Professional Documents

Culture Documents

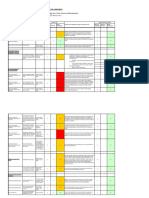

Critical Lift Plan - Checklist

Uploaded by

Delia HarsanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Critical Lift Plan - Checklist

Uploaded by

Delia HarsanCopyright:

Available Formats

CRITICAL LIFT PLAN / CHECKLIST

Complete This Checklist in Conjunction with the Crane Operator

Location/Site: Specific Area of Location/Site for Critical Lift:

Date of Critical Lift: _______________ Crane Operator: ___________________________________

Contractor’s Representative Responsible For Lift:

Company Representative Responsible for Critical Lift:

Description Of Item(s) To Be Lifted:

Weight Of Item To Be Lifted: ______________________ Actual Estimated

Weight Estimated By: _______ Weight Confirmed By:___________________________

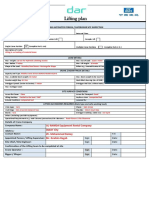

Mobile Cranes

(Do Not Lift From Tires (On Rubber) Unless Necessary)

Mobile Crane’s Rated Capacity (Load Chart) On Outriggers On Rubber Boom

Length: Gross Rated Capacity (GRC):________________________

Boom Angle: Capacity Deductions (CD):__________________________

Load Radius: Net Rated Capacity (GRC - CD):______________________

Quadrant::

Overhead Cranes Hoists

Overhead Crane’s Rated Capacity:________________ Hoist’s Rated Capacity: _______________

Rigging Method To Be Used: Designated Rigger Or Tag-Man:

Sling Configuration: Sling’s Rated Capacity:

Inspection Of Rigging and Hoisting Equipment

Lift Unit Inspector: Date:

Rigging Inspector: Date:

Comments (Include any discrepancies and corrective actions):

Pre-Lift Inspection

YES NO N/A

Area clear of unauthorized personnel?

Barricades in place?

Swing clearance adequate?

Adequate clearance from power lines?

Signalmen in place?

Blocking of outriggers adequate?

Ground stable/level?

All tires off the ground (preferred)? Hoist

line in line with center of gravity of load?

Weather conditions adequate?

Inspected By:_________________________ Time:_______ Date:_______

Effective Date: 01/01/18 Page 1 of 4 Rev # 1

Original: Corp Office Retention: 3 years

Copy: Crane Operator

CRITICAL LIFT PLAN / CHECKLIST

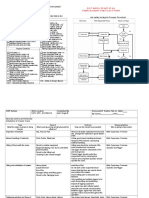

Diagram the path that the load is to follow:

Is there sufficient clearance for the load at every point along the path?

If practical, is piping, vessels, tanks, etc. which the load will cross blown down, emptied, isolated, protected, etc.?

Remarks/Comments:

Checklist Completed By:______ Date:_____________________

Checklist Approved By

(Company Representative):______ Date:_____________________

Effective Date: 01/01/18 Page 2 of 4 Rev # 1

Original: Corp Office Retention: 3 years

Copy: Crane Operator

CRITICAL LIFT PLAN / CHECKLIST

CRITICAL LIFTS

Critical Lifts are Lifts where the load weight is NOTE: Even though the actual load weight

≥75% of the rated capacity of the Crane may be small compared to the base rating of

relative to boom angle or Lifts requiring the use the crane, it can still be a Critical Lift. For

of more than one crane or derrick. Exercise the example, a 1-ton load on a 50-ton capacity

following precautions during Critical Lifts: crane may seem insignificant, but if that

crane’s rated capacity at the actual load radius

is only 2,400 lbs., the lift becomes critical.

SUPPORTING SURFACE

The ground must be compact and stable. BOOM ANGLE

The boom angle, if necessary for determining

BLOCKING the crane’s capacity, must be determined

exactly. Do not rely on the crane’s boom angle

Unless crane sits on a concrete pad, outrigger indicator.

blocking must be used and crawlers should be

on pads or cribbing.

WIND

LEVEL Wind effects must be considered and the

Critical Lift delayed if the loads are significant.

The machinery deck or boom foot pins must be If the wind speeds are in excess of 30 mph, do

absolutely level. not make the Critical Lift. If the speeds are

more than 20 mph, consider postponing it.

LOAD

REEVING

The load weight must be determined exactly.

The reeving must be balanced.

CENTER OF GRAVITY

LOAD RIGGING

The location of the load’s C of G must be

determined and the crane hook positioned Check for adequacy and security. The weight

above it. of rigging must be known exactly.

LOAD RADIUS OPERATION

The radius must be measured exactly. All control, machine and load movements must

be made as slowly and smoothly as possible.

BOOM LENGTH CAUTION: The determination of these

parameters by untrained personnel or by

The boom length must be determined exactly. using uncalibrated instruments is

extremely hazardous.

Effective Date: 01/01/18 Page 3 of 4 Rev # 1

Original: Corp Office Retention: 3 years

Copy: Crane Operator

CRITICAL LIFT CHECKLIST

BOOM ANGLE INDICATORS AND CRITICAL LIFTS

Boom angle indicators are required For these reasons, using boom angle indicator readings

on all mobile cranes but they must during Critical Lifts can be misleading. Rely on load radius

not be relied on for accuracy during (where possible); or, if the boom angle must be used (for

Critical Lifts because: example when lifting from a jib), assume the correct reading

to be lower than what the indicator actually says.

• They can give as much as a 2 reading error in boom angle, which

can substantially affect the gross capacity reading on the load chart.

• The indicators are mounted on the

base section of the boom and may

not register the deflection of the

extended sections under heavy load,

particularly if the wear pads are worn

excessively. Consequently, the boom

angle may actually be lower than the

indicator reads.

Effective Date: 01/01/18 Page 4 of 4 Rev # 1

Original: Corp Office Retention: 3 years

Copy: Crane Operator

You might also like

- Crane Lift ChecklistDocument1 pageCrane Lift ChecklistHamid Ali100% (5)

- MAN BASKET Inspection ReportDocument2 pagesMAN BASKET Inspection ReportbasdNo ratings yet

- Course Material For Rigger-Latest - Final CHVR 2010Document138 pagesCourse Material For Rigger-Latest - Final CHVR 2010Tarek Ahmed100% (1)

- Crane Lift Plan: Company Name Project: ClientDocument5 pagesCrane Lift Plan: Company Name Project: Clientscottie Mailau100% (1)

- Checklist: Mobile Crane SafetyDocument2 pagesChecklist: Mobile Crane SafetyJohn Kurong100% (5)

- Lifting PlanDocument9 pagesLifting Plansatyabrath dhalNo ratings yet

- Critical Lifting Plan 10T, 80% Capacity, One Side 10m: Al-Dur Ii Iwpp ProjectDocument1 pageCritical Lifting Plan 10T, 80% Capacity, One Side 10m: Al-Dur Ii Iwpp ProjectJianping KeNo ratings yet

- Lifting Plan Template - Portacamp Container 20'' (East Side 1)Document2 pagesLifting Plan Template - Portacamp Container 20'' (East Side 1)dadang16100% (3)

- Risk Assessment Tower CraneDocument3 pagesRisk Assessment Tower CraneChoubi Choubaca91% (11)

- Tower Crane Daily Inspection FormDocument1 pageTower Crane Daily Inspection FormZainul Hazwan83% (6)

- Lifting Plan: General Information: LP - 01 / Rev 00Document8 pagesLifting Plan: General Information: LP - 01 / Rev 00Ram BeesettiNo ratings yet

- Crane Lifting Calculation SheetDocument1 pageCrane Lifting Calculation SheetAkbar Dawood100% (1)

- Critical Lift Plan For Overhead Cranes: (Net Load)Document6 pagesCritical Lift Plan For Overhead Cranes: (Net Load)Alex Sandro Borges PereiraNo ratings yet

- JSA For Crawler Crane Installation FormDocument3 pagesJSA For Crawler Crane Installation FormDaniel Prakoso0% (1)

- Crawler Crane Checklist Rev 0Document2 pagesCrawler Crane Checklist Rev 0Maizatul Akmar Manshor100% (2)

- Lifting Plan For 62.07 RepairDocument6 pagesLifting Plan For 62.07 RepairLaith Salman100% (1)

- Lifting Plan Site InspectionDocument5 pagesLifting Plan Site Inspectionkhaled redaNo ratings yet

- PMF 015 HSE 151 v1 Lifting PlanDocument8 pagesPMF 015 HSE 151 v1 Lifting Plansikandar1234No ratings yet

- HIRA For Crawler Crane de AssemblingDocument14 pagesHIRA For Crawler Crane de AssemblingSANJAY MISHRA33% (3)

- Vibro Hammer ChecklistDocument2 pagesVibro Hammer ChecklistAbdus Samad100% (1)

- Lifting PlanDocument35 pagesLifting PlanAva GhaziNo ratings yet

- Mobile Crane Lift PlanDocument2 pagesMobile Crane Lift PlanSagar Sharma100% (1)

- Critical Lift Form - 16-3 - Final FillableDocument6 pagesCritical Lift Form - 16-3 - Final FillableKazim NawazNo ratings yet

- Lifting Plan For Equipment - MMSPDocument14 pagesLifting Plan For Equipment - MMSPClifford100% (1)

- TRA of Lifting - TailDocument3 pagesTRA of Lifting - TailTharaka Perera100% (1)

- New Mobile Crawler Crane ChecklistDocument2 pagesNew Mobile Crawler Crane ChecklistsunilNo ratings yet

- Crane Lift PermitDocument2 pagesCrane Lift Permitgullipalli srinivasa raoNo ratings yet

- Stereochemistry MSCDocument29 pagesStereochemistry MSCBapu Thorat50% (2)

- Lifting Plan for PipesDocument5 pagesLifting Plan for Pipesjafo_211No ratings yet

- Factory made uPVC windows installationDocument2 pagesFactory made uPVC windows installationAmit Singh100% (2)

- Petroleum Development Oman Lift Plan for Lifting Turbine RotorDocument7 pagesPetroleum Development Oman Lift Plan for Lifting Turbine RotorVuthpalachaitanya KrishnaNo ratings yet

- Critical Lift Plan Details for Saudi AramcoDocument2 pagesCritical Lift Plan Details for Saudi Aramcobabjihanumanthu100% (2)

- Manlift ChecklistDocument1 pageManlift ChecklistFarid Brango0% (1)

- Crane Lift Plan InstructionsDocument4 pagesCrane Lift Plan InstructionsSamuel LumbanrajaNo ratings yet

- MCM Lifting Operation ChecklistDocument8 pagesMCM Lifting Operation ChecklistHein SiNo ratings yet

- Shock Classification and PathophysiologyDocument40 pagesShock Classification and PathophysiologyErick Anca100% (2)

- HSE-BMS-011 Crane & Lifting SafetyDocument51 pagesHSE-BMS-011 Crane & Lifting SafetySatya NaiduNo ratings yet

- EHSDP0120.9 Crane Operation Pre-Lift ChecklistDocument1 pageEHSDP0120.9 Crane Operation Pre-Lift Checklistshravani mangalpalliNo ratings yet

- General lifting layout and checklistDocument2 pagesGeneral lifting layout and checklistMohd Firdaus KamaruddinNo ratings yet

- Lifting Plan Blank (PDF Library)Document4 pagesLifting Plan Blank (PDF Library)Alina UribeNo ratings yet

- Lifting Equipements Checklist-1Document59 pagesLifting Equipements Checklist-1areks3100% (1)

- Gin Wheels or Pulley WheelsDocument1 pageGin Wheels or Pulley WheelsNanang RizalNo ratings yet

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- Lift Plan TrainingDocument73 pagesLift Plan TrainingMohammad AbdullahNo ratings yet

- 3074 - Use of Genie Man LiftDocument1 page3074 - Use of Genie Man Liftcmrig74No ratings yet

- Mechatronics Test Questions Set - 1Document13 pagesMechatronics Test Questions Set - 1ChippyVijayanNo ratings yet

- Practice Quiz M1 (Ungraded) - MergedDocument22 pagesPractice Quiz M1 (Ungraded) - MergedAbdullah Abdullah100% (1)

- Lift Plan Drawing GCC - Tandem LiftDocument1 pageLift Plan Drawing GCC - Tandem LiftBrijesh 'Robin'0% (1)

- Mobile Crane Lifting PermitDocument1 pageMobile Crane Lifting PermitWaqas IslamNo ratings yet

- A Lifting Plan Using ExcavatorDocument1 pageA Lifting Plan Using ExcavatorSyed Fawad ShahNo ratings yet

- Astm D2467-2013Document8 pagesAstm D2467-2013Renato CorrêaNo ratings yet

- Crane Assembly and Dismantling and ModificationDocument1 pageCrane Assembly and Dismantling and Modificationsrinibas mohapatraNo ratings yet

- Textiles and Clothing SustaninabilityDocument134 pagesTextiles and Clothing Sustaninabilitydike100% (1)

- Construction Lifting PlanDocument5 pagesConstruction Lifting PlanJuma KavesuNo ratings yet

- Tower Crane Method StatmentDocument6 pagesTower Crane Method StatmentMosarub HossainNo ratings yet

- IR-II U&O DBN PRE-LIFT CHECKLISTDocument1 pageIR-II U&O DBN PRE-LIFT CHECKLISTmiaicarbaNo ratings yet

- A61 Appointed Persons Theory Test Questions For Candidates PDFDocument6 pagesA61 Appointed Persons Theory Test Questions For Candidates PDFChandra Kumar100% (1)

- Forklift Lifting PlanDocument4 pagesForklift Lifting Planikponmwonsa100% (1)

- Lifting Gas Metering PackageDocument10 pagesLifting Gas Metering PackageikponmwonsaNo ratings yet

- Safe Use of Cranes: Site Lifting PlanDocument26 pagesSafe Use of Cranes: Site Lifting PlanMuhammad BabarNo ratings yet

- Egyptian Drilling Company Non-Routine Lift ChecklistDocument2 pagesEgyptian Drilling Company Non-Routine Lift Checklistmohamed atef0% (1)

- Hero LetterDocument3 pagesHero LetterArunachalam Muthiah0% (1)

- Lifting Plan Worksheet: Project: Efficiency, Energy and Environment Improvement Project Phase IDocument1 pageLifting Plan Worksheet: Project: Efficiency, Energy and Environment Improvement Project Phase Iคุณพ่อน้อง บิ๊กบอสNo ratings yet

- 11 - FORAGERS by Sam BoyerDocument106 pages11 - FORAGERS by Sam BoyerMurtaza HussainNo ratings yet

- Flowchart Hpg1034Document1 pageFlowchart Hpg1034SharulNo ratings yet

- 2.1 Precautions For Tower Crane Dismantle: Chapter II DismantlingDocument6 pages2.1 Precautions For Tower Crane Dismantle: Chapter II DismantlingYoutube SaleemNo ratings yet

- RB Crane Operation ChecklistDocument1 pageRB Crane Operation ChecklistAli KaziNo ratings yet

- OHSE-CL-02 EHSDP0120.9 Crane Operation Pre-Lift ChecklistDocument1 pageOHSE-CL-02 EHSDP0120.9 Crane Operation Pre-Lift ChecklistEmmanuel kusimoNo ratings yet

- Mobile Crane Safety: Factors Affecting Rated CapacityDocument3 pagesMobile Crane Safety: Factors Affecting Rated Capacityparamarthasom1974No ratings yet

- Errata Introduction To Quantum Mechanics, David Griffiths, 2nd Ed.Document3 pagesErrata Introduction To Quantum Mechanics, David Griffiths, 2nd Ed.Marcel BezerraNo ratings yet

- With Machine Room - GAD-01Document1 pageWith Machine Room - GAD-01Nagarajan SNo ratings yet

- Conduction Calorimetric Investigation of The Effect of Retarders On The Hydration of Portland CementDocument15 pagesConduction Calorimetric Investigation of The Effect of Retarders On The Hydration of Portland CementAlfredo Landaverde GarcíaNo ratings yet

- IRRIGATION ENGINEERING MCQDocument40 pagesIRRIGATION ENGINEERING MCQpriya dharshini100% (1)

- Computational Models For Trunk Trajectory Planning and Load Distribution: A Test-Bed For Studying Various Clinical Adaptation and Motor Control Strategies of Low Back Pain PatientsDocument13 pagesComputational Models For Trunk Trajectory Planning and Load Distribution: A Test-Bed For Studying Various Clinical Adaptation and Motor Control Strategies of Low Back Pain PatientsOTorresGonzalezNo ratings yet

- Iot PresentationDocument9 pagesIot PresentationAbdul Majid ShaikhNo ratings yet

- FCV585 FCV620 Operator's Manual G 1-7-11Document57 pagesFCV585 FCV620 Operator's Manual G 1-7-11Katia QuispeNo ratings yet

- Week 7: Nurses Role in Disaster: Home Mitigation and PreparednessDocument10 pagesWeek 7: Nurses Role in Disaster: Home Mitigation and PreparednessRose Ann LacuarinNo ratings yet

- History of FlightDocument10 pagesHistory of FlightHanin AlanaziNo ratings yet

- 30-300 MHZ Transmission Line Trainer Tla05Document1 page30-300 MHZ Transmission Line Trainer Tla05Kishor HandoreNo ratings yet

- General Description: Effective Distance Depends On Antenna, Tag and EnvironmentDocument2 pagesGeneral Description: Effective Distance Depends On Antenna, Tag and EnvironmentSHASHANK BHUSHANNo ratings yet

- EU Food Label GuidanceDocument99 pagesEU Food Label GuidanceMunteanu CristianNo ratings yet

- Hydromechanical Piercing Perforation: Oil Service Innovation TechnologiesDocument8 pagesHydromechanical Piercing Perforation: Oil Service Innovation TechnologiesЕлена ПаниотNo ratings yet

- New Patient Needing Continuous Renal Replacement Therapy (CRRT)Document9 pagesNew Patient Needing Continuous Renal Replacement Therapy (CRRT)sergey_1972No ratings yet

- Form WorkDocument25 pagesForm Workhina khanNo ratings yet

- Beyond Schein DentalDocument9 pagesBeyond Schein DentaltomdietzlerNo ratings yet

- AABB Accredited DNA Testing FacilitiesDocument2 pagesAABB Accredited DNA Testing Facilitiesjosueduran75No ratings yet

- Interpuls Novinki 2014Document64 pagesInterpuls Novinki 2014BaklanovaSVNo ratings yet

- MFJ-854 RF MeterDocument5 pagesMFJ-854 RF MeterHappyJoeNo ratings yet

- Memorial Garden Policies and Guidelines St. Mark's Episcopal Church, Raleigh, North CarolinaDocument7 pagesMemorial Garden Policies and Guidelines St. Mark's Episcopal Church, Raleigh, North Carolinaestela maria dulaganNo ratings yet