Professional Documents

Culture Documents

ARI ARMATUREN - Ball Float Steam Trap CONA

Uploaded by

rahimi mohamadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ARI ARMATUREN - Ball Float Steam Trap CONA

Uploaded by

rahimi mohamadCopyright:

Available Formats

Operating and installation instructions

Ball float steam traps

CONA®S (PN16 - 160)

PN16 / PN40

- with flanges (series 631....1)

- with screwed sockets (series 631....2)

- with socket weld ends (series 631....3) PN16 / PN40

- with butt weld ends (series 631....4) - with flanges (series 639....1)

PN160

- with flanges (series 631....1)

- with socket weld ends (series 631....3)

PN63 / PN100 - with butt weld ends (series 631....4)

- with flanges (series 631....1) Angle pattern:

- with socket weld ends (series 631....3) - with flanges (series 632....1)

- with butt weld ends (series 631....4) - with butt weld ends (series 632....4)

Contents

1.0 General information on operating 5.5 Installation position.............................................. 2-8

instructions ..................................................2-2 5.5.1 Possible installation positions ................. 2-9

2.0 Notes on possible dangers.........................2-2 6.0 Putting the valve into operation ................ 2-9

2.1 Significance of symbols ...................................... 2-2 7.0 Care and maintenance.............................. 2-10

2.2 Explanatory notes on safety information ............. 2-2 7.1 Cleaning and/or replacing the steam trap ......... 2-10

3.0 Storage and transport ................................2-2 7.2 Changing the installation position.......................2-11

4.0 Description...................................................2-3 7.3 Options blow down valve / manual air

4.1 Scope of application............................................ 2-3 vent valve .......................................................... 2-12

4.2 Operating principles ............................................ 2-3 7.4 Union for pressure compension line resp.

external vent...................................................... 2-12

4.3 Diagram............................................................... 2-4

7.5 Tightening torques............................................. 2-13

4.4 Technical data - remarks ..................................... 2-6

4.5 Marking ............................................................... 2-6 8.0 Troubleshooting ........................................ 2-14

5.0 Installation....................................................2-7 9.0 Troubleshooting table .............................. 2-14

5.1 General notes on installation............................... 2-7 10.0 Dismantling the valve or the body ........ 2-15

5.2 Installation instructions for welding ..................... 2-8 11.0 Warranty / Guarantee .............................. 2-15

5.3 Controller adjustment .......................................... 2-8

5.4 Steam trap testing through ultrasonic

measurement ...................................................... 2-8

Rev. 0040805000 3616 englisch

Operating and installation instructions

CONA®S - Ball float steam traps

1.0 General information on operating instructions

These operating instructions provide information on mounting and maintaining the fittings.

Please contact the supplier or the manufacturer in case of problems which cannot be

solved by reference to the operating instructions.

They are binding on the transport, storage, installation, start-up, operation, maintenance

and repair.

The notes and warnings must be observed and adhered to.

- Handling and all work must be carried out by expert personnel or all activities must be

supervised and checked.

It is the owner’s responsibility to define areas of responsibility and competence and to

monitor the personnel.

- In addition, current regional safety requirements must be applied and observed when

taking the fittings out of service as well as when maintaining and repairing them.

The manufacturer reserves the right to introduce technical modifications at any time.

These Operating Instructions comply with the requirements of EU Directives.

2.0 Notes on possible dangers

2.1 Significance of symbols

ATTENTION !

... Warning of general danger.

2.2 Explanatory notes on safety information

In these Operating and Installation Instructions dangers, risks and items of safety

information are highlighted to attract special attention.

Information marked with the above symbol and “ATTENTION!” describe practices, a failure

to comply with which can result in serious injury or danger of death for users or third parties

or in material damage to the system or the environment. It is vital to comply with these

practices and to monitor compliance.

All other information not specifically emphasised such as transport, installation, operating

and maintenance instructions as well as technical data (in the operating instructions,

product documentation and on the device itself) must also be complied with to the fullest

extent in order to avoid faults which in turn can cause serious injury to persons or damage

to property.

3.0 Storage and transport

ATTENTION !

- Protect against external force (like impact, vibration, etc.).

- Valves must not be used to take external forces, e.g. they are not designed for

use as climbing aids, or as connecting points for lifting gear.

- Suitable materials handling and lifting equipment should be used.

See catalog sheet for weights.

- At -20°C to +65°C.

- The paint is a base coat to protect against corrosion during transportation and storage.

Do not damage paint protection.

Page 2-2 Rev. 0040805000 3616

Operating and installation instructions

CONA®S - Ball float steam traps

4.0 Description

4.1 Scope of application

Float-type steam traps with level control and thermal regulation are used for the drainage of

industrial steam facilities.

ATTENTION !

- Refer to the data sheet for applications, limits on use and possibilities.

- Certain media require or preclude the use of special materials.

- The valves are designed for standard operating conditions. If conditions exceed

these requirements, e.g. aggressive or abrasive media, the operator should

state the higher requirements when ordering.

- Valves made from grey cast iron are not authorised for use in systems subject

to TRD 110.

The information complies to the Pressure Equipment Directive 2014/68/EU.

It is the responsibility of the machine planner to ensure compliance.

The special markings on the valve must be taken into account.

Refer to the catalogue sheet to see which materials are used in standard versions.

Please contact the supplier or the manufacturer if you have any questions.

4.2 Operating principles

(see Fig. 7a and b page 11)

The steam trap is controlled by a swivel-mounted ball float (Pos. 24.16). An integral

bimetallic element (Pos. 24.6) provides automatic starting ventilation in the cold state.

At temperatures less than 90°C, the bi-metallic element holds the discharge orifice open,

allowing air and other gasses to escape. At 90°C the bi-metallic element is fully closed and

discharge is controlled only by the float mechanism (Pos. 24.16). At the higher

temperatures, air is automatically evacuated (Pos. 24.12), ejector style, with the

condensate.

If the amount of condensate decreases or if there is no condensate, the ball float (Pos.

24.16) faces and locks the valve ball (Pos. 24.4) on the seat (Pos. 24.1). If the steam trap is

acted upon only by vapour, the condensate-flooded seat (Pos. 24.1) remains shut.

The valve ball (Pos. 24.4) also works with the seat (Pos. 24.1) as a non-return valve.

Rev. 0040805000 3616 Page 2-3

Operating and installation instructions

CONA®S - Ball float steam traps

4.3 Diagram

Fig. 1: CONA®S - series 631 PN16-40

DN15-50

Fig. 2: CONA®S - series 631 PN63-100

PN63 without erosion deflector (pos. 29)

DN15-50

Page 2-4 Rev. 0040805000 3616

Operating and installation instructions

CONA®S - Ball float steam traps

Fig. 3: CONA®S - series 631 PN160

DN15-50

Fig. 4: CONA®S - series 632 PN160

DN15-50

Rev. 0040805000 3616 Page 2-5

Operating and installation instructions

CONA®S - Ball float steam traps

Fig. 5: CONA®S - series 639 PN16-40

DN50-100

Refer to the data sheet for information about materials with designations and figure numbers.

4.4 Technical data - remarks

for

- Principal dimensions,

- Pressure-temperature-ratings, operating limits,

- Valves with different types of connection, etc.

refer to datasheet.

4.5 Marking

Details of the CE-marking on the valve:

CE-marking

0090 Notified body

AWH Manufacturer Address of manufacturer:

refer to item 11.0 Warranty / Guarantee

Typ Type

Bj. Year of manufacture

Page 2-6 Rev. 0040805000 3616

Operating and installation instructions

CONA®S - Ball float steam traps

5.0 Installation

5.1 General notes on installation

The following points should be taken into account besides the general principles governing

installation work:

ATTENTION !

- Remove flange covers if present.

- The interior of valve and pipeline must be free from foreign particles.

- The float steam trap can be installed for vertical or horizontal flow. Note

installation position with reference to flow, see mark on valve.

- Steam line systems should be designed to prevent water accumulation.

- Lay pipelines so that damaging transverse, bending and torsional forces are

avoided.

- Protect valves from dirt during construction work.

- Connection flanges must mate exactly.

- Valves must not be used to take external forces, e.g. they are not designed for

use as climbing aids, or as connecting points for lifting gear.

- Suitable materials handling and lifting equipment should be used.

See data sheet for weights.

- Centre gaskets between the flanges.

- Precautions against freezing should be taken as a matter of course in any

facilities susceptible to frost. If a system not in operation is in a position

susceptible to freezing, we recommend that the drain plug (Pos. 50) on the

unpressurised steam trap be unscrewed, the residual condensate drained off,

the seal faces cleaned and the plug screwed down again.

The sealing ring (Pos. 49) should be replaced if necessary.

(see Fig. 1 page 4 - Fig. 5 page 6)

- Planners / construction companies or operators are responsible for positioning and

installing products.

- The valves are designed for application, not influenced from weather.

- For application outside or in adverse environments like corrosion-promoting conditions

(sea water, chemical vapours, etc.), special constructions or protective measures are

recommended.

Rev. 0040805000 3616 Page 2-7

Operating and installation instructions

CONA®S - Ball float steam traps

5.2 Installation instructions for welding

(refer to Fig. 3 page 5)

Please note that only qualified persons using appropriate equipment and working in

accordance with technical rules are allowed to install fittings by welding.

The responsibility for this lies with the system owner.

Please refer to the catalogue sheet for information on type and instructions relating to

welding socket weld ends/butt weld ends.

When welding products to the pipeline system they should be adequately cooled to prevent

any adverse effect on the complete controller assembly (Pos. 24) or possibly the flat gasket

(Pos. 17). The heat-affected zone should be restricted to the immediate weld seam area!

Note pre- and post-welding heat treatment in accordance with Material Fact Sheet DIN EN

10222.

If there are plans to acid clean the facility before putting it into operation, the controllers

(Pos. 24) should be dismantled completely, replaced by acid cleaning inserts, and

reassembled after acid cleaning (see 7.1). In such an event please contact the

manufacturer.

5.3 Controller adjustment

The controller is set by the manufacturer as stated in the order and does not need

changing. Should the operating parameters have changed fundamentally compared with

the particulars in the order, please contact the manufacturer to change the controller!

5.4 Steam trap testing through ultrasonic measurement

Testing the operation of the steam trap in the installed state is straightforward with the

“ARImetec®-S” mulitfunctional testing device.

Refer to data sheet “ARImetec®-S”.

5.5 Installation position

(refer to Fig. 6 page 9 and Fig. 7a and b page 11)

The float steam trap can be installed for vertical or horizontal flow. This should be stated

when ordering.

If the installation position is not stated it will be supplied for vertical flow.

It is possible to change the installation position at a later stage (see 7.2).

However the steam trap must always be installed so that the ball float (Pos. 24.16) can

work in a vertical plane.

ATTENTION !

The vent tube (Pos. 24.12) must point up!

Page 2-8 Rev. 0040805000 3616

Operating and installation instructions

CONA®S - Ball float steam traps

5.5.1 Possible installation positions

Horizontal installation:

Inlet from the left side (ZL)

Vertical installation (standard): Horizontal installation:

Inlet from the top Inlet from the right side (ZR)

Fig. 6

6.0 Putting the valve into operation

ATTENTION !

- Before putting the valve into operation, check material, pressure, temperature

and direction of flow.

- Regional safety instructions must be adhered to.

- Residues in piping and valves (dirt, weld beads, etc.) inevitably lead to leakage.

- Touching the valve when it is operating at high (> 50 °C) or low (< 0 °C) media

temperatures can cause injury.

Affix warning notice or protective insulation as appropriate!

Before putting a new plant into operation or restarting a plant after repairs or

modification, always make sure that:

- All works has been completed!

- The valve is in the correct position for its function.

- Safety devices have been attached.

Rev. 0040805000 3616 Page 2-9

Operating and installation instructions

CONA®S - Ball float steam traps

7.0 Care and maintenance

Maintenance and maintenance-intervals have to be defined by the operator according to

the requirements.

ATTENTION !

- refer to item 10.0 and 11.0 prior to dismantling and repair work!

- refer to item 6.0 before restarting the plant !

Prior to installation, threads and seal faces should be coated with temperature-

stable lubricant (e.g. “OKS Anti-Seize Paste” white/metal-free for PN 16-40 or

“Rivolta” lubricant and parting agent for PN 63 onwards).

7.1 Cleaning and/or replacing the steam trap

(refer to Fig. 1 page 4- Fig. 5 page 6 and Fig. 7a and b page 11)

- Dismantle hood (Pos. 16) by slackening hexagonal nuts (Pos. 28) and cheese-head screw

(Pos. 27).

- While removing the hood (Pos. 16) swivel it upwards through approx. 45o to avoid twisting

the vent tube (Pos. 24.12).

Dismantle studs (Pos. 27) PN63-160 if necessary.

- Remove dirt from body (Pos. 1) and hood (Pos. 16); tiny dirt particles can be removed by

flushing out the ducts and rinsing the body (Pos. 1). Clean the strainer (Pos. 2).

- If necessary dismantle the float controller (Pos. 24) and clean separately or change float

controller.

- Unscrew the hollow-core screw (Pos. 24.10) of the float controller (Pos. 24) from the body

(Pos. 1).

- Pull complete float controller (Pos. 24) out to remove, taking care with the sealing ring

(Pos. 11). (From PN63 onwards metal seal with no sealing ring (Pos. 11)).

- Do not make any changes to spindle adjustment (Pos. 24.3), the float controller (Pos. 24)

is set by the manufacturer (except in the case of extremely high back pressures, when

please consult the manufacturer).

- Check lifting force of the ball float (Pos. 24.16) by immersing the whole controller (Pos. 24)

in a water bath with the vent tube (Pos. 24.12) pointing upwards – spindle (Pos. 24.3) in a

horizontal position. When immersed in the water bath the ball float (Pos. 24.16) must float

to the top. If the ball float (Pos. 24.16) sinks (i.e. goes under) the complete controller (Pos

24) should be replaced!

- The flat gasket (Pos. 17) and sealing ring (Pos. 11) should be replaced if used.

PN100-160:

- Special wear bushing is used. This can, if necessary, be changed after dismantling the

controller (Pos. 24). It is used to protect the body (Pos. 1) from blasting wear.

- Assemble in reverse order (refer to item 7.5).

Page 2-10 Rev. 0040805000 3616

Operating and installation instructions

CONA®S - Ball float steam traps

7.2 Changing the installation position

(refer to Fig. 1 page 4- Fig. 5 page 6 und Fig. 7a and b page 11)

- Position body (Pos. 1) as desired, bearing in mind the direction of flow.

- Remove hood (Pos 16), then slacken hollow-core screw (Pos. 24.10) approximately 1/2

turn.

- Rotate controller (Pos. 24) 90º in the direction required

ATTENTION !

The vent tube (Pos. 24.12) must point upwards!

- Tighten hollow-core screw (Pos. 24.10) by holding against nozzle part (Pos. 24.11).

- Inspect and if necessary replace body seal (Pos. 17).

- Put on hood (Pos. 16) with the drain plug (Pos. 50) pointing diagonally down.

- Fit hexagonal nuts (Pos. 28) (see 7.5) and tighten crosswise.

PN63:

- A resilient sleeve (Pos. 30) is also fitted to the union of body (Pos. 1) and hood (Pos 16).

Fig. 7a: CONA®S - series 631 PN63

Bild 7b: Controller, cpl

Rev. 0040805000 3616 Page 2-11

Operating and installation instructions

CONA®S - Ball float steam traps

7.3 Options blow down valve / manual air vent valve

(siehe Fig. 1 page 4 and Fig. 8 page 12)

ATTENTION !

Escape of hot medium under pressure!

Observe item 2.2 !

Accumulated dirt and condensate can be removed from the

hood (Pos. 16) through the blow down valve by opening the

pressure screw (Pos. 46.1). When opening, hold against blow

down valve (Pos. 46).

Accumulating inert gases can also be discharged to the

environment using the manual air vent valve (Pos. 51) by

opening the pressure screw (Pos 51.1).

During operation it is imperative to observe general working

safety conditions and possibly fit devices to guard against

scalding/injury.

Note section 7.5 when installing and operating the option.

Fig. 8

7.4 Union for pressure compension line resp. external vent

By connecting a pressure compensation

line to the union (Pos. 52) it is possible to

return the accumulating inert gases to the

system and to bypass the controller using a

Series 614 diverter as an external vent.

Note section 7.5 when installing the option.

Fig. 9

Page 2-12 Rev. 0040805000 3616

Operating and installation instructions

CONA®S - Ball float steam traps

7.5 Tightening torques

(siehe Fig. 1 page 4 - Fig. 9 page 12)

Torque (Nm)

Pos. CONA S PN16

DN15-20 DN25 DN32-50

24 Controller 60 60 100

50 Plug 50 50 50

27 Cheese head screw M10 / M12 / M16 15 25 50

51 Manual air vent valve 50 50 50

51.1 Pressure screw 30 30 30

46 Blow down valve 50 50 50

46.1 Pressure screw 30 30 30

52 Union for pressure compension line 50 50 50

Torque (Nm)

Pos. CONA S PN40-160

DN15-20 DN25 DN32-50

24.8 Hex. nut M4 5 5 10

50 Plug 70 70 70

51 Manual air vent valve 70 70 70

51.1 Druckschraube 30 30 30

46 Blow down valve 70 70 70

46.1 Pressure screw 30 30 30

Torque (Nm)

Pos. CONA S PN40

DN15-20 DN25 DN32-100

24 Controller 60 60 100

27 Cheese head screw M12 / M12 / M16 25 30 60

52 Union for pressure compension line 70 70 70

Torque (Nm)

Pos. CONA S PN63-100

DN15-20 DN25 DN32-50

24 Controller 130 130 130

28 Hex. nut M20 150 150 150

Torque (Nm)

Pos. CONA S PN160

DN15-20 DN25 DN32-50

24 Controller 130 130 130

28 Hex. nut M20 180 180 180

Page 2-13 Rev. 0040805000 3616

Operating and installation instructions

CONA®S - Ball float steam traps

8.0 Troubleshooting

In the event of malfunction or faulty operating performance check that the installation and

adjustment work has been carried out and completed in accordance with these Operating

Instructions.

ATTENTION !

-

It is essential that the safety regulations are observed when identifying faults.

If malfunctions cannot be eliminated with the help of the following table

“9.0 troubleshooting table”, the supplier or manufacturer should be consulted.

9.0 Troubleshooting table

ATTENTION !

- refer to item 10.0 and 11.0 prior to dismantling and repair work!

- refer to item 6.0 before restarting the plant !

Fault Possible cause Corrective measures

No flow Installed in wrong flow direction Fit valve in direction of flow arrow.

Note installation position; refer to item

5.5.1!

Flange covers not removed Remove flange covers

Ball float (Pos. 24.16) defective Check lifting force; refer to item 7.1

Little flow Wrong installation position Note installation position;

refer to item 5.5.1

Correct installation position;

refer to item 7.2

Strainer clogged (Pos. 2) Clean strainer; refer to item 7.1

Piping system clogged Check piping system

Wrong controller size choosen Correct selection acc. to flow diagram

Changed upstream pressure or back Correct selection acc. to flow diagram

pressure operating conditions

Excessive amount of inert gases in sys- Use pressure compensation line and

tem external vent option; refer to item 7.4

No closure or internal Controller clogged Clean strainer and controller;

leakage refer to item 7.1

Controller worn out Change controller; refer to item 7.1

Controller incorrectly screwed into body Check seal face between body and con-

troller, tighten controller correctly; refer

to item 7.5

Controller operated above safe operating Observe operating limits as per data

pressure sheet, i.e. possibly select different con-

troller

External leakage Hood (Pos. 16) not properly tightened Tighten; refer to item 7.5

with hex. nut (Pos. 28) or cheese-head

screw (Pos. 27)

Flat gasket (Pos. 17) defective Replace sealing;

refer to item 7.1

Page 2-14 Rev. 0040805000 3616

Operating and installation instructions

CONA®S - Ball float steam traps

10.0 Dismantling the valve or the body

ATTENTION !

The following points must be observed:

- Pressureless pipe system.

- Medium must be cool.

- Plant must be drained.

11.0 Warranty / Guarantee

The extent and period of warranty cover are specified in the "Standard Terms and

Conditions of Albert Richter GmbH & Co. KG“ valid at the time of delivery or, by way of

departure, in the contract of sale itself.

We guarantee freedom of faults in compliance with state-of-the-art technology and the

confirmed application.

No warranty claims can be made for any damage caused as the result of incorrect handling

or disregard of operating and installation instructions, datasheets and relavant regulations.

This warranty also does not cover any damage which occurs during operation under

conditions deviating from those laid down by specifications or other agreements.

Justified complaints will be eliminated by repair carried out by us or by a specialist

appointed by us.

No claims will be accepted beyond the scope of this warranty. The right to replacement

delivery is excluded.

The warranty shall not cover maintenance work, installation of external parts, design

modifications or natural wear.

Any damage incurred during transport should not be reported to us but rather to the

competent cargo-handling depot, the railway company or carrier company immediately or

else claims for replacements from these companies will be invalidated.

Technology for the Future.

GERMAN QUALITY VALVES

ARI-Armaturen Albert Richter GmbH & Co. KG, D-33750 Schloß Holte-Stukenbrock

Telephone (+49 5207) 994-0 Telefax (+49 5207) 994-158 or 159

Internet: http://www.ari-armaturen.com E-mail: info.vertrieb@ari-armaturen.com

Rev. 0040805000 3616 Page 2-15

You might also like

- Data Sheet-HV MotorsDocument4 pagesData Sheet-HV MotorsPramod B.WankhadeNo ratings yet

- Switchgear Specification For High Voltage Switchgears CT PT BreakerDocument26 pagesSwitchgear Specification For High Voltage Switchgears CT PT BreakerSumit TyagiNo ratings yet

- STP Piping BoqDocument4 pagesSTP Piping Boqdhanu_lagwankarNo ratings yet

- TABLE-3 LIST OF ATTACHMENTS - Rev 0Document5 pagesTABLE-3 LIST OF ATTACHMENTS - Rev 0Anonymous AyDvqgNo ratings yet

- ACS NTX Family Line PDFDocument22 pagesACS NTX Family Line PDFedsonpaveli-1No ratings yet

- Enxt P 84L WH CR PC SD-113307-220VDC PDFDocument1 pageEnxt P 84L WH CR PC SD-113307-220VDC PDFAwnish KumarNo ratings yet

- Karet Single - Line A1Document1 pageKaret Single - Line A1priyoNo ratings yet

- Iec60865 1Document8 pagesIec60865 1Amritesh PandeyNo ratings yet

- Parameter Estimation For Induction Machines Based On Sensitivity AnalysisDocument6 pagesParameter Estimation For Induction Machines Based On Sensitivity AnalysisRoberto SuNo ratings yet

- Induced Vibration HXDocument7 pagesInduced Vibration HXPatricia.PNo ratings yet

- Transactions Apparatus Systems, Vol - PAS-98, No.1: 97 Ieee Power and Jan/Feb 1979Document13 pagesTransactions Apparatus Systems, Vol - PAS-98, No.1: 97 Ieee Power and Jan/Feb 1979awolNo ratings yet

- Design and Construction of 0 500V 3KVA Variac With Digital DisplayDocument9 pagesDesign and Construction of 0 500V 3KVA Variac With Digital DisplayEditor IJTSRDNo ratings yet

- Rittal Ri4Power Technical SpecificationDocument14 pagesRittal Ri4Power Technical SpecificationarkupiNo ratings yet

- Info Iec60617 DBDocument11 pagesInfo Iec60617 DBsikander843562No ratings yet

- 8.9.1.22 - GC-1202 - Hazardous Area ClassificationDocument3 pages8.9.1.22 - GC-1202 - Hazardous Area Classificationkagasaw023No ratings yet

- 15-Chapter 4 Short Circuit Analysis-Objectives and MethodologyDocument4 pages15-Chapter 4 Short Circuit Analysis-Objectives and MethodologyRyan Anthony UmaliNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument11 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocument4 pagesUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiNo ratings yet

- Cable TrayDocument24 pagesCable TraysalamrefighNo ratings yet

- 7-12-0021 Rev 5Document1 page7-12-0021 Rev 5cynideNo ratings yet

- Single Line Diagram r6Document1 pageSingle Line Diagram r6Quảng Thành NamNo ratings yet

- PTI RAW - Version 30 Manual PsseDocument49 pagesPTI RAW - Version 30 Manual PssedmauriciosNo ratings yet

- Product List (Claro) v19.2dDocument12 pagesProduct List (Claro) v19.2dJames Adrian Abalde SaboNo ratings yet

- 6-pulse converter technical overviewDocument10 pages6-pulse converter technical overviewNirmal mehtaNo ratings yet

- 175-Ir022501, (850146), 07.12.2017Document2 pages175-Ir022501, (850146), 07.12.2017Rami ELLOUMINo ratings yet

- Product Data Sheet: Circuit Breaker Compact NS2000N - 2000 A - 3 Poles - Fixed - Without Trip UnitDocument2 pagesProduct Data Sheet: Circuit Breaker Compact NS2000N - 2000 A - 3 Poles - Fixed - Without Trip UnitDelfin Vargas100% (1)

- E09-X02 - 0 Medium Voltage Motor Control Center Data SheetDocument3 pagesE09-X02 - 0 Medium Voltage Motor Control Center Data SheetMuhammad IrfanNo ratings yet

- Earthing Case StudiesDocument10 pagesEarthing Case StudiesVIKRAM DESAINo ratings yet

- 11d Pms Rev00a Ongc 27jul15Document3 pages11d Pms Rev00a Ongc 27jul15abhiNo ratings yet

- 7-12-0037 Rev 3Document1 page7-12-0037 Rev 3cynideNo ratings yet

- 01 PDFDocument6 pages01 PDFSherif AdelNo ratings yet

- Item 1 - Transformer Rectifier UnitDocument8 pagesItem 1 - Transformer Rectifier UnitNoor A QasimNo ratings yet

- ERW Steel Tubes Guide (IS 1239 & 1161 StandardsDocument1 pageERW Steel Tubes Guide (IS 1239 & 1161 Standardsdyke_enggNo ratings yet

- Basic Valve & SizingDocument8 pagesBasic Valve & SizingRio Ananda PutraNo ratings yet

- Three-Phase Induction Motor Dynamic Mathematical ModelDocument3 pagesThree-Phase Induction Motor Dynamic Mathematical Modelsajs201100% (3)

- NEMA Force Allowed On The Flange - Pipelines, Piping and Fluid Mechanics Engineering - Eng-TipsDocument4 pagesNEMA Force Allowed On The Flange - Pipelines, Piping and Fluid Mechanics Engineering - Eng-Tipsyundtech974No ratings yet

- Battery Charger Formula IEEE 946Document2 pagesBattery Charger Formula IEEE 946Lordwin JacksonNo ratings yet

- Technicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015Document25 pagesTechnicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015spidervinoNo ratings yet

- 7-12-0014 Rev 5Document1 page7-12-0014 Rev 5cynideNo ratings yet

- Book 22Document35 pagesBook 22Mohd SalehNo ratings yet

- (Metasol MCCB) Catalog en 202105Document160 pages(Metasol MCCB) Catalog en 202105LUATNo ratings yet

- Data Sheet UPSDocument13 pagesData Sheet UPSAdi Toto HaryonoNo ratings yet

- M3BP315MLB6 110KW PDFDocument1 pageM3BP315MLB6 110KW PDFPablo CorreaNo ratings yet

- E300 Overload Relay Presentation - INTERNAL Long (Updated 11052015)Document22 pagesE300 Overload Relay Presentation - INTERNAL Long (Updated 11052015)marquez182No ratings yet

- ABBOfflineOrderNumberTool Ver 15.41b 758059 ENgDocument75 pagesABBOfflineOrderNumberTool Ver 15.41b 758059 ENgsavijolaNo ratings yet

- 7-12-0008 Rev 5Document1 page7-12-0008 Rev 5cynideNo ratings yet

- Parameter: Data Sheet For 3 Phase TransformerDocument1 pageParameter: Data Sheet For 3 Phase Transformermkbhat17kNo ratings yet

- Fuji MCCB BW SeriesDocument44 pagesFuji MCCB BW SeriesVictor Toledano100% (2)

- Raychem EPKTDocument6 pagesRaychem EPKTSaravana KumarNo ratings yet

- En 50464-4Document3 pagesEn 50464-4Mahmoud ShaheenNo ratings yet

- Bi MettalicDocument16 pagesBi Mettalickhan103No ratings yet

- Operating and Installation Instructions: Thermodynamic Steam Traps Cona TD (PN40 - 63)Document13 pagesOperating and Installation Instructions: Thermodynamic Steam Traps Cona TD (PN40 - 63)khan103No ratings yet

- Operating and Installation Instructions: Automatic Air Vent (PN16 - 40)Document10 pagesOperating and Installation Instructions: Automatic Air Vent (PN16 - 40)thirumurugan sNo ratings yet

- Stop Needle Valves,: Type SNV-ST and SNV-SSDocument8 pagesStop Needle Valves,: Type SNV-ST and SNV-SSLucioRimacNo ratings yet

- Strainer InstallationDocument10 pagesStrainer InstallationNhuan Pham VanNo ratings yet

- Safety Relief Valves Operation ManualDocument21 pagesSafety Relief Valves Operation ManualSumit JadhavNo ratings yet

- Operating and Installation Instructions: Straight Through Control Valves - STEVI 440 / 441, 445 / 446Document20 pagesOperating and Installation Instructions: Straight Through Control Valves - STEVI 440 / 441, 445 / 446widuri nirmalaNo ratings yet

- IRC5-IRB1400 Prod Man Part2 3HAC021111-001 - References - Rev - enDocument52 pagesIRC5-IRB1400 Prod Man Part2 3HAC021111-001 - References - Rev - enadriano_falavinha9186No ratings yet

- Type A31A High PerformanceDocument24 pagesType A31A High PerformanceJesus BolivarNo ratings yet

- Rockwool InsulationDocument4 pagesRockwool Insulationrahimi mohamadNo ratings yet

- Bolts Screws Hex Hexagon Nuts Washers Threaded Rods Din 933 934 7989 125 127 4034 975 555 IsoDocument43 pagesBolts Screws Hex Hexagon Nuts Washers Threaded Rods Din 933 934 7989 125 127 4034 975 555 IsoAli FikarNo ratings yet

- Steel Shell Boiler: Responsibility For Energy and EnvironmentDocument12 pagesSteel Shell Boiler: Responsibility For Energy and Environmentrahimi mohamadNo ratings yet

- ARI ARMATUREN - Ball Float Steam Trap CONADocument15 pagesARI ARMATUREN - Ball Float Steam Trap CONArahimi mohamadNo ratings yet

- DB WCFX-E-R134a-50-60HzDocument40 pagesDB WCFX-E-R134a-50-60Hzrahimi mohamadNo ratings yet

- Malaysia MalaysiaDocument68 pagesMalaysia MalaysiaNirbhay KumarNo ratings yet

- WM-G10-Complete Model Selection-Jan 2013Document52 pagesWM-G10-Complete Model Selection-Jan 2013rahimi mohamadNo ratings yet

- 9666 PDFDocument2 pages9666 PDFrahimi mohamadNo ratings yet

- Section 7: Metric PVC Piping SystemDocument19 pagesSection 7: Metric PVC Piping Systemrahimi mohamadNo ratings yet

- D1300 Internal Circlips - Circlips For Bores - DIN 472: Manufacturer's ChoiceDocument5 pagesD1300 Internal Circlips - Circlips For Bores - DIN 472: Manufacturer's Choicerb andhaleNo ratings yet

- EV Seg VP744-5DZ1-04F-M-X555Document62 pagesEV Seg VP744-5DZ1-04F-M-X555memosurf3775No ratings yet

- DB WCFX-E-R134a-50-60HzDocument40 pagesDB WCFX-E-R134a-50-60Hzrahimi mohamadNo ratings yet

- DB DCLC-R134a-50HzDocument36 pagesDB DCLC-R134a-50Hzrahimi mohamad100% (2)

- DB AVX-B-R134a-50-60HzDocument32 pagesDB AVX-B-R134a-50-60Hzrahimi mohamadNo ratings yet

- Metric, Flat Washers, DIN 125, Part 2, Type A, Zinc Plated: Page 1 of 1 REV-05 Date: October 3, 2014 M.FW - HV300.ZDocument2 pagesMetric, Flat Washers, DIN 125, Part 2, Type A, Zinc Plated: Page 1 of 1 REV-05 Date: October 3, 2014 M.FW - HV300.ZSolomon RajNo ratings yet

- DB WCFX-E-R134a-50-60HzDocument40 pagesDB WCFX-E-R134a-50-60Hzrahimi mohamadNo ratings yet

- ASTM F436M-09 Circular Washer DimensionsDocument1 pageASTM F436M-09 Circular Washer DimensionsRaditya PurnamahadiNo ratings yet

- Morris CatalogueDocument64 pagesMorris Cataloguerahimi mohamadNo ratings yet

- Find the right external circlip fastDocument5 pagesFind the right external circlip fastrahimi mohamadNo ratings yet

- Spur Gears PDFDocument75 pagesSpur Gears PDFrahimi mohamadNo ratings yet

- Bolts Screws Hex Hexagon Nuts Washers Threaded Rods Din 933 934 7989 125 127 4034 975 555 IsoDocument43 pagesBolts Screws Hex Hexagon Nuts Washers Threaded Rods Din 933 934 7989 125 127 4034 975 555 IsoAli FikarNo ratings yet

- D1300 Internal Circlips - Circlips For Bores - DIN 472: Manufacturer's ChoiceDocument5 pagesD1300 Internal Circlips - Circlips For Bores - DIN 472: Manufacturer's Choicerb andhaleNo ratings yet

- Atalhos - Inventor PDFDocument14 pagesAtalhos - Inventor PDFSteven AndersonNo ratings yet

- SS Welded Mesh PDFDocument24 pagesSS Welded Mesh PDFrahimi mohamadNo ratings yet

- Compression 4 1Document46 pagesCompression 4 1tobby12No ratings yet

- SBER Seamless Stainless 6Document15 pagesSBER Seamless Stainless 6georgadam1983No ratings yet

- Rockwool InsulationDocument4 pagesRockwool Insulationrahimi mohamadNo ratings yet

- Stainless Welding FittingsDocument16 pagesStainless Welding FittingsShane HancockNo ratings yet

- 9666 PDFDocument2 pages9666 PDFrahimi mohamadNo ratings yet

- Pipe FittingsDocument158 pagesPipe FittingsGiraldoCarpioRamosNo ratings yet

- Project Name: Glass BalustradeDocument11 pagesProject Name: Glass BalustradeNp Pw100% (1)

- 122 - Motion For Leave To File Rule 11 MotionDocument3 pages122 - Motion For Leave To File Rule 11 MotionRipoff ReportNo ratings yet

- Indian Standard: Specification For Reels and Drums For Bare ConductorsDocument13 pagesIndian Standard: Specification For Reels and Drums For Bare ConductorsUppala Krishna ChaitanyaNo ratings yet

- Routine Pile Load Test-Ga-13.04.2021Document1 pageRoutine Pile Load Test-Ga-13.04.2021Digambar JadhavNo ratings yet

- DENR CC 2022 1st - Edition FIN 25 - March - 2022Document234 pagesDENR CC 2022 1st - Edition FIN 25 - March - 2022CENRO BANGUED PLANNINGNo ratings yet

- Geotextile Its Application To Civil Engineering ODocument7 pagesGeotextile Its Application To Civil Engineering OezequilNo ratings yet

- Lista Carti Audio Dezvoltare PersonalaDocument4 pagesLista Carti Audio Dezvoltare PersonalaNicu Osan50% (2)

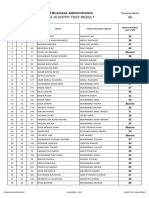

- Entry Test Result MPhil 2014 PDFDocument11 pagesEntry Test Result MPhil 2014 PDFHafizAhmadNo ratings yet

- Engg Maths Sem 3 Curve FittingDocument13 pagesEngg Maths Sem 3 Curve FittingRonak Raju ParmarNo ratings yet

- Ficha Técnica Lithonia-JcblDocument9 pagesFicha Técnica Lithonia-JcblEmiliano HernándezNo ratings yet

- GUEST REGISTRATION CARDDocument1 pageGUEST REGISTRATION CARDRasmi Ranjan Kar100% (1)

- Microprocessor 8086 Memory and ArchitectureDocument13 pagesMicroprocessor 8086 Memory and ArchitecturehrrameshhrNo ratings yet

- CasesDocument8 pagesCasesLinh TrịnhNo ratings yet

- Report On Indian Education SystemDocument7 pagesReport On Indian Education SystemYashvardhanNo ratings yet

- Robotic Surgery History and SystemsDocument28 pagesRobotic Surgery History and SystemsLidhi DileepNo ratings yet

- Capital Harness XC LaunchDocument36 pagesCapital Harness XC LaunchnizarfebNo ratings yet

- NTPC Limited: (A Government of India Enterprise)Document7 pagesNTPC Limited: (A Government of India Enterprise)Yogesh PandeyNo ratings yet

- RCT Methodology ChecklistDocument6 pagesRCT Methodology ChecklistSyahidatul Kautsar NajibNo ratings yet

- Mil STD 1686CDocument18 pagesMil STD 1686CNam NguyenNo ratings yet

- ISO 9001 Quality Management ProceduresDocument7 pagesISO 9001 Quality Management ProceduresFendi100% (1)

- Analyzing Air Asia in Business Competition Era: AirasiaDocument14 pagesAnalyzing Air Asia in Business Competition Era: Airasiashwaytank10No ratings yet

- OE-254/GRC antenna parts listDocument2 pagesOE-254/GRC antenna parts listVictor GarciaNo ratings yet

- LTE Data Analysis - Project Proposal N.2Document22 pagesLTE Data Analysis - Project Proposal N.2Syed SafwanNo ratings yet

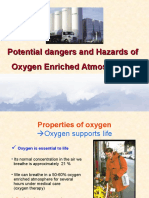

- OxygenDocument18 pagesOxygenbillllibNo ratings yet

- Truck-Mounted Cranes: For Applications With Large Vehicles HB-R Series, The Perfect SolutionDocument4 pagesTruck-Mounted Cranes: For Applications With Large Vehicles HB-R Series, The Perfect SolutionRodrigo LealNo ratings yet

- Psychrometrics Drying Problems SEODocument5 pagesPsychrometrics Drying Problems SEOStephanie Torrecampo Delima100% (2)

- Decolonising The FutureDocument20 pagesDecolonising The Futurebybee7207No ratings yet

- Internship Projects: Rotor Shaft Analysis and DesignDocument19 pagesInternship Projects: Rotor Shaft Analysis and DesignSanjay IraniNo ratings yet

- How efficient is a wind turbineDocument8 pagesHow efficient is a wind turbinejNo ratings yet

- Petition For ReviewDocument18 pagesPetition For ReviewJay ArNo ratings yet