Professional Documents

Culture Documents

Complex Lift Plan and Checklist

Uploaded by

sudeesh kumar100%(1)100% found this document useful (1 vote)

360 views3 pagesOriginal Title

Complex Lift plan and checklist

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

360 views3 pagesComplex Lift Plan and Checklist

Uploaded by

sudeesh kumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Complex lift Plan

*The following details are a minimum requirement*

1/. ACTIVITY DETAILS

Item identification Expected lift date

Work Method Statement no. Permit to work no.

Load dimensions (mm) Length Width Height

Lifting activity description:

2/. CRANE INFORMATION

Type of crane Truck mounted Crawler Crane Other

Brand name Model

Location of lift

3/. RIGGING WEIGHT

Main hook block Kg Shackles Kg Other Kg

Chokers / Slings Kg Jib Kg Other Kg

Spreader Bar Kg Ball Hook Kg Other Kg

Hoist load line Kg Whip line Kg Other Kg

4/. LOAD CALCULATION

1 Length of boom m

2 Maximum required working radius m

3 Crane chart capacity at radius Kg

4 Weight of object to be lifted Kg

5 Rigging weight Kg

6 TOTAL LIFTING WEIGHT (4+5) Kg

7 Utilized load capacity ((6/3)*100) %

9 Number of parts of hoist line

10 Rated capacity per part of line Kg

11 Load per part of line. Kg

5/. ACCESSORY LIST

Item WLL SWL No. of Item WLL SWL No. of

6/. SITE CONDITIONS

Max. permissible wind speed (m/s)

Ground condition / mat requirements

(confirmed by civil engineer)

Ground protection

7/. APPLICANT

Designation Company Name Signature Date

Samsung Lifting specialist

Subcontractor focal point

Subcontractor lift supervisor

8/. ATTACHMENTS

Item Yes No

Permit to work

Complex lift checklist

Complex lifting rigging study (as specified in the Complex lifting checklist)

**Pre-Lift Checklist MUST be completed prior to actual lifting.

Complex Lifting Check List

Item Minimum Requirements Yes No N/A

1/. Complex lifting summary data sheet completed

2/. Detailed written step-by-step methodology prepared

3/. Certified equipment Drawing with vendor calculated weights

3.1/. Plan view with crane location(s) relative to the lift item.

Movements, obstructions, information shown as listed below

3.1.a/. Location and size of underground facilities

3.1.b/. Dimensions for centerline of lift equipment to C.O.G. of the lift item at

the beginning of lift and at final set.

3.1.c/. All swinging and travelling of lift equipment including clearances

3.1.d/. At final set locations, note any required rotation of load

3.4/. Elevation view with data charts and crane locations relative to the

lift item. All movements and obstructions shall be clearly shown

as listed below:

3.4.a/. Dimension for centerline of equipment to C.O.G. of the lift item at the

beginning of lift and at final set.

3.4.b/. All swinging and travelling of lift equipment and clearances

3.4.c/. Rigging assembly and all lifting attachments clearly labeled.

4/. Crane details consisting of the following:

4.1/. Lift crane data chart (s) consisting of:

4.1.a/. Crane make / model and configuration - applicable to this lift

4.1.b/. Capacity and Radius chart (s) - applicable to this lift

5/. Calculations - crane

5.1/. Lift crane

5.1.a/. Total rigging weight including all accessories, hook blocks, jib etc

5.1.b/. Maximum load and load transfer calculated

5.1.c/. % chart capacity calculated

5.1.d/. % tipping capacity calculated

5.1.e/. % structural capacity calculated

Item Minimum Requirements Yes No N/A

6/. Calculations - rigging

6.1/. Item load weight

6.2/. Detailed rigging drawing (s)

6.3/. Accessory list

7/. Crane and Rigging Gear Certificates listed below:

7.1/. Lift crane - inspection and load test (3rd party and site)

7.2/. Load line , Whip line, & Boom hoist line

7.3/. Spreader beam

7.4/. Slings

7.5/. Shackles

7.6/. Links

7.7/. Hydraulic / Manual pin extractor

7.8/. All items color coded

7.9/. Others - Specify:-

8/. Site conditions

8.1/. Environmental

8.1.a/. Maximum acceptable wind speed assessed

9/.

The following notations shall appear in the body of the procedure.

9.1/. All rigging will be attached and then visually inspected by Samsung and

Subcontractor Lifting Supervisor

9.2/. Subcontractor Lifting Supervisor is responsible for verifying that all

prescribed conditions are met prior to the lift

9.3/. Cranes shall be inspected and deemed in good operational condition

prior to the lift

9.4/. The use of tag lines will be specified

9.5/. Load weight verified against calculated engineering weight and

one of the following weights to be calculated

9.5.a/. Calibrated hook scale

9.6/. Third party engineering review undertaken as required by Samsung

9.7/. Standby crane operator available

9.8/. Lift schedule planned

9.9/. Known hazards assessed and reviewed

10/. Pre-lift meeting to discuss step-by-step methodology including roles and

responsibilities of all parties

Check List completed by: Date

You might also like

- Cargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasFrom EverandCargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasRating: 5 out of 5 stars5/5 (11)

- 1a. Lifting Data Sheet (General Lifting)Document4 pages1a. Lifting Data Sheet (General Lifting)Mohd Fadli100% (1)

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- Rigging Plan for 10-Ton Well Head LiftingDocument2 pagesRigging Plan for 10-Ton Well Head LiftingAli Ahmed PathanNo ratings yet

- G18-2-LP-003 DG - Lifting PlanDocument25 pagesG18-2-LP-003 DG - Lifting PlanMohammed JassimNo ratings yet

- Lifting Plan Site InspectionDocument4 pagesLifting Plan Site Inspectionkhaled redaNo ratings yet

- Maj Concslb 043 0Document1 pageMaj Concslb 043 0Mohammed JassimNo ratings yet

- Sling AnglesDocument1 pageSling AnglesyogihardNo ratings yet

- Hoist Classification: Cmaa Service Class C and DDocument2 pagesHoist Classification: Cmaa Service Class C and DJesús Alberto Díaz CostaNo ratings yet

- Lifting Plan and FarmDocument7 pagesLifting Plan and FarmAbid RehmanNo ratings yet

- 01 Horizontal Angle CalculationDocument3 pages01 Horizontal Angle CalculationMbalekelwa MpembeNo ratings yet

- Samuel Francis Lifting Engineer ResumeDocument5 pagesSamuel Francis Lifting Engineer Resumeanthony jamesNo ratings yet

- Employer Information: Crane Company DateDocument3 pagesEmployer Information: Crane Company DatekaniniuserNo ratings yet

- zoomlion-truck-QY100 HDocument16 pageszoomlion-truck-QY100 Hالبديري بهاءNo ratings yet

- Round SlingsDocument9 pagesRound Slingswalkerproductions20009116100% (1)

- Wilco External Stairs Lift PlanDocument25 pagesWilco External Stairs Lift PlanEdgar ChecaNo ratings yet

- GBP Calculation Kobelco 7300Document2 pagesGBP Calculation Kobelco 7300Gorga Simamora0% (1)

- PROJECT NO: 26071: Date Prepared by Location Tipe/Jenis Crane Objective Crane DataDocument10 pagesPROJECT NO: 26071: Date Prepared by Location Tipe/Jenis Crane Objective Crane DataadityaNo ratings yet

- Crane Safety WorkbookDocument34 pagesCrane Safety WorkbookozdoguNo ratings yet

- TÜV Rheinland Arabia Services CalendarDocument1 pageTÜV Rheinland Arabia Services Calendarshoaib2scribedNo ratings yet

- BP Lifting Plan for Loading and Unloading EquipmentDocument36 pagesBP Lifting Plan for Loading and Unloading EquipmentAbdul Majid ZNo ratings yet

- Power Transport Components Dimensions and Weights Are Container Capable For Cost Effective Transport Throughout The WorldDocument15 pagesPower Transport Components Dimensions and Weights Are Container Capable For Cost Effective Transport Throughout The WorldVasanthan MohanNo ratings yet

- BS 1290 Wire Rope Sling and Slings Legs For General Lifi E97 PDFDocument16 pagesBS 1290 Wire Rope Sling and Slings Legs For General Lifi E97 PDFNazmi O. Abu JoudahNo ratings yet

- Lifting Pressure Vessel with 2 Main Cranes and 1 Tail CraneDocument12 pagesLifting Pressure Vessel with 2 Main Cranes and 1 Tail Cranezeusvares100% (1)

- Alison Generator: Critical Lift PlanDocument1 pageAlison Generator: Critical Lift Plansurakanti pratap reddyNo ratings yet

- Flowchart Hpg1034Document1 pageFlowchart Hpg1034SharulNo ratings yet

- PPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaDocument80 pagesPPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaThanh Anh MaiNo ratings yet

- Lifting Device Used in ConstructionDocument18 pagesLifting Device Used in ConstructionAr Deyvanai Kannan100% (1)

- Mewps Operator Practical Only Assessment Sheets 2021 MercuryDocument4 pagesMewps Operator Practical Only Assessment Sheets 2021 MercuryWILLIAM KEAGUE100% (1)

- Crosby Rigging EquipmentDocument20 pagesCrosby Rigging EquipmentJason MillerNo ratings yet

- Appendix A1 Mobile Cranes Lift Plans Addendum Standard Lift Plan FormDocument1 pageAppendix A1 Mobile Cranes Lift Plans Addendum Standard Lift Plan FormharryNo ratings yet

- Floods 027Document10 pagesFloods 027Rakan PierwszyNo ratings yet

- NLP 296 LoadingUnloading Positioning of Pipe Stack 500TDocument8 pagesNLP 296 LoadingUnloading Positioning of Pipe Stack 500TAhmed AliNo ratings yet

- Rigging Assessment PresentationDocument42 pagesRigging Assessment Presentationpraba praba100% (1)

- Calculating Sling Angles PDFDocument1 pageCalculating Sling Angles PDFRobert Johns100% (1)

- Cranes Hoisting and RiggingDocument25 pagesCranes Hoisting and Riggingkanakarao1No ratings yet

- "Simplified Crane Data Sheet" - Api 2C 7'Th Edition - Fixed PlatformDocument1 page"Simplified Crane Data Sheet" - Api 2C 7'Th Edition - Fixed PlatformvuongNo ratings yet

- Offshore Personnel Transfer by Crane Guidelines - Rev 0Document32 pagesOffshore Personnel Transfer by Crane Guidelines - Rev 0wahyu nugrohoNo ratings yet

- Tandem lifting plan WHR boilerDocument7 pagesTandem lifting plan WHR boilertfpl hseNo ratings yet

- February 2012 Wire Rope ExchangeDocument80 pagesFebruary 2012 Wire Rope ExchangeWire Rope ExchangeNo ratings yet

- Pad-eye Design for 5 Mton Lifting LoadDocument2 pagesPad-eye Design for 5 Mton Lifting LoadPaulo MoreiraNo ratings yet

- LIFT PLAN CHECKLISTDocument4 pagesLIFT PLAN CHECKLISTMohd FadliNo ratings yet

- Lifting Operations & Lifting EquipmentDocument19 pagesLifting Operations & Lifting Equipmentegy pureNo ratings yet

- 03 Crane Lift Data Sheet 300T - U7Document2 pages03 Crane Lift Data Sheet 300T - U7pegasusharpNo ratings yet

- Multiple Crane LiftingDocument11 pagesMultiple Crane LiftingAbdul Majid ZulkarnainNo ratings yet

- Wire Rope Slings Care and Use GuideDocument4 pagesWire Rope Slings Care and Use GuideRajNo ratings yet

- Load Analysis for Flare ErectionDocument14 pagesLoad Analysis for Flare Erectionshaheer0% (1)

- Referensi Rigging PlanDocument4 pagesReferensi Rigging PlanLaurentius CalvinNo ratings yet

- Lifting Procedure PDFDocument25 pagesLifting Procedure PDFAhmad Husnul MutaqinNo ratings yet

- Code of Practice For Safe Lifting Operations at Workplaces OnlineDocument38 pagesCode of Practice For Safe Lifting Operations at Workplaces OnlineSaminathan Munisamy100% (1)

- Lifting Sling Load EquationsDocument2 pagesLifting Sling Load EquationsFabio Okamoto100% (1)

- Ammar Imad Resume PDFDocument8 pagesAmmar Imad Resume PDFAli AdnanNo ratings yet

- LP 1T Pipes Critical Crane Lift Plan 25T Crane CPFDocument1 pageLP 1T Pipes Critical Crane Lift Plan 25T Crane CPFMPS PSKNo ratings yet

- PMF 015 HSE 151 v1 Lifting PlanDocument8 pagesPMF 015 HSE 151 v1 Lifting Plansikandar1234No ratings yet

- How To Calculate SWL Lifting Points - SciencingDocument2 pagesHow To Calculate SWL Lifting Points - SciencingyogihardNo ratings yet

- Lift & Tail CalcsDocument3 pagesLift & Tail Calcsnazeer_mohdNo ratings yet

- Overhead CraneDocument4 pagesOverhead Craneahmedzizo_2No ratings yet

- Chp7 Cranes Revision 2011Document64 pagesChp7 Cranes Revision 2011Shruti IyengarNo ratings yet

- Lifting Plan: General Information: LP - 01 / Rev 00Document8 pagesLifting Plan: General Information: LP - 01 / Rev 00Ram BeesettiNo ratings yet

- RasGas onshore lift plan manualDocument2 pagesRasGas onshore lift plan manualReda Elawady100% (1)

- FTW Matrix: # Name Nationality Jinsya No Date of Birth Examin by FTW Examination FTW ExpiryDocument1 pageFTW Matrix: # Name Nationality Jinsya No Date of Birth Examin by FTW Examination FTW Expirysudeesh kumarNo ratings yet

- Standard For Colour Coding of Pipework For Identification of Fluids & ServicesDocument13 pagesStandard For Colour Coding of Pipework For Identification of Fluids & Servicessudeesh kumarNo ratings yet

- SBC Standard For Basic DesignDocument6 pagesSBC Standard For Basic Designsudeesh kumarNo ratings yet

- Technical DatasheetDocument2 pagesTechnical Datasheetsudeesh kumarNo ratings yet

- Quality Control SystemDocument9 pagesQuality Control Systemsudeesh kumar100% (1)

- Sandblasting & Painting Progress Daily Register ForDocument2 pagesSandblasting & Painting Progress Daily Register Forsudeesh kumarNo ratings yet

- Organization Chart of Project: Page 1 of 1 Date Revision Checked Approved 27/feb/20 R01 Wael SalehDocument1 pageOrganization Chart of Project: Page 1 of 1 Date Revision Checked Approved 27/feb/20 R01 Wael Salehsudeesh kumarNo ratings yet

- Post Applied For: HSE/Safety Engineer: Kamal AhmadDocument3 pagesPost Applied For: HSE/Safety Engineer: Kamal Ahmadsudeesh kumarNo ratings yet

- Verifying IOSH Managing Safely Certificate PDFDocument2 pagesVerifying IOSH Managing Safely Certificate PDFsudeesh kumar0% (1)

- Hot Work MSDocument2 pagesHot Work MSsudeesh kumarNo ratings yet

- Carbon Steel Above Ground A1Document26 pagesCarbon Steel Above Ground A1sudeesh kumarNo ratings yet

- Workplace Emergency Action Plan ChecklistDocument2 pagesWorkplace Emergency Action Plan Checklistsudeesh kumarNo ratings yet

- PR139390 - RFP Technical Questionnaire - 20191222Document5 pagesPR139390 - RFP Technical Questionnaire - 20191222sudeesh kumar100% (1)

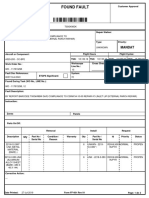

- Incident Investigation ReportDocument2 pagesIncident Investigation Reportsudeesh kumarNo ratings yet

- Clause 9.1.2 - Customer Satisfaction Questionnaire Performance (Clause9)Document1 pageClause 9.1.2 - Customer Satisfaction Questionnaire Performance (Clause9)imranghouriNo ratings yet

- Clause 10.2 - Corr Action Plan (Management Action ...Document3 pagesClause 10.2 - Corr Action Plan (Management Action ...sudeesh kumarNo ratings yet

- Clause 9.2.2 - Internal Audit Report or NC ReportDocument2 pagesClause 9.2.2 - Internal Audit Report or NC Reportsudeesh kumarNo ratings yet

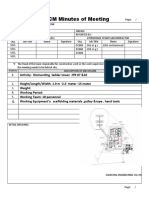

- S-PCM Minutes of Meeting: DCBM Sitemgr Eng Mohammad DCBM Hsemgr DCBMDocument3 pagesS-PCM Minutes of Meeting: DCBM Sitemgr Eng Mohammad DCBM Hsemgr DCBMsudeesh kumarNo ratings yet

- Hazard Identification and Risk Assessment Worksheet for Degassing Station ProjectDocument8 pagesHazard Identification and Risk Assessment Worksheet for Degassing Station Projectsudeesh kumarNo ratings yet

- Zubair New Degassing ScaffoldingDocument1 pageZubair New Degassing Scaffoldingsudeesh kumarNo ratings yet

- New Degassing Project Task Method StatementDocument2 pagesNew Degassing Project Task Method Statementsudeesh kumarNo ratings yet

- 1-Risk Assessment For Hot Work ParmitDocument4 pages1-Risk Assessment For Hot Work Parmitsudeesh kumarNo ratings yet

- Produce Water Tank S.PCMDocument3 pagesProduce Water Tank S.PCMsudeesh kumarNo ratings yet

- Scaffold Dismantling TaskDocument2 pagesScaffold Dismantling Tasksudeesh kumarNo ratings yet

- Produce Water Tank S.PCMDocument3 pagesProduce Water Tank S.PCMsudeesh kumarNo ratings yet

- S-PCM Minutes of Meeting: Train 02Document4 pagesS-PCM Minutes of Meeting: Train 02sudeesh kumarNo ratings yet

- Zubair New Degassing Project Task MethodDocument2 pagesZubair New Degassing Project Task Methodsudeesh kumarNo ratings yet

- S-PCM Meeting Minutes Sandblasting & PaintingDocument5 pagesS-PCM Meeting Minutes Sandblasting & Paintingsudeesh kumarNo ratings yet

- S-PCM Minutes of Meeting: Produce Water Tank 001/002Document5 pagesS-PCM Minutes of Meeting: Produce Water Tank 001/002sudeesh kumarNo ratings yet

- S-PCM Meeting Minutes Insulation InstallDocument5 pagesS-PCM Meeting Minutes Insulation Installsudeesh kumarNo ratings yet

- Ameet Sir Working 28.10.2017Document71 pagesAmeet Sir Working 28.10.2017saurabhNo ratings yet

- KLKDR1200 26Document1 pageKLKDR1200 26Carlos GuzmanNo ratings yet

- 3040LE Cable-CompleteDocument13 pages3040LE Cable-CompleteZafer IlhanNo ratings yet

- Gaurav Bera 18101103064 Machine DrawingDocument3 pagesGaurav Bera 18101103064 Machine Drawingderek brainNo ratings yet

- Afiladora Wood Mizer Shop SeriesDocument58 pagesAfiladora Wood Mizer Shop SeriesCesar Edgardo Lopez PortilloNo ratings yet

- Lab4 GearsDocument38 pagesLab4 Gearsahmed awadNo ratings yet

- Services Unlimited, Inc./ Parts Guru: S13752 686 Edition: 13.11.2015 120VDocument31 pagesServices Unlimited, Inc./ Parts Guru: S13752 686 Edition: 13.11.2015 120VCasa CristeaNo ratings yet

- Foundation RCD of Footings 7-1Document6 pagesFoundation RCD of Footings 7-1Chris Michelle JapinNo ratings yet

- DHP482 Makita PDFDocument72 pagesDHP482 Makita PDFatorresh090675No ratings yet

- Maintain Ladle Tilting MachineDocument17 pagesMaintain Ladle Tilting Machinenailulfalah17No ratings yet

- KAS 81,000,000 Pengeluaran 1. Beli Items 53,900,000 95.6% 2. Transport JKT 2,500,000 4.4% 3. Fee 4,050,000 7.2% Total Pengeluaran SisaDocument4 pagesKAS 81,000,000 Pengeluaran 1. Beli Items 53,900,000 95.6% 2. Transport JKT 2,500,000 4.4% 3. Fee 4,050,000 7.2% Total Pengeluaran SisabettafNo ratings yet

- Repuestos Rexroth-AA4VG90DA2D2-32L PDFDocument36 pagesRepuestos Rexroth-AA4VG90DA2D2-32L PDFRafael RodriguezNo ratings yet

- Statement 010901000061985Document18 pagesStatement 010901000061985Rv Raman100% (1)

- Customer Approval for Inlet Lip RepairDocument2 pagesCustomer Approval for Inlet Lip Repairjr primeNo ratings yet

- Biw Interview QusDocument3 pagesBiw Interview QusSujay AvatiNo ratings yet

- ITA Side Shift Spec SheetDocument8 pagesITA Side Shift Spec SheetSean CarvalhoNo ratings yet

- CMV Mini (50HzDocument12 pagesCMV Mini (50HzMouyed Al QasemNo ratings yet

- Dual Bicarb STD Install ManualDocument26 pagesDual Bicarb STD Install ManualIsLaM RaGaBNo ratings yet

- Plant Visits and Seminar MEGAWIDEDocument5 pagesPlant Visits and Seminar MEGAWIDEEngr SantosNo ratings yet

- IICL - CCP 07 June 2023Document31 pagesIICL - CCP 07 June 2023Galih AlamsyahNo ratings yet

- Falcon Parts CatalogueDocument475 pagesFalcon Parts Catalogueravirajendra959No ratings yet

- 10 Minutes: Operator's / Service ManualDocument24 pages10 Minutes: Operator's / Service ManualPablo SalcedoNo ratings yet

- 325 Air Compressor Parts ManualDocument16 pages325 Air Compressor Parts ManualSilvio Roman100% (1)

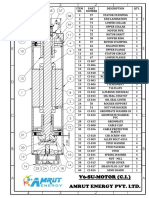

- Amrut Energy Pvt. Ltd. V6-SU-MOTOR (C.I.) V6-SU-MOTOR (C.I.)Document1 pageAmrut Energy Pvt. Ltd. V6-SU-MOTOR (C.I.) V6-SU-MOTOR (C.I.)IMTB MumbaiNo ratings yet

- Code 62: High Performance Motor FeaturesDocument5 pagesCode 62: High Performance Motor FeaturesSACHINNo ratings yet

- Vu/Vhliquidringvacuumpumps: Technical DataDocument22 pagesVu/Vhliquidringvacuumpumps: Technical DataIMAM HARYADINo ratings yet

- Liebert Intelecool Manual PDFDocument21 pagesLiebert Intelecool Manual PDFjuanmanuel2020No ratings yet

- Dupagro EWCO LEWCO Ellis - Williams EW446 W-440 W-446LP SK250 ST250 Interchangeablilty List and Original ManualDocument22 pagesDupagro EWCO LEWCO Ellis - Williams EW446 W-440 W-446LP SK250 ST250 Interchangeablilty List and Original ManualMarcelo MalagoNo ratings yet

- 5.Re-Bar Check SheetDocument7 pages5.Re-Bar Check SheetsochealaoNo ratings yet

- Construction Features and Operating Principles of Oil Centrifugal PurifierDocument4 pagesConstruction Features and Operating Principles of Oil Centrifugal PurifierŇel DanNo ratings yet