Professional Documents

Culture Documents

LP 1T Pipes Critical Crane Lift Plan 25T Crane CPF

Uploaded by

MPS PSKOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LP 1T Pipes Critical Crane Lift Plan 25T Crane CPF

Uploaded by

MPS PSKCopyright:

Available Formats

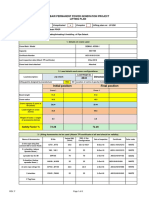

Critical Lifting Operation Plan

Current Colour Code

Facility PSK

Work Location CPF

Permit to Work Number

Lift Category Non Routine - Critical

Weight of load 1t Actual or Estimated Estimated

Crane Type and Capacity 25T Crane Registration DNO Approved

Description of Task Including the Load

UTILIZING 25T CRANE TO LIFT PIPES OVER THE SEPARATOR OUTLET LINES TO CONNECT TO SEPARATOR DUMPLINES

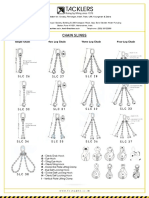

Lifting Equipment to be use (Size of Chains, Slings, Shackles include rigging configuration and WLL for each lift)

1 x 25T MOBILE CRANE

Radius:16m

Boom Length: 24m

Crane capacity: 2.65T SWL

2 X 2T SWL x 6tmtr WEBBING SLINGS(minimum)

1 x Taglines

Hazard Analysis On Site Pre-Lift Checklist

Yes/No Yes/No

Are there any Cultural or Communication Difficulties Identified Yes Tool Box Talk Complete Lifting Operation Explained to Team

Conflicting Tasks SIMOPS Power lines Excavations in Area No Pre-Start Inspection of Crane and Checklist Complete

Has the Centre of Gravity of the Load Been Assessed Yes Lifting Equipment/Accessories Inspected

Will the Load or Crane Pass Over Live Equipment No Lifting and Landing Areas Inspected

Are there Approved Lifting Points on Load Yes Check Environmental conditions and Wind Speed

Is the Crane Operator Certified Yes Ensure Timber dunnage or Pads are Under Outriggers

Is the Banksman Slinger Certified No Inspect Load for Dropped Objects

Method of slinging/attaching/detaching the load assessed Yes Check for Adequate Tail Swing of Crane

Is Working Under a Suspended Load Required No Barricades and Information Tags in Place

Will the Operator Have Full Visibility of the Load Yes Will Taglines be Used to Control the Load

Lifting Operation Sequence (Step by step)

1. All persons involved in the lifting operation to attend the TBT and go through the step by step details of the lift plan.

2. Barricade off the work area.

3. Rigger/Banksman to inspect all the lifting gear as mentioned above.

4. Crane operator to complete daily inspection checklist on the crane before lifting operations.

6. Crane operator to set required boom length on initial set up of the crane.

7. Crane operator to carry out dry run from pick up point over to the end completion point of the lifting operation with no load.Set boom lenght and radius.

8. Crane operator check outrigger pads for ground movement. (stability)

8. Rigger/Banksman to attach lifting sling set to the cranes aux hook.

10. Rigger/ Banksman to instruct crane operator using hand signals to slowly take the known weight of the load inching slowly up on hook.

11. When crane operator has full weight of the load signal to crane operator to stop hooking up and Rigger/Banksman then checks for dropped objects and balance of the

secure load.

12. Once load is fully secured attach 1 taglines to the lift for control/orient the load.

13. Rigger/Banksman at end point of the lift to give clear hand signals to crane operator and lift load as mentioned.

14. Repeat steps above until all loads into position

15. On completion of the lifting operation Rigger/Banksman to derig lifting gear and carry out a post -use inspection of the lifting accessories pack up crane and demobilize

utilizing a flagman.

16. Ensure the lifting site is clear and tidy then carry out debrief and learning outcomes with team.

Note: Ensure crane operator does not exceed 90% of the crane load charts SW

Any change to the lifting plan must be reviewed, agreed, and communicated to the work party involved in the operation.

Communication Methods to be used

Radio Verbal Hand Signals

Yes Yes

Lift Plan Prepared By

Name Saman Date 19-10-2022 Signed Saman

Approved By Rigging and lifting Advisor

Name Jiyar Adam Date 19-10-2022 Signed

Authorized By Field manager or Site Controller when lifting over Live Lines

Name Date Signed

You might also like

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- Generic lifting plan titleDocument3 pagesGeneric lifting plan titlemuhammad umarNo ratings yet

- Lifting Plan TemplateDocument16 pagesLifting Plan TemplatezwvvsoNo ratings yet

- Appendix - Nlng-lp-017 - Lift Plan For Lifting and Installation of Roof Trusses of Amenities Building (19418) - Comments From MosesDocument32 pagesAppendix - Nlng-lp-017 - Lift Plan For Lifting and Installation of Roof Trusses of Amenities Building (19418) - Comments From MosesAdebayo M JayeolaNo ratings yet

- Swift TS06E Risk AssessmentDocument9 pagesSwift TS06E Risk AssessmentsouravrobinNo ratings yet

- D Lifting Plan Using Tele HandlerDocument1 pageD Lifting Plan Using Tele HandlerSyed Fawad ShahNo ratings yet

- Samuel Francis Lifting Engineer ResumeDocument5 pagesSamuel Francis Lifting Engineer Resumeanthony jamesNo ratings yet

- Petroleum Development Oman L.L.C.: Method Statement For Lifting OperationDocument2 pagesPetroleum Development Oman L.L.C.: Method Statement For Lifting Operationpreventing becej0% (1)

- The VLSI Ruby II Advanced Communication ProcessorDocument1 pageThe VLSI Ruby II Advanced Communication ProcessorvlkumashankardeekshithNo ratings yet

- Complicated Lifting Operation Plan: Non Routine Complicated MAX With Lifting Gear Actual or Estimated Crane RegistrationDocument1 pageComplicated Lifting Operation Plan: Non Routine Complicated MAX With Lifting Gear Actual or Estimated Crane RegistrationAva GhaziNo ratings yet

- LP-0008 - Load and Off-Load Rental MEWP 17teDocument6 pagesLP-0008 - Load and Off-Load Rental MEWP 17teRustam36No ratings yet

- LiftingDocument5 pagesLiftingBoma IpaliboNo ratings yet

- Petroleum Development Oman Lift Plan for Lifting Turbine RotorDocument7 pagesPetroleum Development Oman Lift Plan for Lifting Turbine RotorVuthpalachaitanya KrishnaNo ratings yet

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Document3 pagesStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanNo ratings yet

- Chain Chain SlingsDocument8 pagesChain Chain SlingsDharmendra MeenaNo ratings yet

- NLP 296 LoadingUnloading Positioning of Pipe Stack 500TDocument8 pagesNLP 296 LoadingUnloading Positioning of Pipe Stack 500TAhmed AliNo ratings yet

- BP 42 Guidance On The Safe Use of Container Lifting LugsDocument7 pagesBP 42 Guidance On The Safe Use of Container Lifting LugsGaniyuNo ratings yet

- Anything: RiggingDocument20 pagesAnything: Riggingallyssa monica duNo ratings yet

- Lifting Plan Registration PDFDocument1 pageLifting Plan Registration PDFScribdTranslationsNo ratings yet

- Lift Plan 1 REV1Document4 pagesLift Plan 1 REV1AkimBiNo ratings yet

- Maj Concslb 043 0Document1 pageMaj Concslb 043 0Mohammed JassimNo ratings yet

- Lifting Plan Calculation (QTZ200 Tower Crane)Document3 pagesLifting Plan Calculation (QTZ200 Tower Crane)Ilham KelanaNo ratings yet

- Efogen Rigging SlingingDocument52 pagesEfogen Rigging SlingingBalasuperamaniam RamanNo ratings yet

- Hoisting and Rigging Plan: Location: Date of Lift: Load Description: Lift Director Ordinary: Critical: Multiple CranesDocument5 pagesHoisting and Rigging Plan: Location: Date of Lift: Load Description: Lift Director Ordinary: Critical: Multiple CranesAfdalNo ratings yet

- LIFT PLAN CHECKLISTDocument4 pagesLIFT PLAN CHECKLISTMohd FadliNo ratings yet

- Hoisting and Rigging Plan ChecklistDocument5 pagesHoisting and Rigging Plan ChecklistRaja GuruNo ratings yet

- Offshore - Appointed Person Lifting NewDocument335 pagesOffshore - Appointed Person Lifting NewAdnan Abdul RehimNo ratings yet

- G18-2-LP-003 DG - Lifting PlanDocument25 pagesG18-2-LP-003 DG - Lifting PlanMohammed JassimNo ratings yet

- Wilco External Stairs Lift PlanDocument25 pagesWilco External Stairs Lift PlanEdgar ChecaNo ratings yet

- TÜV Rheinland Arabia Services CalendarDocument1 pageTÜV Rheinland Arabia Services Calendarshoaib2scribedNo ratings yet

- Contoh LIfting Plan #1Document5 pagesContoh LIfting Plan #1KevinNo ratings yet

- 2.LOAD CHART AT-22 T133750C (Color) PDFDocument21 pages2.LOAD CHART AT-22 T133750C (Color) PDFRoy Ferdy MassoloNo ratings yet

- Critical Lift Critical Lift Plan Required YES: (Note: Never Exceed 75% of Each Crane's Capacity in A Multi-Crane Lift.)Document4 pagesCritical Lift Critical Lift Plan Required YES: (Note: Never Exceed 75% of Each Crane's Capacity in A Multi-Crane Lift.)cute1t100% (1)

- Lifting Operations & Lifting EquipmentDocument19 pagesLifting Operations & Lifting Equipmentegy pureNo ratings yet

- Compliance Assistance Checklist For PrecastDocument6 pagesCompliance Assistance Checklist For PrecasttatonyNo ratings yet

- B Lifting Plan Using LorryDocument1 pageB Lifting Plan Using LorrySyed Fawad ShahNo ratings yet

- Forklift Loading Stem StocksDocument4 pagesForklift Loading Stem Stocksreda mesbahNo ratings yet

- Introduction To Lifting PlanDocument44 pagesIntroduction To Lifting PlanÐôùxBébê Ðê MãmäñNo ratings yet

- Lifting PlanDocument2 pagesLifting PlanMidhunRameshThuvasseryNo ratings yet

- Sling Length and TensionDocument4 pagesSling Length and TensionMo'tasem SerdanehNo ratings yet

- Erection Method Statement - Birla White (Gotan)Document15 pagesErection Method Statement - Birla White (Gotan)SEPL SEPLNo ratings yet

- Referensi Rigging PlanDocument4 pagesReferensi Rigging PlanLaurentius CalvinNo ratings yet

- EDCINTL - hse.FM.080.R4-Critical Lift Permit Crane ADocument2 pagesEDCINTL - hse.FM.080.R4-Critical Lift Permit Crane ABogdan-Gabriel SchiopuNo ratings yet

- Corporate Lifting Expert Leads SafetyDocument3 pagesCorporate Lifting Expert Leads Safetyanthony jamesNo ratings yet

- Method Statement For Lifting Operations - Builders SafetyDocument2 pagesMethod Statement For Lifting Operations - Builders SafetyMuhammad Sami Parvez100% (1)

- CP For Safe Lifting OperationDocument26 pagesCP For Safe Lifting OperationLaughlikesiao HeheNo ratings yet

- Tools & Tackles Monthly InspectionDocument4 pagesTools & Tackles Monthly InspectionDeepu ChandranNo ratings yet

- LIFTING PLAN DETAILSDocument1 pageLIFTING PLAN DETAILSZubair KhawarNo ratings yet

- Tandem Lifting Container SWGDocument1 pageTandem Lifting Container SWGarifNo ratings yet

- Lifting Supervision EssentialsDocument28 pagesLifting Supervision EssentialsYahya YusufzayNo ratings yet

- Lifting Procedure: 1.0 GeneralDocument4 pagesLifting Procedure: 1.0 GeneralMagdy BakryNo ratings yet

- Lifting Plan Counter WeightDocument1 pageLifting Plan Counter WeightAzhar RimaNo ratings yet

- Alison Generator: Critical Lift PlanDocument1 pageAlison Generator: Critical Lift Plansurakanti pratap reddyNo ratings yet

- Guide Crane-Lifted Work PlatformsDocument13 pagesGuide Crane-Lifted Work PlatformssheqarayzanNo ratings yet

- Crane Lifting Calculation SheetDocument1 pageCrane Lifting Calculation SheetAkbar Dawood100% (1)

- Lifting Plan Vibro Hammer GEO 2021Document7 pagesLifting Plan Vibro Hammer GEO 2021bangunNo ratings yet

- USSC - SGI-2015-ring Loc Technical Manual PDFDocument73 pagesUSSC - SGI-2015-ring Loc Technical Manual PDFAzad pravesh khanNo ratings yet

- Heavy Lifting PostersDocument1 pageHeavy Lifting Postersjohn rajNo ratings yet

- INFINITY LIFT planDocument1 pageINFINITY LIFT planWeru MorrisNo ratings yet

- Lifting Plan For 62.07 RepairDocument6 pagesLifting Plan For 62.07 RepairLaith Salman100% (1)

- Parallel Operation of Transformers ExplainedDocument4 pagesParallel Operation of Transformers Explainedashad ashaNo ratings yet

- AXtension Invoice Processing - User Manual - AX2012Document187 pagesAXtension Invoice Processing - User Manual - AX2012Peter JanssenNo ratings yet

- Dell Vs HPDocument10 pagesDell Vs HPAubin CvrNo ratings yet

- Bombas de TransDocument2 pagesBombas de TransenriqueNo ratings yet

- AMS Connection - PROFIBUS PA Via DP - PA Coupler - TopWorx Engineering WikiDocument10 pagesAMS Connection - PROFIBUS PA Via DP - PA Coupler - TopWorx Engineering Wikishafi ullaNo ratings yet

- Work at Heigh at Night SafetyDocument49 pagesWork at Heigh at Night SafetyKhuda BukshNo ratings yet

- Installations Performed by SAP Setup Fail With Error 0x0000007b (123) On Windows 10 Build 1709Document2 pagesInstallations Performed by SAP Setup Fail With Error 0x0000007b (123) On Windows 10 Build 1709Zakaria BouhouchNo ratings yet

- Sample 100Document12 pagesSample 100john cartarNo ratings yet

- ThyssenKrupp - TWIN ElevatorsDocument12 pagesThyssenKrupp - TWIN ElevatorsThyssenKrupp india50% (2)

- ICT583 Unit Guide 2022Document18 pagesICT583 Unit Guide 2022Irshad BasheerNo ratings yet

- 2g Audit TrakerDocument24 pages2g Audit TrakerPankaj KumarNo ratings yet

- IJ200EDocument2 pagesIJ200EAri AnNo ratings yet

- Samsung Le26r71b 72b Le32r71b r72b Le37r72b Le40r71b 72b Chassis-Gbd26ke Gbd32ke Gbd40ke Gbr26ke Gbr32ke Gbr37ke Gbr40ke SMDocument223 pagesSamsung Le26r71b 72b Le32r71b r72b Le37r72b Le40r71b 72b Chassis-Gbd26ke Gbd32ke Gbd40ke Gbr26ke Gbr32ke Gbr37ke Gbr40ke SMCiubotaru Elena100% (1)

- Injector Sleeve Installation On 2008-2017 Detroit Diesel DD15 & 16 Diesel EnginesDocument2 pagesInjector Sleeve Installation On 2008-2017 Detroit Diesel DD15 & 16 Diesel EnginesIonut-alexandru IordacheNo ratings yet

- Digital Control of Switching Mode Power Supply Simone Buso 2Document77 pagesDigital Control of Switching Mode Power Supply Simone Buso 2Ahmed58seribegawanNo ratings yet

- ARM8020 Users' Manual H (V6.0.13)Document12 pagesARM8020 Users' Manual H (V6.0.13)João Francisco MontanhaniNo ratings yet

- International Journal of Multimedia and Ubiquitous EngineeringDocument10 pagesInternational Journal of Multimedia and Ubiquitous EngineeringPeter Osundwa KitekiNo ratings yet

- Of Paper / Films: Roll Hardness TesterDocument1 pageOf Paper / Films: Roll Hardness TesterSanjay TarteNo ratings yet

- ANSI-IEEE Device Numbers PDFDocument12 pagesANSI-IEEE Device Numbers PDFMario SamudioNo ratings yet

- JBVNL Physical Inventory Process GuideDocument12 pagesJBVNL Physical Inventory Process GuideFuad InsanNo ratings yet

- Project Review On Ultrasonic Distance Measurement: Prakhar Shrivastava, Praveen Kumar, Ankit TiwariDocument3 pagesProject Review On Ultrasonic Distance Measurement: Prakhar Shrivastava, Praveen Kumar, Ankit TiwariSuraj UpadhyayNo ratings yet

- Formats of Information SourcesDocument25 pagesFormats of Information Sourcesvince artuzNo ratings yet

- Plugs Modulares AmpDocument14 pagesPlugs Modulares AmpAstrid Marin PalaciosNo ratings yet

- 6 Plus Price in Pakistan - Google SearchDocument1 page6 Plus Price in Pakistan - Google SearchZeeshan UmraniNo ratings yet

- Axis Statement Kirandeep KaurDocument2 pagesAxis Statement Kirandeep KaurTanvi DhingraNo ratings yet

- IBM ToolBox For Java JTOpenDocument772 pagesIBM ToolBox For Java JTOpenSharique HussainNo ratings yet

- (30 Disember) FK Jadual Peperiksaan Akhir Dan Pengawasan Semester 1 Sesi 2022-2023Document3 pages(30 Disember) FK Jadual Peperiksaan Akhir Dan Pengawasan Semester 1 Sesi 2022-2023NazrinNo ratings yet

- Audio Catalogue: We Supply SoundDocument64 pagesAudio Catalogue: We Supply SoundAlvin Novandi Ega PradanaNo ratings yet

- STAMFORD S0 S1 Brochure - Secured - 0Document8 pagesSTAMFORD S0 S1 Brochure - Secured - 0ThijsNo ratings yet