Professional Documents

Culture Documents

Liberty Galati S.A. - Romania: Inspection Certificate 20607255 ACCORDING TO: EN 10204/2004/3.1 DATE: 05.11.2019

Uploaded by

Felicia CioabaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liberty Galati S.A. - Romania: Inspection Certificate 20607255 ACCORDING TO: EN 10204/2004/3.1 DATE: 05.11.2019

Uploaded by

Felicia CioabaCopyright:

Available Formats

Quality Management System

certified by Lloyd's Register

Quality Assurance

1035

QP00006_CPR2013-07-01_GA_V004

LIBERTY GALATI S.A. - Romania

QP00016_CPR2013-07-01_GA_V004

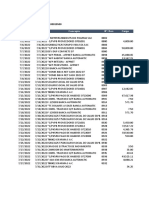

CUSTOMER / CLIENT : MAIRON GALATI SA INSPECTION CERTIFICATE 20607255 ORDER / COMANDA : 800009/50064988

PRODUCT / PRODUS : HOT ROLLED HEAVY PLATES DISPATCH / AVIZ EXPEDITIE : 7001294864

STEEL GRADE/MARCA OTEL: S355J2+N ACCORDING TO : EN 10204/2004/3.1 WAGON / ID TRANSPORT : DB86MTS/DB10MAT-

NORM / STANDARD : EN 10025/2-2004; DATE : 05.11.2019 TRACKING NO. :

PO.NO. : Noiembrie 2019

TOTAL NUMBER OF PIECES: 11 / TOTAL WEIGHT: 15.446,00 KG

NO PLATE HEAT NO CUST.MAT.CODE DIMENSIONS PC TEST NO WEIGHT UTS YTS L0 El Type_ Temp CHPVL CHPVL CHPVL KV Test

CHPV

MMxMMxMM N/mm2 N/mm2 mm % °C J J J

1 474781/1019/1/1 Y913776 6,00x2000x12000 1 2678 1.130 514 373 70 27 5 -20 59 62 53 2678

2 472098/1019/1/2 Y913856 8,00x2000x12000 1 8186 1.507 563 441 80 25 7,5 -20 100 92 96 8186

3 472394/1019/4/2 Y913856 8,00x2000x12000 1 8906 1.507 553 432 80 26 7,5 -20 80 90 85 8906

4 472394/1019/4/3 Y913856 8,00x2000x12000 1 8906 1.507 553 432 80 26 7,5 -20 80 90 85 8906

5 472639/1019/1/3 Y914159 8,00x2000x12000 1 8901 1.507 576 395 0 7,5 -20 80 86 76 8901

6 473180/1019/2/2 Y925215 6,00x2000x12000 1 884 1.130 494 419 80 26 7,5 -20 86 80 82 884

7 472656/1019/2/3 Y937503 6,00x2000x12000 1 8893 1.130 517 426 70 26 5 -20 55 50 48 8893

8 472638/1019/1/1 Y937505 8,00x2000x12000 1 8897 1.507 522 411 80 29 7,5 -20 95 97 90 8897

9 472638/1019/1/2 Y937505 8,00x2000x12000 1 8897 1.507 522 411 80 29 7,5 -20 95 97 90 8897

10 472643/1019/3/1 Y937517 8,00x2000x12000 1 8905 1.507 544 428 80 26 7,5 -20 103 96 96 8905

11 472643/1019/3/2 Y937517 8,00x2000x12000 1 8905 1.507 544 428 80 26 7,5 -20 103 96 96 8905

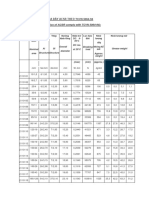

CHEMICAL COMPOSITION (%) - L = Heat , P = Product

HEAT NO ---C-- --Si-- --Mn-- ---P-- ---S-- --Al-- --As-- --Ti-- ---V-- --Cu-- --Ni-- --Cr-- --Mo-- --Nb-- ---B-- --H2-- --N2-- --Zr-- --Ca-- --Sn-- CEV2

L 913776 0,17 0,22 1,47 0,009 0,009 0,042 0,0000 0,002 0,002 0,02 0,01 0,02 0,002 0,002 0,0004 0,0001 0,0105 0,0000 0,0008 0,0000 0,42

L 913856 0,18 0,20 1,51 0,012 0,004 0,037 0,0000 0,002 0,002 0,03 0,02 0,03 0,007 0,002 0,0004 0,0002 0,0044 0,0000 0,0010 0,0000 0,44

L 914159 0,18 0,22 1,48 0,010 0,003 0,026 0,0000 0,002 0,002 0,03 0,01 0,02 0,001 0,003 0,0004 0,0006 0,0070 0,0000 0,0001 0,0000 0,43

L 925215 0,09 0,27 1,10 0,009 0,005 0,042 0,0000 0,016 0,002 0,03 0,02 0,03 0,003 0,017 0,0002 0,0002 0,0070 0,0000 0,0000 0,0000 0,29

L 937503 0,15 0,17 1,05 0,015 0,004 0,026 0,0000 0,002 0,002 0,03 0,01 0,02 0,003 0,001 0,0003 0,0002 0,0068 0,0000 0,0007 0,0000 0,34

L 937505 0,15 0,21 1,09 0,016 0,005 0,037 0,0000 0,002 0,002 0,03 0,02 0,02 0,004 0,001 0,0003 0,0002 0,0048 0,0000 0,0012 0,0000 0,34

L 937517 0,17 0,22 1,47 0,015 0,003 0,030 0,0000 0,003 0,002 0,02 0,01 0,02 0,006 0,002 0,0003 0,0001 0,0042 0,0000 0,0018 0,0000 0,42

Steelmaking process: Delivery condition: Normalizing rolled THIRD PART INSPECTION HEAD OF QUALITY CONTROL

Made by BOF-Continuous Casting BORS IONUT

Galvanizing class Checking of marking,surface,shape and

dimensions-ok

Carbon equivalent formula: Surface: EN 10163/2-2004,class A,subclass 1

CEV2 = C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15 SIGNATURE

Tolerance:

Sizes: EN 10029/2010,tab,1 class

A,tab.2,tab.3

Flatness: EN 10029/2010,class N, tab.4

ADAMACHE PROFIRA

INSPECTOR'S STAMP INSPECTOR

LIBERTY GALATI S.A. No.1 Calea Smirdan, We hereby certify that the material has been made by an approved process and satisfactorily tested in accordance with the requirements specified in the order with Cod: F SAP 017 rev.1

Galati, Postcode 800698, Romania satisfactory results. All raw materials used in steel production are tested for radioactive contamination. Therefore we guarantee, that our products are free of

radioactive contamination and do not exceed the clearing limit value of 0,1 Bq/g, according with the Radiation Protection Ordinance (StrlSchVO Annex III, Section 5) Page:1 /01

www.libertygalati.ro

You might also like

- 2010 - Caliber JEEP BOITE T355Document484 pages2010 - Caliber JEEP BOITE T355thierry.fifieldoutlook.comNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionFrom EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionNo ratings yet

- Boost productivity and networking with a co-working café in Iligan CityDocument4 pagesBoost productivity and networking with a co-working café in Iligan CityJewel Cabigon0% (1)

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Arcelormittal Galati S.A. - Romania: Inspection Certificate 20564275 According To: en 10204/2004/3.1 Date: 26.11.2018Document1 pageArcelormittal Galati S.A. - Romania: Inspection Certificate 20564275 According To: en 10204/2004/3.1 Date: 26.11.2018Felicia Cioaba100% (2)

- Inventory Valiuation Raw QueryDocument4 pagesInventory Valiuation Raw Querysatyanarayana NVSNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Cooling Tower FundamentalsDocument17 pagesCooling Tower FundamentalsGaurav RathoreNo ratings yet

- Risus License Information PDFDocument1 pageRisus License Information PDFSam CorbenNo ratings yet

- Method Statement For Planter WaterproofingDocument8 pagesMethod Statement For Planter WaterproofingMonali Varpe0% (1)

- 1 MergedDocument93 pages1 MergedAditiNo ratings yet

- Fe 66 Hospital Granada Jul-29Document2 pagesFe 66 Hospital Granada Jul-29Oscar BerruecosNo ratings yet

- Liberty Galati S.A. - Romania: Inspection Certificate 20614009 ACCORDING TO: EN 10204/2004/3.1 DATE: 20.01.2020Document1 pageLiberty Galati S.A. - Romania: Inspection Certificate 20614009 ACCORDING TO: EN 10204/2004/3.1 DATE: 20.01.2020Felicia CioabaNo ratings yet

- Liberty Galati S.A. - Romania: Inspection Certificate 20617901 ACCORDING TO: EN 10204/2004/3.1 DATE: 16.02.2020Document1 pageLiberty Galati S.A. - Romania: Inspection Certificate 20617901 ACCORDING TO: EN 10204/2004/3.1 DATE: 16.02.2020Felicia CioabaNo ratings yet

- Tabel Percobaan Flow MeasuringDocument5 pagesTabel Percobaan Flow MeasuringLutfhi HanafiNo ratings yet

- Fluid Report: Client: Unit: Project: Location: Tag: FilenameDocument2 pagesFluid Report: Client: Unit: Project: Location: Tag: FilenameAnonymous C05BLcNo ratings yet

- Datasheet KPPDocument1 pageDatasheet KPPRogelio LiceaNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Pled2 08l 5k As Un Na G l1Document3 pagesPled2 08l 5k As Un Na G l1robertovm2002No ratings yet

- Bulletins Victaulic ConnectionsDocument5 pagesBulletins Victaulic Connectionstahar lyesNo ratings yet

- 805AA Flexor 5 SAE 100 R5: Wire BraidDocument1 page805AA Flexor 5 SAE 100 R5: Wire BraidRodrigo Pessoa VespaNo ratings yet

- Movimientos en Moneda NacionalDocument4 pagesMovimientos en Moneda NacionalBETANCOURT PI�A NICOLENo ratings yet

- Analisis BetaDocument3 pagesAnalisis Betavalentina GonzalezNo ratings yet

- BUL 4462 Product Overview Hose Bulletin UK MainDocument4 pagesBUL 4462 Product Overview Hose Bulletin UK MainTuan buivietNo ratings yet

- SMD (ZV)Document15 pagesSMD (ZV)Igor PNo ratings yet

- Parts inventory document cost analysisDocument62 pagesParts inventory document cost analysisEdwinNo ratings yet

- So Part 3Document174 pagesSo Part 3EdwinNo ratings yet

- Bbva Soles Ago 2022.Document16 pagesBbva Soles Ago 2022.Andres Luna PilaresNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Tuberia PVC y CPVC SCH 80Document1 pageTuberia PVC y CPVC SCH 80Ramón PortocarreroNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Denji Copper Tube Price ListDocument2 pagesDenji Copper Tube Price ListMartin TjoaNo ratings yet

- DIEPA X4 Serie navigation rope specificationsDocument9 pagesDIEPA X4 Serie navigation rope specificationssebastianvmNo ratings yet

- Movimentação de Entrada e Saída de Produtos e Notas FiscaisDocument11 pagesMovimentação de Entrada e Saída de Produtos e Notas FiscaisJose EduardoNo ratings yet

- Quotation Oferta-23-0293 Rev1 EFV KIBO VINSON Tejado 1 20230523Document4 pagesQuotation Oferta-23-0293 Rev1 EFV KIBO VINSON Tejado 1 20230523Juan PalomoNo ratings yet

- Profit and administrative expenses report for Golden Inn HotelDocument82 pagesProfit and administrative expenses report for Golden Inn HotelAlejandro GonzalezNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Hydro N Matic - Indonesia - IfanDocument1 pageHydro N Matic - Indonesia - IfanPutra SNo ratings yet

- Daftar Persediaan Unit Rumah Janatipark Per Tanggal 3 Oktober 2017 Ready Stock Harga Harga Lama Kenaikan 2,4% KERASDocument13 pagesDaftar Persediaan Unit Rumah Janatipark Per Tanggal 3 Oktober 2017 Ready Stock Harga Harga Lama Kenaikan 2,4% KERASNdank SutrisnoNo ratings yet

- Ap Markfe Bud)Document2 pagesAp Markfe Bud)Venu KumarNo ratings yet

- Calibre Z (Ohm/Km) Z (Ohm/M) Long Tramoz (Tramo) Volt LineaDocument2 pagesCalibre Z (Ohm/Km) Z (Ohm/M) Long Tramoz (Tramo) Volt LineaHermes SotaquiraNo ratings yet

- KetulDocument5 pagesKetulNikhil OjhaNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- HMB From HYSYSDocument9 pagesHMB From HYSYSmuhammad lukmanNo ratings yet

- 4220-0104-009 List of Commissioning Equipment Rev ADocument4 pages4220-0104-009 List of Commissioning Equipment Rev AqaiserNo ratings yet

- Deni̇s Gi̇yi̇mDocument2 pagesDeni̇s Gi̇yi̇mozel tekstilNo ratings yet

- Catalogo de Motores Weq I-2018 PDFDocument75 pagesCatalogo de Motores Weq I-2018 PDFLuis Alberto Miranda TerrazasNo ratings yet

- Packing List CB10000039Document7 pagesPacking List CB10000039TarunNo ratings yet

- Form Pengajuan Warranty ClaimDocument4 pagesForm Pengajuan Warranty ClaimAstrid Dwi PutryNo ratings yet

- New Holland Parts List May 2020Document1,636 pagesNew Holland Parts List May 2020fabianofg250% (1)

- Praktikum Propulsi BDocument5 pagesPraktikum Propulsi BMokoNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Micron Transformer ADocument1 pageMicron Transformer AÁngel HernándezNo ratings yet

- Luminaria 1 CanchaDocument3 pagesLuminaria 1 CanchaMarcos HernandezNo ratings yet

- Catalogo Tenaz e Garras de Içamento (Tecnico)Document34 pagesCatalogo Tenaz e Garras de Içamento (Tecnico)Perfinaço Segurança [Perfinaço]No ratings yet

- GPI Price List Rucika Wavin Lite Maret 2018Document1 pageGPI Price List Rucika Wavin Lite Maret 2018Budi SantonyNo ratings yet

- Construction Materials ReportDocument3 pagesConstruction Materials ReportPhilippeJonathanKouassiNo ratings yet

- Program calculates vapor pipe pressure dropDocument4 pagesProgram calculates vapor pipe pressure dropwestewrNo ratings yet

- ĐẶC TÍNH KỸ THUẬT CỦA DÂY ACSR THEODocument2 pagesĐẶC TÍNH KỸ THUẬT CỦA DÂY ACSR THEONcodeAnhNo ratings yet

- 2c9 - MC & SC DetailsDocument47 pages2c9 - MC & SC DetailsKumarNo ratings yet

- PTC Thermistors For Overcurrent Protection: Leaded Disks, Coated, 230 VDocument17 pagesPTC Thermistors For Overcurrent Protection: Leaded Disks, Coated, 230 VJohnDoeNo ratings yet

- VMOTODocument2 pagesVMOTOAna Cristina RibeiroNo ratings yet

- Technical information on tensile strength, tightening torque and stainless steelDocument13 pagesTechnical information on tensile strength, tightening torque and stainless steelAngelo PereiraNo ratings yet

- Air-Compressor User ManualDocument67 pagesAir-Compressor User ManualSAMIR BEL HADJ HMIDANo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Decl Conf MSA 10015364 LZYF 345258Document1 pageDecl Conf MSA 10015364 LZYF 345258Felicia CioabaNo ratings yet

- Certificat de Calitate TobimarDocument1 pageCertificat de Calitate TobimarFelicia CioabaNo ratings yet

- STEM Challenges - Description 1Document23 pagesSTEM Challenges - Description 1Felicia CioabaNo ratings yet

- Quality Management Certified SystemDocument1 pageQuality Management Certified SystemFelicia CioabaNo ratings yet

- 93329e0 4823smart PDFDocument1 page93329e0 4823smart PDFFelicia CioabaNo ratings yet

- DoP - ARCWELD - AS2 - LEA - 617 - 0Document1 pageDoP - ARCWELD - AS2 - LEA - 617 - 0Felicia Cioaba100% (1)

- CQF Internet User Manual For Suppliers - ENG PDFDocument63 pagesCQF Internet User Manual For Suppliers - ENG PDFFelicia CioabaNo ratings yet

- CS Sec IDocument7 pagesCS Sec IFelicia CioabaNo ratings yet

- Inspection Certificate for ARCWELD G3Si1 WireDocument1 pageInspection Certificate for ARCWELD G3Si1 WireFelicia CioabaNo ratings yet

- Dec Conf CabluDocument3 pagesDec Conf CabluFelicia CioabaNo ratings yet

- Sample Prayer For Final Thesis DefenseDocument6 pagesSample Prayer For Final Thesis Defensefjfyj90y100% (2)

- Consumer PerceptionDocument61 pagesConsumer PerceptionPrakhar DwivediNo ratings yet

- Microsoft Security Product Roadmap Brief All Invitations-2023 AprilDocument5 pagesMicrosoft Security Product Roadmap Brief All Invitations-2023 Apriltsai wen yenNo ratings yet

- Since 1977 Bonds Payable SolutionsDocument3 pagesSince 1977 Bonds Payable SolutionsNah HamzaNo ratings yet

- FND Global and FND Profile PDFDocument4 pagesFND Global and FND Profile PDFSaquib.MahmoodNo ratings yet

- TN Govt RecruitmentDocument12 pagesTN Govt RecruitmentPriyanka ShankarNo ratings yet

- Timesheet 25Document1 pageTimesheet 25Gwenzieh TugadeNo ratings yet

- WhatsoldDocument141 pagesWhatsoldLuciana KarajalloNo ratings yet

- Pro Ducorit UkDocument2 pagesPro Ducorit Uksreeraj1986No ratings yet

- LQRDocument34 pagesLQRkemoNo ratings yet

- Hercules Segers - Painter EtchterDocument4 pagesHercules Segers - Painter EtchterArtdataNo ratings yet

- Mfi in GuyanaDocument19 pagesMfi in Guyanadale2741830No ratings yet

- A Critical Review: Constructive Analysis in English and Filipino 1 SEMESTER 2021-2022Document4 pagesA Critical Review: Constructive Analysis in English and Filipino 1 SEMESTER 2021-2022roseNo ratings yet

- Assessment of Concrete Strength Using Flyash and Rice Husk AshDocument10 pagesAssessment of Concrete Strength Using Flyash and Rice Husk AshNafisul AbrarNo ratings yet

- Diesel fuel system for Caterpillar 3208 engineDocument36 pagesDiesel fuel system for Caterpillar 3208 engineLynda CarrollNo ratings yet

- Netutils ToturialDocument35 pagesNetutils ToturialLuis SanchoNo ratings yet

- Quick Reference To Psychotropic Medications: AntidepressantsDocument2 pagesQuick Reference To Psychotropic Medications: AntidepressantsNaiana PaulaNo ratings yet

- Barcode BasicsDocument3 pagesBarcode Basicsnikhilbajpai_88No ratings yet

- FLANSI CAP SONDA CatalogsDocument30 pagesFLANSI CAP SONDA CatalogsTeodor Ioan Ghinet Ghinet DorinaNo ratings yet

- P150EDocument4 pagesP150EMauro L. KieferNo ratings yet

- Parison of Dia para FerroDocument4 pagesParison of Dia para FerroMUNAZIRR FATHIMA F100% (1)

- Get TRDocDocument209 pagesGet TRDoc10131No ratings yet

- Latest Information Technology Trends 2023Document5 pagesLatest Information Technology Trends 2023Salveigh C. TacleonNo ratings yet