Professional Documents

Culture Documents

Petroleum Development Oman Lift Plan for Lifting Turbine Rotor

Uploaded by

Vuthpalachaitanya KrishnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Petroleum Development Oman Lift Plan for Lifting Turbine Rotor

Uploaded by

Vuthpalachaitanya KrishnaCopyright:

Available Formats

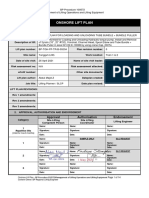

Petroleum Development Oman

LIFT PLAN FOR LIFTING OPERATION

PROJECT

ACTIVITY G2803 Major Inspection Turbine rotor lifting at Hubara Station

CONTARCTOR MJBES

Lifting Category Routine / Non routine Location / RIG No HUBARA

To ensure the safety of the personnel/ equipment/ asset involved in

OBJECTIVE

lifting activities

Deploy competent individuals with valid competence card

MANPOWER A designated lifting supervisor (person in charge PIC and banks

man)

Signaller: Co-ordinate the lifting movements and maintains radio-

and/or visual communication with crane operator and persons close to

the load

Slinger: Inspect the rigging, select rigging to suit the load, install the

accessories and connect/disconnect the load

RESPONSIBILITIES Lifting supervisor (PIC): Co-ordinate and control all aspects of lifting

operations on site. (Banks man can be the lifting supervisor for routine

lift). To ensure lifting operation is implementing according to the Lift

plan)

Crane Operator: Pre-use inspection of crane and rig up of the crane;

operating the crane and perform the lift in a safe manner taking the

signals from the Banks man / Signaller only, unless in an emergency.

LIFTING EQUIPMENT All Lifting Equipment carry out the actual lifting shall have a valid third-

party certification as per SP2275.

IF IN DOUBT – STOP THE JOB AND ASK

1. Load Details

Total Weight 11.300 Ton Load Dimensions L= 16ft Type of Load Rotor(Turbine)

Method (s) Of Communication to be used Radio Verbal Hand Signals

2. Lifting Accessories: Current Color Code=

Crane-1 Crane-2

Qty Description SWL Weight Qty Description SWL Weight

Total Rigging Weight Total Rigging Weight

3. Rigging method:

Vertical Hitch Bridle Hitch with eye pads Choker Hitch Basket Hitch

4. Crane and Load Chart Details

CRANE-1 CRANE-2

Crane SWL 90.0T Crane SWL

Gross Weight of Crane 50T Gross Weight of Crane

Hook Block Weight 600KG Hook Block Weight

Required Boom Length 31.40mt Required Boom Length

Maximum Radius 16mt Maximum Radius

Capacity @Max Radius 12.5ton Capacity @Max Radius

Crane Utilization (%) Crane Utilization (%)

5. Ground Bearing Pressure (For Non-routine complex)

Maximum Site Ground Bearing Capacity:

CRANE-1 CRANE-2

Gross Weight (Crane + Hook block Gross Weight (Crane + Rigging +

+ Rigging + Load) Load)

Out rigger spreader mat size & Out rigger spreader mat size &

type type

Gross Weight/ Area of mat Gross Weight/ Area of mat

Ground Bearing Pressure Ground Bearing Pressure

NOTE: Ground Bearing Pressure shall not exceed the Maximum Site Ground Bearing Capacity

6. Support document

Sketch and rigging arrangement.

Specific load chart

Task risk assessment*

Lifting crew competence cards

Lifting equipment inspection certificates i.e. cranes and lifting gears.

*For Non routine operation step-by-step instruction with a specific TRA shall be attached.

7. Steps of lifting operation:

8. Sketch and rigging arrangement.

10 QUESTIONS FOR A SAFE LIFT

NO DESCRIPTION Yes No

01 Is everyone aware of and do they fully understand the lifting procedures?

Yes

02 Has everyone attended the toolbox talk? Yes

Has a pre-use inspection of the Lifting Equipment been carried out and are Yes

the Lifting Accessories tagged or marked with:

03 - Safe Working Load

- A unique identification number

- A valid certification date

04 Are all safety devices working? Yes

05 Does everyone know the lifting supervisor of the lift? Yes

06 Is everyone competent and aware of his or her tasks? Yes

Is there a current Lift Plan and risk assessment and does everybody Yes

07

understand the job and precautions?

Is everyone aware about environmental limits (e.g. maximum permissible Yes

08

wind speed) for the lift?

09 Is the lift area controlled and is the lifting path clear? Yes

10 Are signalling methods and communication agreed and understood? Yes

Note: Never start any lifting operation until all concerned have been briefed in a Pre-Start

Meeting, ensuring that they understand their role and responsibilities and that they have signed

onto the Permit-to-Work or record of attendance at the Pre-Start Meeting.

Approval

Name Signature Date Valid until

Lift plan preparer

Approved by

Note: Generic / Routine lift plan can be reviewed and approved by contractor qualified appointed

person.

You might also like

- Lifting PlanDocument9 pagesLifting Plansatyabrath dhalNo ratings yet

- Banksman SlingerDocument9 pagesBanksman SlingerPirlo PoloNo ratings yet

- Critical Lifting Plan 10T, 80% Capacity, One Side 10m: Al-Dur Ii Iwpp ProjectDocument1 pageCritical Lifting Plan 10T, 80% Capacity, One Side 10m: Al-Dur Ii Iwpp ProjectJianping KeNo ratings yet

- Petroleum Development Oman L.L.C.: Method Statement For Lifting OperationDocument2 pagesPetroleum Development Oman L.L.C.: Method Statement For Lifting Operationpreventing becej0% (1)

- Crane Lifting Calculation SheetDocument1 pageCrane Lifting Calculation SheetAkbar Dawood100% (1)

- Critical Lift Plan For Overhead Cranes: (Net Load)Document6 pagesCritical Lift Plan For Overhead Cranes: (Net Load)Alex Sandro Borges PereiraNo ratings yet

- D Lifting Plan Using Tele HandlerDocument1 pageD Lifting Plan Using Tele HandlerSyed Fawad ShahNo ratings yet

- HoistingRiggingPlan PDFDocument5 pagesHoistingRiggingPlan PDFHadiwinata DjakariaNo ratings yet

- Crawler Crane Checklist Rev 0Document2 pagesCrawler Crane Checklist Rev 0Maizatul Akmar Manshor100% (2)

- Checklist Inspection For CraneDocument1 pageChecklist Inspection For CraneMohammed Rashid Al-kalbaniNo ratings yet

- Lifting Plan For 62.07 RepairDocument6 pagesLifting Plan For 62.07 RepairLaith Salman100% (1)

- Lifting Plan Site InspectionDocument5 pagesLifting Plan Site Inspectionkhaled redaNo ratings yet

- PMF 015 HSE 151 v1 Lifting PlanDocument8 pagesPMF 015 HSE 151 v1 Lifting Plansikandar1234No ratings yet

- Complicated Lifting Operation Plan: Non Routine Complicated MAX With Lifting Gear Actual or Estimated Crane RegistrationDocument1 pageComplicated Lifting Operation Plan: Non Routine Complicated MAX With Lifting Gear Actual or Estimated Crane RegistrationAva GhaziNo ratings yet

- Method Statement & Lift PlanDocument6 pagesMethod Statement & Lift PlanGodfred Quarm100% (1)

- Lifting PlanDocument35 pagesLifting PlanAva GhaziNo ratings yet

- Generic lifting plan titleDocument3 pagesGeneric lifting plan titlemuhammad umarNo ratings yet

- EDCINTL - hse.FM.080.R4-Critical Lift Permit Crane ADocument2 pagesEDCINTL - hse.FM.080.R4-Critical Lift Permit Crane ABogdan-Gabriel SchiopuNo ratings yet

- Maeda-Onaka, Joint Venture: Generic Lifting PlanDocument4 pagesMaeda-Onaka, Joint Venture: Generic Lifting PlanJaycee Pagador100% (1)

- 3-Pre-Lift Checklist Rev A 06302015Document2 pages3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- 2014 Hoisting Rigging Plan 10-6-14 Final Posted To WebsiteDocument23 pages2014 Hoisting Rigging Plan 10-6-14 Final Posted To WebsiteSudiatmoko Supangkat100% (1)

- New Mobile Crawler Crane ChecklistDocument2 pagesNew Mobile Crawler Crane ChecklistsunilNo ratings yet

- FC 4.1.5 - Flexible Steel Wire Rope Sling (FSWR) Inspection Checklist FormDocument2 pagesFC 4.1.5 - Flexible Steel Wire Rope Sling (FSWR) Inspection Checklist FormJosef Demner Tiu Paspe100% (1)

- Planned Critical Lift Crane PermitDocument5 pagesPlanned Critical Lift Crane PermitsurnaikNo ratings yet

- LP 1T Pipes Critical Crane Lift Plan 25T Crane CPFDocument1 pageLP 1T Pipes Critical Crane Lift Plan 25T Crane CPFMPS PSKNo ratings yet

- 3 Green Lift Checklist FormDocument2 pages3 Green Lift Checklist FormHưng Hoàng DuyNo ratings yet

- Lifting 50 RedaDocument1 pageLifting 50 Redausman khalid0% (1)

- Manlift ChecklistDocument1 pageManlift ChecklistFarid Brango0% (1)

- Crane Lift Plan InstructionsDocument4 pagesCrane Lift Plan InstructionsSamuel LumbanrajaNo ratings yet

- Unloading Gas Turbine Generator PlanDocument9 pagesUnloading Gas Turbine Generator Planamritrj444No ratings yet

- MCM Lifting Operation ChecklistDocument8 pagesMCM Lifting Operation ChecklistHein SiNo ratings yet

- Travel ItineraryDocument3 pagesTravel ItineraryDGBFly Travel&ToursNo ratings yet

- Method Statement For Lifting Operations - Builders SafetyDocument2 pagesMethod Statement For Lifting Operations - Builders SafetyMuhammad Sami Parvez100% (1)

- General lifting layout and checklistDocument2 pagesGeneral lifting layout and checklistMohd Firdaus KamaruddinNo ratings yet

- Critical Lift Plan - ChecklistDocument4 pagesCritical Lift Plan - ChecklistDelia HarsanNo ratings yet

- Lifting Plan Blank (PDF Library)Document4 pagesLifting Plan Blank (PDF Library)Alina UribeNo ratings yet

- B Lifting Plan Using LorryDocument1 pageB Lifting Plan Using LorrySyed Fawad ShahNo ratings yet

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- Lifting Plan Site InspectionDocument4 pagesLifting Plan Site Inspectionkhaled redaNo ratings yet

- Total Offer With 6048000Document14 pagesTotal Offer With 6048000Vuthpalachaitanya KrishnaNo ratings yet

- Mobile Crane Lifting PermitDocument1 pageMobile Crane Lifting PermitWaqas IslamNo ratings yet

- Work Method Statement: Wms Rev. NoDocument5 pagesWork Method Statement: Wms Rev. NoKarthik babu100% (1)

- A Lifting Plan Using ExcavatorDocument1 pageA Lifting Plan Using ExcavatorSyed Fawad ShahNo ratings yet

- BP Lifting Plan for Loading and Unloading EquipmentDocument36 pagesBP Lifting Plan for Loading and Unloading EquipmentAbdul Majid ZNo ratings yet

- Trustcamp Crane Lifting Plan11Document6 pagesTrustcamp Crane Lifting Plan11Sayed DarwishNo ratings yet

- LP-0008 - Load and Off-Load Rental MEWP 17teDocument6 pagesLP-0008 - Load and Off-Load Rental MEWP 17teRustam36No ratings yet

- 08 STD Specifications - Building - 2019 PDFDocument919 pages08 STD Specifications - Building - 2019 PDFalfieNo ratings yet

- Lube Oil AnalysisDocument8 pagesLube Oil AnalysisVuthpalachaitanya KrishnaNo ratings yet

- Construction Lifting PlanDocument5 pagesConstruction Lifting PlanJuma KavesuNo ratings yet

- Crane Jib Check ListDocument1 pageCrane Jib Check ListsawkariqbalNo ratings yet

- IR-II U&O DBN PRE-LIFT CHECKLISTDocument1 pageIR-II U&O DBN PRE-LIFT CHECKLISTmiaicarbaNo ratings yet

- A61 Appointed Persons Theory Test Questions For Candidates PDFDocument6 pagesA61 Appointed Persons Theory Test Questions For Candidates PDFChandra Kumar100% (1)

- Lifting Beams and SpreadersDocument2 pagesLifting Beams and SpreadersNadeem MalikNo ratings yet

- Safe Use of Cranes: Site Lifting PlanDocument26 pagesSafe Use of Cranes: Site Lifting PlanMuhammad BabarNo ratings yet

- Egyptian Drilling Company Non-Routine Lift ChecklistDocument2 pagesEgyptian Drilling Company Non-Routine Lift Checklistmohamed atef0% (1)

- Pdf 檔案使用 "Pdffactory Pro" 試用版本建立: Pth 1 Ee10 NDocument2 pagesPdf 檔案使用 "Pdffactory Pro" 試用版本建立: Pth 1 Ee10 NZlatko Mrki HrncicNo ratings yet

- ERA Design Manual For Low Volume Roads Part DDocument280 pagesERA Design Manual For Low Volume Roads Part DHannaNo ratings yet

- Methodology, O&M PhylosophyDocument11 pagesMethodology, O&M PhylosophyVuthpalachaitanya KrishnaNo ratings yet

- Maliha - Q88 10th Dec 19Document12 pagesMaliha - Q88 10th Dec 19himaanshumohanNo ratings yet

- Pre Crane Lift ChecklistDocument1 pagePre Crane Lift Checklistg665013No ratings yet

- Flowchart Hpg1034Document1 pageFlowchart Hpg1034SharulNo ratings yet

- Cranes Hoisting and RiggingDocument25 pagesCranes Hoisting and Riggingkanakarao1No ratings yet

- Suspended personnel platform checklistDocument1 pageSuspended personnel platform checklistmark lester caluzaNo ratings yet

- Document Reference LEEA-030.2a2Document1 pageDocument Reference LEEA-030.2a2engmuhmud100% (1)

- Rigging Up Checklist: Rig ModelDocument2 pagesRigging Up Checklist: Rig Model89simbuNo ratings yet

- Chain Pulley Block or Chain Hoist Safety Dos and Don'tsDocument5 pagesChain Pulley Block or Chain Hoist Safety Dos and Don'tsAkram BadranNo ratings yet

- Tandem Lifting Container SWGDocument1 pageTandem Lifting Container SWGarifNo ratings yet

- OSHA Man Basket User ManualDocument9 pagesOSHA Man Basket User Manualwalid EttihNo ratings yet

- CV of MR Chaitanya Krishna - SR Maint .MNGRDocument3 pagesCV of MR Chaitanya Krishna - SR Maint .MNGRVuthpalachaitanya KrishnaNo ratings yet

- 1725 SH 3001 H 001A-ModelDocument1 page1725 SH 3001 H 001A-ModelVuthpalachaitanya KrishnaNo ratings yet

- 8808YB Shahid IDDocument2 pages8808YB Shahid IDVuthpalachaitanya KrishnaNo ratings yet

- Ruhul AmeenDocument9 pagesRuhul AmeenVuthpalachaitanya KrishnaNo ratings yet

- RFP 05-2023 (TPPMC) - Addendum No. 2Document17 pagesRFP 05-2023 (TPPMC) - Addendum No. 2Vuthpalachaitanya KrishnaNo ratings yet

- Final Schedule of PricesDocument6 pagesFinal Schedule of PricesVuthpalachaitanya KrishnaNo ratings yet

- Bill of QuantitiesDocument3 pagesBill of QuantitiesVuthpalachaitanya KrishnaNo ratings yet

- 4.tender Board Registration CertificateDocument2 pages4.tender Board Registration CertificateVuthpalachaitanya KrishnaNo ratings yet

- Cover PageDocument2 pagesCover PageVuthpalachaitanya KrishnaNo ratings yet

- 1.letter of TenderDocument4 pages1.letter of TenderVuthpalachaitanya KrishnaNo ratings yet

- 5.CR For Operation & MaintenanceDocument1 page5.CR For Operation & MaintenanceVuthpalachaitanya KrishnaNo ratings yet

- Appendix To Form of BidDocument2 pagesAppendix To Form of BidVuthpalachaitanya KrishnaNo ratings yet

- Commercial Offer IndexDocument2 pagesCommercial Offer IndexVuthpalachaitanya KrishnaNo ratings yet

- 24-30 March Weekly ReportDocument13 pages24-30 March Weekly ReportVuthpalachaitanya KrishnaNo ratings yet

- Machinery & EquipmentDocument1 pageMachinery & EquipmentVuthpalachaitanya KrishnaNo ratings yet

- MJBES G-6401 Monthly Timesheet (AUG-2022) PDFDocument9 pagesMJBES G-6401 Monthly Timesheet (AUG-2022) PDFVuthpalachaitanya KrishnaNo ratings yet

- Pre Bid QueriesDocument1 pagePre Bid QueriesVuthpalachaitanya KrishnaNo ratings yet

- 1.letter of TenderDocument4 pages1.letter of TenderVuthpalachaitanya KrishnaNo ratings yet

- Quote To NanostoneDocument2 pagesQuote To NanostoneVuthpalachaitanya KrishnaNo ratings yet

- MJBES G-6401 Timesheet (-2022)Document1 pageMJBES G-6401 Timesheet (-2022)Vuthpalachaitanya KrishnaNo ratings yet

- Unit G 2803 Lifting Plan Sketch-Turbine Rotor: 31.4 MetersDocument1 pageUnit G 2803 Lifting Plan Sketch-Turbine Rotor: 31.4 MetersVuthpalachaitanya KrishnaNo ratings yet

- GT Spare PartsDocument6 pagesGT Spare PartsVuthpalachaitanya KrishnaNo ratings yet

- Boiler Layup Procedures.Document3 pagesBoiler Layup Procedures.Vuthpalachaitanya KrishnaNo ratings yet

- M701F Series MistsubishiDocument13 pagesM701F Series MistsubishiVuthpalachaitanya KrishnaNo ratings yet

- ValveDocument9 pagesValveVuthpalachaitanya KrishnaNo ratings yet

- Application Form For Opening Individual / Joint AccountDocument4 pagesApplication Form For Opening Individual / Joint AccountVuthpalachaitanya KrishnaNo ratings yet

- Giant 3030 15W40Document1 pageGiant 3030 15W40ibrahim maulanaNo ratings yet

- M Introduction, Service ManualDocument24 pagesM Introduction, Service Manualepilef7575No ratings yet

- If The Ledge of 3 MTR Is Maintained On Galhar Side, The Ledge Available On Dul Side Is ZeroDocument75 pagesIf The Ledge of 3 MTR Is Maintained On Galhar Side, The Ledge Available On Dul Side Is ZeroAaron WilsonNo ratings yet

- Overall PDFDocument190 pagesOverall PDFAnamNo ratings yet

- Local Company Proposes Half-Marathon: Questions 1-2 Refer To The Following ArticleDocument11 pagesLocal Company Proposes Half-Marathon: Questions 1-2 Refer To The Following ArticleThúy Mai HồNo ratings yet

- Regenerative Braking SystemDocument8 pagesRegenerative Braking Systemsanjay sureshNo ratings yet

- Energisation of Q50 Relay for Traction and BrakingDocument2 pagesEnergisation of Q50 Relay for Traction and BrakingCTLC SURNo ratings yet

- Subansiri Record in Dam Concrete ProductionDocument2 pagesSubansiri Record in Dam Concrete ProductionVignesh AyyathuraiNo ratings yet

- ADOT Specific Requirements For SSL's MSE Plus Concrete Panel Wall SystemDocument24 pagesADOT Specific Requirements For SSL's MSE Plus Concrete Panel Wall SystemDiegoDiazBarrantesNo ratings yet

- International North-South Transport Corridor (INSTC)Document6 pagesInternational North-South Transport Corridor (INSTC)singamsetty kavyaNo ratings yet

- Luzon Stevedoring Vs CTADocument4 pagesLuzon Stevedoring Vs CTAAnn MarinNo ratings yet

- Cuplock Scaffolding SystemDocument6 pagesCuplock Scaffolding SystemJyles Sirab100% (1)

- Ho 113Document210 pagesHo 113Lavern SipinNo ratings yet

- Major Events in Nissan's HistoryDocument3 pagesMajor Events in Nissan's HistoryMehdi RostamiNo ratings yet

- XC60 Owners Manual MY11 en-GB Tp18267Document430 pagesXC60 Owners Manual MY11 en-GB Tp18267nagyzoltan077No ratings yet

- U321 Exopro Auto Trans Mva TDSDocument2 pagesU321 Exopro Auto Trans Mva TDSWings TechNo ratings yet

- CS 450 Inspection of Highway Structures: Design Manual For Roads and BridgesDocument139 pagesCS 450 Inspection of Highway Structures: Design Manual For Roads and BridgesgordonNo ratings yet

- Compound Word ListDocument15 pagesCompound Word ListAngela MorilloNo ratings yet

- Management of Overspeed Events in CruiseDocument7 pagesManagement of Overspeed Events in CruiseFelipe Alberto González RoblesNo ratings yet

- Tracked Vehicle-Problem SolvingDocument7 pagesTracked Vehicle-Problem SolvingF. Hakimi0% (1)

- CMVR-chapter2 1 PDFDocument28 pagesCMVR-chapter2 1 PDFbhavana borkerNo ratings yet

- MICC Report To PlenaryDocument92 pagesMICC Report To PlenaryAvadhut PalkarNo ratings yet

- ASF Act 1975 (Amd Dec 2012)Document10 pagesASF Act 1975 (Amd Dec 2012)yusha habibNo ratings yet

- Ola Cabs-Growth Strategies of A Taxi Aggregator Startup: September 2018Document8 pagesOla Cabs-Growth Strategies of A Taxi Aggregator Startup: September 2018Shobhit SharmaNo ratings yet