for innumerable applications. lubricants, on request.

320 HILUBRIC WL 320 320 0.895 260

HYDRAULIC OIL (AW & HLP TYPE)

HYDRAULIC OIL HILUBRIC AW Series

HILUBRIC AW, HLP, HLP–HN Series Kinematic Viscosity

Viscosity Index Flash point (°C)

ISO VG Product Name (mm²/s @ 40°C)

ASTM D 2270 ASTM D 92

ASTM D 445

Product Description : Application :

15 HILUBRIC AW 15 15 100 165

The HILUBRIC HLP & AW Series Hydraulic Oils are HILUBRIC Series Hydraulic oils satisfy the

Premium grade, High quality mineral oil based, High requirements of a best quality Hydraulic oil for high, 22 HILUBRIC AW 22 22 100 180

viscosity index hydraulic oils. These oils have medium and low pressure Hydraulic systems requiring

characteristic of excellent viscosity temperature clean & high performance hydraulic oil, such as

relationship as well as anti-wear, anti-oxidation, anti- 32 HILUBRIC AW 32 32 100 190

corrosion and anti-foaming. INDUSTRIAL POWER PACKS, CNC MACHINES &

LATHES, MACHINING CENTRES 46 HILUBRIC AW 46 46 100 200

These Hydraulic Oils are also available in the NAS

Clean grade in the brand name of HILUBRIC PLASTIC MOLDING MACHINE (Injection, Blow, 68 HILUBRIC AW 68 68 100 200

HLP–HN Series Hydraulic Oils. Extrusion)

100 HILUBRIC AW 100 100 100 200

RUBBER MOLDING MACHINE (Injection,

Specification : Compression, Extrusion)

150 HILUBRIC AW 150 150 99 240

HILUBRIC Series Hydraulic Oils meet the International DIE - CASTING MACHINE (Al, Cu, Steel, Ceramic,

quality Hydraulic Oil Specification of DIN 51524 Part 2, other materials) 220 HILUBRIC AW 220 220 98 240

HLP Type.

MATERIAL HANDLING EQUIPMENTS/FORK LIFTS

These Hydraulic Oils provide maximum designed life to

a Hydraulic system due to minimized abrasion & wear, TEXTILE MACHINES (Knitting/ Weaving/ Loom

compatibility with various materials of Hydraulic system accessories)

as well as minimized sludge and varnish formation.

LAND MOUNTED & SHIP CRANE HYDRAULIC HILUBRIC HLP Series

SYSTEMS

HYDRAULIC OPERATED UNDERWATER TOOLS

Kinematic Viscosity

Viscosity Index Flash point (°C)

ISO VG Product Name (mm²/s @ 40°C)

ASTM D 2270 ASTM D 92

ELEVATORS, ESCALATORS, BUILDING LIFTS ASTM D 445

OTHER POWER TRANSMISSION EQUIPMENTS 15 HILUBRIC HLP15 15 100+ 165

22 HILUBRIC HLP 22 22 100+ 180

32 HILUBRIC HLP 32 32 100+ 190

46 HILUBRIC HLP 46 46 100+ 200

68 HILUBRIC HLP 68 68 100+ 200

100 HILUBRIC HLP 100 100 100 200

150 HILUBRIC HLP 150 150 100 240

220 HILUBRIC HLP 220 220 100 240

GEAR OIL (MINERAL OIL & SYNTHETIC TYPE)

HILUBRIC GR Series

Kinematic Viscosity

GEAR OIL Viscosity Index Flash point (°C)

ISO VG Product Name (mm²/s @ 40°C)

ASTM D 2270 ASTM D 92

ASTM D 445

HILUBRIC GR, GR SYN HC SERIES 46 HILUBRIC GR 46 46 100 200

68 HILUBRIC GR 68 68 100 210

Product Description : Application :

100 HILUBRIC GR 100 100 98 210

A] Hilubric GR Series A] Hilubric GR Series

150 HILUBRIC GR 150 150 98 220

HILUBRIC GR Series of Gear Oils are Lead free, These Gear Oils are most suited for worm, Spur

Gear oils having favorable viscosity-temperature Helical and Bevel type of enclosed gears with

relationship for the noise less functioning of an splash and circulation type lubrication up to 120 °C 220 HILUBRIC GR 220 220 98 220

enclosed Gear box system. temperature.

320 HILUBRIC GR 320 320 98 240

The excellent extreme pressure characteristics as The use of high performance Hilubric GR Series is

well as load carrying properties of these Gear oils advisable in severe industrial environments, e.g. in 460 HILUBRIC GR 460 460 97 240

make them a favorite choice of various Industrial the cement, lime and gypsum industry, in iron and

and marine Gear box users. The HILUBRIC GR steel works, crane transmissions, also in maritime

Series of Gear Oils have very good anti-wear, anti- environments and in special cases where a high 680 HILUBRIC GR 680 680 96 260

oxidation, anti-corrosion as well as anti-foaming degree of freedom from maintenance is regarded as

characteristics. important.

B] Hilubric GR SYN HC Series

B] Hilubric GR SYN HC Series

Hilubric GR SYN HC Series of Gear Oils are special

quality, high performance Synthetic Gear Oils with These Gear Oils are most suited for nearly all types

enhanced additive package. These products offer of enclosed gears and toothings which are

maximum protection from grey staining subjected to heavy mechanical loading and high HILUBRIC GR SYN HC Series

(micropitting) & thus offering increased operational temperature operating conditions. Also suitable for

life of Bearings, Gear tooth, Seals etc. long term effective lubrication of Gear Couplings, Kinematic Viscosity

slideways, plain and roller bearings, joints and Viscosity Index Flash point (°C)

ISO VG Product Name (mm²/s @ 40°C)

Specification: circulating lubrication systems of any type. ASTM D 2270 ASTM D 92

ASTM D 445

A] HILUBRIC GR Series of Gear Oils meet the

International quality Gear Oil Specification of DIN 150 HILUBRIC GR SYN HC 150 140 > 125 > 230

51517 PART 3, CLP Type.

220 HILUBRIC GR SYN HC 220 221 > 125 > 230

B] HILUBRIC GR SYN HC Series of Gear Oils meet

the international quality Gear Oil Specification of

320 HILUBRIC GR SYN HC 320 333 > 125 > 230

DIN 51517 PART 3, CLP (HC) Type

460 HILUBRIC GR SYN HC 460 462 > 125 > 235

HEAT TRANSFER OIL / THERMIC FLUID SPINDLE OIL

HILUBRIC TT & SYN TT Series HILUBRIC N Series

Product description : Application: Product description : Specification : Application :

HILUBRIC TT-1: (Mineral oil based Heat transfer oil) HILUBRIC –TT-1 Oil can be used in open and HILUBRIC N Series of Spindle HILUBRIC N Series of Spindle HILUBRIC N Series of Spindle

closed Industrial installations where temperature oils are formulated from high Oils meet the International oils are specially suitable for the

The HILUBRIC TT-1 Oil is a high performance Heat requirement ranges from quality base oil & hence they are quality specification of DIN effective lubrication of

Transfer Oil for closed and Indirect heating systems of – 13 °C up to 320 °C. highly resistant to oxidation. 51517 Part 2 for “CL” Type of hydrodynamic spindle bearings

various Industrial processes. The higher heat transfer Oils. of machine tools used for

rate and better operating efficiency of this Oil results in This Heat Transfer Oil is preferably used by These oils have very good anti - grinding operations.

to lower operating cost. The HILUBRIC TT-1 oil is process industries like chemical plants, extrusion rust, anti - corrosion and anti -

formulated from, highly refined mineral oil base stocks machines, molding machines as well as die-casting foaming characteristics. This Oil

having excellent resistance to chemical oxidation as machines. easily separates from the water

well as thermal cracking. due to very good demulsibility.

HILUBRIC SYN TT Series of synthetic heat transfer

fluids are best suited for the die temperature control The Extreme pressure additive

HILUBRIC SYN TT SERIES: (Synthetic Heat in die-casting and injection moulding industries, technology of HILUBRIC N

Transfer Fluid) where maximum bulk temperature requirement is Series of Spindle oils reduces

300 °C to 360 °C & maximum film temperature is the abrasion and wear of critical

HILUBRIC SYN TT-Series of Synthetic Heat Transfer 310 °C to 370 °C. Operating temperature range for spindle components by

Fluids have excellent ageing, oxidation stability and Hilubric Syn TT series of synthetic heat transfer absorbing the pressure

are specially suitable for closed heat transfer systems fluids ranges from - 50 °C to 360 °C generated and maintaining the

with low pressure circulation of the fluid. The long effective lubricant film over entire

service life and freedom from deposits makes these critical lubrication surface.

oils a favorable choice among its users.

HILUBRIC TT & SYN TT SERIES HILUBRIC N Series

Kinematic Viscosity

Viscosity Index Flash point (°C)

Kinematic ISO VG Product Name (mm²/s @ 40°C)

Specific Heat ASTM D 2270 ASTM D 92

Viscosity Pour Point (°C) Flash point (°C) ASTM D 445

Product Name (300°C)

(mm²/s @ 40°C) ASTM D 97 ASTM D 92 kJ/Kg K

ASTM D 445 2 HILUBRIC N 2 2 100 108

HILUBRIC TT-1 32 < = - 13 215 2.9 5 HILUBRIC N 5 5 100 140

HILUBRIC SYN TT-2 22 < = - 50 180 2.8 7 HILUBRIC N 7 7 100 145

10 HILUBRIC N 10 10 100 150

HILUBRIC SYN TT-3 21 < = - 48 185 2.8

15 HILUBRIC N 15 15 100 160

HILUBRIC SYN TT-4 16.5 < = - 33 200 2.6

OUR SPECIALTIES INCLUDE...

FIRE RESISTANT HYDRAULIC FLUIDS:

CLEANERS: HISAFE Series of HFA Type Fluids

HISAFE Series of HFB Type Fluids

HICLEAN L Series of Liquid Cleaner HISAFE Series of HFC Type Fluids

HICLEAN P Series of Powder Cleaner HISAFE Series of HFDU Type Fluids

HISAFE Series of HFDR Type Fluids

CUTTING COOLANTS: HEAT TREATING QUENCHANTS:

HICUT Series of Neat Cutting Oils

HIQUENCH Series of Cold Quenching Oils

HICUT Series of Soluble Cutting Oils

HIQUENCH MT Series of Hot Quenching Oils

HICUT Series of Bio Stable Semi Synthetic Cutting Oils

HIGRIND Series of Synthetic Grinding & Cutting Oils HIQUENCH P Series of Polymer Quenchants

DIECASTING & FORGING LUBRICANTS:

HEAT TREATING SALT BATHS,

HILUBRIC L Series of Die Release Agents PROTECTIVE AGENTS:

HILUBRIC PL Series of Plunger Lubricants

HILUBRIC PP Series of Solid Plunger Lubricants HICARB Series of Carburising Chemicals

HILUBRIC FW Series of Water Extendable Hot Forging Lubricants HISALT Series of Heat Treating Salts

HILUBRIC OG Series of Oil Based Hot Forging Lubricants

nd

10, Kitab Mahal, (2 floor), 192, Dr. D. N. Road, Fort Mumbai - 400 001.

Tel.: + 91 22-2368 6617 Fax : + 91 22-2368 4644

e-mail : ho@hawcoindia.com, web : www.hardcastlepetrofer.com

Works :

Plot No. 1906, 1908, 1910 & 1912, Tel. : + 91 260-278 0377

GIDC Phansa Road, Fax : + 91 260-278 0664

Sarigam - 396 155, e-mail : sarigam@hawcoindia.com

Dist.: Valsad, Gujarat.

METAL FORMING, DRAWING:

Regional Offices :

HIFORM Series for Metal Forming

HIDRAW Series for Deep Drawing & Wire Drawing North

Plot No. 706, Madhuban Building, Tel. : + 91 11-26473207, 26473208

55, Nehru Place, Fax : + 91 11-26473209

New Delhi - 110 019 e-mail : delhi@hawcoindia.com

East

2 N C Dutta Sarani, Tel. : +91 33-2210 6349 / 3242

Sagar Estate, 6501

3rd Floor, Room No. 7, Fax : +91 33-2230 9782

Kolkata - 700 001 e-mail : calcutta@hawcoindia.com

South

Greams Dugar, No. 64 Tel. : + 91 44-2829 0375

ROLLING: First Floor, South Wing e-mail : chennai@hawcoindia.com

Greams Road, Chennai - 600 006

HIROLL Series of Rolling Oil

HIRUSTAVERT Series of Rust Preventive Oil West

MSR Capital, Unit No. 05 & 06, Tel. : + 91 93251 31964

2nd Floor, Morwadi Court Road, e-mail : pune@hawcoindia.com

Pimpri, Pune - 411 018

Branch Offices :

Ludhiana Jamshedpur

K - 122, Phase Vll, Tin Shed

RUST PREVENTIVES: Focal Point, N– Road, Bistupur

Ludhiana - 141 010 Jamshedpur - 831 001

Tel.: +91 161 - 3225305 Tel.: +91 657-3247101

HIRUSTAVERT O Series of Oil Based Rust Preventives

e-mail : delhi@hawcoindia.com e-mail : calcutta@hawcoindia.com

HIRUSTAVERT S Series of Solvent Based Rust Preventives

HIRUSTAVERT DW Series of De-Watering Fluids Bengaluru Vadodara

HIRUSTAVERT WD Series of Water-Extendable Rust Preventives No. 235, 2nd Stage, 2nd Phase Office No. H-102,

15th ‘C’ Cross, Mahalakshmipura, Dreamland Complex,

HBCS, W.C. Road, Bengaluru - 560 086 Manjalpur, Vadodara - 390 011

Tel.: +91 88844 26000 e-mail : pune@hawcoindia.com

e-mail : chennai@hawcoindia.com Tel.: +91 265-2660867

Wherever you are, count on HARDCASTLE PETROFER’s Expertise, Quality and Dedication

You might also like

- Industrial Electronic Equipment ServiceDocument16 pagesIndustrial Electronic Equipment ServiceStar Suresh100% (1)

- Quotation 00: Solar Pani System Quote To: Ship ToDocument1 pageQuotation 00: Solar Pani System Quote To: Ship ToSolar Paani SystemNo ratings yet

- Enquiry in Put Format Customer DetailsDocument2 pagesEnquiry in Put Format Customer DetailssasigunaNo ratings yet

- 01 Machine Quotation New 1554191822390Document2 pages01 Machine Quotation New 1554191822390CB Narendra KumarNo ratings yet

- BB Engineering 02.12.2021Document1 pageBB Engineering 02.12.2021sriganeshmaharshiNo ratings yet

- Samvrudhi Technologies: Revised Quotation 250Document5 pagesSamvrudhi Technologies: Revised Quotation 250ŤhåýğųŢjNo ratings yet

- Anderol FGCS-2Document1 pageAnderol FGCS-2Martín BaezaNo ratings yet

- CNC Machine NameDocument5 pagesCNC Machine NameRajaNo ratings yet

- LARAN Sales Invoice - TT Steel 79Document3 pagesLARAN Sales Invoice - TT Steel 79likith.mallesh.14No ratings yet

- Company Profile PDFDocument17 pagesCompany Profile PDFranjithjoyNo ratings yet

- Mobil Vactra Oil Numbered Seiries BroshureDocument2 pagesMobil Vactra Oil Numbered Seiries BroshureAnibal RiosNo ratings yet

- Company Profile Hand Book: Sri Ragavendra Precision WorksDocument11 pagesCompany Profile Hand Book: Sri Ragavendra Precision WorksVedha TechnologiesNo ratings yet

- Transfer Learning and Fine-TuningDocument32 pagesTransfer Learning and Fine-TuningDevyansh GuptaNo ratings yet

- Conveyors: Perma Lubrication Systems ForDocument6 pagesConveyors: Perma Lubrication Systems ForTamal Tanu RoyNo ratings yet

- Klübersynth BEM 44-4600 - FlyerDocument2 pagesKlübersynth BEM 44-4600 - FlyerHizuafi Khairul100% (1)

- Kafuter K 704Document2 pagesKafuter K 704ketab_doostNo ratings yet

- Eipl Company ProfileDocument78 pagesEipl Company ProfileEr Sundeep RachakondaNo ratings yet

- Tax Invoice: For Gunatheetha Earth Moving Solutions PVT LTD.Document1 pageTax Invoice: For Gunatheetha Earth Moving Solutions PVT LTD.nagaraj spNo ratings yet

- Company Profile: Panorama Solutions PVT LTDDocument11 pagesCompany Profile: Panorama Solutions PVT LTDRamakrishna GNo ratings yet

- Chair BillDocument1 pageChair BillNAGARJUNANo ratings yet

- G P Industry - 850 VDocument12 pagesG P Industry - 850 VRamdas pawankarNo ratings yet

- Karcher Quotation List - 2023Document12 pagesKarcher Quotation List - 2023veereshmyb28No ratings yet

- Spr170321a20839 12133 1Document1 pageSpr170321a20839 12133 1aaanathanNo ratings yet

- Invoice Vat 16-17 10 PDFDocument1 pageInvoice Vat 16-17 10 PDFVenu GopalNo ratings yet

- Rishi Consfab ProfiileDocument24 pagesRishi Consfab ProfiileCaldwellNo ratings yet

- Lubrication ChartDocument2 pagesLubrication Chartkaushal kishoreNo ratings yet

- Klüberpaste ME 31-52: Product InformationDocument2 pagesKlüberpaste ME 31-52: Product InformationMassimiliano VolaNo ratings yet

- RustX - Corrosion Due To Cutting FluidDocument21 pagesRustX - Corrosion Due To Cutting FluidmukulsareenNo ratings yet

- Superior Electric Machines Pvt Ltd Quotation for Blowers under 40 charactersDocument2 pagesSuperior Electric Machines Pvt Ltd Quotation for Blowers under 40 charactersMUNINo ratings yet

- QuotationDocument1 pageQuotationSathish KumarNo ratings yet

- Tig Welding AMTQuotation - 218Document1 pageTig Welding AMTQuotation - 218MOHIT GARGNo ratings yet

- Technical Topic Procedure For Flushing Oil-Flooded Rotary Screw Air CompressorsDocument2 pagesTechnical Topic Procedure For Flushing Oil-Flooded Rotary Screw Air Compressorsdhavit wijayantoNo ratings yet

- Product Line Card Industrial MRO 2014Document1 pageProduct Line Card Industrial MRO 2014Project Sales CorpNo ratings yet

- IFB Industries: Leaders in Home Appliances and Fine Blanking ComponentsDocument4 pagesIFB Industries: Leaders in Home Appliances and Fine Blanking ComponentsBalaji EzhilanNo ratings yet

- 2014 609 - Mobil SHC 524 Synthetic Hydraulic Oil Success StoryDocument1 page2014 609 - Mobil SHC 524 Synthetic Hydraulic Oil Success StoryMudabbir Shan Ahmed100% (1)

- Sneha IndustriesDocument13 pagesSneha IndustriesDrVishwanatha HNNo ratings yet

- Coolant GuideDocument2 pagesCoolant Guidepurwa cuteNo ratings yet

- Daily Report For The Month of July 2012Document23 pagesDaily Report For The Month of July 2012Chethan PuttaswamyNo ratings yet

- Lubrication of GearsDocument6 pagesLubrication of GearsCesar VasquesNo ratings yet

- P-107 Quick GuideDocument2 pagesP-107 Quick GuidesunhuynhNo ratings yet

- Customer Contact Database with Lead TrackingDocument17 pagesCustomer Contact Database with Lead TrackingCorrosion FactoryNo ratings yet

- Indicative Packing List - Sanvira Carbon PDFDocument6 pagesIndicative Packing List - Sanvira Carbon PDFuvsarathiNo ratings yet

- Never-Seez India BusinessDocument1 pageNever-Seez India BusinessProject Sales CorpNo ratings yet

- Increase Industrial Profits with Synthetic LubricantsDocument9 pagesIncrease Industrial Profits with Synthetic LubricantsJako MishyNo ratings yet

- 08 Brahma Sutra Volume 08Document149 pages08 Brahma Sutra Volume 08Chigo AryaNo ratings yet

- Hal Part10Document10 pagesHal Part10Anil SargarNo ratings yet

- Parsons Quotation Fixtures 2019Document1 pageParsons Quotation Fixtures 2019Bharath ShettyNo ratings yet

- Coolants CoolantManagementDocument2 pagesCoolants CoolantManagementHeineken Ya Praneetpongrung100% (1)

- Sales ProfileDocument4 pagesSales ProfileayeshatoolsNo ratings yet

- Cumi BondedDocument18 pagesCumi BondedAvijitSinharoyNo ratings yet

- Your Benefit: Optimised Lubrication Management: Enhanced Reliability and Efficiency in Your PlantDocument2 pagesYour Benefit: Optimised Lubrication Management: Enhanced Reliability and Efficiency in Your PlantVelibor Karanovic100% (1)

- Udaygo Aadhar-Msme CertificateDocument1 pageUdaygo Aadhar-Msme CertificateRavindra Babu100% (1)

- High Speed Spindle Design and Construction - Modern Machine ShopDocument24 pagesHigh Speed Spindle Design and Construction - Modern Machine ShopJayakrishnaNo ratings yet

- Quote 023Document1 pageQuote 023Matthew LeeNo ratings yet

- Imtex 2023 Showcases Latest Machine Tools & Digital Manufacturing TechDocument3 pagesImtex 2023 Showcases Latest Machine Tools & Digital Manufacturing Techsunziv19No ratings yet

- List of OilDocument2 pagesList of Oilinigo71No ratings yet

- Molykote P37 in 500 Grams Brush Top TinsDocument1 pageMolykote P37 in 500 Grams Brush Top TinsProject Sales CorpNo ratings yet

- Keyboard shortcuts for navigating and working in TallyPrimeDocument16 pagesKeyboard shortcuts for navigating and working in TallyPrimeBalbir jhaNo ratings yet

- INDIA - Plastics CustomersDocument5 pagesINDIA - Plastics Customersmannu057No ratings yet

- Industrial LubricantsDocument8 pagesIndustrial LubricantsDharmesh patelNo ratings yet

- Health Insurance Plans in India - SANADocument11 pagesHealth Insurance Plans in India - SANAShrenika RautNo ratings yet

- Health Insurance Plans in India - SANADocument11 pagesHealth Insurance Plans in India - SANAShrenika RautNo ratings yet

- Group Health Insurance Plans in India - SANADocument5 pagesGroup Health Insurance Plans in India - SANAShrenika RautNo ratings yet

- Group Health Insurance Plans in India - SANADocument5 pagesGroup Health Insurance Plans in India - SANArohan kumarNo ratings yet

- Health Insurance Plans in India - SANADocument11 pagesHealth Insurance Plans in India - SANAShrenika RautNo ratings yet

- Quenching Oils - Hardcastle PetroferDocument22 pagesQuenching Oils - Hardcastle Petroferrohan kumarNo ratings yet

- Health Insurance Plans in IndiaDocument10 pagesHealth Insurance Plans in Indiarohan kumarNo ratings yet

- Health Insurance Plans in India - SANADocument11 pagesHealth Insurance Plans in India - SANAShrenika RautNo ratings yet

- Group Health Insurance Plans in India - SANADocument5 pagesGroup Health Insurance Plans in India - SANAShrenika RautNo ratings yet

- Quenching Oils - Hardcastle PetroferDocument22 pagesQuenching Oils - Hardcastle Petroferrohan kumarNo ratings yet

- Food Service Management Software - KSOFTPLDocument16 pagesFood Service Management Software - KSOFTPLrohan kumarNo ratings yet

- Rehab Center in India - Alpha Healing CenterDocument6 pagesRehab Center in India - Alpha Healing Centerrohan kumarNo ratings yet

- Group Gratuity Fund Advisory - Kapadia GlobalDocument14 pagesGroup Gratuity Fund Advisory - Kapadia Globalrohan kumarNo ratings yet

- Patient Management Software - KSOFTPLDocument11 pagesPatient Management Software - KSOFTPLrohan kumarNo ratings yet

- Hardcastle PetroferDocument16 pagesHardcastle Petroferrohan kumarNo ratings yet

- Neat Cutting Oils-Manufacturer & Supplier in India - Hardcastle PetroferDocument14 pagesNeat Cutting Oils-Manufacturer & Supplier in India - Hardcastle Petroferrohan kumarNo ratings yet

- Facility Management Services - KSOFTPLDocument12 pagesFacility Management Services - KSOFTPLrohan kumarNo ratings yet

- Actuarial Consulting Firm in India - Kapadia GlobalDocument12 pagesActuarial Consulting Firm in India - Kapadia Globalrohan kumarNo ratings yet

- Rehabilitation Center in India - Alpha Healing CenterDocument6 pagesRehabilitation Center in India - Alpha Healing Centerrohan kumarNo ratings yet

- Neat Cutting Oils-Manufacturer & Supplier in India - Hardcastle PetroferDocument14 pagesNeat Cutting Oils-Manufacturer & Supplier in India - Hardcastle Petroferrohan kumarNo ratings yet

- Neat Cutting Oils-Manufacturer & Supplier in India - Hardcastle PetroferDocument14 pagesNeat Cutting Oils-Manufacturer & Supplier in India - Hardcastle Petroferrohan kumarNo ratings yet

- Actuarial Consulting Firm in India - Kapadia GlobalDocument12 pagesActuarial Consulting Firm in India - Kapadia Globalrohan kumarNo ratings yet

- Quenching Oils - Hardcastle PetroferDocument22 pagesQuenching Oils - Hardcastle Petroferrohan kumarNo ratings yet

- Group Gratuity Fund Advisory - Kapadia GlobalDocument14 pagesGroup Gratuity Fund Advisory - Kapadia Globalrohan kumarNo ratings yet

- Group Gratuity Fund Advisory - Kapadia GlobalDocument14 pagesGroup Gratuity Fund Advisory - Kapadia Globalrohan kumarNo ratings yet

- Neat Cutting Oils-Manufacturer & Supplier in India - Hardcastle PetroferDocument14 pagesNeat Cutting Oils-Manufacturer & Supplier in India - Hardcastle Petroferrohan kumarNo ratings yet

- Actuarial Consulting Firm in India - Kapadia GlobalDocument12 pagesActuarial Consulting Firm in India - Kapadia Globalrohan kumarNo ratings yet

- Neat Cutting Oils-Manufacturer & Supplier in India - Hardcastle PetroferDocument14 pagesNeat Cutting Oils-Manufacturer & Supplier in India - Hardcastle Petroferrohan kumarNo ratings yet

- Quenching Oils - Hardcastle PetroferDocument22 pagesQuenching Oils - Hardcastle Petroferrohan kumarNo ratings yet

- 2009 PKC Brochure PDFDocument17 pages2009 PKC Brochure PDFMarco Aurelio DuranNo ratings yet

- Netherlands:Phd Contact Mechanics, Friction and Contact Fatigue On Polymeric SurfacesDocument2 pagesNetherlands:Phd Contact Mechanics, Friction and Contact Fatigue On Polymeric SurfacesFaisal ShahzadNo ratings yet

- Dynagard Blue & Dynagard E Specification Sheets 012309Document2 pagesDynagard Blue & Dynagard E Specification Sheets 012309rogerpfrNo ratings yet

- AOT Sucker RodDocument20 pagesAOT Sucker RodJose Gabriel Hernandez FelixNo ratings yet

- MS For Exterior CoatingDocument69 pagesMS For Exterior Coatingismail karakuzuNo ratings yet

- Reutilizacion CaterpillarDocument50 pagesReutilizacion CaterpillarJorge EspinozaNo ratings yet

- Sk575 Parts & Service ManualDocument251 pagesSk575 Parts & Service ManualAnibal Jose Cruz Larez100% (2)

- Coconut Milk Machine Squeezes and ShredsDocument24 pagesCoconut Milk Machine Squeezes and Shredsnaveeen chackoNo ratings yet

- Military Plating Spec-1Document11 pagesMilitary Plating Spec-1Durbha RaviNo ratings yet

- Failure Analysis For Plain BearingsDocument5 pagesFailure Analysis For Plain BearingsPuchit SpkNo ratings yet

- Performance of Centrifugal Pump Mechanic PDFDocument6 pagesPerformance of Centrifugal Pump Mechanic PDF최승원No ratings yet

- Rexnord Chain TroubleshootingDocument40 pagesRexnord Chain TroubleshootingAneeq RaheemNo ratings yet

- Seminar MAIN PAGES ON WDA 1Document15 pagesSeminar MAIN PAGES ON WDA 1OmkarNo ratings yet

- LowSpeed Failure MotorsDocument23 pagesLowSpeed Failure MotorsMichel Brassard AppliedNo ratings yet

- Oilcheck MANUALDocument2 pagesOilcheck MANUALOrlando MarucaNo ratings yet

- F1714 1479757-1Document7 pagesF1714 1479757-1Thaweekarn ChangthongNo ratings yet

- Marbett Component Solutions For BeverageDocument48 pagesMarbett Component Solutions For Beverageabsalon_jarvNo ratings yet

- Calculo de Factor PVDocument9 pagesCalculo de Factor PVAnonymous H3I29yjNo ratings yet

- Understanding belt tracking patterns and causes of belt swayDocument29 pagesUnderstanding belt tracking patterns and causes of belt swayNishantKumarGauravNo ratings yet

- PHD ChasalevrisDocument325 pagesPHD ChasalevrisJoel Morales PerezNo ratings yet

- High Alumina Ceramics: 2.ceramic Page 1 of 2Document2 pagesHigh Alumina Ceramics: 2.ceramic Page 1 of 2venka07No ratings yet

- Increasing The Performance of Chain Sprocket by Using Cryogenic Treated and Normalizing in Superficial Heat TreatmentDocument18 pagesIncreasing The Performance of Chain Sprocket by Using Cryogenic Treated and Normalizing in Superficial Heat Treatmentthai avvaiNo ratings yet

- RRS Full NotesDocument164 pagesRRS Full NotesAzhar KhanNo ratings yet

- B. Gerard, - Fundamentals of Hardfacing by Fusion Welding, Welding Alloys Group, USADocument35 pagesB. Gerard, - Fundamentals of Hardfacing by Fusion Welding, Welding Alloys Group, USAScienticsPeerNo ratings yet

- Wartsila 32 Bearing Assessment PDFDocument8 pagesWartsila 32 Bearing Assessment PDFHeryanto Syam100% (1)

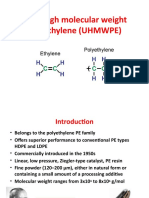

- Ultra high molecular weight polyethylene (UHMWPE) applicationsDocument32 pagesUltra high molecular weight polyethylene (UHMWPE) applicationsApoorva MNNo ratings yet

- Shell Corena S3 RJ Compressor Oil TDSDocument3 pagesShell Corena S3 RJ Compressor Oil TDSAnonymous oAbjbl4HNo ratings yet

- Comminution of Ceramics in Stirred Media Mills and Wear ofDocument8 pagesComminution of Ceramics in Stirred Media Mills and Wear of王柏昆No ratings yet

- PTFE Bronze Wear - enDocument1 pagePTFE Bronze Wear - enAli AlashryNo ratings yet

- Metal FormingDocument33 pagesMetal FormingSamir KhNo ratings yet