Professional Documents

Culture Documents

Method Statement: Fabrication of Rebar Cages in Caisson

Method Statement: Fabrication of Rebar Cages in Caisson

Uploaded by

hanisahhamzahCopyright:

Available Formats

You might also like

- Method Statement For Prefabrication and Erection-PipingDocument10 pagesMethod Statement For Prefabrication and Erection-PipingAhmed Gomaa92% (60)

- Clark 080 PDFDocument591 pagesClark 080 PDFBenedito José dos santos FerreiraNo ratings yet

- CE201 Reinforced & Prestressed Concrete Structures (2010)Document88 pagesCE201 Reinforced & Prestressed Concrete Structures (2010)asdasNo ratings yet

- Bridge Condition Rating Data Modeling Using Deep Learning AlgorithmDocument15 pagesBridge Condition Rating Data Modeling Using Deep Learning AlgorithmPalisa Arafin100% (1)

- Narrow Steel Box Girder Article, JapanDocument12 pagesNarrow Steel Box Girder Article, JapanGolam Mostofa100% (1)

- Lift Plan Request FormDocument3 pagesLift Plan Request FormNazzta allezNo ratings yet

- D12 - Workpack Challenge Rev.1Document179 pagesD12 - Workpack Challenge Rev.1anjangandak2932100% (5)

- Manual de Operaci - N Link - Belt PDFDocument232 pagesManual de Operaci - N Link - Belt PDFana mileidy castañedaNo ratings yet

- Drilled ShaftsDocument16 pagesDrilled Shaftsmahajanniket0% (1)

- Chapter 6 Bearing CapacityDocument34 pagesChapter 6 Bearing CapacityhfenangadNo ratings yet

- Dynamic Loading and Testing of Bridges in Ontario PDFDocument11 pagesDynamic Loading and Testing of Bridges in Ontario PDFChathurika Supeshala GamageNo ratings yet

- AASHTO LRFD ShearConnector PDFDocument11 pagesAASHTO LRFD ShearConnector PDFAshraf Mohamed YehiaNo ratings yet

- Bridge Bearings, Expansion Joints & ParapetsDocument81 pagesBridge Bearings, Expansion Joints & ParapetsSAMNo ratings yet

- ICPLG1247 - 2m Post Spacing - Ezy-Guard HC - Bridge Barrier Side MountDocument44 pagesICPLG1247 - 2m Post Spacing - Ezy-Guard HC - Bridge Barrier Side Mountvisva scgNo ratings yet

- Concrete StandardsDocument48 pagesConcrete StandardsDejana AnaNo ratings yet

- Typical Values of Soil Friction Angle For Different Soils According To USCSDocument5 pagesTypical Values of Soil Friction Angle For Different Soils According To USCSCHIKARANo ratings yet

- Pile Analysis Summary:: Input DataDocument2 pagesPile Analysis Summary:: Input DataPatrick Henri100% (1)

- Research Programs: Investigation of Prefabricated Steel-Truss Bridge Deck SystemsDocument70 pagesResearch Programs: Investigation of Prefabricated Steel-Truss Bridge Deck SystemssungshinnNo ratings yet

- Design Considerations of Construction of Embakments LGEDDocument16 pagesDesign Considerations of Construction of Embakments LGEDAnshuman SinghNo ratings yet

- Scouring AnalysisDocument1 pageScouring AnalysisAldrin TadifaNo ratings yet

- Strut and Tie Models Recommended ReadingDocument2 pagesStrut and Tie Models Recommended ReadingBadr AmmarNo ratings yet

- MBR - DTMR - Design Criteria For Large Box Culverts PDFDocument9 pagesMBR - DTMR - Design Criteria For Large Box Culverts PDFfatherofgeorgeNo ratings yet

- GEO2019 Emad Farouz CBIS Drilled ShaftsDocument24 pagesGEO2019 Emad Farouz CBIS Drilled ShaftsOanh PhanNo ratings yet

- Pier Scour Predition Computations From HEC-18 Utilizing Equations 6.3, 6.4, 6.5, 6.6, 6.7, 6.8 and Tables 6.1, 6.2 6.3Document6 pagesPier Scour Predition Computations From HEC-18 Utilizing Equations 6.3, 6.4, 6.5, 6.6, 6.7, 6.8 and Tables 6.1, 6.2 6.3AryaSniperNo ratings yet

- BD 62 07 As Built, Operational and Maintenance Records For Highway Structures (2007)Document41 pagesBD 62 07 As Built, Operational and Maintenance Records For Highway Structures (2007)tpslaterNo ratings yet

- Skid ResistanceDocument5 pagesSkid ResistanceFiaz GujjarNo ratings yet

- A23b - Chalenges For Underwater Concrete Repair in Deep WaterDocument12 pagesA23b - Chalenges For Underwater Concrete Repair in Deep WaterJoão Carlos Protz ProtzNo ratings yet

- 20 Steel Bridge ConstructionDocument62 pages20 Steel Bridge Constructionqu1627No ratings yet

- I Shape Beam-Column Per AISC 360-10 Input: Global Unit DefinitionsDocument8 pagesI Shape Beam-Column Per AISC 360-10 Input: Global Unit DefinitionsDhimas Surya NegaraNo ratings yet

- Brass Culvert 2.7 TechnicalManualDocument35 pagesBrass Culvert 2.7 TechnicalManualEdelyn Lindero AmbosNo ratings yet

- A325 Tension Control Bolts PDFDocument1 pageA325 Tension Control Bolts PDFBoris GalindoNo ratings yet

- TechSpan Brochure PDFDocument6 pagesTechSpan Brochure PDFuet22No ratings yet

- Bridge & Flyover DrainageDocument1 pageBridge & Flyover DrainageSantoso100% (1)

- Part Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Document11 pagesPart Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Anonymous KHIyWRIWmaNo ratings yet

- Asphalt Plug JointDocument103 pagesAsphalt Plug JointMahmood MuftiNo ratings yet

- Pipe CulvertDocument12 pagesPipe CulvertSumit HackNo ratings yet

- EPC Schedule 101 125Document173 pagesEPC Schedule 101 125nidha hamidNo ratings yet

- PSCG LRFD Design GuideDocument10 pagesPSCG LRFD Design GuideRC Dela RocaNo ratings yet

- Bearing Capacity of Strip and Circular Footings in Sand Using Finite ElementsDocument9 pagesBearing Capacity of Strip and Circular Footings in Sand Using Finite ElementsOum MahmdNo ratings yet

- IPIFDocument3 pagesIPIFFrangelin Dianne SarabiaNo ratings yet

- Roadside Barriers TrainingDocument94 pagesRoadside Barriers TrainingSumyth PNo ratings yet

- Runway Design and Structural Design of An Airfield PavementDocument18 pagesRunway Design and Structural Design of An Airfield PavementspruhatechNo ratings yet

- A Review of Cross-Hole Ultrasonic Logging For Foundation Integrity Testing and Its Evaluation CriteriaDocument6 pagesA Review of Cross-Hole Ultrasonic Logging For Foundation Integrity Testing and Its Evaluation CriterialimaNo ratings yet

- Homework No. 1 (10 Points) : CES-5325 / CGN-4930 Design of Highway Bridges - Spring Term 2005Document2 pagesHomework No. 1 (10 Points) : CES-5325 / CGN-4930 Design of Highway Bridges - Spring Term 2005ingamarraNo ratings yet

- Contract Agreement of IpankDocument21 pagesContract Agreement of IpankRahmat SantanaNo ratings yet

- Free Download Here: British Standard Code of Practice Cp110 PDFDocument2 pagesFree Download Here: British Standard Code of Practice Cp110 PDFخالد حسن0% (1)

- CSCWorld Tedds Calculations British Standards and Eurocodes 20140826Document3 pagesCSCWorld Tedds Calculations British Standards and Eurocodes 20140826shawnmckenzie840% (1)

- Sika Ferrogard - 903+: Corrosion Inhibiting Impregnation (Improved Formulation)Document5 pagesSika Ferrogard - 903+: Corrosion Inhibiting Impregnation (Improved Formulation)KpChua100% (1)

- Link Slab Design EXDocument4 pagesLink Slab Design EXAmbrishNo ratings yet

- 01-Cam-Road Part 1 - GeometryDocument69 pages01-Cam-Road Part 1 - GeometryRatanak SanNo ratings yet

- Deepseal 201 SpecificationDocument2 pagesDeepseal 201 SpecificationjanithbogahawattaNo ratings yet

- Rock Sizing For Culvert Outlets PDFDocument0 pagesRock Sizing For Culvert Outlets PDFwrobinsonf2scomNo ratings yet

- Box Pushing Technology PresentationDocument13 pagesBox Pushing Technology PresentationVirendra Kumar PareekNo ratings yet

- Improved Live Load Deflection Criteria For Steel BridgesDocument147 pagesImproved Live Load Deflection Criteria For Steel BridgesChester SmithNo ratings yet

- HSFG Bolt PDFDocument6 pagesHSFG Bolt PDFSatish PawarNo ratings yet

- Chapter-9 Pipe CulvertsDocument6 pagesChapter-9 Pipe CulvertsvinuthNo ratings yet

- Expansion Joints and Bridge BearingsDocument54 pagesExpansion Joints and Bridge BearingsbrelightsNo ratings yet

- Loads Evaluation: TerraceDocument9 pagesLoads Evaluation: Terraceandreeah37No ratings yet

- Design of Foundations AssignmentDocument8 pagesDesign of Foundations AssignmentLutfan LubaibNo ratings yet

- Stone ColumnDocument18 pagesStone ColumnSaravanan Panneervel0% (1)

- Vibration Based SHMDocument20 pagesVibration Based SHMSri N100% (1)

- Hydraulic Guidelines & FormsDocument22 pagesHydraulic Guidelines & FormsMahmoud Breama100% (1)

- BH-8 00Document2 pagesBH-8 00Naveen ChodagiriNo ratings yet

- FCM General PDFDocument48 pagesFCM General PDFNabeel AhmadNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- TC 500 Service ManualDocument119 pagesTC 500 Service ManualNathan RittenhouseNo ratings yet

- Truck Cranes 2015 GBDocument12 pagesTruck Cranes 2015 GBconsultor9010No ratings yet

- HarvestersDocument132 pagesHarvestersLeTraitimbenletkNo ratings yet

- Truck Crane stc1300cDocument23 pagesTruck Crane stc1300cTatamulia Bumi Raya MallNo ratings yet

- Crane Safety PosterDocument2 pagesCrane Safety PosterJuzer MotorwalaNo ratings yet

- MS Hollowcore Plank Placing Rev A WFDocument12 pagesMS Hollowcore Plank Placing Rev A WFChoubi ChoubacaNo ratings yet

- Vdocuments - MX Setting Procedure Evs HMF Tech Procedure Evs 11 16pdf Setting ProcedureDocument37 pagesVdocuments - MX Setting Procedure Evs HMF Tech Procedure Evs 11 16pdf Setting ProcedureKrum Kashavarov100% (1)

- Hydraulic Lifting Products Brochure-2020Document18 pagesHydraulic Lifting Products Brochure-2020igorNo ratings yet

- 248 Hylab HSL SeriesDocument2 pages248 Hylab HSL SeriesSokjo0ker17No ratings yet

- Rolloos Crane Camera SystemDocument4 pagesRolloos Crane Camera Systemsyahmi.developerNo ratings yet

- User Manual - X-904 - Rev. 2023.0Document31 pagesUser Manual - X-904 - Rev. 2023.0Sajith VenkitachalamNo ratings yet

- LP 1T Pipes Critical Crane Lift Plan 25T Crane CPFDocument1 pageLP 1T Pipes Critical Crane Lift Plan 25T Crane CPFMPS PSKNo ratings yet

- MOS-Live Line CrossingDocument8 pagesMOS-Live Line CrossingEngr Muhammad Azam ThaheemNo ratings yet

- Puyuan Crawler Crane Technical ManualDocument10 pagesPuyuan Crawler Crane Technical ManualMechanic BerdasiNo ratings yet

- Rough Terrain Crane 1: ModelDocument36 pagesRough Terrain Crane 1: ModelВиталий Рогожинский100% (3)

- EOT CraneDocument84 pagesEOT CraneSambhav Poddar80% (5)

- SP-2202 Specification For Electric Overhead Traveling CranesDocument15 pagesSP-2202 Specification For Electric Overhead Traveling CranesHaitham Mohammad100% (1)

- 72 516 PDFDocument65 pages72 516 PDFJITENDRA KUMAR SHARMANo ratings yet

- 007 Quote - Emergency MV. Andhika Kanishka (08.01.2019) .No.007.-Signed PDFDocument5 pages007 Quote - Emergency MV. Andhika Kanishka (08.01.2019) .No.007.-Signed PDFEdy SukmonoNo ratings yet

- JSA Format Erection of Exchanger 903-E-01Document5 pagesJSA Format Erection of Exchanger 903-E-01sakthi venkatNo ratings yet

- ICE301B Operation ManualDocument119 pagesICE301B Operation ManualAleksandrNo ratings yet

- Catalogue Xrba Xr2 Xf9 enDocument26 pagesCatalogue Xrba Xr2 Xf9 envili75No ratings yet

- 2A. TRA For Al Ghuwaifat ProjectDocument25 pages2A. TRA For Al Ghuwaifat ProjectAjaz AhmedNo ratings yet

- Steel Mats of CranesDocument1 pageSteel Mats of CranesMohamed FathyNo ratings yet

- 9500-30 20180101 PartsSpecsDocument131 pages9500-30 20180101 PartsSpecsLê Phan Đồng HưngNo ratings yet

Method Statement: Fabrication of Rebar Cages in Caisson

Method Statement: Fabrication of Rebar Cages in Caisson

Uploaded by

hanisahhamzahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement: Fabrication of Rebar Cages in Caisson

Method Statement: Fabrication of Rebar Cages in Caisson

Uploaded by

hanisahhamzahCopyright:

Available Formats

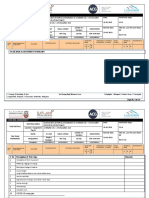

METHOD STATEMENT

FABRICATION OF REBAR CAGES IN

CAISSON

MAJU STRUCKTUR SDN. BHD.

Maju Strucktur Sdn Bhd

Project Hand Dug Caisson

Method Statement – Fabrication Of Rebar Cage In

Title: Caisson

n

1.0 Introduction

Method of fabricate rebar cage in caisson to be adopted when the conventional method

of rebar cage place in cannot be used. (fabricate rebar cage outside and lifted into the

caisson hole by service crane). This could be happened to the congested area, heavy

traffic or on the hill where is inaccessible by the service crane.

2.0 Manpower

Site personnel who involved in this work are:

a) Site Supervisor

b) Generator

c) Barbender

d) Authorized gas tester (A.G.T)

e) Entry Supervisor (E.S)

3.0 Machineries

a) Air Compressor.

b) Generator Set.

c) Electrical Chain Hoist.

d) Bar Cutting and Bending Machine

e) Temporary Hoisting Frame.

f) Ventilator Fan

g) Crane Lifted Work Platform

h) Gas Detector Machine

4.0 Sequence of Work

a) Cutting steel bar to request size and bending spiral link as per construction drawing.

b) Using lifting frame to lift down 1st layer spiral link and rebar into caisson.

c) Start tie 1st layer spiral link with rebar.

d) Install scaffolding to continue tie to higher level.

e) Drilling hanging bar (Normally T20) for hanging second layer spiral link.

f) Lifting down second layer main bar by mobile crane.

g) Start tie 2nd layer rebar with spiral link.

h) Install scaffold up to 3rd layer high.

i) Drilling higher level (3rd layer) hanging bar for hanging 3rd layer spiral link.

j) Lifting down 3rd layer main bar (Internal).

k) Fabricate spiral link with internal main bar.

l) Lastly fabricate external main bar and spiral link.

m) Submit RFWI to consultant for inspection.

n) Dismantle lifting frame and ready for concreting.

MAJU STRUCKTUR SDN. BHD.

Maju Strucktur Sdn Bhd

Project Hand Dug Caisson

Method Statement – Fabrication Of Rebar Cage In

Title: Caisson

n

5.0 SAFETY PRECAUTIONS AND MEASURES

Caisson excavation work involves a high degree of risk due to the unexpected underground

conditions such as gasses, erosion of soil, failing objects and careless acts of workers.

Therefore, works must always be carried out with great caution and with sufficient safety

equipment, to ensure full proof ventilation system with standby equipment provision.

a) Caisson work platform protection :

The work platform must be erected with full design, complete tools and

supervise by PIC

Construct 600mm high toe boards or timber around the work platform to

prevent debris or equipment and workers from falling during the fabrication

rebar cage.

b) Workers Safety :

All caissons workers must see safely helmet, safety belt whistle, body harness,

working shoes, dust mask and proper clothing.

Workers inside the caisson hole must be attended with hoist controller on top

and shall be alert at all times

.

Smoking is prohibited inside all caissons.

Workers must attach safety harness to mancage when going up or down

caisson and must be careful when ascending or descending equipment..

Adequate lighting and fresh air must be provided at all times to workers inside

the caisson hole.

c) Equipment, tools and machineries :

All equipment and tools must be inspected regularly and properly maintained

by the workers and supervisors.

All hoists shall be checked regularly and service from time to time.

Inspected safety system to be verified safe by safety personnel.

d) Hazard Identification, Risk Assessment and Determining Control (HIRADC) :

Refer to Appendix 1 for HIRADC

MAJU STRUCKTUR SDN. BHD.

You might also like

- Method Statement For Prefabrication and Erection-PipingDocument10 pagesMethod Statement For Prefabrication and Erection-PipingAhmed Gomaa92% (60)

- Clark 080 PDFDocument591 pagesClark 080 PDFBenedito José dos santos FerreiraNo ratings yet

- CE201 Reinforced & Prestressed Concrete Structures (2010)Document88 pagesCE201 Reinforced & Prestressed Concrete Structures (2010)asdasNo ratings yet

- Bridge Condition Rating Data Modeling Using Deep Learning AlgorithmDocument15 pagesBridge Condition Rating Data Modeling Using Deep Learning AlgorithmPalisa Arafin100% (1)

- Narrow Steel Box Girder Article, JapanDocument12 pagesNarrow Steel Box Girder Article, JapanGolam Mostofa100% (1)

- Lift Plan Request FormDocument3 pagesLift Plan Request FormNazzta allezNo ratings yet

- D12 - Workpack Challenge Rev.1Document179 pagesD12 - Workpack Challenge Rev.1anjangandak2932100% (5)

- Manual de Operaci - N Link - Belt PDFDocument232 pagesManual de Operaci - N Link - Belt PDFana mileidy castañedaNo ratings yet

- Drilled ShaftsDocument16 pagesDrilled Shaftsmahajanniket0% (1)

- Chapter 6 Bearing CapacityDocument34 pagesChapter 6 Bearing CapacityhfenangadNo ratings yet

- Dynamic Loading and Testing of Bridges in Ontario PDFDocument11 pagesDynamic Loading and Testing of Bridges in Ontario PDFChathurika Supeshala GamageNo ratings yet

- AASHTO LRFD ShearConnector PDFDocument11 pagesAASHTO LRFD ShearConnector PDFAshraf Mohamed YehiaNo ratings yet

- Bridge Bearings, Expansion Joints & ParapetsDocument81 pagesBridge Bearings, Expansion Joints & ParapetsSAMNo ratings yet

- ICPLG1247 - 2m Post Spacing - Ezy-Guard HC - Bridge Barrier Side MountDocument44 pagesICPLG1247 - 2m Post Spacing - Ezy-Guard HC - Bridge Barrier Side Mountvisva scgNo ratings yet

- Concrete StandardsDocument48 pagesConcrete StandardsDejana AnaNo ratings yet

- Typical Values of Soil Friction Angle For Different Soils According To USCSDocument5 pagesTypical Values of Soil Friction Angle For Different Soils According To USCSCHIKARANo ratings yet

- Pile Analysis Summary:: Input DataDocument2 pagesPile Analysis Summary:: Input DataPatrick Henri100% (1)

- Research Programs: Investigation of Prefabricated Steel-Truss Bridge Deck SystemsDocument70 pagesResearch Programs: Investigation of Prefabricated Steel-Truss Bridge Deck SystemssungshinnNo ratings yet

- Design Considerations of Construction of Embakments LGEDDocument16 pagesDesign Considerations of Construction of Embakments LGEDAnshuman SinghNo ratings yet

- Scouring AnalysisDocument1 pageScouring AnalysisAldrin TadifaNo ratings yet

- Strut and Tie Models Recommended ReadingDocument2 pagesStrut and Tie Models Recommended ReadingBadr AmmarNo ratings yet

- MBR - DTMR - Design Criteria For Large Box Culverts PDFDocument9 pagesMBR - DTMR - Design Criteria For Large Box Culverts PDFfatherofgeorgeNo ratings yet

- GEO2019 Emad Farouz CBIS Drilled ShaftsDocument24 pagesGEO2019 Emad Farouz CBIS Drilled ShaftsOanh PhanNo ratings yet

- Pier Scour Predition Computations From HEC-18 Utilizing Equations 6.3, 6.4, 6.5, 6.6, 6.7, 6.8 and Tables 6.1, 6.2 6.3Document6 pagesPier Scour Predition Computations From HEC-18 Utilizing Equations 6.3, 6.4, 6.5, 6.6, 6.7, 6.8 and Tables 6.1, 6.2 6.3AryaSniperNo ratings yet

- BD 62 07 As Built, Operational and Maintenance Records For Highway Structures (2007)Document41 pagesBD 62 07 As Built, Operational and Maintenance Records For Highway Structures (2007)tpslaterNo ratings yet

- Skid ResistanceDocument5 pagesSkid ResistanceFiaz GujjarNo ratings yet

- A23b - Chalenges For Underwater Concrete Repair in Deep WaterDocument12 pagesA23b - Chalenges For Underwater Concrete Repair in Deep WaterJoão Carlos Protz ProtzNo ratings yet

- 20 Steel Bridge ConstructionDocument62 pages20 Steel Bridge Constructionqu1627No ratings yet

- I Shape Beam-Column Per AISC 360-10 Input: Global Unit DefinitionsDocument8 pagesI Shape Beam-Column Per AISC 360-10 Input: Global Unit DefinitionsDhimas Surya NegaraNo ratings yet

- Brass Culvert 2.7 TechnicalManualDocument35 pagesBrass Culvert 2.7 TechnicalManualEdelyn Lindero AmbosNo ratings yet

- A325 Tension Control Bolts PDFDocument1 pageA325 Tension Control Bolts PDFBoris GalindoNo ratings yet

- TechSpan Brochure PDFDocument6 pagesTechSpan Brochure PDFuet22No ratings yet

- Bridge & Flyover DrainageDocument1 pageBridge & Flyover DrainageSantoso100% (1)

- Part Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Document11 pagesPart Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Anonymous KHIyWRIWmaNo ratings yet

- Asphalt Plug JointDocument103 pagesAsphalt Plug JointMahmood MuftiNo ratings yet

- Pipe CulvertDocument12 pagesPipe CulvertSumit HackNo ratings yet

- EPC Schedule 101 125Document173 pagesEPC Schedule 101 125nidha hamidNo ratings yet

- PSCG LRFD Design GuideDocument10 pagesPSCG LRFD Design GuideRC Dela RocaNo ratings yet

- Bearing Capacity of Strip and Circular Footings in Sand Using Finite ElementsDocument9 pagesBearing Capacity of Strip and Circular Footings in Sand Using Finite ElementsOum MahmdNo ratings yet

- IPIFDocument3 pagesIPIFFrangelin Dianne SarabiaNo ratings yet

- Roadside Barriers TrainingDocument94 pagesRoadside Barriers TrainingSumyth PNo ratings yet

- Runway Design and Structural Design of An Airfield PavementDocument18 pagesRunway Design and Structural Design of An Airfield PavementspruhatechNo ratings yet

- A Review of Cross-Hole Ultrasonic Logging For Foundation Integrity Testing and Its Evaluation CriteriaDocument6 pagesA Review of Cross-Hole Ultrasonic Logging For Foundation Integrity Testing and Its Evaluation CriterialimaNo ratings yet

- Homework No. 1 (10 Points) : CES-5325 / CGN-4930 Design of Highway Bridges - Spring Term 2005Document2 pagesHomework No. 1 (10 Points) : CES-5325 / CGN-4930 Design of Highway Bridges - Spring Term 2005ingamarraNo ratings yet

- Contract Agreement of IpankDocument21 pagesContract Agreement of IpankRahmat SantanaNo ratings yet

- Free Download Here: British Standard Code of Practice Cp110 PDFDocument2 pagesFree Download Here: British Standard Code of Practice Cp110 PDFخالد حسن0% (1)

- CSCWorld Tedds Calculations British Standards and Eurocodes 20140826Document3 pagesCSCWorld Tedds Calculations British Standards and Eurocodes 20140826shawnmckenzie840% (1)

- Sika Ferrogard - 903+: Corrosion Inhibiting Impregnation (Improved Formulation)Document5 pagesSika Ferrogard - 903+: Corrosion Inhibiting Impregnation (Improved Formulation)KpChua100% (1)

- Link Slab Design EXDocument4 pagesLink Slab Design EXAmbrishNo ratings yet

- 01-Cam-Road Part 1 - GeometryDocument69 pages01-Cam-Road Part 1 - GeometryRatanak SanNo ratings yet

- Deepseal 201 SpecificationDocument2 pagesDeepseal 201 SpecificationjanithbogahawattaNo ratings yet

- Rock Sizing For Culvert Outlets PDFDocument0 pagesRock Sizing For Culvert Outlets PDFwrobinsonf2scomNo ratings yet

- Box Pushing Technology PresentationDocument13 pagesBox Pushing Technology PresentationVirendra Kumar PareekNo ratings yet

- Improved Live Load Deflection Criteria For Steel BridgesDocument147 pagesImproved Live Load Deflection Criteria For Steel BridgesChester SmithNo ratings yet

- HSFG Bolt PDFDocument6 pagesHSFG Bolt PDFSatish PawarNo ratings yet

- Chapter-9 Pipe CulvertsDocument6 pagesChapter-9 Pipe CulvertsvinuthNo ratings yet

- Expansion Joints and Bridge BearingsDocument54 pagesExpansion Joints and Bridge BearingsbrelightsNo ratings yet

- Loads Evaluation: TerraceDocument9 pagesLoads Evaluation: Terraceandreeah37No ratings yet

- Design of Foundations AssignmentDocument8 pagesDesign of Foundations AssignmentLutfan LubaibNo ratings yet

- Stone ColumnDocument18 pagesStone ColumnSaravanan Panneervel0% (1)

- Vibration Based SHMDocument20 pagesVibration Based SHMSri N100% (1)

- Hydraulic Guidelines & FormsDocument22 pagesHydraulic Guidelines & FormsMahmoud Breama100% (1)

- BH-8 00Document2 pagesBH-8 00Naveen ChodagiriNo ratings yet

- FCM General PDFDocument48 pagesFCM General PDFNabeel AhmadNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- TC 500 Service ManualDocument119 pagesTC 500 Service ManualNathan RittenhouseNo ratings yet

- Truck Cranes 2015 GBDocument12 pagesTruck Cranes 2015 GBconsultor9010No ratings yet

- HarvestersDocument132 pagesHarvestersLeTraitimbenletkNo ratings yet

- Truck Crane stc1300cDocument23 pagesTruck Crane stc1300cTatamulia Bumi Raya MallNo ratings yet

- Crane Safety PosterDocument2 pagesCrane Safety PosterJuzer MotorwalaNo ratings yet

- MS Hollowcore Plank Placing Rev A WFDocument12 pagesMS Hollowcore Plank Placing Rev A WFChoubi ChoubacaNo ratings yet

- Vdocuments - MX Setting Procedure Evs HMF Tech Procedure Evs 11 16pdf Setting ProcedureDocument37 pagesVdocuments - MX Setting Procedure Evs HMF Tech Procedure Evs 11 16pdf Setting ProcedureKrum Kashavarov100% (1)

- Hydraulic Lifting Products Brochure-2020Document18 pagesHydraulic Lifting Products Brochure-2020igorNo ratings yet

- 248 Hylab HSL SeriesDocument2 pages248 Hylab HSL SeriesSokjo0ker17No ratings yet

- Rolloos Crane Camera SystemDocument4 pagesRolloos Crane Camera Systemsyahmi.developerNo ratings yet

- User Manual - X-904 - Rev. 2023.0Document31 pagesUser Manual - X-904 - Rev. 2023.0Sajith VenkitachalamNo ratings yet

- LP 1T Pipes Critical Crane Lift Plan 25T Crane CPFDocument1 pageLP 1T Pipes Critical Crane Lift Plan 25T Crane CPFMPS PSKNo ratings yet

- MOS-Live Line CrossingDocument8 pagesMOS-Live Line CrossingEngr Muhammad Azam ThaheemNo ratings yet

- Puyuan Crawler Crane Technical ManualDocument10 pagesPuyuan Crawler Crane Technical ManualMechanic BerdasiNo ratings yet

- Rough Terrain Crane 1: ModelDocument36 pagesRough Terrain Crane 1: ModelВиталий Рогожинский100% (3)

- EOT CraneDocument84 pagesEOT CraneSambhav Poddar80% (5)

- SP-2202 Specification For Electric Overhead Traveling CranesDocument15 pagesSP-2202 Specification For Electric Overhead Traveling CranesHaitham Mohammad100% (1)

- 72 516 PDFDocument65 pages72 516 PDFJITENDRA KUMAR SHARMANo ratings yet

- 007 Quote - Emergency MV. Andhika Kanishka (08.01.2019) .No.007.-Signed PDFDocument5 pages007 Quote - Emergency MV. Andhika Kanishka (08.01.2019) .No.007.-Signed PDFEdy SukmonoNo ratings yet

- JSA Format Erection of Exchanger 903-E-01Document5 pagesJSA Format Erection of Exchanger 903-E-01sakthi venkatNo ratings yet

- ICE301B Operation ManualDocument119 pagesICE301B Operation ManualAleksandrNo ratings yet

- Catalogue Xrba Xr2 Xf9 enDocument26 pagesCatalogue Xrba Xr2 Xf9 envili75No ratings yet

- 2A. TRA For Al Ghuwaifat ProjectDocument25 pages2A. TRA For Al Ghuwaifat ProjectAjaz AhmedNo ratings yet

- Steel Mats of CranesDocument1 pageSteel Mats of CranesMohamed FathyNo ratings yet

- 9500-30 20180101 PartsSpecsDocument131 pages9500-30 20180101 PartsSpecsLê Phan Đồng HưngNo ratings yet