Professional Documents

Culture Documents

Crane Assembly and Dismantling and Modification

Uploaded by

srinibas mohapatraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crane Assembly and Dismantling and Modification

Uploaded by

srinibas mohapatraCopyright:

Available Formats

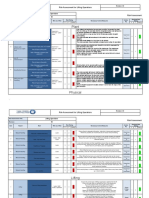

FORMAT NO EPIL/VAD/HSE/10/01

HSE MANAGEMENT SYSTEM REV 0

CONSOLIDATED ACTIVITY RISK (CAR) - REGISTERS DATE

PAGE Page 1 of 1

ACTIVITY ACTIVITY ASPECTS/ HAZARDS / THREATS WORST CASE RISK POTENTIAL CONTROLS THAT CAN MINIMIZE THE RISK TO ALARP RESPONSIBLE

REF. CODE SOURCE OF HAZARDS EVENTS/ IMPACTS P A E R LEVEL PARTY

EPIL-VAD CRANE 1. Unauthorized 1. The modification of the crane is Collapse of the M M - - ENGINEERING:

-CAR-016 ASSEMBLY / Modification not done in line with the design & boom structure/ 1. Sequence of crane Assembly/ dismantling &

DISMANTLING & 2. Poor supports authorization. crane Modification.

MODIFICATION 3. Handling / Shifting 2. The Crane boom not supported.

4. Lifting Equipments & 3. The Assembly / dismantling Personal injury / PROCEDURE :

Accessories operation is not supervised by damage to the 1. Safe Assembly/ Dismantling & Modification procedure

5. Working at height competent personnel. crane.

6. Jack up system 4. Lifting equipment & accessories SKILL / TRAINING:

7. Testing & certification are testes, certified & color coded. 1. Working at height

8. Design of footing & 5. Personnel not competent to 2. Training of the Riggers

supports perform the crane assembly/ 3. Safe Assembly/ Dismantling & modification practices

modification. in line with Manufactures recommendations.

6. Checking of joints, joints pin &

safety features not done prior

INSPECTIONS & AUDITS:

lifting of the boom.

1. Inspection & approval of the assembly / modification.

7. No testing, certification / re

2. Third party testing & certification of the crane &

certification done after the

recertification following modification.

completion of the modification

8. The wire rope winding, rewinding,

FORMATS & RECORDS:

laughing jib connection not

1. Third party certifications

checked.

9. Jack up system for the Tower

crane failed & additional supports OTHER HSE MEASURES:

not provided. 1. Ensure the crane is Assembled, dismantled &

10. The footing, support, jack up modified inline with manufacturer recommendations.

system not designed in line with 2. Ensure only authorized & competent personnel are

operation requirements allowed to Assemble/ dismantle / modify the crane.

3. Ensure the footing, supports & jack up system

designed in line with the job requirements &

manufacturer recommendations.

4. Ensure during Assembly/ Dismantle/ Modification the

boom is properly supported, (At least two supporting

points for section apart from adjacent support near to

the joint for operation.)

5. Following assembly & modification ensure the joints

are inspected and approved prior lifting of the boom.

6. Ensure Third party recertification following any

modification & repair on the crane.

COST IMPLICATION: Yes

Page 1 of 1

You might also like

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- Method StatementDocument14 pagesMethod StatementArulkumar SR CHETTINo ratings yet

- Document No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomDocument3 pagesDocument No: Date: 17-03-12: Method Statement For The Lifting of E & I RoomShaikh Mohd QaisarNo ratings yet

- Rebar Job Hazard AnalysisDocument1 pageRebar Job Hazard Analysisjoker batmanNo ratings yet

- Chain Pulley Block or Chain Hoist Safety Dos and Don'tsDocument5 pagesChain Pulley Block or Chain Hoist Safety Dos and Don'tsAkram BadranNo ratings yet

- Suspended Loads Safety Tips (39Document3 pagesSuspended Loads Safety Tips (39my_agautamNo ratings yet

- Tower Scaffolds: What You Need To DoDocument3 pagesTower Scaffolds: What You Need To DoMario Marasigan100% (1)

- Part VI (E) - Piling Work SafetyDocument26 pagesPart VI (E) - Piling Work SafetyBinz100% (2)

- IR-II U&O DBN PRE-LIFT CHECKLISTDocument1 pageIR-II U&O DBN PRE-LIFT CHECKLISTmiaicarbaNo ratings yet

- Risk Assessment Erection of Precast Concrete ElementsDocument2 pagesRisk Assessment Erection of Precast Concrete ElementsBunyamin Selimoglu100% (1)

- TBT RiggingDocument2 pagesTBT RiggingAl DubNo ratings yet

- Safe Working Procedure ExcavationsDocument4 pagesSafe Working Procedure ExcavationsMunaku TafadzwaNo ratings yet

- Hazard Risk Assessment of Jack HammerDocument14 pagesHazard Risk Assessment of Jack HammerAkhtar BahramNo ratings yet

- ScaffoldingDocument16 pagesScaffoldingHSENo ratings yet

- Construction Lifting PlanDocument5 pagesConstruction Lifting PlanJuma KavesuNo ratings yet

- All JSAsDocument88 pagesAll JSAsQamar KhanNo ratings yet

- Gin Wheels or Pulley WheelsDocument1 pageGin Wheels or Pulley WheelsNanang RizalNo ratings yet

- Risk Assessment Template For Combo Roof Waterproofing Work.Document14 pagesRisk Assessment Template For Combo Roof Waterproofing Work.Majaga MabhenaNo ratings yet

- Tandem Lifting Container SWGDocument1 pageTandem Lifting Container SWGarifNo ratings yet

- Maeda-Onaka, Joint Venture: Generic Lifting PlanDocument4 pagesMaeda-Onaka, Joint Venture: Generic Lifting PlanJaycee Pagador100% (1)

- 029 - Scaffolding Inspection ChecklistDocument5 pages029 - Scaffolding Inspection ChecklistYayan NantoNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- PTW Critical Lifting OperationDocument5 pagesPTW Critical Lifting Operationfikadu alemiNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Job Safety Analysis WorksheetDocument7 pagesJob Safety Analysis WorksheetMohamedSaidNo ratings yet

- Generic lifting plan titleDocument3 pagesGeneric lifting plan titlemuhammad umarNo ratings yet

- Lifting Operations Risk AssessmentDocument4 pagesLifting Operations Risk AssessmentIdris AdeniranNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- Cutting WorkDocument1 pageCutting WorkGudduNo ratings yet

- Scaffolding JSA for Olefins PlantDocument10 pagesScaffolding JSA for Olefins PlantTri SubaktiNo ratings yet

- HSE Q&A Hseprof ComDocument12 pagesHSE Q&A Hseprof ComUzma AhmedNo ratings yet

- 3074 - Use of Genie Man LiftDocument1 page3074 - Use of Genie Man Liftcmrig74No ratings yet

- Critical Lift Plan - ChecklistDocument4 pagesCritical Lift Plan - ChecklistDelia HarsanNo ratings yet

- Assessment of Lifting OperationDocument18 pagesAssessment of Lifting Operationafif atmajaNo ratings yet

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Document9 pagesSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- 2.1 Precautions For Tower Crane Dismantle: Chapter II DismantlingDocument6 pages2.1 Precautions For Tower Crane Dismantle: Chapter II DismantlingYoutube SaleemNo ratings yet

- Scaffolding SafetyDocument20 pagesScaffolding SafetyKate Ann Baja IINo ratings yet

- RA - 11 - For Dewatering WorksDocument19 pagesRA - 11 - For Dewatering WorksIbrahim EsmatNo ratings yet

- Rigging JSA RiggerDocument12 pagesRigging JSA RiggeraQiLGunawanNo ratings yet

- 9 Use of Hand Roller Compactor SafetyDocument2 pages9 Use of Hand Roller Compactor SafetyarchieNo ratings yet

- HLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistDocument1 pageHLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistLemuel Petronio100% (2)

- Crane Lift PlanDocument4 pagesCrane Lift Planabdalla el-saadaneyNo ratings yet

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile Capknabpsho50% (2)

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- Mobile Elevated Work Platforms (MEWP) Program: Provo, UtahDocument14 pagesMobile Elevated Work Platforms (MEWP) Program: Provo, UtahStephanie ScottNo ratings yet

- Man-machine-interface-Training Module SAMIR 11 R4Document10 pagesMan-machine-interface-Training Module SAMIR 11 R4Sheri Diĺl0% (1)

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- Risk Assessment-Pnuematic Test. DraftDocument3 pagesRisk Assessment-Pnuematic Test. DraftKono Nor AtanNo ratings yet

- 3-Pre-Lift Checklist Rev A 06302015Document2 pages3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- Hydra SafetyDocument2 pagesHydra Safetykalyan1990No ratings yet

- Safe Lifting Operations ProcedureDocument7 pagesSafe Lifting Operations ProcedureJoozza MandaNo ratings yet

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- Rescue Plan SRS 1Document4 pagesRescue Plan SRS 1Salah Abd EldayemNo ratings yet

- Permit To Work - Mobile CraneDocument2 pagesPermit To Work - Mobile CraneMIDWEST BUILDING DEMOLITIONS100% (1)

- Mobile Scaffold Training: Safe Work PracticesDocument41 pagesMobile Scaffold Training: Safe Work PracticesEHS AcefireNo ratings yet

- Confined Space Entry PlanDocument2 pagesConfined Space Entry PlanAmeerHamzaWarraichNo ratings yet

- Risk Assessment - Lifting OperationsDocument3 pagesRisk Assessment - Lifting Operationsdnmule100% (2)

- Daily Safety ChecklistDocument4 pagesDaily Safety ChecklistKalyan ReddyNo ratings yet

- Lifting Plan For Equipment - MMSPDocument14 pagesLifting Plan For Equipment - MMSPClifford100% (1)

- Mining and Environment IndiaDocument37 pagesMining and Environment IndiaRavi KumarNo ratings yet

- FORM - Construction SafetyDocument22 pagesFORM - Construction Safetysrinibas mohapatraNo ratings yet

- Safety-e-Bulletin September-2020Document10 pagesSafety-e-Bulletin September-2020srinibas mohapatraNo ratings yet

- Meg Project, Lstk-3, Iocl Refinery, Paradip Monthly HSE Activity Plan August, 2020Document4 pagesMeg Project, Lstk-3, Iocl Refinery, Paradip Monthly HSE Activity Plan August, 2020srinibas mohapatraNo ratings yet

- HSE Duty Roster for NRP Projects Private Limited at Paradip RefineryDocument1 pageHSE Duty Roster for NRP Projects Private Limited at Paradip Refinerysrinibas mohapatraNo ratings yet

- Easyhr Safety SignsDocument66 pagesEasyhr Safety Signssrinibas mohapatraNo ratings yet

- Challenges and Proposed Action Plan For DGMS: Ministry of Labour & Employment Directorate General of Mines SafetyDocument4 pagesChallenges and Proposed Action Plan For DGMS: Ministry of Labour & Employment Directorate General of Mines Safetysrinibas mohapatraNo ratings yet

- Env - Water PDFDocument34 pagesEnv - Water PDFsrinibas mohapatraNo ratings yet

- Electrical Safety Checklist MEG ProjectDocument9 pagesElectrical Safety Checklist MEG Projectsrinibas mohapatraNo ratings yet

- Small-Scale Vermicomposting - P2paysDocument30 pagesSmall-Scale Vermicomposting - P2paysPennsylvania Association for Sustainable Agriculture100% (1)

- Impact of Mining On The EnvironmentDocument45 pagesImpact of Mining On The Environmentsrinibas mohapatraNo ratings yet

- Toolbox Talk ConstructionDocument1 pageToolbox Talk ConstructionAdel Suker100% (1)

- Safety Data Sheet for Black PaintDocument14 pagesSafety Data Sheet for Black Paintsrinibas mohapatraNo ratings yet

- To Identifying Critical Environmental Considerations in Emergency Shelter Site Selection, Construction, Management and DecommissioningDocument34 pagesTo Identifying Critical Environmental Considerations in Emergency Shelter Site Selection, Construction, Management and Decommissioningsrinibas mohapatraNo ratings yet

- Msds 21190607Document13 pagesMsds 21190607srinibas mohapatraNo ratings yet

- Msds 1303j136Document14 pagesMsds 1303j136srinibas mohapatraNo ratings yet

- EBTL-HAZIRA HAZARD ID AND RISK ASSESSMENTDocument4 pagesEBTL-HAZIRA HAZARD ID AND RISK ASSESSMENTsrinibas mohapatraNo ratings yet

- Environmental Checklist: 1. Mining 1Document5 pagesEnvironmental Checklist: 1. Mining 1srinibas mohapatraNo ratings yet

- HIRA 013 Working Over Water.Document2 pagesHIRA 013 Working Over Water.srinibas mohapatra100% (1)

- EBTL-HAZIRA HAZARD ID AND RISK ASSESSMENTDocument4 pagesEBTL-HAZIRA HAZARD ID AND RISK ASSESSMENTsrinibas mohapatraNo ratings yet

- Msds 25200h69Document13 pagesMsds 25200h69srinibas mohapatraNo ratings yet

- ESSAR BULK TERMINAL LIMITED - HAZIRA HAZARD IDENTIFICATIONDocument4 pagesESSAR BULK TERMINAL LIMITED - HAZIRA HAZARD IDENTIFICATIONsrinibas mohapatraNo ratings yet

- EBTL-HAZIRA HAZARD ID AND RISK ASSESSMENTDocument4 pagesEBTL-HAZIRA HAZARD ID AND RISK ASSESSMENTsrinibas mohapatraNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- Electrical Panel Installation St.6Document1 pageElectrical Panel Installation St.6srinibas mohapatraNo ratings yet

- HIRA 009 Bunkering.Document4 pagesHIRA 009 Bunkering.srinibas mohapatraNo ratings yet

- EBTL-HAZIRA HAZARD ID AND RISK ASSESSMENTDocument4 pagesEBTL-HAZIRA HAZARD ID AND RISK ASSESSMENTsrinibas mohapatraNo ratings yet

- EBTL-HAZIRA HAZARD ID AND RISK ASSESSMENTDocument4 pagesEBTL-HAZIRA HAZARD ID AND RISK ASSESSMENTsrinibas mohapatraNo ratings yet

- HIRA 003 Welding and Cutting.Document4 pagesHIRA 003 Welding and Cutting.srinibas mohapatraNo ratings yet

- Safety ObservationDocument76 pagesSafety Observationsrinibas mohapatra0% (1)

- Water Desalination Using Electrodialysis (EDDocument18 pagesWater Desalination Using Electrodialysis (EDibrahimawad06No ratings yet

- Ignition HMI To SLC Through ANC-100e or ANC-120eDocument6 pagesIgnition HMI To SLC Through ANC-100e or ANC-120eJonathanNo ratings yet

- Bungalow House Plans Photos PhilippinesDocument16 pagesBungalow House Plans Photos PhilippinesDaryl Badajos100% (1)

- Determining drag coefficient using Stokes' lawDocument3 pagesDetermining drag coefficient using Stokes' lawMadhuvan Yadav0% (1)

- Airflow HVLT LVLT Lm1 User ManualDocument8 pagesAirflow HVLT LVLT Lm1 User Manualnewlimpoh0% (1)

- B BackGroundDocument11 pagesB BackGroundIndra RamdhanNo ratings yet

- Polymer IntroDocument15 pagesPolymer IntroYUG PRATAP SINGHNo ratings yet

- D 2172 - 01 RdixnziDocument13 pagesD 2172 - 01 RdixnziJhony CotaNo ratings yet

- Chemical Engineering Facts at Your Fingertips Guidebook - 2016 PDFDocument14 pagesChemical Engineering Facts at Your Fingertips Guidebook - 2016 PDFKimberly Conley50% (2)

- General ISO Geometrical TolerancesDocument2 pagesGeneral ISO Geometrical TolerancesMaheshNo ratings yet

- Principles of Digital Signal Processing - Lecture Notes, Study Material and Important Questions, AnswersDocument11 pagesPrinciples of Digital Signal Processing - Lecture Notes, Study Material and Important Questions, AnswersM.V. TV0% (1)

- Dr. Leach's Filter Potpourri: Transfer FunctionsDocument33 pagesDr. Leach's Filter Potpourri: Transfer FunctionsAhmad FauziNo ratings yet

- Introduction To Chemical Kinetics: CHEM 102 T. HughbanksDocument16 pagesIntroduction To Chemical Kinetics: CHEM 102 T. HughbanksKarthikNo ratings yet

- Methodology For Increase The Rating of Overhead LinesDocument6 pagesMethodology For Increase The Rating of Overhead LinesHariprasad gantyalaNo ratings yet

- An Interview With An Ofw Civil EngineerDocument3 pagesAn Interview With An Ofw Civil EngineerYath DreNo ratings yet

- Listening Scripts Kls 4Document5 pagesListening Scripts Kls 4dedepamulangNo ratings yet

- Nireesh Nagaraj: Astute It Business Executive - Vice PresidentDocument3 pagesNireesh Nagaraj: Astute It Business Executive - Vice PresidentUtpal GhoshNo ratings yet

- Production of Acrylonitrile (ANKB40303Document75 pagesProduction of Acrylonitrile (ANKB40303NUR AKMAL HISHAMNo ratings yet

- Microprocessor AND Microcontroller Practical Lab File: Name-Enrollment No. - Course/Branch - Btech/MaeDocument11 pagesMicroprocessor AND Microcontroller Practical Lab File: Name-Enrollment No. - Course/Branch - Btech/MaeShuktika SrivastavaNo ratings yet

- 132-LogSat JRC JLN-720 Instruct Manual 1-10-2019Document134 pages132-LogSat JRC JLN-720 Instruct Manual 1-10-2019Sunil S I ShippingNo ratings yet

- 1.1 Translational KinematicsDocument92 pages1.1 Translational Kinematicseurybondoc90No ratings yet

- Data Warehousing - FundamentalsDocument3 pagesData Warehousing - FundamentalsJinendraabhiNo ratings yet

- Bombe 4Document154 pagesBombe 4Adith K PNo ratings yet

- DS Ass IDocument2 pagesDS Ass Inalluri_08No ratings yet

- Ficha Tecnica Ciac Hi Wall 60 HZ R-22Document1 pageFicha Tecnica Ciac Hi Wall 60 HZ R-22Eduardo GarcíaNo ratings yet

- Introduction Letter - 3.4.21Document2 pagesIntroduction Letter - 3.4.21Gunjan PatelNo ratings yet

- SBI4U - Unit 2 - Version ADocument56 pagesSBI4U - Unit 2 - Version AAllan Anthiah100% (3)

- Alluminio TeoriaDocument91 pagesAlluminio TeoriaxypangioNo ratings yet

- Blue Brain Tech Creates Virtual Human MindDocument19 pagesBlue Brain Tech Creates Virtual Human MindDanielle HoltNo ratings yet

- Basics of Seismic InterpretationDocument21 pagesBasics of Seismic InterpretationMahmoud Said100% (5)