Professional Documents

Culture Documents

Crawler Crane Checklist Rev 0

Uploaded by

Maizatul Akmar ManshorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crawler Crane Checklist Rev 0

Uploaded by

Maizatul Akmar ManshorCopyright:

Available Formats

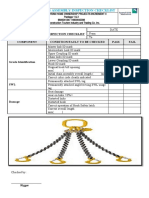

Crawler Crane Inspection Checklist

Project site: Pre inspection

Supplier: Crane: / Operator: Delivery

PMA No.: Operator name: Monthly

PMA Exp. Date: Comp. DOSH Reg. No.:

Inspection date: Comp. DOSH Reg. Exp. Date: Daily

No. Part Item Inspection method M T W T F S S Inspection photo

① Overload When overloaded, the operation will

limiter be stopped with alarm sound

Over winding

② Before hook reaches to the top,

prevention Over-winding

operation stops with alarm sound

device Overload limiter prevention device

③ Luffing limit Inclination range of angle boom should

device be properly controlled

Hook latch shouldn’t have any

④ Hook & Sheave abnormality such as detachment and

should rotate smoothly Luffing limit device Hook & Sheave

⑤ Brake & Clutch Functions of brake, clutch, controlling

gear should be normal

Reverse rotation limit device and

⑥ Backlash

brakes should working properly

device Brake & Clutch

without any problem Backlash device

Angle boom should not have crack or

⑦ Angle

deformation and connection part

boom (lattice)

should be in good condition

Its weight should comply with manual

⑧ Counter

and stably fixed without being

weight

arbitrarily manipulated Angle boom Counter weight

Track should not have deformation or

⑨ Track and iron

damage and ground should be in a

plate

good condition

There should be no wire cut on wire

⑩ Wire rope rope and end treatment should be

good Track Wire rope

Anti-break It shall be installed from drum to end

⑪ away of wire complying with manufacturer standard

rope to prevent from break away.

Socket and Wire rope end termination including

⑫ wire rope wedge socket size shall be complying Socket &

end termination with safety standard. Anti-Brake away termination

CCYR RJ Crawler Crane Inspection Checklist Page 1 of 2

No. Part Item Inspection method M T W T F S S Inspection photo

Ground Ensure its leveled and steel plate to

13 condition be placed – crane to be stationed on.

M T W T F S S

Inspector's/ operator

opinion

Verify by Site

supervisor / lifting

supervisor

Engineer/ Asst. HSE

Inspector/ PM / PM Representative

Operator (Full Name) (Full Name)

(signature) (signature) (signature)

Note:

1. Ensure that the crane is in good working condition.

2. Pre inspection before delivery at site to be conducted at supplier yard.

3. Crane to be operated by competent operator registered with DOSH.

4. Operator to hold valid CIDB and must be produced when required.

5. Crane to be inspected once it’s assemble at project site.

6. Crane to be inspected by DOSH once assembled before operational.

7. Ensure that DOSH inspector have endorsed the log book and all comments are

observed rectified before allowing crane to be operational.

8. PMA and Competency of operator to be displayed at operator cabin.

9. It is the operator’s responsibility to ensure that inspections are carried out.

10. Operator to maintain a log book to record maintenance or any repair works carried

out on machinery.

11. Ensure crane work area is secured with barriers and appropriate signages

displayed prominently visible.

12. Ensure crane is station on steel plate at all time while lifting operations are

progressing. Ground condition to be assessed before movement.

13. Site supervisor / lifting supervisor to ensure that operator has carried out

inspection by recording on checklist.

14. HSE representative to review and verify that daily inspection has taken place.

15. Where crane is over 10 years must be periodically inspected by 3rd party every

3months.

16. This checklist to be return to HSE department once completed weekly to be kept

as record.

CCYR RJ Crawler Crane Inspection Checklist Page 2 of 2

You might also like

- IO64 and IO1000 Technical Reference ManualDocument320 pagesIO64 and IO1000 Technical Reference ManualCristián Ceballos Rucán50% (4)

- JSA For Crawler Crane Installation FormDocument3 pagesJSA For Crawler Crane Installation FormDaniel Prakoso0% (1)

- Form-092-Excavator Safety ChecklistDocument2 pagesForm-092-Excavator Safety Checklistshamroz khan100% (2)

- Crane Inspection ChecklistDocument1 pageCrane Inspection Checklistrig4No ratings yet

- Monthly Forklift Inspection Checklist OHS PR 009 FM 01 0412Document1 pageMonthly Forklift Inspection Checklist OHS PR 009 FM 01 0412cmrig74100% (2)

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- Suspended personnel platform checklistDocument1 pageSuspended personnel platform checklistmark lester caluzaNo ratings yet

- A Lifting Plan Using ExcavatorDocument1 pageA Lifting Plan Using ExcavatorSyed Fawad ShahNo ratings yet

- Excavator SlidesDocument15 pagesExcavator SlidesDaeng KulleNo ratings yet

- Shackle Checklist FormDocument1 pageShackle Checklist FormРашад ИбрагимовNo ratings yet

- PMF 015 HSE 151 v1 Lifting PlanDocument8 pagesPMF 015 HSE 151 v1 Lifting Plansikandar1234No ratings yet

- Critical Lift Plan - ChecklistDocument4 pagesCritical Lift Plan - ChecklistDelia HarsanNo ratings yet

- Service Truck Driver SOPDocument3 pagesService Truck Driver SOPVenkadesh PeriathambiNo ratings yet

- Crane Monthly Inspection FormDocument5 pagesCrane Monthly Inspection FormMohammad Zaenal ArifinNo ratings yet

- Excavator Safety ChecklistDocument2 pagesExcavator Safety ChecklistTANWIR AHEMADNo ratings yet

- Federal legislation on steam boilers and pressure vesselsDocument46 pagesFederal legislation on steam boilers and pressure vesselsExsan OthmanNo ratings yet

- Checklist For Heavy Equipment - 1Document15 pagesChecklist For Heavy Equipment - 1Katita ChascaNo ratings yet

- Form-093-Dump Truck Safety ChecklistDocument2 pagesForm-093-Dump Truck Safety Checklistshamroz khan100% (2)

- 007 Mobile Crane ChecklistDocument2 pages007 Mobile Crane Checklistchandral86No ratings yet

- 007 Mobile Crane ChecklistDocument2 pages007 Mobile Crane ChecklistJoshua ThomasNo ratings yet

- Tower Cranes CommisioningDocument15 pagesTower Cranes Commisioningpammu18No ratings yet

- Lifting-Lashing Gear Inspection ChecklistDocument1 pageLifting-Lashing Gear Inspection Checklistdnmule100% (1)

- Crawler Crane Annual InspectionDocument3 pagesCrawler Crane Annual InspectionMark SolmundsonNo ratings yet

- New Mobile Crawler Crane ChecklistDocument2 pagesNew Mobile Crawler Crane ChecklistsunilNo ratings yet

- Telehandler checklistDocument1 pageTelehandler checklistjapv_pasNo ratings yet

- Petroleum Development Oman Lift Plan for Lifting Turbine RotorDocument7 pagesPetroleum Development Oman Lift Plan for Lifting Turbine RotorVuthpalachaitanya KrishnaNo ratings yet

- Unlocked - F031 - Tower Crane Inspection Report - Rev 0Document2 pagesUnlocked - F031 - Tower Crane Inspection Report - Rev 0Minami ChiengNo ratings yet

- Checklist For Equipment Inspection BOOM PLACERDocument2 pagesChecklist For Equipment Inspection BOOM PLACERIdada Ezekiel100% (1)

- Forklift Service and Maintenance ReportDocument1 pageForklift Service and Maintenance ReportBarathNo ratings yet

- B Lifting Plan Using LorryDocument1 pageB Lifting Plan Using LorrySyed Fawad ShahNo ratings yet

- Vehicle Crane Inspection ChecklistDocument2 pagesVehicle Crane Inspection ChecklistSn Ahsan100% (1)

- Inspection Checklist Overhead Crane PDFDocument2 pagesInspection Checklist Overhead Crane PDFMOST PASONNo ratings yet

- Tower Crane Daily Inspection Form PDFDocument1 pageTower Crane Daily Inspection Form PDFMd Imteyaz AnsariNo ratings yet

- MCM Lifting Operation ChecklistDocument8 pagesMCM Lifting Operation ChecklistHein SiNo ratings yet

- Presentation On RIG and CRANESDocument58 pagesPresentation On RIG and CRANESSathya NarayanaNo ratings yet

- HSE Inspection and ReportsDocument4 pagesHSE Inspection and ReportsOmerfAtaNo ratings yet

- 02 Crawler Checklist Monthly ChecklistDocument1 page02 Crawler Checklist Monthly Checklistjohn rajNo ratings yet

- Vehicle inspection checklistDocument1 pageVehicle inspection checklistChaudhary Wasim MurtazaNo ratings yet

- Operator'S Pre-Operation Checklist Electric Pallet Jack: Have A Qualified Mechanic Correct All ProblemsDocument1 pageOperator'S Pre-Operation Checklist Electric Pallet Jack: Have A Qualified Mechanic Correct All ProblemsPradeep ShindeNo ratings yet

- Boom Placer Inspection ChecklistDocument1 pageBoom Placer Inspection ChecklistMyo LwinNo ratings yet

- Egyptian Drilling Company Non-Routine Lift ChecklistDocument2 pagesEgyptian Drilling Company Non-Routine Lift Checklistmohamed atef0% (1)

- 3 Green Lift Checklist FormDocument2 pages3 Green Lift Checklist FormHưng Hoàng DuyNo ratings yet

- Rigging Up Checklist: Rig ModelDocument2 pagesRigging Up Checklist: Rig Model89simbuNo ratings yet

- 3 Mobile Crane ChecklistDocument5 pages3 Mobile Crane ChecklistEriq100% (1)

- Chain Pulley Block or Chain Hoist Safety Dos and Don'tsDocument5 pagesChain Pulley Block or Chain Hoist Safety Dos and Don'tsAkram BadranNo ratings yet

- Mobile CraneDocument2 pagesMobile CraneRashidi Rahman33% (3)

- Safety in Mobile CranesDocument60 pagesSafety in Mobile CranesSwapnil pupulwad100% (1)

- Truck Crane Inspection FormDocument3 pagesTruck Crane Inspection FormAdhy Darmawan100% (1)

- Daily crane checklistDocument1 pageDaily crane checklistPablo Hidalgo ValenzuelaNo ratings yet

- Pre Crane Lift ChecklistDocument1 pagePre Crane Lift Checklistg665013No ratings yet

- Crane Daily Inspection Checklist-Sa 9466Document1 pageCrane Daily Inspection Checklist-Sa 9466Ricardo DalisayNo ratings yet

- FC 4.1.4 - Chain Sling Assembly Inspection Checklist FormDocument2 pagesFC 4.1.4 - Chain Sling Assembly Inspection Checklist FormJosef Demner Tiu Paspe100% (1)

- 14.lifting Operations & Lifting EquipmentDocument28 pages14.lifting Operations & Lifting EquipmentbabadapbadapNo ratings yet

- Crane Inspection FormDocument2 pagesCrane Inspection FormWisnu Suryo Andriyanto AndriyantoNo ratings yet

- Tower Crane Test ReportDocument10 pagesTower Crane Test Reportguthale100% (2)

- Cps Crane MaintenanceDocument13 pagesCps Crane MaintenanceTarek HareedyNo ratings yet

- Bar Cutting MachineDocument1 pageBar Cutting Machinesaurav roy100% (1)

- Self Erecting Crane InspectionDocument1 pageSelf Erecting Crane InspectionCarlos SyafiqNo ratings yet

- Lifting Plans.Document11 pagesLifting Plans.sadafnoor997No ratings yet

- Tower Crane Safety ChecklistDocument2 pagesTower Crane Safety ChecklistJishad Nalakath100% (3)

- Form 092 Excavator Safety ChecklistDocument2 pagesForm 092 Excavator Safety Checklistshamroz khan67% (3)

- Material Handling Equipment Test Method Rev. 2 (Dood)Document8 pagesMaterial Handling Equipment Test Method Rev. 2 (Dood)ThomasNo ratings yet

- Boom Lift Crane Inspection Checklist CCYRDocument3 pagesBoom Lift Crane Inspection Checklist CCYRMaizatul Akmar ManshorNo ratings yet

- DB Box Inspection Checklist CCYRDocument3 pagesDB Box Inspection Checklist CCYRMaizatul Akmar Manshor100% (1)

- Checklist for Air CompressorDocument1 pageChecklist for Air CompressorMaizatul Akmar ManshorNo ratings yet

- 21.0 Daily Checklist For Electrically Powered Tools - Circular SawDocument1 page21.0 Daily Checklist For Electrically Powered Tools - Circular SawMaizatul Akmar ManshorNo ratings yet

- 24.0 Daily Checklist For Electrically Powered Tools - DrillDocument1 page24.0 Daily Checklist For Electrically Powered Tools - DrillMaizatul Akmar ManshorNo ratings yet

- Factories and Machinery (Safety, Health and Welfare) - 1983 PDFDocument25 pagesFactories and Machinery (Safety, Health and Welfare) - 1983 PDFMuhammad Fikri HasmoriNo ratings yet

- 23.0 Daily Checklist For Electrically Powered Tools - Demolition HammerDocument1 page23.0 Daily Checklist For Electrically Powered Tools - Demolition HammerMaizatul Akmar ManshorNo ratings yet

- 22.0 Daily Checklist For Electrically Powered Tools - CutterDocument1 page22.0 Daily Checklist For Electrically Powered Tools - CutterMaizatul Akmar ManshorNo ratings yet

- Factories Act 1970 PDFDocument48 pagesFactories Act 1970 PDFZarra FaktNo ratings yet

- Factories and Machinery (Special Scheme of Inspection) 2014Document27 pagesFactories and Machinery (Special Scheme of Inspection) 2014Clayton Kok100% (1)

- OSHMS Guideline-DOSHDocument77 pagesOSHMS Guideline-DOSHMohd ZulhaidyNo ratings yet

- Forklift OSHA 3949Document1 pageForklift OSHA 3949Luffy11No ratings yet

- Chapter 1 OSH Legislations in MalaysiaDocument81 pagesChapter 1 OSH Legislations in MalaysiaMaizatul Akmar ManshorNo ratings yet

- Guidance Document For Fuel Burning Equipments and Air Pollution Control SystemsDocument95 pagesGuidance Document For Fuel Burning Equipments and Air Pollution Control Systemshafidhrahadiyan2No ratings yet

- Performance Monitoring of Air Poolution Control SystemsDocument30 pagesPerformance Monitoring of Air Poolution Control SystemsFauzan HardiNo ratings yet

- Dimensions: VAZ-2T1-FK-V1Document1 pageDimensions: VAZ-2T1-FK-V1richard_qrNo ratings yet

- Introduction Drilling Machine SafetyDocument12 pagesIntroduction Drilling Machine SafetyaliNo ratings yet

- Cummins ISL G Engine Electronic Components OverviewDocument3 pagesCummins ISL G Engine Electronic Components OverviewVictor Newman0% (1)

- Fibre Optic Cable For Repeatered Submarine Systems: Oalc4Document2 pagesFibre Optic Cable For Repeatered Submarine Systems: Oalc4Lm BealhyNo ratings yet

- DRYPRO SIGMA Service Manual With Parts List - A4A9IA01EN03 - 140514 - FixDocument214 pagesDRYPRO SIGMA Service Manual With Parts List - A4A9IA01EN03 - 140514 - FixRichard JonesNo ratings yet

- Xps 13 Plus 9320 Spec SheetDocument2 pagesXps 13 Plus 9320 Spec SheetRaluca RunceanuNo ratings yet

- Studio: PT Indovickers FurnitamaDocument6 pagesStudio: PT Indovickers FurnitamaPutri NamarinaNo ratings yet

- Smart Watch Phone User GuideDocument2 pagesSmart Watch Phone User GuideIRT ShopNo ratings yet

- Chevrolet N300P Parts CatalogueDocument2 pagesChevrolet N300P Parts Cataloguecifer.xiongNo ratings yet

- YST-SW160/90: Active Servo Processing Subwoofer System Caisson de Grave Avec Asservissement ActifDocument12 pagesYST-SW160/90: Active Servo Processing Subwoofer System Caisson de Grave Avec Asservissement ActifIvan DJNo ratings yet

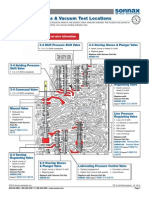

- 722 6 VacTestLocationsDocument4 pages722 6 VacTestLocationsUrszula WalczewskaNo ratings yet

- IDSC21-E Jumper SettingsDocument2 pagesIDSC21-E Jumper Settingsa4000tNo ratings yet

- White 1810 Sewing Machine Instruction ManualDocument47 pagesWhite 1810 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Ge Vat2000 Manual PDFDocument193 pagesGe Vat2000 Manual PDFraulraul82100% (1)

- 3 4 W Control CablesDocument3 pages3 4 W Control CablesJaya SankaNo ratings yet

- Science: Quarter 2 - Module 5: Simple Electric Motor and GeneratorDocument26 pagesScience: Quarter 2 - Module 5: Simple Electric Motor and GeneratorRHANDY EVANGELISTANo ratings yet

- ComPact NSX - LV431630Document3 pagesComPact NSX - LV431630R TNo ratings yet

- NKT 12-42kv GB BsDocument54 pagesNKT 12-42kv GB BsvhgiaoNo ratings yet

- Parking Radar: Parking Aid, or As Eye S' For Robo T Projec TsDocument0 pagesParking Radar: Parking Aid, or As Eye S' For Robo T Projec TsBalvendra SinghNo ratings yet

- CarrierDocument240 pagesCarrierBlue Bluey100% (1)

- Kabel Nyy Supreme LV PVC CableDocument5 pagesKabel Nyy Supreme LV PVC CableHerman Saputra100% (2)

- HUMY/SCS 3000: Operating ManualDocument21 pagesHUMY/SCS 3000: Operating ManualPaulo Cesar BenettiNo ratings yet

- Universal Angle Grinder: GWS 26-230 - 3 601 G56 4D0Document6 pagesUniversal Angle Grinder: GWS 26-230 - 3 601 G56 4D0David MurilloNo ratings yet

- Air Conditioning: Multi Interface BoardDocument49 pagesAir Conditioning: Multi Interface BoardRaymondwongNo ratings yet

- FC-6 Operation ManualDocument4 pagesFC-6 Operation ManualbigdrsmithNo ratings yet

- RTX100 Spec Sheet1Document2 pagesRTX100 Spec Sheet1RojasNo ratings yet

- Intro To Computer AssignmentDocument5 pagesIntro To Computer AssignmentRizwan KhokharNo ratings yet

- Audi Self Study ProgramDocument76 pagesAudi Self Study ProgramJorge Gonzalez Perez100% (1)

- U18 Hall Sensor FanDocument6 pagesU18 Hall Sensor FanscribdxtestxNo ratings yet