Professional Documents

Culture Documents

Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic Fluid

Uploaded by

aliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic Fluid

Uploaded by

aliCopyright:

Available Formats

Hydraulic systems No. 1 or No.

2 - Fill with hydraulic fluid

DMC: BD500-A-J12-10-29-01AAA-210C-A

Language: sx/US

Issue no: 004

Issue Date: 2017/10/26

Title: Hydraulic systems No. 1 or No. 2 - Fill with hydraulic fluid

Security classification: Class01

Responsible partner Bombardier/ 3AB48

company:

Originator: Bombardier/ 3AB48

Applicability: 50001-54999, 55001-59999

Brex data module

reference:

Quality assurance First verification: Table top

status:

Reason for updating: To update the procedure and requirement after job completion.

See applicability on the BD500-A-J12-10-29-01AAA-210C-A

first page of the DM

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 1

Intentionally left blank

See applicability on the BD500-A-J12-10-29-01AAA-210C-A

first page of the DM

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 2

Hydraulic systems No. 1 or No. 2 - Fill with hydraulic fluid

References

Table 1 References

Data Module/Technical Publication Title

BD500-A-J12-10-29-01AAA-231A-A Hydraulic systems No. 1 or No. 2 - Bleed

BD500-A-J12-10-29-01AAA-562A-A Hydraulic systems No. 1 or No. 2 - Depressurize

hydraulics

BD500-A-J12-10-29-01AAA-762A-A Hydraulic systems No. 1 or No. 2 - Pressurize

hydraulics

BD500-A-J24-00-00-01AAA-561A-A Electrical power - General - De-Energize electrical

network

BD500-A-J24-00-00-01AAA-761A-A Electrical power - General - Energize electrical network

BD500-A-J24-00-00-01AAA-913G-A Electrical/Electronic safety precautions - General

maintenance safety procedure

BD500-A-J27-00-00-01AAA-913G-A Flight control safety precautions - General maintenance

safety procedure

BD500-A-J29-00-00-01AAA-913G-A Hydraulic technical precautions - General maintenance

safety procedure

BD500-A-J51-26-00-01AAA-251A-A Solvent cleaning - Clean with chemical agent

Common information

This data module gives the procedure to fill the hydraulic system No. 1 or No. 2 (written as

"hydraulic system" in this procedure). The hydraulic systems are installed in Wing To Body

Fairing (WTBF). The procedure for the hydraulic system No. 1 is given. Differences for the

hydraulic system No. 2 are identified.

Preliminary requirements

Production maintenance data

Zones 195 Aft wing to fuselage fairing,

left side

Zones 196 Aft wing to fuselage fairing,

right side

Zones 211 Flight compartment, left side

Zones 212 Flight compartment, right

side

Access points 195CB Door

See applicability on the first page of the DM BD500-A-J12-10-29-01AAA-210C-A

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 3

Access points 196CB Door

Required conditions

Table 2 Required conditions

Action/Condition Data Module/Technical publication

Make sure that the aircraft is safe for

maintenance.

Obey all the electrical/electronic safety BD500-A-J24-00-00-01AAA-913G-A

precautions.

Obey all the flight control safety BD500-A-J27-00-00-01AAA-913G-A

precautions.

Obey all the hydraulic safety precautions. BD500-A-J29-00-00-01AAA-913G-A

Obey the solvent cleaning standard BD500-A-J51-26-00-01AAA-251A-A

practices.

Make sure that the landing gears are down

and locked.

Make sure that the thrust reversers are

stowed.

Make sure that the ground spoiler are

stowed.

Make sure that the Multi Function Spoiler

(MFS) are stowed.

Energize the electrical network. BD500-A-J24-00-00-01AAA-761A-A

Make sure that the electronic circuit

breakers that follow are OUT on the circuit

breaker synoptic page:

Name CB Number/Location

EDP 1A D-PRESS CDC1-5-11

PTU SEL VLV CDC1-9-12

EDP 2A D-PRESS CDC2-5-11

ACMP 2B EPC1-AC-2B

Depressurize the hydraulic system No. 1 or BD500-A-J12-10-29-01AAA-562A-A

No. 2.

See applicability on the first page of the DM BD500-A-J12-10-29-01AAA-210C-A

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 4

Action/Condition Data Module/Technical publication

Make sure the SLAT/FLAP lever is locked

with the cockpit lever locking tool (K0377,

Pt. No. A706775).

Put warning placards on the HYD PTU

and 2B switches to give a warning not to

pressurize the hydraulic systems No. 1 and

No. 2.

Make sure that the access panels are

removed. Refer to the access points table

above for details.

Support equipment

Table 3 Support equipment

Name Identification/Reference Quantity Remark

Hydraulic filler-hand 06-4005-3611 1

carry (2 quart)

Container, fluid - 1 US STD-0078 1

Gal. (3.8 L)

Hydraulic fill coupling 44004-04A-E17 1

Lock cockpit lever A706775 1

Consumables, materials, and expendables

Table 4 Consumables, materials, and expendables

Name Identification/Reference Quantity Remark

Hydraulic fluid, 02-001 AR

phosphate ester base

Hydraulic fluid, 02-007 AR

phosphate ester base

Cloths, cleaning, low-lint 05-001 AR

Isopropyl alcohol (IPA) 11-004 AR

See applicability on the first page of the DM BD500-A-J12-10-29-01AAA-210C-A

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 5

Spares

Table 5 Spares

Name Identification/Reference Quantity Remark

None

Safety conditions

None

Procedure

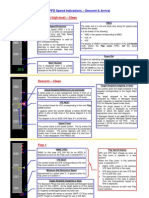

1 Fill the hydraulic system as follows:

Refer to Fig. 1, Fig. 2, and Fig. 3.

1.1 On the reservoir, push and hold the manual depress valve for approximately 20

seconds.

CAUTION

Keep the container below the work area at all times, hydraulic fluid can drain during

maintenance.

1.2 Put the container (Commercially available, Pt. No. STD-0078) under the work

area.

1.3 On the hydraulic service panel, remove the cap (1) from the fill quick disconnect

coupling (2).

1.4 Connect the hydraulic fill coupling (98441, Pt. No. 44004-04A-E17) with the fill

line of the hydraulic servicing unit (59603, Pt. No. 06-4005-3611).

1.5 Connect the other end of the hydraulic fill coupling (98441, Pt. No. 44004-04A-

E17) to the fill quick disconnect coupling (2).

See applicability on the first page of the DM BD500-A-J12-10-29-01AAA-210C-A

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 6

CAUTION

To prevent damage to the aircraft, make sure to fill the reservoir using a hand pump

connected to the fill port of the hydraulic service panel. If a power pump is used, make

sure the output pressure and flow are limited to 70 psig and 0.5 GMP respectively.

1.6 Fill the hydraulic system reservoir with the hydraulic fluid (02-001) or (02-007)

until the fluid level reaches above the lower limit on the visual indicator in

accordance with placard. Refer to Fig. 3.

Note

Both hydraulic fluids are interchangeable and can be mixed in all

proportions.

1.7 On the reservoir, push the bleed/relief valve while pumping hydraulic fluid into

the reservoir until all air is bled from the reservoir.

Note

This releases all air from the reservoir.

1.8 Pressurize the hydraulic system No. 1 and No. 2 with the aircraft pumps. Refer

to BD500-A-J12-10-29-01AAA-762A-A.

1.9 After pressurization, make sure that change in level in the visual indicator do

not exceed percentage listed in Fig. 3.

1.10 If the change in level exceeds the percentage listed in Fig. 3, bleed the

applicable system. Refer to BD500-A-J12-10-29-01AAA-231A-A.

1.11 Depressurize the hydraulic system No. 1 and No. 2. Refer to BD500-A-

J12-10-29-01AAA-562A-A.

1.12 Disconnect the hydraulic fill coupling (98441, Pt. No. 44004-04A-E17) from the

fill quick disconnect coupling (2).

1.13 Install the cap (1) on the fill quick disconnect coupling (2).

1.14 Disconnect the hydraulic fill coupling (98441, Pt. No. 44004-04A-E17) from the

fill line of the hydraulic servicing unit (59603, Pt. No. 06-4005-3611).

1.15 If necessary, use cloth (05-001) to clean the hydraulic fluid leakage from the

work area with Isopropyl Alcohol (IPA) (11-004).

See applicability on the first page of the DM BD500-A-J12-10-29-01AAA-210C-A

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 7

HYD 1 HYD 2

PTU SWITCH 2B SWITCH

STATUS AIR DOOR ELEC FLT CTRL

HYDRAULIC CONTROL PANEL

FUEL HYD AVIONIC INFO CB

HYD 1 HYD 3 HYD 2

40 °C 40 °C 40 °C

76% 76% 76%

1A 3A 3B 2B 2A

PTU

2750 PSI 2790 PSI 2790 PSI

L ELEVATOR L ELEVATOR R ELEVATOR R

RUDDER RUDDER RUDDER

GND SPOILER AILERON AILERON

FLT SPOILER FLT SPOILER FLT SPOILER

FLAP FLAP SLAT

GEAR SLAT NOSE STEER

L REVERSER REVERSER R

PTU

HYDRAULIC SYNOPTIC PAGE

ICN-BD500-A-J121029-C-3AB48-21825-A-003-01

Fig. 1 Hydraulic systems No. 1 or No. 2 - Fill with hydraulic fluid

- (Sheet 1 of 1)

See applicability on the first page of the DM BD500-A-J12-10-29-01AAA-210C-A

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 8

BLEED/ RELIEF

VALVE

MANUAL DEPRESS

VALVE

VISUAL INDICATOR

HYDRAULIC

RESERVOIR FR55 SERVICE PANEL

(REF) (REF)

FR54

ICN-BD500-A-J121029-C-3AB48-21826-A-001-01

Fig. 2 Hydraulic systems No. 1 or No. 2 - Fill with hydraulic fluid

- (Sheet 1 of 1)

See applicability on the first page of the DM BD500-A-J12-10-29-01AAA-210C-A

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 9

SYSTEM 1 RESERVOIR

FLUID LEVEL CHECK CONDITIONS

- THRUST REVERSERS STOWED

- LANDING GEAR EXTENDED

- GROUND SPOILERS STOWED

- MULTI- FUNCTION SPOILERS STOWED

- SYSTEM DEPRESSURIZED (PUMPS OFF)

- RESERVOIR DEPRESSURIZED (DEPRESS DUMP VALVE)

FLUID TEMP RANGE LEVEL LIMITS

[DEG C] [DEG F] PERCENT

- 40 to - 18 - 40 to 0 29% to 41%

- 17 to 4 1 to 40 38% to 49%

5 to 27 41 to 80 46% to 58%

27 to 49 81 to 120 55% to 67%

49 to 71 121 to 160 65% to 76%

72 to 93 161 to 200 75% to 86%

AFTER PRESSURIZATION, CHANGE IN LEVEL

SHALL NOT EXCEED 10%

CAUTION

APPROVED FLUIDS

BAMS 564- 003, TYPE IV AND V, CLASS 1.

FOR SERVICING PROCEDURE REFER TO THE

MAINTENANCE MANUAL

ICN-BD500-A-J121029-C-3AB48-21827-A-001-01

Fig. 3 Hydraulic systems No. 1 or No. 2 - Fill with hydraulic fluid

- (Sheet 1 of 2)

See applicability on the first page of the DM BD500-A-J12-10-29-01AAA-210C-A

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 10

SYSTEM 2 RESERVOIR

FLUID LEVEL CHECK CONDITIONS

- THRUST REVERSERS STOWED

- MULTI- FUNCTION SPOILERS STOWED

- SYSTEM DEPRESSURIZED (PUMPS OFF)

- RESERVOIR DEPRESSURIZED (DEPRESS DUMP VALVE)

FLUID TEMP RANGE LEVEL LIMITS

[DEG C] [DEG F] PERCENT

- 40 to - 18 - 40 to 0 29% to 40%

- 17 to 4 1 to 40 38% to 49%

5 to 27 41 to 80 46% to 57%

27 to 49 81 to 120 55% to 66%

49 to 71 121 to 160 64% to 75%

72 to 93 161 to 200 74% to 85%

AFTER PRESSURIZATION, CHANGE IN LEVEL

SHALL NOT EXCEED 12%

CAUTION

APPROVED FLUIDS

BAMS 564- 003, TYPE IV AND V, CLASS 1.

FOR SERVICING PROCEDURE REFER TO THE

MAINTENANCE MANUAL

ICN-BD500-A-J121029-C-3AB48-21828-A-001-01

Fig. 3 Hydraulic systems No. 1 or No. 2 - Fill with hydraulic fluid

- (Sheet 2 of 2)

See applicability on the first page of the DM BD500-A-J12-10-29-01AAA-210C-A

BD500-A-J12-10-29-01AAA-210C-A

2017-10-26 Page 11

Requirements after job completion

Required conditions

Table 6 Required conditions

Action/Condition Data Module/Technical publication

Remove all tools, equipment, and unwanted

materials from the work area.

Make sure that the electronic circuit

breakers that follow are IN on the circuit

breaker synoptic page:

Name CB Number/Location

EDP 1A D-PRESS CDC1-5-11

PTU SEL VLV CDC1-9-12

EDP 2A D-PRESS CDC2-5-11

ACMP 2B EPC1-AC-2B

De-energize the electrical network. BD500-A-J24-00-00-01AAA-561A-A

Make sure that the access panels are

installed. Refer to the access points table

above for details.

Remove the cockpit lever locking tool.

Remove the warning placard.

See applicability on the first page of the DM BD500-A-J12-10-29-01AAA-210C-A

BD500-A-J12-10-29-01AAA-210C-A

End of data module

2017-10-26 Page 12

You might also like

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsFrom EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNo ratings yet

- 700 29 027 BasicDocument13 pages700 29 027 BasicHimanshu Pant100% (1)

- Winsheld PDFDocument34 pagesWinsheld PDFAnonymous FAa4A3akdNo ratings yet

- Isi 23.28.00028Document3 pagesIsi 23.28.00028Anonymous SIS1ieNo ratings yet

- FAA 2012 0721 0009 - Attachment - 5Document119 pagesFAA 2012 0721 0009 - Attachment - 5CHIMONo ratings yet

- A330 Easa Tcds A.004 - Issue 50Document64 pagesA330 Easa Tcds A.004 - Issue 50Pablo CarmonaNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument58 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- ASB 412-14-160B Page 1 of 7 Export Classification C, ECCN EAR99 Approved For Public ReleaseDocument7 pagesASB 412-14-160B Page 1 of 7 Export Classification C, ECCN EAR99 Approved For Public Releasesebastian eduardoNo ratings yet

- Capability List: 10 December 2014 Wa/Capabilitylist/001Document7 pagesCapability List: 10 December 2014 Wa/Capabilitylist/001Nana FaridaNo ratings yet

- Isi-45.00.00039 01dec2017.p6Document40 pagesIsi-45.00.00039 01dec2017.p6sithuNo ratings yet

- 24 Electrical PowerDocument164 pages24 Electrical PowermarkNo ratings yet

- 29-11-000-2 Hydraulic System A - Maintenance PracticesDocument13 pages29-11-000-2 Hydraulic System A - Maintenance PracticesJoel CordovaNo ratings yet

- 14WN Test 2Document7 pages14WN Test 2Ahsan AvioniqueNo ratings yet

- Kulite Pressure Transducer HandbookDocument76 pagesKulite Pressure Transducer Handbookpmud123No ratings yet

- 343 Rack 800vuDocument1 page343 Rack 800vuMohammad NorouzzadehNo ratings yet

- B 737 DraftDocument98 pagesB 737 DraftAlrino Dwi PrasetyoNo ratings yet

- Service Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional InformationDocument11 pagesService Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional Informationa_sharafiehNo ratings yet

- 57-49-23 Wing Leading Edge Access Panels PDFDocument24 pages57-49-23 Wing Leading Edge Access Panels PDFJheremy GilNo ratings yet

- Illustrated Parts Catalog, Sa 4047-76C-4Document18 pagesIllustrated Parts Catalog, Sa 4047-76C-4Ananda Fiqry AlkahfiNo ratings yet

- Avianca RotablesDocument42 pagesAvianca RotablesEstevam Gomes de AzevedoNo ratings yet

- FTI ForceTec BrochureDocument6 pagesFTI ForceTec Brochureoğuzhan karahanNo ratings yet

- Aircraft Maintenance Manual: TASK 12 13 24 610 801 Servicing of The IDGDocument12 pagesAircraft Maintenance Manual: TASK 12 13 24 610 801 Servicing of The IDGCHIMONo ratings yet

- A318/A319/A320/A321: Service BulletinDocument22 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document6 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- Control Pitch, Roll and Yaw Axis of AircraftDocument49 pagesControl Pitch, Roll and Yaw Axis of AircraftRavi PansheriyaNo ratings yet

- Alert Service BulletinDocument94 pagesAlert Service BulletinFrank MasonNo ratings yet

- List Boeing 737Document1 pageList Boeing 737sssavNo ratings yet

- Offwing Alide InstallDocument16 pagesOffwing Alide InstallAndreea MăgureanuNo ratings yet

- Hdg. Amm Thy May 05Document67 pagesHdg. Amm Thy May 05Şevval YalınNo ratings yet

- Bro ATR42MP 2012 PDFDocument16 pagesBro ATR42MP 2012 PDFfranz_zero2No ratings yet

- 3510A Model 377 Series PN 3510A377 CMM 25-25-69 (3510A377) Rev 3Document357 pages3510A Model 377 Series PN 3510A377 CMM 25-25-69 (3510A377) Rev 3mikeNo ratings yet

- A320-Mel-Cdl-Cdd StatusDocument18 pagesA320-Mel-Cdl-Cdd StatusvproNo ratings yet

- Service Bulletin Atr72: Transmittal Sheet Revision No. 12Document16 pagesService Bulletin Atr72: Transmittal Sheet Revision No. 12Pradeep K sNo ratings yet

- Chapter 8 - Environmental Control System: REV 3, May 03/05Document40 pagesChapter 8 - Environmental Control System: REV 3, May 03/05julian marinNo ratings yet

- Aircraft Weighing and Balancing Highlights Revision 54Document42 pagesAircraft Weighing and Balancing Highlights Revision 54Kais Graidia50% (2)

- Illustrated Parts Catalog: Aquila A211 / A212Document440 pagesIllustrated Parts Catalog: Aquila A211 / A212KrasakKrusuk Si MaulNo ratings yet

- Easa TCDS A.084 - Atr - 42 - Atr - 72 03 17102012Document35 pagesEasa TCDS A.084 - Atr - 42 - Atr - 72 03 17102012mpusNo ratings yet

- CMM (Component Maintenance Manual) Index: Cat Ata No. CAI Part Number Manual / Rev Date RevDocument2 pagesCMM (Component Maintenance Manual) Index: Cat Ata No. CAI Part Number Manual / Rev Date RevHuda LestraNo ratings yet

- FAA document details Boeing 757 aircraft type certificationDocument13 pagesFAA document details Boeing 757 aircraft type certificationBRAIYAM ALEXANDER MORENO VARGAS100% (2)

- Boeing 737 Parts Inventory Ep Tij MX 2Document6 pagesBoeing 737 Parts Inventory Ep Tij MX 2Bobby Robert MaengkomNo ratings yet

- A320fam Iae Ata79 Oil PDFDocument42 pagesA320fam Iae Ata79 Oil PDFshabbirjama103No ratings yet

- AS350b3plus PDFDocument638 pagesAS350b3plus PDFbux26No ratings yet

- HandbookOnRTIAct2005 - Latest (Sep 18) PDFDocument93 pagesHandbookOnRTIAct2005 - Latest (Sep 18) PDFPsycho Soldier100% (1)

- Vietnam A321 Fleet MBD Se Ip RecommendationDocument1 pageVietnam A321 Fleet MBD Se Ip RecommendationLee Nguyen LeNo ratings yet

- A320-214 - Yom 2014 (Sale)Document6 pagesA320-214 - Yom 2014 (Sale)Francisco SoFuentesNo ratings yet

- Type Ratings FaaDocument14 pagesType Ratings FaaricardotorresNo ratings yet

- Exterior Inspection B737-800Document14 pagesExterior Inspection B737-800Me KeenNo ratings yet

- Thales Ife Amm 44-27-26-Rev. 02Document756 pagesThales Ife Amm 44-27-26-Rev. 02joartus100% (1)

- Pilatus PC-12/47EDocument84 pagesPilatus PC-12/47EHaneet Bhardwaj100% (1)

- Cf6cmm PDFDocument85 pagesCf6cmm PDFHaithem BrebishNo ratings yet

- P03-0201MM Rev 2 EAP FLEET PDFDocument436 pagesP03-0201MM Rev 2 EAP FLEET PDFSergey SereginNo ratings yet

- SVC A330Document9 pagesSVC A330Maria Amparo Corredor TorresNo ratings yet

- 3151 GN Fault Khi Nha Leak Measurement Valve Lead To Nws InopDocument2 pages3151 GN Fault Khi Nha Leak Measurement Valve Lead To Nws InopThai NguyenNo ratings yet

- A320 Family ReferenceDocument1 pageA320 Family Referencejoshua corpuzNo ratings yet

- Goodyear AMT MSC-PROPer Tire Spec 2012-001 Rev 1Document16 pagesGoodyear AMT MSC-PROPer Tire Spec 2012-001 Rev 1Muhammad Imran RosadinNo ratings yet

- EASA TCDS - DHC-8 - Iss 12Document34 pagesEASA TCDS - DHC-8 - Iss 12bittekeinspam123100% (1)

- Faa A320 TcdsDocument90 pagesFaa A320 Tcdsuanaa hyyNo ratings yet

- Boeing 717Document7 pagesBoeing 717s3m3staNo ratings yet

- Dozova NAD+ Vitamin Supplement Supports Healthy Aging, Energy - Sehetna-EgDocument4 pagesDozova NAD+ Vitamin Supplement Supports Healthy Aging, Energy - Sehetna-EgaliNo ratings yet

- Accomplishment of SB 72-1074Document7 pagesAccomplishment of SB 72-1074aliNo ratings yet

- Speed Tape Airbus - Descent & ArrivalDocument4 pagesSpeed Tape Airbus - Descent & Arrivalapi-3805097100% (29)

- ENGINE - On-Wing Flexible Borescope Inspection of Metallic/Hybrid VSV SystemDocument15 pagesENGINE - On-Wing Flexible Borescope Inspection of Metallic/Hybrid VSV SystemaliNo ratings yet

- Accomplishment Instructions of CFM56 - 7B - SB - REV - 72-0636Document8 pagesAccomplishment Instructions of CFM56 - 7B - SB - REV - 72-0636aliNo ratings yet

- Ce 19 11Document1 pageCe 19 11KaungMyatToeNo ratings yet

- 2020 AMC ProgramDocument247 pages2020 AMC ProgramaliNo ratings yet

- Scribd Download - Com A320 Computer Reset Nov11Document18 pagesScribd Download - Com A320 Computer Reset Nov11hayri yilmazNo ratings yet

- A320 NEO Vs CEO Comparison StudyDocument15 pagesA320 NEO Vs CEO Comparison StudyArpit Saraswat100% (4)

- GE90 Bore Scope Inspection TrainingDocument1 pageGE90 Bore Scope Inspection TrainingaliNo ratings yet

- Type-Certificate Data Sheet: An Agency of The European UnionDocument28 pagesType-Certificate Data Sheet: An Agency of The European UnionaliNo ratings yet

- Engine Yearbook 2017Document5 pagesEngine Yearbook 2017ali100% (1)

- Engine FailureDocument2 pagesEngine Failuresaudia686100% (18)

- PFD & ND A320 A330Document8 pagesPFD & ND A320 A330Amit Saha90% (21)

- Aircraft MaintenanceDocument24 pagesAircraft MaintenancePeter GeorgeNo ratings yet

- A320 Automation PDFDocument1 pageA320 Automation PDFaliNo ratings yet

- Aircraft MaintenanceDocument24 pagesAircraft MaintenancePeter GeorgeNo ratings yet

- Aircraft MaintenanceDocument24 pagesAircraft MaintenancePeter GeorgeNo ratings yet

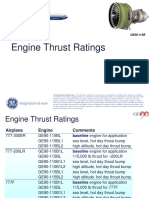

- Thrust Rating Summary 11-6-2009Document2 pagesThrust Rating Summary 11-6-2009aliNo ratings yet

- Type-Certificate Data Sheet: An Agency of The European UnionDocument24 pagesType-Certificate Data Sheet: An Agency of The European UnionaliNo ratings yet

- En - US - 201612021119839 - User Manual - Fileen - USDocument37 pagesEn - US - 201612021119839 - User Manual - Fileen - USaliNo ratings yet

- V2500 PDFDocument214 pagesV2500 PDFaliNo ratings yet

- C3N Software Focus Team UpdateDocument9 pagesC3N Software Focus Team UpdatealiNo ratings yet

- Fuel cfm56Document12 pagesFuel cfm56aliNo ratings yet

- Nacelle cfm56Document13 pagesNacelle cfm56aliNo ratings yet

- Fleet Status - cfm56Document14 pagesFleet Status - cfm56aliNo ratings yet

- Thrust Rating Summary 11-6-2009Document2 pagesThrust Rating Summary 11-6-2009aliNo ratings yet

- Combustor Cwcs - cfm56Document21 pagesCombustor Cwcs - cfm56ali100% (2)

- Achivment Cwcs - cfm56Document16 pagesAchivment Cwcs - cfm56aliNo ratings yet

- UTE Beam ContinuationDocument14 pagesUTE Beam ContinuationmichaelNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- Turbomachines Classified by Fluid Medium and Work DirectionDocument45 pagesTurbomachines Classified by Fluid Medium and Work Directionkuma alemayehuNo ratings yet

- Thomson Glide ScrewDocument12 pagesThomson Glide ScrewRuben PauwelsNo ratings yet

- DX50 Engine ServiceManualDocument285 pagesDX50 Engine ServiceManualjonathanrioscNo ratings yet

- Rectangular or round ductwork weight take-off sheetDocument1 pageRectangular or round ductwork weight take-off sheetrrductinstallersNo ratings yet

- 4 Types of LoadersDocument22 pages4 Types of LoadersIntan Kusuma100% (1)

- Falcon Parts CatalogueDocument475 pagesFalcon Parts Catalogueravirajendra959No ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test Reportnadeem shaikhNo ratings yet

- Bus Bar Selection Chart AluminiumDocument1 pageBus Bar Selection Chart AluminiumJit0% (1)

- Manufacturing Technology: Course ContentsDocument6 pagesManufacturing Technology: Course ContentsGosai RahulNo ratings yet

- Product Instruction Manual A4 Pouch Laminating System Peak Lite - PL220Document4 pagesProduct Instruction Manual A4 Pouch Laminating System Peak Lite - PL220pointing140No ratings yet

- ProjectDocument38 pagesProjectdhanabalNo ratings yet

- Kop-Grid Couplings: Table No. 4 Kop-Grid Couplings - Hubs, Grid, Cover, Seal and Fastener KitsDocument2 pagesKop-Grid Couplings: Table No. 4 Kop-Grid Couplings - Hubs, Grid, Cover, Seal and Fastener Kitsvictor perdomoNo ratings yet

- Wolverine JunctionDocument1 pageWolverine JunctionsdNo ratings yet

- NA Region EHS Standard Manual LiftingDocument16 pagesNA Region EHS Standard Manual LiftingMarthaNo ratings yet

- PLC Problems PDFDocument5 pagesPLC Problems PDFNyan Linn HtunNo ratings yet

- ES 205-Mechanics of Deformable Bodies: Module 1: Introduction (Concept of Stress)Document39 pagesES 205-Mechanics of Deformable Bodies: Module 1: Introduction (Concept of Stress)Steven Claude DigamonNo ratings yet

- 010 - Rubber HoseDocument1 page010 - Rubber Hosehentai savemeNo ratings yet

- Katalog Pesawat #Rev3Document13 pagesKatalog Pesawat #Rev3Wataru Ardhy MizunoNo ratings yet

- Catalogo Machuelos Threading Tools To Jis StandardDocument68 pagesCatalogo Machuelos Threading Tools To Jis StandardnabilahanakhairunnidaNo ratings yet

- Warré Beekeeping Lift PlansDocument21 pagesWarré Beekeeping Lift PlansengrezgarNo ratings yet

- Manual Husky 1050Document28 pagesManual Husky 1050Shania GintingNo ratings yet

- Main specifications of a slewing craneDocument1 pageMain specifications of a slewing cranepawanNo ratings yet

- Answer: No They Don't, Even If The Vernier and Micrometer Caliper Are Both Used ForDocument5 pagesAnswer: No They Don't, Even If The Vernier and Micrometer Caliper Are Both Used ForJayeon ChannelNo ratings yet

- Plant Visits and Seminar MEGAWIDEDocument5 pagesPlant Visits and Seminar MEGAWIDEEngr SantosNo ratings yet

- Heavy Hex Nut, ASTM A194/A194M and ASME SA194/SA194M, Grade 2H, ZincDocument2 pagesHeavy Hex Nut, ASTM A194/A194M and ASME SA194/SA194M, Grade 2H, ZincJ.GuerhardNo ratings yet

- XS252TVDocument2 pagesXS252TVSteven LeeNo ratings yet

- Vu/Vhliquidringvacuumpumps: Technical DataDocument22 pagesVu/Vhliquidringvacuumpumps: Technical DataIMAM HARYADINo ratings yet

- Tekton ManualDocument4 pagesTekton ManualJosueNo ratings yet