MCM POWER CO.

,Ltd

LIFTING OPERATION CHECKLIST

This Lifting Operation Checklist must be completed and submitted with the PTW application for every Lifting Operation. Subsequently the PTW

Applicant of the work operation shall conduct daily pre-work inspection and record his findings on this checklist. Failure to complete this or any part of

this checklist shall result in the disapproval for the PTW application and/or automatically result in the revocation of the PTW.

Project : ___________________________________________________________ Company : _________________________________________

Location : ______________________________________________________________________ Month & Week : _________________________

Date

Items To Check Mon Tue Wed Thur Fri Sat Sun Remarks / Instructions

1.0 Documentation Check

1.1 Lifting Plan conducted and trained to all personnel involved in

the lifting operation (See 3.0 - Lifting Plan)

1.2 For Tracked / Wheeled mounted type of Cranes: Crane Access

provided with design & calculations by Competent Person and

constructed in accordance to his design.

1.3 The constructed crane access inspected by the Competent

Person and issued with acknowledgement for safe use.

1.4 Daily checks conducted for the Crane Access by the appointed

Person In-Charge and the checks recorded in the Movement of

Cranes & Rigs Checklist.

1.5 For Tower Cranes: PE endorsed Tower Crane Layout Plan

provided & the zoning of the boundary limits clearly indicated

on the plan.

1.6 Lifting Machine (LM) (e.g. crawler crane, mobile crane, tower

crane, etc.) tested by an Authorised Examiner (AE) & issued

with valid LM certificate.

1.7 Daily checks conducted on the lifting machine by the operator

and the checks recorded in the daily checklist & submitted to

Site WSH Personnel.

1.8 Regular monthly maintenance conducted fo rthe Lifting Machine

& maintenance records submitted to Site WSH Personnel.

1.9 Lifting Gear / Appliance (LG/LA) intended for use been tested

by an AE & issued with valid LG / LA certificates.

1.10 LG/LA checked daily by the Lifting Supervisor, correctly colour-

coded & the checks recorded in the daily LG / LA checklist.

1.11 For Lifting Man-Cage: Provided with PE design & calculations

and issued with a valid 6-month test certificate by an AE.

1.12 Structural design & the lifting points of loads (e.g. self-

fabricated lifting receptacles, system formwork, rebar cages,

lifting frames for diesel tanks, generator sets, etc.) provided

with PE design & calculations and endorsed safe to be use for

lifting.

1.13 Lifting Personnel (i.e. Lifting Supervisor, crane operator, rigger

& signalman) trained, qualified & appointed to carry out lifting

operation.

1.14 Approval / permit given by/or informed to the relevant

authorities when lifting operation is intended to be carried out

over areas, such as public roads, railway lines, private property,

etc.

1.15 Risk Assessment provided & trained to all personnel involved in

the lifting operation.

1.16 Safe Work Procedure provided and trained to all personnel

involved in the lifting operation.

Page 1 of _____

� MCM POWER CO.,Ltd

1.17 PTW for lifting operation approved by the PM or his designate

and still within its valid duration.

Page 2 of _____

� MCM POWER CO.,Ltd

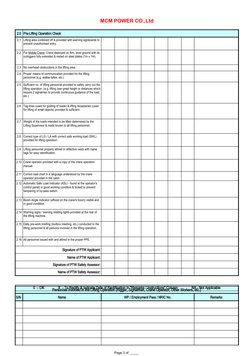

2.0 Pre-Lifting Operation Check

2.1 Lifting area cordoned off & provided with warning signboards to

prevent unauthorised entry.

2.2 For Mobile Crane: Crane deployed on firm, level ground with its

outriggers fully extended & rested on steel plates (1m x 1m).

2.3 No overhead obstructions in the lifting area.

2.4 Proper means of communication provided for the lifting

personnel (e.g. walkie-talkie, etc.)

2.5 Sufficient no. of lifting personnel provided to safely carry out the

lifting operation. (e.g. lifting over great height or distances which

require 2 signalmen to provide continuous guidance of the load,

etc.)

2.6 Tag lines (used for guiding of loads) & lifting receptacles (used `

for lifting of small objects) provided & sufficient.

2.7 Weight of the loads intended to be lifted determined by the

Lifting Supervisor & made known to all lifting personnel.

2.8 Correct type of LG / LA with correct safe working load (SWL)

provided for lifting operation.

2.9 Lifting personnel properly attired in reflective vests with name

tags for easy identification.

2.10 Crane operator provided with a copy of the crane operation

manual.

2.11 Correct load chart in a language understood by the crane

operator provided in the cabin.

2.12 Automatic Safe Load Indicator (ASLI - found at the operator's

control panel) in good working condition & locked to prevent

tampering of by-pass switch.

2.13 Boom Angle Indicator (affixed on the crane's boom) visible and

in good condition.

2.14 Warning signs / warning rotating lights provided at the rear of

the lifting machine.

2.15 Daily pre-work briefing (toolbox meeting, etc.) conducted to the

lifting personnel & all persons involved in the lifting operation.

2.16 All personnel issued with and attired in the proper PPE.

Signature of PTW Applicant:

Name of PTW Applicant:

Signature of PTW Safety Assessor:

Name of PTW Safety Assessor:

ü - OK X - To Rectify & Indicate Date of Rectification In "Remarks / Instructions" Column NA - Not Applicable

Personnel Involved in the Lifting Operation (Rigger, Signalman, Crane Operator, Other Workers, etc.)

S/N Name WP / Employment Pass / NRIC No. Remarks

Page 3 of _____

�MCM POWER CO.,Ltd

Page 4 of _____

� MCM POWER CO.,Ltd

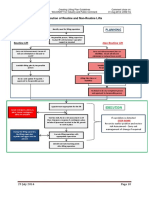

(3.0) LIFTING PLAN

Project : Lifting Plan No.

Company: Date:

Name of Risk Assessment / Reference No.

Name of Safe Work Procedure / Reference No.

S/N Type of Lifting Machine LM No. Date of Expiry Location of Lifting Machine

(A) Description of the Types of Lifting Operation to be Carried Out

State the different types of lifting operations that are planned to be carried out by the lifting machine for the duration of the applied PTW. (A lifting machine maybe

used in numerous types of daily lifting activities, such as, lifting of rebars, formwork, concrete buckets during concreting, in support of housekeeping, installation of

precast components, etc.)

(B) Weight of Loads to be Lifted

(State the different weight of the loads planned to be lifted, e.g. bundle of rebar, bucket of concrete, pallet of bricks, pack of plywood, etc.)

(C) Types & Details of Lifting Gear / Appliance to be Used (e.g. Chain Slings, Wire Ropes, Canvas Slings, etc.)

(State the types of lifting gears / appliances planned to be used for the lifting operation, e.g. chain slings, wire ropes, two-legged, four-legged, thimble-ended, fitted

with lifting hooks, etc. and its Safe Working Load - SWL)

Page 5 of _____

�MCM POWER CO.,Ltd

Page 6 of _____

� MCM POWER CO.,Ltd

(3.0) LIFTING PLAN

Examples of the Methods Used in Rigging of Loads

(D) Attach / Sketch the Methods Used for Rigging of Loads

(Attach or sketch the method for rigging the different types of loads planned to be lifted, indicating the lifting points of the load)

(E) Attach / Sketch the Layout of the Area whereby the Lifting Operation will be carried out and how the lifting machine will be

deployed

(F) Method of Communication: q Walkie-Talkie q Hand Signals q Others (Pls Specify): ________________________

Name of PTW Applicant: Signature:

Page 7 of _____

� MCM POWER CO.,Ltd

Name of PTW Safety Assessor: Signature:

Page 8 of _____