Professional Documents

Culture Documents

RT - Procedure PDF

RT - Procedure PDF

Uploaded by

Trịnh Quốc Tuyến100%(1)100% found this document useful (1 vote)

393 views25 pagesOriginal Title

RT- Procedure.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

393 views25 pagesRT - Procedure PDF

RT - Procedure PDF

Uploaded by

Trịnh Quốc TuyếnCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 25

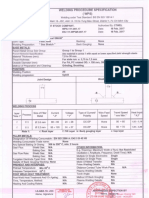

| NDTPROCEDURE _[FrsesireneTrANDTRTOOT]

Rev F

RADIOGRAPHIC TESTING | tesved date 02-2018

PROCEDURE [rape coe]

RADIOGRAPHIC TESTING

PROCEDURE

{LR INSURANCE, INC.

ee

2013

1 | 9202018 | Approval

Tadfor [A WU SON | Mal aA

o ‘Sig, Review and Prepared | Reviewed &

ae Approval by |_Aemroved by | Approved by | Reviewed by

e| Ose | oeectpion | Tana Gots tae 8 | Aue

NDT PROCEDURE Procedure No. __TTAINOTIRTIOOT|

[Rie OL |

[ee eee

RADIOGRAPHIC TESTING | sues aate oz wulz013

PROCEDURE rae aT

4. INTRODUCTION

This procedure is developed to cover the general requirements for Radiographic

Examination services provided and cartied out by TTAsia Co., Ltd

2, SCOPE.

‘This procedure defines the conditions of performing the radiographic examination in

accordance with the ASME Boiler and Pressure Vessel Code for slee! butt-welded

Joints in thickness up to 50mm,

The procedure is applied for demonstration of Lilama 18 JSC to comply with

requirement of ASME boiler and vessel code, Section |, V, Vill, Div 1 & 2, 2070

Edition, 2011 Addenda and ASME 831.1, 2007 Edition, 2008 Addenda

3, REFERENCES

= ASME Boller and Pressure Vessel Code, Section |, V, Vill Div 1 & 2, 2010

Eziton, 2011 Addenda,

— ASME Power Piping Code B31.1, 2007 Edition, 2009 Addenda

ASTM E 94-04, Standard Recommended Practice for Radiographic Testing

- ASTM E 999-99, Standard Guide for contioling the quality of industrial

radiographic film processing

= ASTM E 142 - 04, Standard Method for Controling Quality of Radiographic

Testing,

= ASTM E 747 - 04, Controling Quality of Radiographic Testing Using Wire

Penetrameters

—_ASTME 1032.- 01, Radiographic Examination of Weldments

= SNT-TC-1A, 2008 Ecition Recommended Practice for Personnel! Qualification

‘and Certification in Non-Destructive Testing

= TTA Written Practice for Qualification and Certticaton of NDT Personnel

Document No.: TTA-P-01 Rev.02

NDT PROCEDURE Frccedins Rex PART

hy Fav Ne. oi

EEA RADIOGRAPHIC TESTING | tesued cate o2ul2013

PROCEDURE Pag a

(CHANGE OF RECORD:

Rev. Date | Chango of tom

0 18-Feb-2013 _| Isued for Review and Comments ae

ot

(02-Ju4-2013 _ | Issued for Approved

NOT PROCEDURE [FSSAInTe—TAROTRTANT

Reva: a

RADIOGRAPHIC TESTING | ssuecdate _ —_Densitometer SECEO Speasmater; model SN-10T (USA) or its

equivalent

64 Image quality indicator (1a!)

> Image Quaity Indicator (IA) shall be made as described in SE-747

‘and SE-1025 or equivalent.

> The essential wite shall be as specified in Table T-276 in ASME

‘Section V-2010 Edition, 2011 Addenda.

6.5 intensifying Screens

Lead front and back screen with thickness min. 0.2 mm or vacuum pack fm

sereen shall be used, Chemically coated or fluorescent intensifying screen

shall not used,

Cassette : plastic type.

CALIBRATION

7.4 Source size:

The source size (etfecive focal spot size; X-ray Equipment 1.5% 1.6 mm,

ray source 3,0%3.0 mm), source to fm distance (SFD) and distance from

Source side of object tothe film (OFD) shall be recorded inthe report, and

the geometric un-sharpness shall meet the requirements of para, 10,

‘The aistance between the saurce side of the object and the film surface shall

be as small as possible. Ug.as described in para. 10. shall be satisfied

7.2 Densitometer and Step Wedge Comparison Film:

7.2.1 Densitometers:

> Densitometers shall be calibrated with the readings to be

recorded atleast every 90 days,

Periodic calibration verification checks shall be performed as

described in T-262.3 in ASME Section V-2010 Eaiion, 2011

NDT PROCEDURE [FreedreneTTAROTATOOT

No oi

RADIOGRAPHIC TESTING | issued date = 02vul2013

PROCEDURE aS a

40.

‘Addenda at the beginning of each shit, ater @ hr of continuous

use, or after change of apertures, whichever comes first.

7.2.2 Step Wedge Comparison Film:

‘Step wedge comparison film shall be verified prior to first use, unless

performed by the manufacturer, as follows:

2. The density of the steps on a step wedge compatison flim shall

be verified by a calibrated densitometer.

b. The step wedge comparison fim is acceptable if the density

readings do not vary by more than # 0.05 density units from the.

‘density stated on the step wedge comparison film

‘SURFACE PREPARATION

Surface preparation of butt welds for Radiography shall be as follows:

>

Free from scale or weld slag,

‘Temporary tack welds to be removed and ground smoothly

‘The finish surface may be flushed with the base material or may be have

uniform crown,

Methods of preparation shall be such that over heating or loss of matarial

integrity does not occur.

Surface shall satisfy the requirements of the applicable materials

‘specications, with additional conditioning, if necessary, by any suitable

process to a degree that surface irregularities cannot mask or be confused

with objectionable wels discontinuties.

BACKSCATTER RADIATION PROTECTION

‘Aleed symbol “B with minimum dimension of Yin (13mm) in height and 116 in

(1.5 mm) in thickness, shall be attached to the back of each fm holder during each

exposure to determine if backscatter radiation is exposing the fl,

GEOMETRIC UNSHARPNESS LIMITATION

Geometric unsharpness determination (Ug): geometric unsharpness of the

radiograph shall be determined in accordance with

NDT PROCEDURE Procedure No TTANOTIRTIOOT

Ny 5 [Recor aC

VE RADIOGRAPHIC TESTING | jss.ea ate 02-Ju.2013,

PROCEDURE ar

Ug= Fao

Ug = Geometric unsharpness

F = source size: the maximum projected dimension of the radiating source

(or effective focal spot) in the plane perpencicular tothe distance D from the

\weld or object being radiographed, in (mm),

D = distance from source of radiation to weld or abject being radiographed,

in(mm)

d = distance from source side of weld or object being radiographed to the

fim, in (rm),

D and d shall be determinated at the approximate center of the area of

interest.

‘Geometric unsharpness limitations: geometric unsharpness of the radiograph shall

not exceed the following values: refered to T-274.2 ASME code Section V-2010

Edition, 2011 Addenda

(Rem — [Material Thiskness, ingmm) Ug Maximum, in(rar)

ef Under 2 (50) 0.020 (0.51)

[2 PP through 3 (60-78) (0.030 (0.76)

‘S| Over 3 through 4 (7-100) (0.040 (1.02) :

‘4 Greater than 4 (100) (0.070 (1.78)

‘+ NOTE: Material thickness isthe thickness on which the IQ is bases.

14. USE OF 11 FOR RADIOGRAPHIC

11.4 Selection of Ils

41.14 Material

lis shall be selected from either the same alloy material group or

‘grade as identiied in SE-1025, or SE-747, as applicable, or from an

‘alloy material group or grade with less radiation absorption than the

material being radiographed.

11.1.2 Size

‘The designated hole 10! or essential wire shall be as specified in

‘Table 7-276. A thinner or thicker hole-type 101 may be substituted for

any section thickness listed in table T-276, provided an equivalent IQ!

sensitivity is maintained. See T-283,

NDTPROCEDURE —_[PaedueNo_cTTANOTRTOOT

Revo. oF

RADIOGRAPHIC TESTING |icsueadate 02012013.

PROCEDURE pea

af Wolds with Reinforcements: The thickness on which the 1O1 is

based Is the nominal single-wall thickness plus the estimated

‘weld reinforcement not to exceed the maximum permitted by

the referencing Code Section. Backing rings or strips shall not

bbe considered as part of the thickness in 101 selection, The

‘actual measurement ofthe weld reinforcement is not required.

b/ Welds without Reinforcements: The thickness on which the IQ!

is based is the nominal single-wall thickness, Backing rings or

‘trips shall not be considered as part of the welds thickness in

12} selection,

lls shall be selected and placed on the weldment in the area of

interest being radiographed as shown in Table T-276 and Table T-

233.2 in ASME Section V, 2010 Edition, 2011 Addenda,

le

3.2

WIRE IQ] DESIGNATION, WIRE DIAMETER, AND WIRE IDENTYFY

set A, ‘SetB

We ein wire entity | ee crerin ‘Wee icentity

0032 008 1 010 028 é

once 010 2 0013 00 7

0.005 018 3 0016 oat ®

000s 6 4 0.020 ost @

0.008 020 3 0.025, 068 10

0010 026 6 0082 081 1

setc. ‘Set

02 oat 1" 0400 254 16

0.040 1.02 2 0726 320 7

‘one0 42 13 0.460 400 18

(063 180 [1 0200 508 19

NDT PROCEDURE _[Poseduel TTANBTRTOOT

RevNa, oF

RADIOGRAPHIC TESTING | tssved date 02-5u.2013

PROCEDURE ae ee

080 | 203 6 0280 635 2

[100 254 6 0320 on 2

Table T:276

Ol SELECTION

vo

om Sgeitis Thee Range oa

Le es Grnudon exncantte | Cengattn Eta ie

pt0925, Woes. wet i 5 ae

See © @ 2 2

Om8ar6rragh OHO Owasinemn ia? | 7 © ¢

Oneasowranna7s —Gwi27memnwe | 2 8 7 7

[owa7sorn tc Ow ianmenase | a » ®

[ow taba ts0 Owasamomans | ” ® :

[ow tsbmah2e0 Owsntmomcee | = * * °

Owecotoni2e® —owrsonmamess | « ® % *

Owtsitwnah as Owessiaun ree | = © © @

Oecsitman ee Owrtet soem ee | wo * * =

[Retmmmme Owitanmmm:| © 6 © 4

[cnetnsoomen etn owasrmeaa | mew | me

[ow teoemh 608 Owrseemmunaane | 180 2 va *

(ve toes 2000 Ow sObAtE HBO | 70D 7 e %

112. Placement of Ils

IQs Placement for welds - Wire IQs: The IQs) shall be placed on

the weld so thatthe length ofthe wires Is perpendicular tothe length

of the weld

= IQIs Placement for welds - Hole IQIs: The IQl{s) may be placed

‘adjacent to or an te wold,

= The IQ\(s) shail be placed on the source side of the weld being

‘examined except as permitted in the paragraph below

NDT PROCEDURE [Procedure No. TTAINDTIRTIOOT

[eaters <1 AOR]

RADIOGRAPHIC TESTING | issues ate

PROCEDURE Page

= Where inaccessibility prevents hand placing the 1I(s) on the source

side, t shal be placed on the flim side in contact with the weld being

examined. A lead letter "F* shall be placed adjacent to on the IA

Identincation number(s) but shall not be in the area of interest, except

when geometric configuration makes it impractical.

11.3 Number of IQs

When one or more film holder are used for an exposure, at least one IQ!

Jmage shall appear on each radiograph except as outlined in special cases

‘as shown below.

11.9.1 Mutipe 1s

‘Multiple !Ols: If the requirements of 7-262 are met by using more than

‘one IQ, one shall be representative ofthe lightest area of interest and

the other the darkest area of interest; the intervening densities on the

radiograph shall be considered as having acceptable density

11.3.2 Special Cases.

1, For cylindrical components where the source is placed on the

‘axis of the component for a single exposure, at least three IQs,

‘spaced approximately 120 deg apart, are required under the following

conditions:

‘a. When the complete circumference is radiographed using one

‘or more fim hokiers, or.

b. When a section or sections of the circumference, where the

length between the ends of the outermost sections span 240

deg or more deg, is radiographed using one or more fim

holders. Additional fim locations may be required to obtain

necessary I] spacing

2. For cylindrical components where the source is placed on the

‘axis of the component for a single exposure, at least three IQls, with

| NDT PROCEDURE | Pecedure No__TTANOTIRTIOOT

ie

RADIOGRAPHIC TESTING | issued dato 02-Jul-2013

PROCEDURE ree era

fone placed at each end of the span of the circumference

Fadiographed and one in the approximate center of the span, are

required under the following conditions:

a, When a section of the circumference, the length of which is

‘feater than 120 deg and less than 240 deg, is radiographes

Using just one flm holders, or

'b. When a section or sections of the circumference, where the

length between the ends of the outermost sections span less

than 240 deg, is radiographed using more than one fin holder.

3. In (1) and (2) above, where sections of longitudinal welds

‘adjoining the circumferential weld are radiographed simultaneously

with the circumferential weld, an additional 1Q1 shall be placed on

‘each longitudinal weld at the end of the section most remote from the

junction withthe circumferential weld being radiographed.

4. For spherical components where the source is placed at the

‘center of the component for a single exposure, at least three IGls,

spaced approximately 120 deg apart, are required under the folowing

conditions:

‘a. When a complete circumference is radiographed using one or

‘more film holders, oF

b. When a section or sections of @ circumference, where the

length between the ande of outermost sections epan 240 deg

fF mote deg, is radiographed using one or more film holders.

Additional film locations may be required to obtain necessary

101 spacing

5. For spherical components where the source is placed at the

center of component for a single exposure, at least three IQs, with

fone placed at each end of the radiographed span of the

NDT PROCEDURE Precedze No TTANDTIRTOOT

Rev No. or

RADIOGRAPHIC TESTING [iccucadate 02 vui2oie

PROCEDURE tee ae

circumference radiographed and one in the approximate center ofthe

‘9pan, are required under folowing conditions:

‘@, When @ section of @ circumference, the length of which is

‘greater than 120 deg and less than 240 deg, is rediographed

Using just one film holders, or

b. When @ section or sections of a circumference, where the

length between the ends of the outermost sections span less,

than 240 deg is radiographed using more than one film holder.

6. In (4) and (6) above, where other welds are radiographed

simultaneously with the circumferential weld, one addtional 101 shall

bbe placed on each other weld.

7. Fer segments of a fat or curved (.., elipsoidal, tore spherical,

tori conical, eliptical, etc.) component where the source is placed

perpendicular to the center of the length of weld for a single exposure

‘when using more than three film holders, et least three IQs, one

placed at each end of the radiographed span and one in the

‘approximate center of the span, are required.

8. When an array of components in a cicle is radiographed, at

least one 10! shall show on each component image.

8. In order to maintain the continuity of records. involving

subsequent exposures, all radiographs exhibiting Ils that qualify the

techniques permitted in accordance with (1) through (7) above shall

be retained.

42, RADIOGRAPHIC DENSITY

121 Density tmitaions.

Density limitations: The transmitted fim density through the radiographic

image adjacent to the designated wire of a wire [Ql and the area of interest

shall be:

INET EOC EUR eg ose om

Ne, OF

RADIOGRAPHIC TESTING | \ss.20 date 02.Ju42013

PROCEDURE lenesocaaa i

= 1.8 minimum for single film viewing for radiograph made with X-ray

Source

= 2.0 minimum for single film viewing for radiograph made with Gamma

Ray Source

= For composite viewing of multiple fim exposures, each fim of

‘composi set shall have a minimum density of 13

= Maximum density shal be 4.0 fr eitrer single or composite viewing,

- A tolerance of 0.05 in density is allowed for variations between

densitometer reasings,

412.2 Density Variation

Density Variation: If the density of the raciograph anywhere through the are

of interest varies by more than minus 15% or plus 30% from the density

through the body ofthe hole IAI or adjacent to the designated wire ofa wire

1, within the minimumimaximum allowable densty ranges specified in 12.1

see Table 12.2, then an additonal IQ! shall be used for each exceptional

area or areas and the radiograph retaken,

Table 12.2 Density Variation

‘Senay [Desert pay) [Dens variation (Gamma Ray

SenoieCerstY [fin oensty [Win Density | Max Density [Min Dens

a3 [180 2a Na nase

Tn 180 2A 200 | 200

aa 120, 2 2.00 20

a2 1a 2a 2.00 2.60

FE 196 2s 00 20

| a a 265 [208 25

(ers 2a 276 23 276

[ete sansa [anaes [Ovanaiet a PE

aga 230 | 298 230 2.98

28 238, 3.08 238 3.08

[eae 255, 32 255 322

Br zs a6 264 3a |

zaman ma 3 72a

[28 355 2a 36s

229 B76 2a 376

Procedure Na_TTANDTRTOOT

sg || aN a

[RADIOGRAPHIC TESTING | issuec date o2-Jue2013

| PROCEDURE = ee

ener 20 | 307 258 aan

3s 3.06 a0 306 38

Fa 35) 400 aus, ‘00

38 a 00 323 aco]

39) 3 a0) 332 ‘00

“ a0) 00 ao [400

4, EXAMINATION TECHNIQUE

= A single-vall exposure technique shall be used for radiography whenever

practical

= When itis net practical to use a single-wall technique, a double-wal technique

shall be used

= The direction of the central beam of radiation shall be centered onthe area of

interest whenever practical

‘An adequate number of exposures, which is not necessarily to be the

‘minimum number stated in the sections below, shall be made to demonstrate

that the required coverage has been cbtained

13.1 Single-wal technique

In this technique, the reciation passes through only one wall ofthe wel,

\which is viewed for acceptance an the radiograph, as shown inthe sketches.

[NDT PROCEDURE | Precedue No TTANDTIRTIOO"]

My is reayNeaea Olena]

‘RADIOGRAPHIC TESTING jccuea date 02-Wui2018

PROCEDURE

Page 16/24

18.2 Double-wal technique

When itis not practical to use @ single-wall technique, one of the folowing

double-wall techniques shall be used.

a. Singlewall viewing

= In this technique, the radiation passes through two walls of the

‘weld and only the portion on the film-side wall is viewed for

acceptance on the radiograph,

= When complete coverage is required for circumferential welds, a

‘minimum of three exposures taken 120 deg. to each other shall

bbe made.

~The sketches below show this technique

Optional

b. Double-wall viewing

— For welds in components 89mm or less in nominal outside

diameter, a technique maybe used in which the radiation passes

through two walls and the portions in both walls is viewed for

acceptance on the same radiograph.

= Additional exposures shall be made if the required radiographic

‘coverage cannot be obiained using the minimum number of

‘exposutes as indicated in (bt) and (b2) below.

This technique may be performed by one of two ways as follows:

bi. The radiation beam is offset from the plane of the weld at an

‘angle suficent to separate the Images of the source-side and

‘lm-side portions of the weld so that there is no overlap of the

‘areas to be interpreted. When complete coverage is required,

2 minimum of two exposures taken 90 deg. to each other shall,

bbe made for each joint, as shown in sketches on the right,

NDT PROCEDURE [Pasture No TTAROTIRTIO07

a [RevNo. ical

ve “r-° [RADIOGRAPHIC TESTING malate

L PROCEDURE a

b2. The radiation beam is positioned so that the images of both

walls are superimposed. When complete coverage is required,

‘8 minimum of three exposures taken at 60 deg. or 120 deg. to

‘each ather shall be made for each joint, as shown in sketches,

below:

414, LOCATION MARKERS AND SYSTEM IDENTIFICATION

14.1 Location Markers:

= Location Markers, which may be made of lead and are to appear as

radiographic images on the film, shall be placed on the part, not on the

‘exposure holderieassctte

‘Their location shall be permanent marked on the surface of the part

being radiographed when permitted, or on a map, in a manner

ppermiting area of interest on a radiograph to accurately traceable to its

location on the part

+ Location marker shall be placed as shown in sketches as below:

NDT PROCEDURE | ProcedureNo._“TTANDTIRTIOOT|

[Revo 07

RADIOGRAPHIC TESTING | jssued cate 22013

Page wa

+ Evidence by Images of location marker shall also be provided on the

radiograph that the required coverage of the region being examined

hhad Been obtained and the number of exposures in each technique for

each jointis adequate

14.2 System identification:

‘The area to be examined shal be postvely and unambiguously designated

by projects owner prior to examination. Location on area examined shall be

‘ractablity precisely on the identifications on the radiograph. Lead Numerals,

‘and Alphabets shall be used as markers and shall be placed in manner

without obscuring the area of interest. Marking detail shall include:

> Project name and Manufacturer name (Lama 18 JSC).

> Date of Radiograph taken.

% Vessel identification.

¥

Film tocation

> Weld identification and Welder ID.

> "RI" or fist repair of weld

> "R2" for second repair of wel.

NDT PROCEDURE Proce No —TTANOTRTIOO

Reve! oF

RADIOGRAPHIC TESTING | issues ate o2Jui2013

PROCEDURE Papas]

> "RW for reweld

> RS" for reshoot

48, FILM PROCESSING

TTAsia Co., Ltd, Instruction for flm processing, No: TTA-IND+-03 Rev. 01

16, ACCEPTANCE CRITERIA

17-4 According to ASME VIII, Division 1, 2010 Edition, 2011 Addenda

“The Acceptance ctteria shall be in accordance with UW-51, Div 1 of ASME

Vill, 2010 Edition, 2011 Addenda show as below:

(1) Any indication characterized as 2 crack or zone of incomplete fusion

cr penetration are unacceptable regardless of length.

(2) Any other elongated indication on the radiograph which have length

‘eater than are unacceptable:

> Yhin(@ mm) fort up to% in.(19 mm)

—AP8tfor trom % in(19 mm) to 2 % in(S7 mm)

> %in(19.mm) fort over2-% in (67 mm)

Where: tis the thickness of the weld excluding any allowable reinforcement

For the butt weld joints two members having diferent thicknesses at

the weld, tis the thinner of these two thicknesses. Ifa full penetration

Weld includes a filet weld, the thickness of the throat of the filet shall

be included in

(@) Any group of aligned indications that have an aggregate length

greater than t in a length of 121, except when the distance between

the successive imperfections exceeds 6L where L is the length of the

tongest imperfection inthe group:

(4) Rounded indications in excess of that specified by the acceptance

«given in Appendix 4 of Section Vil, Division 4

17.2 According to ASME SECTION I, 2010 Eeition, 2011 Addenda:

Indications shown on the radiographs of welds and characterized as

imperfection able under the following conditions:

or PROCEDURE —PassseTs resort

eee

RADIOGRAPHIC TESTING issued date ‘02-Jub2013

(1) Any indication characterized as a crack or zone of incomplete fusion

Cr penetration are unacceptable regardless of length.

(2) Any other elongated indication on the radiograph which have length

‘greater than are unacceptable:

> Yin(® mm) fort up to% in(19 me)

% —APBtFor from % in(19 mm) to 2 % in(S7 mm)

> %la(19 mm) for t over 2 % in (57 mm)

Where: ts the thickness ofthe weld excluding any allowable reinforcement.

For the butt weld joints two members having diferent thicknesses at

the weld, ts the thinner of these two thicknesses. I full penetration

Wold includes a filet wold, the thickness of the throat of the fillet shall

be included int.

(8) Any group of aligned indications thet have an aggregate length

greater than t in a length of 121, except when the distance between

the successive imperfections exceeds 6L where L isthe length of the

longest imperfection in the group;

(4) Rounded indications in excess of that specified by the acceptance of

the porosity of the standards given in Appendix A-250 of ASME

SECTION

17.3 According to ASME B31.1 2007 Edition 2009 Addenda

Welds that are shown by radiography to have any of the following types of

‘discontinuities are unacceptable:

(1) Anytype of crack or zone of incomplete fusion or penetration.

@) Any other elongated incieation that hae 2 length greater than

(@)%in(@ mm) fort up to% in419 mm)

(@)—1/3tfor from % in(19 mm) to 2 % in (57 mm)

(©) %in (19 mm) fort over 2 % in (87 mm)

Where: tis the thickness of the weld excluding any allowable reinforcement,

For the butt weld joints two members having diferent thicknesses at

the weld, t thinner of these two thicknesses. If full penetration weld

NDT PROCEDURE Provedare Ne_TTANDVIRTOO?

Raw No. oi

RADIOGRAPHIC TESTING | jssuec dso o2sut2013

} PROCEDURE os Tee |

includes a filet weld, the thickness ofthe throat ofthe filet shall be

included int

(©) Any group of inclusions in line that has an aggregate length greater

than t in a length of 121, except when the distance between the

successive imperfections exceeds 6L where L is the length of the

longest imperfection in the group;

(4) Rounded indications in excess of that show as acceptable in

‘Appendix A-250 of Section | ofthe ASME Boller and Pressure Vessel

Cove.

(©) Root concavity when there Is an abrupt change in density, as

indicated on the radiograph

17-4 According to ASME Vill, Division 2, 2010 Editon, 2011 Addenda:

‘Welds that are shown by radiographyy to have any of the following types of

discontinuities are unacceptable:

4 Linear Indications

(1) Any erack or zone of incomplete fusion or lack of penetration

(2) Any other linear indication that has a length greater than:

(@) 6 mm (Ald in} fort less than or equal to 19 mm (2/4 in),

(b) 9 for t greater than 19 mm (314 in.) and less than or equal to

87 mm 2-114 in),

(6) 19 mm (9/4 in.) for t greater than $7 mm (21/4 in).

Where: t is the thickness of the weld excluding any allowable

reinforcement. For a butt weld joining two members having diferent

thicknesses at the weld, ts the thinner of these two thicknesses. fa

{ull penetration weld includes a filet weld, the thickness of the filet

throat shall be included inthe calculation of

(9) Any group of indications in line that has an aggregate length greater

than t in @ length of 12t except when the distance between the

successive imperfections exceeds GL, where L is the length of the

longest imperfection in the group:

NDT PROCEDURE Procedure No.__TTANOTIRTIOO?

a a

RADIOGRAPHIC TESTING | issued cate (02-Ju.2013

PROCEDURE aa

(4) Internal root weld conditions are acceptable when the density or

Image brightness change as indicated in the radiograph is not abrupt

Linear indications on the radiograph at either edge of such conditions

shall be evaluated in accordance with the other sections of this

paragraph,

4 Rounded Indications

Rounded Indications - incications with a maximum length of three times the

\wicth or less on the radiograph are defined as rounded indications. These

indications may be circular, eliptical, conical, or regular in shape and may

hhave tails, When evaluating the size of an indication, the tail shall be

included,

Aligned Indications - a sequence of four or more rounded indications shall be

‘considered to be aligned when they touch a line parallel to the length of the

‘weld drawn through the center ofthe two outer rounded indications.

(1) Rounded Indication Charts - relevant rounded indications

characterized as imperfections shall not exceed those shown in

Figures 7.5 through 7.10 of ASME Vill Div 2, which ilustrate various

types of assorted, randomly dispersed and clustered rounded

indications for diferent wold thicknesses greater than 3 mm (1/8 in.)

‘The charts for each thickness range represent full-scale 150 mm (6

in.) radiographs, and shall not be enlarged or reduced. The

distributions shown are not necessatily the pattems that may appear

fon the radiograph, but are typical of the concentration and size of

indications permitted.

(2) Relevant Indications - Only those rounded indications that exceed the

following dimensions shall be considered relevant and compared to

the acceptance charts for disposition.

(@) V10 fort less than 3 mm (1/8 in)

(©) 0.4 mm (1/84 in. for t greater than or equal to 3 mm (1/8 in.)

fad less than or equal fo 6 mm (1/4 in.)

NDTPROCEDURE —_[Fessuev_TAROTRTOO:

[Revie oF

RADIOGRAPHIC TESTING | issued cate o2-Juk2013

PROCEDURE a |

(©) 0.8 mm (1/82 in.) fort greater than 6 mm (14 in) and less

than or equal to 50 mm (2in)

(6) 1.5mm (116 in) fort greater than 80 mm (2 in)

(e) Maximum Size of Rounded Indication - the maximum

Permisible size of any indication shell be U& or 4 mm (S32

in), whichever fs smaller except that an isolated indication

‘separated from an adjacent indication by 25 mm (1 in.) or more:

may be V8 , or 6 mm (1/4 in), whichever is less. For t greater

than 50 rm (2 in.) the maximum permissible size ofan isolated

indication shall be increased to 10 mm (3/8 in.).

(0) Algnes Rounded Indications - aligned rounded indications ore

‘acceptable when the summation of the diameters of the

incicalions isles than tina length of 12 (eee Figure 7:3) The

length of groups of aligned rounded indications. and the

spacing between the groups shall meet the requirements of

Figure 74 of ASME Vil Div 2.

{) Clustered Indications - the tustrations for clustered

indications show p fe four times as many indications ina loca

area, as that showin inthe ilustrations for random indications.

‘The length of an acceptable cust shall not exceed the lesser

‘of 25 mm (1 in) oF 2. Where mere than one cluster is present,

the sum ofthe lengths ofthe clusters shall not exceed 25 mm

(1 in.) i a 150 mm (6 in.) length weld

(h) Weld Thickness t less than 3 mm (1/8 in) ~ fr tess than 3

‘mm (18 in) the maximum number of rounded indications shall

fot exceed 12 in. a 150 mm (6 in) length of weld. A

proportionally fewer numberof Indlations shal be permite in

welds less than 150 mm (6 in.) in length.

18.

N [| NDTPROCEDURE —[FreadreR -TTARSTINTAD |

“fe | Rev No

yan RADIOGRAPHIC TESTING | issucc date oa wur2013

a PROCEDURE pag ae

47. REPORTING

‘The examination documents shal consist ofthe radiographic technique detals and

radiograph review resuits which provide the folowing information a minimum:

= ldentfcation, eg, jobicontract number

= Number of radiographs (exposure)

= Xray voltage or isotope type used

= Xray machine focal spat size or isotope physical sources size

= Base material type and thickness, weld thickness, welé reinforcement

thickness, as applicable,

= Welding Process

= Source-to-object distance

= Distance fram source side of object to fm

+ Technique (SWSI, OWI, DWOI , Panoramic, )

= Film manufacturer and manufacturer's typeldesignation

= Number of film in each fm holderfeassette

= Dale of evaluation’ and name of Manfacturer’s evaluator

Radiographic Examination Report shall be made as show in appendix |

attached

SAFETY

Reference to the TTAINDTISAFETY/001 Rev.02

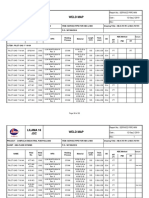

RADIOGRAPHIC

Proce

EXAMINATION REPORT

Page Ta

Poss Cia

centnce ener on Working Area

Ta

nero Sa ae

Dora Rese

Set Rr

SSE

-e Sle = = =

| :

| | L

I | |

as jaa a

i [ a

i sai |

aT

=F aa es

on ee ae

Sean Oa heated oe

Evatnesoy

Sipntire

eNT-To-1A RT Levi

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 0.0 Welding Inspector ExaminationDocument12 pages0.0 Welding Inspector ExaminationTrịnh Quốc TuyếnNo ratings yet

- Asme Guidance Notes: Prepared by TQ. Hoa - 9/2014Document1 pageAsme Guidance Notes: Prepared by TQ. Hoa - 9/2014Trịnh Quốc TuyếnNo ratings yet

- 1811 611 RC 0 B PDFDocument277 pages1811 611 RC 0 B PDFTrịnh Quốc TuyếnNo ratings yet

- Welding Terminology and DefinitionsDocument66 pagesWelding Terminology and DefinitionsTrịnh Quốc TuyếnNo ratings yet

- TTA-NDT-PMI-001 Rev.00 PDFDocument8 pagesTTA-NDT-PMI-001 Rev.00 PDFTrịnh Quốc TuyếnNo ratings yet

- 1.0 Typical Duties of Welding InspectorsDocument27 pages1.0 Typical Duties of Welding InspectorsTrịnh Quốc TuyếnNo ratings yet

- Tta Power 2015 Vi 001Document31 pagesTta Power 2015 Vi 001Trịnh Quốc TuyếnNo ratings yet

- 1811 614 RC 0 B PDFDocument201 pages1811 614 RC 0 B PDFTrịnh Quốc TuyếnNo ratings yet

- Asnt Level 3 - Mai Anh Tai - 2016Document1 pageAsnt Level 3 - Mai Anh Tai - 2016Trịnh Quốc TuyếnNo ratings yet

- Service Pipe Weldmap111Document38 pagesService Pipe Weldmap111Trịnh Quốc TuyếnNo ratings yet

- (Untitled) 2307201315261300Document30 pages(Untitled) 2307201315261300Trịnh Quốc TuyếnNo ratings yet

- Joint Efficiency - Pressure Vessel EngineeringDocument5 pagesJoint Efficiency - Pressure Vessel EngineeringMuthuKumar100% (1)

- WPS 111 001.17Document10 pagesWPS 111 001.17Trịnh Quốc TuyếnNo ratings yet

- Described As 1.7225 42crmo4 in en 10083 - 1: 2006 Previously 709M40 in PD 970: 2001Document2 pagesDescribed As 1.7225 42crmo4 in en 10083 - 1: 2006 Previously 709M40 in PD 970: 2001Trịnh Quốc TuyếnNo ratings yet

- Nguyen Duc Tuyen-111Document2 pagesNguyen Duc Tuyen-111Trịnh Quốc TuyếnNo ratings yet