Professional Documents

Culture Documents

Employability Skills 2nd Sem Final-166 PDF

Uploaded by

SAVITA MAURYA0 ratings0% found this document useful (0 votes)

10 views1 pageOriginal Title

Employability_Skills_2nd_Sem_Final-166.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageEmployability Skills 2nd Sem Final-166 PDF

Uploaded by

SAVITA MAURYACopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

• Better use of floor space.

seeing our ideas implemented

• Less work-in-progress inventories. • To make our job easier, safer Q

• Better flow of work. U

• To improve our Customer Service and make our

A

• Low accident rates customers happier

L

• Low machine break down, higher utilization of • To work smarter and not harder I

machinery's and equipments T

• To improve productivity and Quality Y

• High yield of materials

• To achieve organization growth

• High product quality T

• To become world class O

• Higher productivity

O

The questions like the ones given below would lead to Benefits of Kaizen L

status of present situation. S

Collective wisdom of people brings infinite results

• Are regular 5s checks conducted ?

• Job made easier

• Do people clean up without reminders?

• Drudgery removed from the job

• Do people follow rules and instructions

• Do people wear their uniforms and safety gear • Nuisance removed from the job

properly? • More Safety

• Do people assemble in time?

• More productivity

5D Concept

• Quality Improvement

If we do not follow the 5S concept, ready to accept 5D (5

Devils) • Saves Time and Cost

• Delay • Job Enrichment

• Declining profit Who should do Kaizen?

• Dissatisfied customers Kaizen is to be done by every one, right across the

organization, as everyone is contributing to the organization

• Defects output

• Demoralised Employees Where to do Kaizen?

KAIZEN Kaizen can be done in

Kaizen is basically small small improvements carried out • One's Own work area

by the person who is doing the job in his/her day to day

a) Routine & (b) Non-routine

work. The prime motto being small-small improvements

lead to Big benefits. • Common relevant areas

In Japanese, a) With your department peers &

b) With other department

“KAI” means Continuous

• Other's work area

"ZEN" means Improvement (a) Canteen & (b) Reception, etc.,

“KAIZEN” means Continuous Improvement

• One's own personal area-House

Continuous Improvement everyday through involvement of

every one in the organization is the key for Business When to do Kaizen?

Excellence, which is the prime motto for a Total Quality Whenever there is:

Organization.

• Pain area for individual

Why Kaizen?

• Pain area for organization

• To remain competitive we need to change for better

and hence Kaizen • Dissatisfaction over working Method

• If we do not move forward, we will move backward Individual's or organization's pain area will be mostly

due to the 3 MU's namely

• We may become worse than animals, if we do not use

• MURI - Strain

our ability to think

• MURA - Inconsistency

• Nothing will give more satisfaction, motivation than

• MUDA - Waste

Employability Skills - (NSQF) Quality Tools : Theory 2.5.65 147

Copyright Free Under CC BY Licence

You might also like

- Kaizenppt 1223192122317277 9 PDFDocument12 pagesKaizenppt 1223192122317277 9 PDFgcldesignNo ratings yet

- Pinky Gandhi, Satyajit Gaekwad, Mukesh Ghadavi, Manish JaniDocument13 pagesPinky Gandhi, Satyajit Gaekwad, Mukesh Ghadavi, Manish JaniPinky GandhiNo ratings yet

- Pinky Gandhi, Satyajit Gaekwad, Mukesh Ghadavi, Manish JaniDocument13 pagesPinky Gandhi, Satyajit Gaekwad, Mukesh Ghadavi, Manish JaniPinky GandhiNo ratings yet

- Unit Iv CMSDocument43 pagesUnit Iv CMSsuganthNo ratings yet

- Advanced LeanDocument106 pagesAdvanced Leanlesa011No ratings yet

- Ethics Integrity Trust Training Teamwork Leadership Recognition CommunicationDocument37 pagesEthics Integrity Trust Training Teamwork Leadership Recognition Communicationadnan67No ratings yet

- Employability Skills 2nd Sem Final-167Document1 pageEmployability Skills 2nd Sem Final-167SAVITA MAURYANo ratings yet

- Kaizen and Its ToolsDocument17 pagesKaizen and Its ToolsadwaitanandNo ratings yet

- QC Circle Training Material PDFDocument200 pagesQC Circle Training Material PDFAjit MokalNo ratings yet

- Jatin Badgujar Perils and Pitfalls P23224Document2 pagesJatin Badgujar Perils and Pitfalls P23224Jatin BadgujarNo ratings yet

- Advanced Lean - 1Document50 pagesAdvanced Lean - 1kalite gurusuNo ratings yet

- Advanced Lean Training Manual Band 4Document106 pagesAdvanced Lean Training Manual Band 4EXDE601E100% (39)

- Advanced Lean Training Manual Band 4Document101 pagesAdvanced Lean Training Manual Band 4Abel TorresNo ratings yet

- What Is Six Sigma? - Why Six Sigma?: - Process Improvement Methodology and ToolsDocument2 pagesWhat Is Six Sigma? - Why Six Sigma?: - Process Improvement Methodology and ToolsKapil MohanNo ratings yet

- Fdocuments - in KaizenDocument12 pagesFdocuments - in KaizenAung Thein OoNo ratings yet

- Slide Show Week #1 Lecture - MGT 300Document13 pagesSlide Show Week #1 Lecture - MGT 300MusahaqueNo ratings yet

- The Pricing WorkshopDocument15 pagesThe Pricing WorkshopGishka GileNo ratings yet

- QuestionDocument8 pagesQuestionokanNo ratings yet

- Lean LeadershipDocument38 pagesLean LeadershipRushmiS100% (2)

- Kanban For Quality Management: Oc Tob E R 12, 2017Document23 pagesKanban For Quality Management: Oc Tob E R 12, 2017pietrodpNo ratings yet

- The Visual Workplace: Includes Excerpts From: The Visual Factory, by Michel Greif Productivity PressDocument21 pagesThe Visual Workplace: Includes Excerpts From: The Visual Factory, by Michel Greif Productivity Pressmilou88No ratings yet

- HRM Session 3Document25 pagesHRM Session 3Yash NagarNo ratings yet

- KaizenDocument44 pagesKaizenmentariashNo ratings yet

- KAIZEN DAY (Teaching Material) PDFDocument74 pagesKAIZEN DAY (Teaching Material) PDFGirmaNo ratings yet

- Advanced LeanDocument50 pagesAdvanced LeanMuhammad RehmanNo ratings yet

- AgileScrumCheatSheet PDFDocument1 pageAgileScrumCheatSheet PDFsimish123No ratings yet

- Lean KaizenDocument2 pagesLean Kaizenswahyudi9No ratings yet

- Gemba Kaizen Presentation To IcpakDocument75 pagesGemba Kaizen Presentation To IcpakSeenivasagam SeenuNo ratings yet

- Kaizen Basic No.1 (What Is KAIZEN)Document48 pagesKaizen Basic No.1 (What Is KAIZEN)henokNo ratings yet

- Advanced Lean Training ManualDocument50 pagesAdvanced Lean Training ManualJunjie Chen100% (2)

- JCM Maslow NeedsDocument10 pagesJCM Maslow Needsn3sh25No ratings yet

- Interview Preparation ToolkitDocument9 pagesInterview Preparation ToolkitRick TomersonNo ratings yet

- TSO Engagement WWSC Handout 5.01Document4 pagesTSO Engagement WWSC Handout 5.01kevinNo ratings yet

- The Agile Business AnalystDocument56 pagesThe Agile Business Analystsembalap29No ratings yet

- Achal Dugar Mayank Sinha Priyansh AcharyaDocument12 pagesAchal Dugar Mayank Sinha Priyansh AcharyaBasmah AnsariNo ratings yet

- Enterprise Cost Reduction Through Lean Six Sigma ImplementationDocument13 pagesEnterprise Cost Reduction Through Lean Six Sigma ImplementationNikita Bhavsar ShahNo ratings yet

- Monica Gordon BAEDocument9 pagesMonica Gordon BAEThùy NguyễnNo ratings yet

- Six Sigma Black Belt Wk1-Define & MeasureDocument452 pagesSix Sigma Black Belt Wk1-Define & MeasureRaghavendra Narayanaswamy100% (11)

- Masterclass 1 - The Key ConceptsDocument19 pagesMasterclass 1 - The Key ConceptswayfindingneedsNo ratings yet

- The Lean Lego Game Slides Short iSixSigma PDFDocument37 pagesThe Lean Lego Game Slides Short iSixSigma PDFAlvaro RoblesNo ratings yet

- KaizenDocument23 pagesKaizenandyrockshellNo ratings yet

- Shwetha Nilamber Murugesh KumarDocument33 pagesShwetha Nilamber Murugesh Kumarsayyedwahab123456789No ratings yet

- Kaizen To Improve Operational Excellence PDFDocument275 pagesKaizen To Improve Operational Excellence PDFSathish KumarNo ratings yet

- Unitrends Competition - 2019 AprilDocument52 pagesUnitrends Competition - 2019 Aprilsrinivasan SNo ratings yet

- 2015 Symposium - Lean 101Document47 pages2015 Symposium - Lean 101Nguyen Hoang DungNo ratings yet

- Appex Corporation: Click To Edit Master Title StyleDocument12 pagesAppex Corporation: Click To Edit Master Title Styleshikha guptaNo ratings yet

- PPL Session 15Document20 pagesPPL Session 15thakranisparshNo ratings yet

- Leadership ProjectDocument27 pagesLeadership ProjectGojoNo ratings yet

- Long - Term PhilosophyDocument25 pagesLong - Term Philosophymanivino100% (8)

- CORE VALUES Guiding PrinciplesDocument8 pagesCORE VALUES Guiding PrinciplesFakhrul Azman NawiNo ratings yet

- Six Sigma Session 1 08082020 WILP BITS PILANI 1597550569576 PDFDocument63 pagesSix Sigma Session 1 08082020 WILP BITS PILANI 1597550569576 PDFKrishna PrasathNo ratings yet

- Team Building (New Version)Document21 pagesTeam Building (New Version)Jeverson AudNo ratings yet

- VOIS 3 Year PlanDocument2 pagesVOIS 3 Year PlanSudhanshu KumarNo ratings yet

- 5.3 Lean ProductionDocument39 pages5.3 Lean ProductionP RushitaNo ratings yet

- The New Project Management: Tools for an Age of Rapid Change, Complexity, and Other Business RealitiesFrom EverandThe New Project Management: Tools for an Age of Rapid Change, Complexity, and Other Business RealitiesNo ratings yet

- Service Orient or Be Doomed!: How Service Orientation Will Change Your BusinessFrom EverandService Orient or Be Doomed!: How Service Orientation Will Change Your BusinessRating: 4.5 out of 5 stars4.5/5 (1)

- 201 Ways to Turn Any Employee Into a Star PlayerFrom Everand201 Ways to Turn Any Employee Into a Star PlayerRating: 4 out of 5 stars4/5 (1)

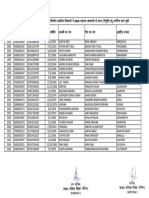

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHSAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHSAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHSAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHSAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHSAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHjaini mauryaNo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHjaini mauryaNo ratings yet

- Employability Skills 2nd Sem Final-132Document1 pageEmployability Skills 2nd Sem Final-132SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-127Document1 pageEmployability Skills 2nd Sem Final-127SAVITA MAURYANo ratings yet

- M0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHDocument1 pageM0Iz0 CSFLD F'K (KK Ifj"Kn) KJK Lapkfyr Ifj"Knh Izkfkfed Fo - Ky Ksa Esa 69000 LGK D V/ Kidksa Ds P U@Fu QFDR GSRQ Vufure P U LWPHjaini mauryaNo ratings yet

- Employability Skills 2nd Sem Final-130Document1 pageEmployability Skills 2nd Sem Final-130SAVITA MAURYANo ratings yet

- Employability Skills - Labour Welfare Legislation Theory 2.4.59 Employees Provident Fund Act (EPF)Document1 pageEmployability Skills - Labour Welfare Legislation Theory 2.4.59 Employees Provident Fund Act (EPF)SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-128Document1 pageEmployability Skills 2nd Sem Final-128SAVITA MAURYANo ratings yet

- Employability Skills - Labour Welfare Legislation Theory 2.4.60 Workmen Compensation ActDocument1 pageEmployability Skills - Labour Welfare Legislation Theory 2.4.60 Workmen Compensation ActSAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-136Document1 pageEmployability Skills 2nd Sem Final-136SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-141Document1 pageEmployability Skills 2nd Sem Final-141SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-136Document1 pageEmployability Skills 2nd Sem Final-136SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-139Document1 pageEmployability Skills 2nd Sem Final-139SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-135Document1 pageEmployability Skills 2nd Sem Final-135SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-138Document1 pageEmployability Skills 2nd Sem Final-138SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-137Document1 pageEmployability Skills 2nd Sem Final-137SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-140Document1 pageEmployability Skills 2nd Sem Final-140SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-144Document1 pageEmployability Skills 2nd Sem Final-144SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-142Document1 pageEmployability Skills 2nd Sem Final-142SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-142Document1 pageEmployability Skills 2nd Sem Final-142SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-143Document1 pageEmployability Skills 2nd Sem Final-143SAVITA MAURYANo ratings yet

- Employability Skills - Quality Tools Exercise 2.5.62 Analyse The Problems Using Quality ToolsDocument1 pageEmployability Skills - Quality Tools Exercise 2.5.62 Analyse The Problems Using Quality ToolsSAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-146Document1 pageEmployability Skills 2nd Sem Final-146SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-145Document1 pageEmployability Skills 2nd Sem Final-145SAVITA MAURYANo ratings yet

- Employability Skills 2nd Sem Final-148Document1 pageEmployability Skills 2nd Sem Final-148SAVITA MAURYANo ratings yet

- Unfinished Chapter 2Document7 pagesUnfinished Chapter 2BenNo ratings yet

- Body Image and Its Correlation With Social MediaDocument18 pagesBody Image and Its Correlation With Social Mediaapi-502946951No ratings yet

- ML QB (Vtu)Document6 pagesML QB (Vtu)Anu CadzieNo ratings yet

- Reinforcement Learning For Test Case Prioritization-Issta17 0 PDFDocument11 pagesReinforcement Learning For Test Case Prioritization-Issta17 0 PDFAnonymous V8m746tJNo ratings yet

- An Interview With Claire BishopDocument6 pagesAn Interview With Claire BishopqueryNo ratings yet

- College English and Business Communication 10th Edition by Camp Satterwhite ISBN Test BankDocument55 pagesCollege English and Business Communication 10th Edition by Camp Satterwhite ISBN Test Bankgladys100% (20)

- CharleneDocument3 pagesCharleneCharlene CapinpinNo ratings yet

- Chapter 1,2,3Document321 pagesChapter 1,2,3Aniket Mhapnkar100% (1)

- Cohen Analizing Neural Time Series PDFDocument615 pagesCohen Analizing Neural Time Series PDFAgustina BirbaNo ratings yet

- Adm. Case No. 5036. January 13, 2003. Rizalino C. Fernandez, Complainant, vs. Atty. Dionisio C. Esidto, RespondentDocument50 pagesAdm. Case No. 5036. January 13, 2003. Rizalino C. Fernandez, Complainant, vs. Atty. Dionisio C. Esidto, RespondentCess Bustamante AdrianoNo ratings yet

- Theory of Motivation - Insight Into Expectancy Theory: Harihar Panigrahi Roll No.: U211029 Ex-PGP 2011-14, XIMBDocument14 pagesTheory of Motivation - Insight Into Expectancy Theory: Harihar Panigrahi Roll No.: U211029 Ex-PGP 2011-14, XIMBHarihar Panigrahi100% (7)

- Human BrainDocument27 pagesHuman BrainSuhail KhanNo ratings yet

- Importance of Quantitative Research Across The FieldsDocument6 pagesImportance of Quantitative Research Across The Fieldsjm88% (24)

- Muf Muf Principle of Language AssessmentDocument15 pagesMuf Muf Principle of Language AssessmentramasutarsaNo ratings yet

- Positive Self-Talk Part 2Document2 pagesPositive Self-Talk Part 2api-396767767No ratings yet

- Vb-Mapp Transition Scoring FormDocument1 pageVb-Mapp Transition Scoring FormEstima CGNo ratings yet

- Lesson Plan 3 MiraclesDocument6 pagesLesson Plan 3 Miraclesapi-313599773No ratings yet

- Promotion Policy Ex RVSD 080523Document42 pagesPromotion Policy Ex RVSD 080523saurabhutekarNo ratings yet

- Licensure Requirements 2016 EditionDocument168 pagesLicensure Requirements 2016 Editionprivatelogic100% (2)

- Methods and Techniques: The K-12 ApproachDocument45 pagesMethods and Techniques: The K-12 Approachlaren100% (1)

- (Pocket Guide To Social Work Research Methods) James Drisko, Tina Maschi - Content Analysis (2015, Oxford University Press) PDFDocument209 pages(Pocket Guide To Social Work Research Methods) James Drisko, Tina Maschi - Content Analysis (2015, Oxford University Press) PDFCarolina Bagattolli100% (2)

- History 4C - Paper #1: Pere GoriotDocument2 pagesHistory 4C - Paper #1: Pere GoriotSteven MackeyNo ratings yet

- Effects of Social Media in Academic Performance of Selected Grade 11 Students in STI College Novaliches SY 2018-2019Document28 pagesEffects of Social Media in Academic Performance of Selected Grade 11 Students in STI College Novaliches SY 2018-2019Aaron Joseph OngNo ratings yet

- Haste, Helen. Constructing The CitizenDocument28 pagesHaste, Helen. Constructing The CitizenManuel Pinto GuerraNo ratings yet

- Thesis Merly and CarmenDocument26 pagesThesis Merly and CarmenDanivie JarantaNo ratings yet

- Ecp712 At2 Lesson PlanDocument6 pagesEcp712 At2 Lesson Planapi-346521585No ratings yet

- Entrepreneurship and EnvironmentDocument19 pagesEntrepreneurship and EnvironmentMURALI100% (1)

- Phonemic Awareness and The Teaching of ReadingDocument10 pagesPhonemic Awareness and The Teaching of ReadingDavid Woo100% (2)

- Types of SpeechDocument17 pagesTypes of SpeechGRACE ZELL Gallego100% (1)

- Critical Appraisal 1Document25 pagesCritical Appraisal 1annisaNo ratings yet