Professional Documents

Culture Documents

Employability Skills 2nd Sem Final-167

Uploaded by

SAVITA MAURYA0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

Employability_Skills_2nd_Sem_Final-167

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageEmployability Skills 2nd Sem Final-167

Uploaded by

SAVITA MAURYACopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

These are three mortal manufacturing sins Preventing Defect Recurrence etc.

Fundamentals of Improvement How to do Kaizen?

Q

U • Improvements do not come about by coincidence. It Kaizen (or) Improvement Process can be broken into 2

A is the result of conscious efforts towards them. Some steps:

L useful clues towards this are:

I 1 Problem Identification &

T • Start with small improvements

2 Problem Solving

Y • Start with our problem and not their problem

Problem is defined as the “deviation from the standard”.

T • Start with easy areas It is the difference between what is expected and what is

O actually occurring. Solution is that which can eliminate or

• Make improvements a daily part of routine

O reduce the difference between the actual and expectation

L • Use group collective wisdom for continuous

S improvement Problem Identification

• Never reject an idea before trying • Understand thoroughly what is happening

• Highlight problems, do not hide them • Question every activity and result of every action

• Do not be afraid of work stoppage • Compare them with standard

Areas of Kaizen

• Never accept status quo

Cost & Time Reduction

• Look where maximum dissatisfaction

Safety

• Look for problems where you think none exist

Waste Elimination

Productivity Improvement • Look at things from customers point of view in terms of

Quality Cost, Delivery

Energy Conservation

Fatigue Reduction Problem Solving

Customer Service • Steps to Problem solving should be:

Quality Improvement • Analysis to find root-cause of the problem

System Introduction • Idea Formulation

Visual Control System

• Idea Selection

5S (House Keeping)

• Improvement

• Sustain Gains

148 Employability Skills - (NSQF) Quality Tools : Theory 2.5.65

Copyright Free Under CC BY Licence

You might also like

- Magic Maze: Props IncludedDocument4 pagesMagic Maze: Props IncludedarneuhüdNo ratings yet

- BuiltLean Get Lean GuideDocument22 pagesBuiltLean Get Lean Guideirda100% (1)

- Plotting A Mystery NovelDocument4 pagesPlotting A Mystery NovelScott SherrellNo ratings yet

- Case Study of Hyper Loop TrainDocument3 pagesCase Study of Hyper Loop TrainkshitijNo ratings yet

- CBMEC 1 Problem SolvingDocument28 pagesCBMEC 1 Problem SolvingThrisha Joy JuanicoNo ratings yet

- 06 Standards and QualityDocument13 pages06 Standards and QualitySafikul HossainNo ratings yet

- Lec 5 Continuous Quality & Process Improvement - CQPIDocument24 pagesLec 5 Continuous Quality & Process Improvement - CQPIWaleed AhmedNo ratings yet

- Employability Skills 2nd Sem Final-162Document1 pageEmployability Skills 2nd Sem Final-162SAVITA MAURYANo ratings yet

- Continuous Process Improvement: Subject: Total Quality Management Instructor: Sumera KaziDocument10 pagesContinuous Process Improvement: Subject: Total Quality Management Instructor: Sumera Kazidua tanveerNo ratings yet

- Problem SolvingDocument55 pagesProblem SolvingHardik SNo ratings yet

- Kaizen Basic No.1 (What Is KAIZEN)Document48 pagesKaizen Basic No.1 (What Is KAIZEN)henokNo ratings yet

- Total Quality Management MMZG 522/ MBAZG522/QMZG532: Rajiv Gupta BITS Pilani Live Lecture 2Document49 pagesTotal Quality Management MMZG 522/ MBAZG522/QMZG532: Rajiv Gupta BITS Pilani Live Lecture 2Manu@777No ratings yet

- Masterclass 1 - The Key ConceptsDocument19 pagesMasterclass 1 - The Key ConceptswayfindingneedsNo ratings yet

- Employability Skills 2nd Sem Final-166 PDFDocument1 pageEmployability Skills 2nd Sem Final-166 PDFSAVITA MAURYANo ratings yet

- Importance of QualityDocument31 pagesImportance of QualityEr Rizwana Qureshi100% (1)

- Quality Management: Dr. Mahmoud M. A. Sayed Department of Mechanical Engineering Canadian International CollegeDocument52 pagesQuality Management: Dr. Mahmoud M. A. Sayed Department of Mechanical Engineering Canadian International CollegeAMRNo ratings yet

- Quality: Fundamentals of Management (MGT 162)Document17 pagesQuality: Fundamentals of Management (MGT 162)izzahkjNo ratings yet

- 8 - Quality Management - 4 PDFDocument46 pages8 - Quality Management - 4 PDFAnonymous j19GEvKNNo ratings yet

- Modern History of Quality ManagementDocument29 pagesModern History of Quality ManagementnalinijevalNo ratings yet

- 5.3 Lean ProductionDocument39 pages5.3 Lean ProductionP RushitaNo ratings yet

- HRM - Total Quality Management (1) - 2Document34 pagesHRM - Total Quality Management (1) - 2Yogesh VyavahareNo ratings yet

- Kaizen CostingDocument17 pagesKaizen Costingrbconsulting_tradingNo ratings yet

- 507 Chapt 1Document28 pages507 Chapt 1emedinillaNo ratings yet

- 1 Introduction PDFDocument42 pages1 Introduction PDFMarah Abu ShakraNo ratings yet

- 5032maa Janmay2324 Quality LectureDocument43 pages5032maa Janmay2324 Quality Lecturebingbong3110No ratings yet

- Zero Defects - Do Correct at First Time: Stephen Lim Kean Jin 0122145412Document17 pagesZero Defects - Do Correct at First Time: Stephen Lim Kean Jin 0122145412Stephen Lim Kean JinNo ratings yet

- The QC Problem Solving ApproachDocument42 pagesThe QC Problem Solving Approachrobin_hope00767% (3)

- RCA - WebinarDocument53 pagesRCA - WebinarAnkurNo ratings yet

- MeasurementDocument105 pagesMeasurementshoumikraihan71No ratings yet

- TQM - Continuous Process ImprovementDocument37 pagesTQM - Continuous Process ImprovementSangram100% (8)

- Section 1 Management and Leadership PDFDocument149 pagesSection 1 Management and Leadership PDFmhmshabanNo ratings yet

- Section 1 Management and Leadership 2022Document158 pagesSection 1 Management and Leadership 2022Sathappan KasiNo ratings yet

- Problem Solving 101Document24 pagesProblem Solving 101Alejandro LealNo ratings yet

- Mgt6 Module 3 TQMDocument73 pagesMgt6 Module 3 TQMEzra HuelgasNo ratings yet

- Long - Term PhilosophyDocument25 pagesLong - Term Philosophymanivino100% (8)

- Kaizen CostingDocument18 pagesKaizen CostingParamjit Sharma100% (12)

- TQM - Continuous Process ImprovementDocument37 pagesTQM - Continuous Process ImprovementsachinNo ratings yet

- TQM - Continuous Process ImprovementDocument37 pagesTQM - Continuous Process ImprovementRitik kumar ChourasiyaNo ratings yet

- Problem Solving ECCDocument33 pagesProblem Solving ECCPhamNo ratings yet

- Unit 2 - Week-1 Introduction To Total Quality Management: Assignment - 01Document5 pagesUnit 2 - Week-1 Introduction To Total Quality Management: Assignment - 01Yusuf AkhterNo ratings yet

- Quality Management and 6 Sigma-Sessions1-6Document66 pagesQuality Management and 6 Sigma-Sessions1-6prasunbnrgNo ratings yet

- Zero DefectDocument16 pagesZero DefectStephen Lim Kean Jin100% (1)

- Six SigmaDocument23 pagesSix SigmaabhiNo ratings yet

- Lean KaizenDocument2 pagesLean Kaizenswahyudi9No ratings yet

- Course Unit 1 Quality Management Jan 2024Document25 pagesCourse Unit 1 Quality Management Jan 2024anshu.kumari.civ20No ratings yet

- Quality Management SummaryDocument4 pagesQuality Management SummaryKashifPervez1No ratings yet

- HA CEDAC Workshop INDO Kaizen PartDocument16 pagesHA CEDAC Workshop INDO Kaizen PartHardi BanuareaNo ratings yet

- Kaizen CostingDocument17 pagesKaizen CostingNidhi ShahNo ratings yet

- Software Requirement Engineering - 04mDocument7 pagesSoftware Requirement Engineering - 04mRashid MehmoodNo ratings yet

- LGT5105 Lec 6 QualityManagementDocument50 pagesLGT5105 Lec 6 QualityManagementTrung Trần ĐứcNo ratings yet

- Systems and Techniques Used in Production Management: Topic 5Document21 pagesSystems and Techniques Used in Production Management: Topic 5Frank Eric ZombokoNo ratings yet

- 5-Session 5 Quality Management Tools & TechniquesDocument51 pages5-Session 5 Quality Management Tools & TechniquesDinusha RathnayakaNo ratings yet

- Kaizen StepsDocument95 pagesKaizen Stepsdev5683No ratings yet

- Lesson 6: Continuous Process ImprovementDocument46 pagesLesson 6: Continuous Process ImprovementBilly Vince AlquinoNo ratings yet

- Total Quality Management: Wiley Education Canada To Support The Textbook Chosen in This CourseDocument40 pagesTotal Quality Management: Wiley Education Canada To Support The Textbook Chosen in This CourseAmir HossainNo ratings yet

- Benchmarking and ComparisionDocument13 pagesBenchmarking and Comparisionpravin.gadge65No ratings yet

- Mod 8 Planning For Solution EvaluationDocument46 pagesMod 8 Planning For Solution Evaluation于芷鸥No ratings yet

- ASQ Six SigmaDocument536 pagesASQ Six Sigmadmrpanda9940100% (2)

- Preso-Session 11-12 PDFDocument25 pagesPreso-Session 11-12 PDFlaalan jiNo ratings yet

- Iqc PDFDocument30 pagesIqc PDFchristina abucayNo ratings yet

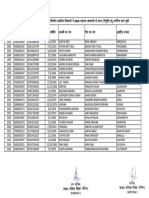

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHSAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHjaini mauryaNo ratings yet

- Employability Skills 2nd Sem Final-127Document1 pageEmployability Skills 2nd Sem Final-127SAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHjaini mauryaNo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHSAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHSAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHSAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHSAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHjaini mauryaNo ratings yet

- Employability Skills 2nd Sem Final-132Document1 pageEmployability Skills 2nd Sem Final-132SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-130Document1 pageEmployability Skills 2nd Sem Final-130SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-136Document1 pageEmployability Skills 2nd Sem Final-136SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-128Document1 pageEmployability Skills 2nd Sem Final-128SAVITA MAURYANo ratings yet

- Employability Skills - Labour Welfare Legislation Theory 2.4.59 Employees Provident Fund Act (EPF)Document1 pageEmployability Skills - Labour Welfare Legislation Theory 2.4.59 Employees Provident Fund Act (EPF)SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-136Document1 pageEmployability Skills 2nd Sem Final-136SAVITA MAURYANo ratings yet

- Employability Skills - Labour Welfare Legislation Theory 2.4.60 Workmen Compensation ActDocument1 pageEmployability Skills - Labour Welfare Legislation Theory 2.4.60 Workmen Compensation ActSAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-139Document1 pageEmployability Skills 2nd Sem Final-139SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-141Document1 pageEmployability Skills 2nd Sem Final-141SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-143Document1 pageEmployability Skills 2nd Sem Final-143SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-137Document1 pageEmployability Skills 2nd Sem Final-137SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-135Document1 pageEmployability Skills 2nd Sem Final-135SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-140Document1 pageEmployability Skills 2nd Sem Final-140SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-138Document1 pageEmployability Skills 2nd Sem Final-138SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-144Document1 pageEmployability Skills 2nd Sem Final-144SAVITA MAURYANo ratings yet

- Employability Skills - Quality Tools Exercise 2.5.62 Analyse The Problems Using Quality ToolsDocument1 pageEmployability Skills - Quality Tools Exercise 2.5.62 Analyse The Problems Using Quality ToolsSAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-145Document1 pageEmployability Skills 2nd Sem Final-145SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-142Document1 pageEmployability Skills 2nd Sem Final-142SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-142Document1 pageEmployability Skills 2nd Sem Final-142SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-148Document1 pageEmployability Skills 2nd Sem Final-148SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-146Document1 pageEmployability Skills 2nd Sem Final-146SAVITA MAURYANo ratings yet

- The Achaeans (Also Called The "Argives" or "Danaans")Document3 pagesThe Achaeans (Also Called The "Argives" or "Danaans")Gian Paul JavierNo ratings yet

- 6426c-Enu Trainerhandbook 2Document392 pages6426c-Enu Trainerhandbook 2mu771_No ratings yet

- Medical Professionalism Across Cultures: A Challenge For Medicine and Medical EducationDocument7 pagesMedical Professionalism Across Cultures: A Challenge For Medicine and Medical EducationYoNo ratings yet

- VW Touareg 2 Brake System EngDocument111 pagesVW Touareg 2 Brake System EngCalin GeorgeNo ratings yet

- The People Lie, But Numbers Don't Approach To HR AnalyticsDocument8 pagesThe People Lie, But Numbers Don't Approach To HR AnalyticsYour HR BuddyNo ratings yet

- 2023 HAC YemenDocument5 pages2023 HAC YemenRick AstleyNo ratings yet

- Induction and Training Road-Map: GenpactDocument27 pagesInduction and Training Road-Map: GenpactShrey KanungoNo ratings yet

- Compiled Notes: Mscfe 610 EconometricsDocument29 pagesCompiled Notes: Mscfe 610 Econometricssadiqpmp100% (1)

- Funal ReportDocument2 pagesFunal ReportApril Jay EgagamaoNo ratings yet

- Potot Vs People DigestDocument1 pagePotot Vs People DigestMary Grace SevillaNo ratings yet

- SAP Manufacturing Implementation Architecture-1Document17 pagesSAP Manufacturing Implementation Architecture-1andriesbuterNo ratings yet

- Supplementary: Materials inDocument5 pagesSupplementary: Materials inEvan Siano BautistaNo ratings yet

- Unit 1 - Foundations of American DemocracyDocument9 pagesUnit 1 - Foundations of American DemocracybanaffiferNo ratings yet

- 26th Sunday in Ordinary Time HNSDocument232 pages26th Sunday in Ordinary Time HNSJeanette FormenteraNo ratings yet

- The Global Workforce Crisis BCG PDFDocument28 pagesThe Global Workforce Crisis BCG PDFdakintaurNo ratings yet

- Outcomes of Democracy: How Do We Assess Democracy?Document7 pagesOutcomes of Democracy: How Do We Assess Democracy?Ankita MondalNo ratings yet

- Sample Activity ReportDocument2 pagesSample Activity ReportKatrina CalacatNo ratings yet

- TV Ads/Commercials Thread (October-December 2010)Document55 pagesTV Ads/Commercials Thread (October-December 2010)Pcnhs Sal100% (1)

- Barnum Distributors Wants A Projection of Cash Receipts and CashDocument1 pageBarnum Distributors Wants A Projection of Cash Receipts and CashAmit PandeyNo ratings yet

- Operant Conditioning of RatsDocument7 pagesOperant Conditioning of RatsScott KaluznyNo ratings yet

- Multiple Choice Questions: Energy and MetabolismDocument75 pagesMultiple Choice Questions: Energy and MetabolismJing LiNo ratings yet

- Antenatal Assessment of Fetal Well Being FileminimizerDocument40 pagesAntenatal Assessment of Fetal Well Being FileminimizerPranshu Prajyot 67No ratings yet

- 2021 06 WJU Circus Fanfare NOV DECDocument28 pages2021 06 WJU Circus Fanfare NOV DECDwarven SniperNo ratings yet

- Aeneid Proem and Book II AnalysisDocument6 pagesAeneid Proem and Book II AnalysisJustin ChangNo ratings yet

- STO Trade Qualifier Application GuideDocument15 pagesSTO Trade Qualifier Application Guidechrisandersen1111No ratings yet

- This Points Are Very Main Part of Self: How To Give Self Introduction in IterviewDocument22 pagesThis Points Are Very Main Part of Self: How To Give Self Introduction in Iterviewvijay kumarNo ratings yet