Professional Documents

Culture Documents

Mec. KL12 PDF

Mec. KL12 PDF

Uploaded by

ElfrinaUliPoebaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mec. KL12 PDF

Mec. KL12 PDF

Uploaded by

ElfrinaUliPoebaCopyright:

Available Formats

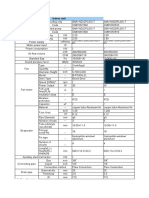

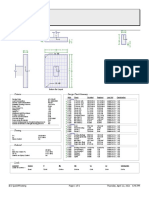

Aspen Exchanger Design and Rating Shell & Tube V11 Page 1

File: Printed: 5/16/2020 at 10:12:08 AM

Basic Geometry

Unit Configuration

Exchanger type BEM Tube number 949

Position Hor Tube length actual m 2.55

Arrangement 1 parallel 1 series Tube passes 1

Baffle type Single segmental Tube type Plain

Baffle number 6 Tube O.D. mm 19.05

Spacing (center-center) mm 285 Tube pitch mm 23.81

Spacing at inlet mm 504.97 Tube pattern 30

Shell Kettle Front head Rear Head

Outside diameter mm 824 824 824

Inside diameter mm 800 800 800

Shell Side Tube Side

Nozzle type Inlet Outlet Inlet Outlet

Number of nozzles 1 1 1 1

Actual outside diameter mm 48.26 42.16 355.6 323.85

Inside diameter mm 40.89 35.05 336.55 304.8

Height under nozzle mm 19.28 19.28

Dome inside diameter mm

Vapor belt inside diameter mm

Vapor belt inside width mm

Vapor belt slot area mm2

No No

Impingement protection

impingement impingement

Distance to tubesheet mm 2415 120

Aspen Exchanger Design and Rating Shell & Tube V11 Page 2

File: Printed: 5/16/2020 at 10:12:08 AM

Tubes

Tubes

Type Plain Total number of tubes 949

Outside diameter mm 19.05 Number of tubes plugged 0

Inside diameter mm 14.83 Tube length actual m 2.55

Wall thickness mm 2.11 Tube length effective m 2.435

Area Ratio Ao/Ai 1.284247 Front tubesheet thickness mm 54.53

Pitch mm 23.81 Rear tubesheet thickness mm 54.53

Pattern 30 Material Carbon Steel

External enhancement Thermal conductivity W/(m-K) 51.5368

Internal enhancement

Low fins Longitudinal fins

Fin density #/m Fin number 0

Fin height mm Fin thickness mm

Fin thickness mm Fin height mm

Tube root diameter mm Fin spacing mm

Tube wall thickness under fin mm Cut and twist length mm

Tube inside diameter under fins mm

Other (high) fins

High Fin Type Default High Fin Thick mm

High Fin Tip Diameter mm High Fin Frequency #/m

Aspen Exchanger Design and Rating Shell & Tube V11 Page 3

File: Printed: 5/16/2020 at 10:12:08 AM

Baffles

Baffles

Type Single segmental Baffle cut: inner/outer/interm

Tubes in window Yes Actual (% diameter) / 29.38 /

Number 6 Nominal (% diameter) / 29.38 /

Spacing (center-center) mm 285 Actual (% area) / 24.51 /

Spacing at inlet mm 504.97 Cut orientation H

Spacing at outlet mm 504.97 Thickness mm 6.35

Spacing at center in/out for G,H,I,J mm Tube rows in baffle overlap 16

Spacing at center for H shell mm Tube rows in baffle window 10.5

End length of the front head mm 562.5 Baffle hole - tube od diam clearance mm 0.79

End length of the rear head mm 562.5 Shell id - tube od diam clearance mm 4.76

Variable Baffle Spacings

Supports-Misc. Baffles

Supports - tube Longitudinal Baffle

Supports in endspace at front head 0 Thickness mm

Supports in endspace at rear head 0 Window length at front end mm

Supports between baffles 0 Window length at center mm

Support blanking baffle No Window length at rear end mm

Supports at U-bend 0

Supports at each G,H,J shell inlet and I shell outlet 0

Supports at center of H shell 0

Supports for K,X shells 0

Special support at inlet nozzle No

Aspen Exchanger Design and Rating Shell & Tube V11 Page 4

File: Printed: 5/16/2020 at 10:12:08 AM

Bundle

Bundle

Shell ID to center 1st tube row mm Tube passes 1

From top 19.28 Tube pass layout Ribbon (single band)

From bottom 19.28 Tube pass orientation Standard (horizontal)

From right 9.48 U-bend orientation Undefined

From left 9.48 Horizontal pass lane width mm

Impingement protection None Vertical pass lane width mm

Impingement plate clearance to tube edge mm Interpass tube alignment No

Impingement plate diameter mm Deviation in tubes/pass 0

Impingement plate width mm Outer tube limit mm 787.3

Impingement plate length mm Shell id - bundle otl diam clearance mm 12.7

Impingement plate thickness mm Tie rod number 6

Gross surface area per shell m² 144.8 Tie rod diameter mm 12.7

Effective surface area per shell m² 138.3 Sealing strips (pairs) 3

Bare tube area per shell m² 138.3 Tube to Tubesheet joint Exp. 2 grv

Finned area per shell m² 0 Tube projection from front tsht mm 3

U-bend area per shell m² 0 Tube projection from rear tsht mm 3

Enhancements

Inserts & Internal enhancements

Tube insert type None

Twist tape 360 deg twist pitch mm

Twisted tape thickness mm

hiTRAN part number

Aspen Exchanger Design and Rating Shell & Tube V11 Page 5

File: Printed: 5/16/2020 at 10:12:08 AM

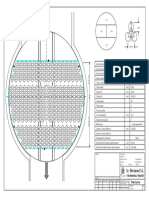

Setting Plan

Views on arrow A

A 4581 Overall

2434

514 533 120 2295 445

S1 T2

562

T1

S1

562

562

599

T1 S2

S2 533 510 1530

Pulling Length 1530

75 75

T2

178

178

562

714

714

150 150

2 Bolts 2 Bolts

Fixed Sliding

Nozzle Data Design Data Units Shell Channel Notes: Company:

Ref OD Wall Standard Notes Design Pressure bar 3 18 Location:

S1 48 mm 3.7 mm Slip on Design Temperature °C 130 105 Service of Unit: Our Reference:

S2 42 mm 3.6 mm Slip on Full Vacuum 0 0 Item No.: Your Reference:

T1 356 mm 9.5 mm Slip on Corrosion Allowance mm 3.175 3.175 Date: Rev No.: Job No.:

T2 324 mm 9.5 mm Slip on Test Pressure bar

Number of Passes 1 1

Radiography 0 0

Company Name

PWHT 0 0 City, State

Internal Volume m³ 0.5541 1.3885 Scale:

Rev: Date: Description Dwg. Chk. Appd. 0

Weight Summary TEMA Type: BEM

Setting Plan

Empty Flooded Bundle Size: 800 - 2550 Dwg No.: Rev:

4185 kg 5920 kg 2540 kg TEMA Class: 0 1

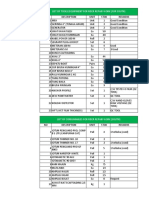

Aspen Exchanger Design and Rating Shell & Tube V11 Page 6

File: Printed: 5/16/2020 at 10:12:08 AM

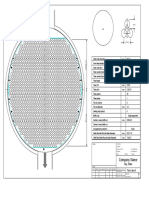

Tubesheet Layout

19.05

949

23.8125

371.2 mm

Shell inside diameter mm 800.0009

Front head inside diameter mm 800.0009

Outer tube limit mm 787.301

Tube number (calcs.) 949

Tube number (layout) 949

Tube length mm 2550

Tube O.D. mm 19.05

Tube pitch mm 23.8125

Tube pattern 30

Tube passes 1

Tie rod number 6

Tie rod diameter mm 12.7

Sealing strips (pairs) 3

Baffle type Single segmental

371.2 mm

Centre to outer baffle cut mm 164.9778

Centre to inner baffle cut

Impingement protection None

Shell Side Inlet Nozzle Inside Diameter mm 40.894

Shell Side Outlet Nozzle Inside Diameter mm 35.052

Notes: Company:

Location:

Service of Unit: Our Reference:

Item No.: Your Reference:

Date: Rev No.: Job No.:

Company Name

City, State

Scale:

Rev: Date: Description Dwg. Chk. Appd. ASME Code Sec VIII Div 1

TEMA Type: BEM

Tube Layout

Size: 800 - 2550 Dwg No.: Rev:

TEMA Class: R - refinery service 2

You might also like

- Solution - Bejan.Convection Heat Transfer - Third Edition PDFDocument280 pagesSolution - Bejan.Convection Heat Transfer - Third Edition PDFHugo Leonardo Leao91% (11)

- Aspen Exchanger Design and Rating Shell & Tube V11Document6 pagesAspen Exchanger Design and Rating Shell & Tube V11ElfrinaUliPoebaNo ratings yet

- Heat Exchanger Design SheetDocument5 pagesHeat Exchanger Design SheetfaroukNo ratings yet

- 130-CJ Current UpdateDocument15 pages130-CJ Current UpdateFaizan AhmedNo ratings yet

- SKF SNL 532 SpecificationDocument5 pagesSKF SNL 532 Specificationshalini15_85No ratings yet

- SNL 508-607 - 20221026Document5 pagesSNL 508-607 - 20221026unaihot3291No ratings yet

- Requirements For Shell and Tube Heat Exchangers - TEMA StandardsDocument1 pageRequirements For Shell and Tube Heat Exchangers - TEMA StandardsLuis Fernando Castrillón MadrigalNo ratings yet

- Page 1 of 6Document6 pagesPage 1 of 6Devesh SinghNo ratings yet

- Detailed DataDocument11 pagesDetailed DataDaniswara Krisna PrabathaNo ratings yet

- SKF SNL 3136 G SpecificationDocument6 pagesSKF SNL 3136 G SpecificationMohamed HardmanNo ratings yet

- E 101EsquemaDentroDocument1 pageE 101EsquemaDentroJ. GonzálezNo ratings yet

- Fine-Fin: High Performance Tubes For Heat ExchangersDocument12 pagesFine-Fin: High Performance Tubes For Heat ExchangersPankaj RaneNo ratings yet

- Fytb 30 WF - 20221021Document6 pagesFytb 30 WF - 20221021FendyNo ratings yet

- SKF SNL 3134 SpecificationDocument5 pagesSKF SNL 3134 SpecificationwiwinsaputramanikNo ratings yet

- SKF SNL 516-613 SpecificationDocument5 pagesSKF SNL 516-613 SpecificationMohamed AliNo ratings yet

- Detailed Design of Free Pot BearingDocument7 pagesDetailed Design of Free Pot BearingDevesh SinghNo ratings yet

- Tubesheet LayoutDocument1 pageTubesheet LayoutTIPAZONo ratings yet

- RAM Connection Standalone CE ReportDocument4 pagesRAM Connection Standalone CE ReportThanh ViệtNo ratings yet

- Company Name: City, StateDocument1 pageCompany Name: City, Stateanggun 119280087No ratings yet

- Tube Lay Out Gas ExchangerDocument1 pageTube Lay Out Gas ExchangerHudaFiHayyatNo ratings yet

- TEE Data SheetDocument12 pagesTEE Data SheetKing1971No ratings yet

- Threading Formulas and DefinitionsDocument17 pagesThreading Formulas and Definitionsx9kqm6pz24No ratings yet

- Asme Sec 8 Div 1 - App 1-10Document11 pagesAsme Sec 8 Div 1 - App 1-10BibinBabuNo ratings yet

- Vessel Weight Calculation'sDocument6 pagesVessel Weight Calculation'sDesign SadhanaNo ratings yet

- 2b. Shear Connection - BTOB (M Project) - 0618Document210 pages2b. Shear Connection - BTOB (M Project) - 0618Omprakash Khodke100% (1)

- Kubic High Static Fcu Tech DataDocument1 pageKubic High Static Fcu Tech Datamir sadat aliNo ratings yet

- Heat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryDocument8 pagesHeat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryaminNo ratings yet

- 125 128Document4 pages125 128Majdi JerbiNo ratings yet

- SKF SY 508 M SpecificationDocument4 pagesSKF SY 508 M Specificationrinaldo KurniawanNo ratings yet

- F2B 40M-WF: Flanged Ball Bearing Unit With Composite or Cast Metal HousingDocument6 pagesF2B 40M-WF: Flanged Ball Bearing Unit With Composite or Cast Metal HousingSakiNo ratings yet

- Column Base Plate (Hinge Type)Document14 pagesColumn Base Plate (Hinge Type)Mesgina G-herNo ratings yet

- Technical Specifications: PlateDocument2 pagesTechnical Specifications: PlateIgnacio LopezNo ratings yet

- TRAUMA Product CatalogueDocument162 pagesTRAUMA Product Cataloguealexander sumaykuNo ratings yet

- Specs PLS C-TDocument12 pagesSpecs PLS C-TMichael MallariNo ratings yet

- SPF 0939Document1 pageSPF 0939Ka KaNo ratings yet

- Executive Summary 3.6 EVAPORATOR (V-102) Table 3.6.7 Evaporator Chemical Design Summary Design PropertiesDocument3 pagesExecutive Summary 3.6 EVAPORATOR (V-102) Table 3.6.7 Evaporator Chemical Design Summary Design PropertiesKangae IlhamNo ratings yet

- SKF SNL 3140split Plummer (Pillow) Block Housing, SNL 30, 31 and 32 Series SpecificationDocument6 pagesSKF SNL 3140split Plummer (Pillow) Block Housing, SNL 30, 31 and 32 Series SpecificationMunkhnasan MonaNo ratings yet

- 1 - 1 Cone D10 2V R0.341205 Beams 10x18 - Geodesic Dome CalculatorDocument3 pages1 - 1 Cone D10 2V R0.341205 Beams 10x18 - Geodesic Dome Calculatordoodo477No ratings yet

- Assgn 2 Has+muto+fdel+anto+irvi+raysDocument134 pagesAssgn 2 Has+muto+fdel+anto+irvi+raysFadel PutraNo ratings yet

- SKF FYJ 515square Flanged Housing For Insert Bearings, Cast Iron, JIS SpecificationDocument4 pagesSKF FYJ 515square Flanged Housing For Insert Bearings, Cast Iron, JIS SpecificationPhước TânNo ratings yet

- Chapter 11 Thread FastenerDocument71 pagesChapter 11 Thread FastenerGirmole WorkuNo ratings yet

- Memoria ASME-Pressure-Vessel-DesignDocument143 pagesMemoria ASME-Pressure-Vessel-DesignJuan MendozaNo ratings yet

- BS Datasheet 97403xxxxxDocument1 pageBS Datasheet 97403xxxxxskanderbn19No ratings yet

- Bios and Filter Mould Construction GuidelinesDocument27 pagesBios and Filter Mould Construction GuidelinesGreen Action Sustainable Technology GroupNo ratings yet

- 16 1 53 - 5 24 Am6 BM6Document1 page16 1 53 - 5 24 Am6 BM6Antonio BermudezNo ratings yet

- HERTZ Cento-PRO CPX165 Tech SheetDocument1 pageHERTZ Cento-PRO CPX165 Tech Sheethugo almeida alvaradoNo ratings yet

- Lec 12 Joining of MaterialsDocument36 pagesLec 12 Joining of MaterialsMohammad BilalNo ratings yet

- CSC - 115 - R - II DHBVN LT XlpeDocument15 pagesCSC - 115 - R - II DHBVN LT XlpeAshish bhattNo ratings yet

- UCFL 204 Oval Flanged Ball Bearing Units - 20210825Document5 pagesUCFL 204 Oval Flanged Ball Bearing Units - 20210825Pistoleiro PapacoNo ratings yet

- Shear Conenction - UpdatedDocument3 pagesShear Conenction - UpdatedAamir SuhailNo ratings yet

- Diffusers Supports Rev.0Document1 pageDiffusers Supports Rev.0Akshay RaskarNo ratings yet

- PanduitProductDetails LCCX4 - 0 38D XDocument2 pagesPanduitProductDetails LCCX4 - 0 38D XabaileyNo ratings yet

- Rotabest TCT Cutter Depth 50 MMDocument1 pageRotabest TCT Cutter Depth 50 MMMoh Widodo Nur CNo ratings yet

- Model Name 2MCW0530A1AA 2MWW0530A1AA: Non-Hydrophilic AluminiumDocument1 pageModel Name 2MCW0530A1AA 2MWW0530A1AA: Non-Hydrophilic AluminiumFranciscoNo ratings yet

- Calculation Result of Current Transformer and Potential TransformerDocument5 pagesCalculation Result of Current Transformer and Potential TransformerMoe Thant OoNo ratings yet

- Banjo Bolt Heat Sink BremboDocument4 pagesBanjo Bolt Heat Sink BremboD4designNo ratings yet

- Sun Gear Data ListDocument5 pagesSun Gear Data ListnguoidiquaNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- Unolastic PDFDocument20 pagesUnolastic PDFJM SubionNo ratings yet

- Development of A New Monte Carlo Reactor Physics Code VTTDocument241 pagesDevelopment of A New Monte Carlo Reactor Physics Code VTTtarek el zayatNo ratings yet

- Lesson 1.2 Real Number Line, Inequality, Intervals, and Absolute ValueDocument19 pagesLesson 1.2 Real Number Line, Inequality, Intervals, and Absolute ValuesdeloagNo ratings yet

- Beams: Diagrams and Formulas For Various Loading ConditionsDocument34 pagesBeams: Diagrams and Formulas For Various Loading ConditionsgaganNo ratings yet

- Detection of Rotor CracksDocument12 pagesDetection of Rotor CracksJoel Morales PerezNo ratings yet

- Auto Transport Trailer: Kit 1509 - Page 16Document16 pagesAuto Transport Trailer: Kit 1509 - Page 16LaVince EllisNo ratings yet

- Syillibus LMD 30203Document2 pagesSyillibus LMD 30203mohdumarhafiziNo ratings yet

- MAM Manual 2 2020Document217 pagesMAM Manual 2 2020Hykal FaridNo ratings yet

- What Do You Mean by Maxima and Minima of A FunctionDocument3 pagesWhat Do You Mean by Maxima and Minima of A FunctionkhanjiNo ratings yet

- SM Cie 2Document2 pagesSM Cie 2vaishaliNo ratings yet

- Design of CorbelDocument3 pagesDesign of CorbelAkshay KumarNo ratings yet

- Light Pollution and Light Wetting On Ceramic (Glass) Insulators As A Cause of Uknown Flashovers On Transmission LinesDocument7 pagesLight Pollution and Light Wetting On Ceramic (Glass) Insulators As A Cause of Uknown Flashovers On Transmission LinesramsesiNo ratings yet

- Lecture 10 - Bulk Forming - Reduction & ExtrusionDocument29 pagesLecture 10 - Bulk Forming - Reduction & ExtrusionSebastian OrdoñezNo ratings yet

- ShiplinePlus TFOI 6 10 12kVDocument2 pagesShiplinePlus TFOI 6 10 12kVAbhi ETAPNo ratings yet

- Analysis and Modelling Guide: Sediment Transport Modelling Method Indicator YES Summary of Key Issues Issue DescriptionDocument4 pagesAnalysis and Modelling Guide: Sediment Transport Modelling Method Indicator YES Summary of Key Issues Issue DescriptionBibhuti Bhusan SahooNo ratings yet

- Lecture 4 Single Degree of Freedom System Free Vibration Response 2Document11 pagesLecture 4 Single Degree of Freedom System Free Vibration Response 2Wael KassemNo ratings yet

- On The Design and Structural Analysis o Fjet Engine Fan Blade StructuresDocument11 pagesOn The Design and Structural Analysis o Fjet Engine Fan Blade StructuresNico ScheggiaNo ratings yet

- 3 PhaseDocument76 pages3 PhaseastridyoungtheoNo ratings yet

- Lab Experiment - 3: Solid State Physics LabDocument12 pagesLab Experiment - 3: Solid State Physics LabAman bansalNo ratings yet

- 03 TS-3 (ELECTROSTATICS C-1 To C-10)Document3 pages03 TS-3 (ELECTROSTATICS C-1 To C-10)lakshya rautelaNo ratings yet

- Solved Problems of ReflectionDocument13 pagesSolved Problems of ReflectionSadek PiashNo ratings yet

- Measurement: Rakesh Kolhapure, Vasudev Shinde, Vijay KambleDocument7 pagesMeasurement: Rakesh Kolhapure, Vasudev Shinde, Vijay KambleVijay KambleNo ratings yet

- Design Detail: Ingenieros Inasa 123 Main St. Anytown, Usa 00000 (000) 000-0000Document6 pagesDesign Detail: Ingenieros Inasa 123 Main St. Anytown, Usa 00000 (000) 000-0000Christian PintoNo ratings yet

- When Can We Say That The Two Triangles Are Similar ?Document20 pagesWhen Can We Say That The Two Triangles Are Similar ?Cleofe SobiacoNo ratings yet

- Datasheet Bu2508dfDocument7 pagesDatasheet Bu2508dfAnonymous nC9gpUWPNo ratings yet

- Digital Sensor Frame - v3 - 0 - 0 - 20191125Document73 pagesDigital Sensor Frame - v3 - 0 - 0 - 20191125llauroNo ratings yet

- IEO English Sample Paper 2 For Class 11 With SolutionsDocument27 pagesIEO English Sample Paper 2 For Class 11 With SolutionsmenekyakiaNo ratings yet

- PHYSICS-23-07 - 11th (J-Batch)Document9 pagesPHYSICS-23-07 - 11th (J-Batch)Raju SinghNo ratings yet

- List of Tools/Equipment For Riser Repair Work (For South)Document4 pagesList of Tools/Equipment For Riser Repair Work (For South)Naufal IkhsanNo ratings yet