Professional Documents

Culture Documents

Thermography of Window Panes-Pinno

Uploaded by

alexanderCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermography of Window Panes-Pinno

Uploaded by

alexanderCopyright:

Available Formats

Thermography of Window Panes –

Problems, Possibilities and Troubleshooting

F. Pinno, K.-P. Möllmann and M. Vollmer,

Brandenburg University of Applied Sciences, Germany

ABSTRACT

Building-thermography measurements of window panes are not only eye catchers due to their different

properties regarding thermal reflections but they are also important for quantitatively analyzing the building

envelope. In order to do so, the emissivity needs to be determined. This can be realized using transmission

and reflection measurements. We studied different window systems (side wall windows as well as velux type

sky light windows) in real buildings as well as a number of simple model systems of single, dual and triple

pane windows. This paper will report results of these measurements and discuss observed problems of

condensation water and dew point, design faults and gas leaks in the insulating glazing systems.

INTRODUCTION

Today we face global climate change and limited supply of non renewable energy resources such as oil and

gas with record prices for oil. The associated costs for industry and the private sector inevitably lead to the

goal of reducing the energy consumption of buildings. Typically, 20% - 30% of the energy inside of buildings

is lost through the window panes. Decreasing the energy flow through window systems is therefore an

important topic today and in the future. The use of dual and triple pane windows with insulating glasses is an

improvement in comparison to single pane windows. Figure 1 gives a typical example for outdoor

thermography. Obviously, the windows are the most prominent features in the IR image. A comparison of

window A and B illustrates the difference between the thermal energy flow through single pane (A) and dual

pane (B) windows. Very often, IR images of windows seem to indicate huge energy flows through the

building envelope but, is this really the case? In order to compare the energy flow exact temperature

measurements of different window systems are necessary. In this paper we want to focus on this problem.

Figure 1. IR imaging of a single (A) and dual (B) pane window with LW camera (left) and visible image (right).

LABORATORY EXPERIMENTS: TRANSMISSION, REFLECTION AND EMISSIVITY OF WINDOWS

In order to study general properties of windows in detail, we developed models for single, as well as air filled

dual and triple pane windows. Each window can be quantitatively characterized by emissivity ε(λ), reflection

r(λ), and transmission t(λ). These are related via Eq. 1:

ε (λ ) = 1 − t (λ ) − r (λ ) (1).

Spectra of t(λ) and r(λ) were recorded with a BRUKER IFS 66 IR spectrometer at an ambient temperature of

T=20°C in the wavelength range of 2.5-18 µm. The model windows had glass thickness of 4 mm and pane

distances of 12 mm (fig. 2). Figure 3 shows spectra for reflection (3a) and transmission (3b) of the single,

InfraMation 2008 Proceedings ITC 126 A 2008-05-14

dual and triple pane window systems. Comparable spectra for reflection and transmission of sheet glass are

shown in [1]. The emissivity ε(λ) is calculated used Eq. 1. The results are shown in Figure 4. Obviously,

there are selective absorption features due to interband absorption at λ= 10µm [2] which manifest themselves

in the reflection spectra (Figure 3a). This means that glass is not grey in the LW region. In the MW region

glass is nearly grey for dual and triple pane windows, but not for the single pane. One consequence is that

we expect problems with MW cameras if the type of window is not known. Problems may also occur in the LW

region. Typically one deals with this in the camera software by introducing average ε - values.

Figure 2. Model of single, dual and triple window Figure 3a. Reflection spectra of the model windows, recorded

panes; the spaces between windows can be filled at an angle of incidence α inc=20° with an FTIR spectrometer.

with gases (or air) or evacuated.

Figure 3b. Transmission spectra of model windows, Figure 4. Emissivity spectra of the model windows

recorded at α inc =0° with an FTIR spectrometer. following from Eq. 1.

In thermography, the emitted radiation from an object, which is detected by an IR camera can be written as

S 2 = const ∫ ε (λ ) ⋅ sens(λ ) ⋅ M (λ , T ) ⋅ tobj (λ ) dλ (2).

ε(λ) is the emissivity of the observed object (Figure 4), sens(λ) is the detector sensitivity [3], M(λ,Τ) is the

specific spectral emission and tobj describes the transmission of the IR camera optics (here tobj=1). Integration

limits are the used IR spectral ranges. For black bodies (ε=1) this signal would be larger (Eq. 3).

S 1 = const ∫ sens(λ ) ⋅ M (λ , T ) ⋅ tobj (λ ) dλ (3)

InfraMation 2008 Proceedings ITC 126 A 2008-05-14

If these two signals S1 and S2 were known, one could calculate the average emissivity εm of the object for the

chosen wavelength range of the camera (Eq. 4).

εm = S 2 / S 1 (4)

This procedure was used to estimate εm values for the window panes. The results for both IR-ranges and

different numbers of panes are shown in Table 1. In the MW range the pane number has an impact on εm. In

the LW range, no influence is expected. In addition the change of εm needs to be taken into account for a

direct comparison between MW and LW results. Griffith and others found comparable values of εm = 0.86 in

the LW range by analyzing spectral data for glass [4]. Obviously, there are many different types of glass

available, hence it is possible that εm values vary from case to case.

window emissivity emissivity

T=20°C εm εm

MW: (3.5-6µm) LW: (8-18µm)

single 0.9 0.87

pane

dual 0.95 0.87

pane

triple 0.96 0.87

pane

Table 1. Average emissivity εm of single, dual and triple

window panes in the MW and the LW range.

INFLUENCE OF AMBIENT AND BACKGROUND TEMPERATURE: LABORATORY EXPERIMENTS

In the following, a number of laboratory experiments will be presented in order to find out, whether ambient

temperature changes will have an influence on temperature measurements inside. Under realistic conditions

the ambient temperature Tamb outside of the building may change during measurements. We measured the

window temperature of the model windows with a MW camera (THV 550) and a LW camera (SC 2000) for

different conditions. All panes had a temperature between 26°C and 27°C, the atmosphere ambient

temperature was Tamb=27°C. The temperature of the background Tback varied from 11°C (this was realized

with a water tank) (Figure 5a) to 26°C (Figure 5b). Using the calculated emissivity (table1) for the analysis of

the IR images, we found too low window temperatures in the MW range (table 2) for the single pane window.

This can be explained using the schematic diagram of Figure 5c. The IR camera receives three radiation

contributions, in particular a contribution from transmitted background radiation. In the LW case, t=0 and

changes of Tback cannot affect measured signals. For the MW range, however the great t-values in particular

of the single pane window, will affect the signal. The reduction of the background temperature leads to a

lower detected radiation signal.

InfraMation 2008 Proceedings ITC 126 A 2008-05-14

Figure. 5a. Single pane, MW IR image of window, Figure 5b. Single pane MW IR image of window,

Tback=11°C. Tback=26°C.

The analysis is summarized in Table 2.

window MW MW

Tback=11°C Tback=26/27°C

average

surface camera setup camera setup

temperature

Tamb=27°C Tamb=27°C

T=26°/27°C

single pane

AR01 T/°C 24.7°C 25.9°C

dual pane

AR01 T/°C 26.3°C 26.6°C

Table 2. Average temperature AR01 of single and dual Figure 5c. Simple model of transmitted, emitted and

window panes in MW range with different conditions Tback. reflected parts of the detected signal.

Figure 6a. Dual pane, MW IR image of window, Figure 6b. Dual pane, MW IR image of window,

Tback=11°C. Tback=27°C.

The analysis is summarized in table 2.

Analogous measurements for a dual pane window are shown in Figure 6 a, b and Table 2. In this case, the

measured temperature does not depend on changes of background temperature. This was expected, since

t(λ) is very small for dual pane windows (Figure 3b).

InfraMation 2008 Proceedings ITC 126 A 2008-05-14

MEASUREMENTS OF REAL SINGLE AND DUAL PANE WINDOWS WITH INDOOR THERMOGRAPHY

In the MW and LW range we measured single and dual pane windows from inside (see also Figure 1a). The

ambient temperature inside was Tamb =22°C and the atmospheric temperature outside Tair=7°C. Using the

calculated emissivity (Table1) for the analysis of the IR images of single pane windows, we found also too low

window temperatures in the MW range (Figure7a). In the LW range, an exact temperature measurement is

possible (Figure 7b), if the exact ambient temperature is known.

The calculated temperatures of dual pane windows in the MW and LW range are nearly similar, due to the

influence of transmission in MW region is distinct lower (see Figure 3b).

Figure 7a. Single pane window MW range AR01 Figure 7b. LW range AR01 T=14.9°C.

T=14.1°C (lower part of window A of fFigure. 1).

The line of the middle is a window catch. It is warmer than the wall because it is directly above a heater.

INDOOR THERMOGRAPHY: VELUX SKY LIGHT WINDOWS, PROBLEMS OF CONDENSATION WATER

In winter and after cloudless nights one observes very often condensation water inside of sky light windows.

The reason for this problem is that Twindow is below the dew point temperature Tdp, which depends on the

ambient temperature and the relative humidity inside [5]. The IR image (SC 2000 in LW range) of such a dual

pane Velux sky light window (Figure 8a, b) illustrates this problem. The conditions inside are Tamb = 20°C and

a relative humidity of 60%, corresponding to a dew point temperature Tdp= 11.7°C [5]. In the profile LI 01

(Figure 8a, b) we find a lower temperature at the edge.

Figure 8a. IR image of a Velux sky light window. The Figure 8b. Temperature profile along LI 01 in Figure 8a.

object on the upper left corner is an electric motor for The dew point was Tdp=12°C.

opening the window.

InfraMation 2008 Proceedings ITC 126 A 2008-05-14

OUTDOOR THERMOGRAPHY: PROBLEMS ASSOCIATED WITH RADIATION TO SKY AND SURROUNDINGS

Night sky problems are analyzed in a comparison paper of K.-P. Möllmann et. al. [6]. Here we just want to

show a few examples of incorrect interpretations of temperature measurements with the LW camera (Figure

9a, b). In the IR image (Figure 9a) there are different tilt angles of the windows with respect to the zenith.

Window (A) has a large tilt angle (angle between surface normal and direction of zenith) in comparison to the

sky light window (C). Therefore, the sky light window C can be more effectively cooled (details, see [6]). In

addition we found in part B of the left window (see Figure 9a) a reflection of roof overhang. In Figure 9b

depicts reflections of a balcony (D) on a window. These examples show some difficulties of exact outside

temperature measurements, which could lead to misinterpretations of thermal images.

Figure 9a. Sky light problems (A) large tilt angle with Figure 9b. Reflection of balcony (D).

respect to the zenith; (C) less tilt angle; (B) reflection of

roof overhang.

COMPARISON OF INDOOR AND OUTDOOR THERMOGRAPHY: PROBLEMS OF SUN AND SHADOW

Other misinterpretations of IR images of windows are possible, in particular also when the temperature

measurement was inside. As an example the analysis of the IR image (LW range) of Figure 10b, without

consideration of conditions outside, could lead to the conclusion, that part of the window (B) is defect, e.g.,

due to a gas leak (Figure 10b). The conditions outside are obvious from Figure 10a. Part of the window (B)

is in the shadow of a building opposite of this window and the higher temperature of the part (A) is an effect of

direct IR irradiation by the sun.

Figure 10a. Sun (A) and shadow (B) at different parts Figure 10b. IR image of dual pane windows from inside.

of dual pane windows. Different temperatures result from different conditions

outside. They are not an effect of a gas leak.

InfraMation 2008 Proceedings ITC 126 A 2008-05-14

COMPARISON OF INDOOR AND OUTDOOR THERMOGRAPHY: GAS LEAK IN THE INSULATING GLAZING SYSTEM

In the final example we want to discuss problems of comparison of indoor and outdoor thermography. With

the LW camera we found a problem of a gas leak in a part of a dual pane window (A), (see Figure 11a, b).

The insulating glass filled with dry air or special gases (mostly argon is used) was damaged, i.e., energy loss

and therefore a lower surface temperature from inside and higher surface temperature from outside was due

to a broken window seal.

A second problem (B) is presented in Figure 11b. The broken rubber gasket between the window frame and

the window itself leads to higher energy loss. With outdoor thermography we couldn’t detect this problem (B)

(see Figure 11a), since reflected radiation from the window frame overhang was dominating and therefore

hiding this thermal leakage.

Figure 11a. Detection of problems outside, A gas leak; Figure 11b. IR image inside, A gas leak, B defect

B reflection of window frame overhang. rubber gasket.

SUMMARY

IR thermal imaging inspections of several window systems have been reported. Thermography can help to

quantitatively analyze the energy loss of buildings. Transmission and reflection measurements from model

windows allow the estimating of emissivities of single, dual and triple window panes in the MW and LW range.

Therefrom average εm values for an analysis can be derived. The influence of ambient and background

temperature were investigated with measurements using simple models of window systems and real single

and dual pane windows. In addition we discussed observed problems of sky light windows, condensation

water, the influence of night sky radiation losses, problems due to direct radiation and shadows, as well as

real gas leaks in an insulating glazing system.

REFERENCES

[1] Holst, G.C.; “Common sense approach to thermal imaging” SPIE PRESS JCD Publishing, Bellingham,

Washington USA, 2000

[2] SCHOTT; “TIE35 Transmittance of optical glass” internet source for download: http://www.us.schott.

com/advanced_optics/english/technical_articles.html

[3] Vollmer, M.; Möllmann, K.P.; F. Pinno.; “Looking through matter: quantitative IR imaging when

observing through IR windows” Inframation 2007 Proceedings, Vol. 8, ITC 121A 2007-05-24, 109-128

[4] Griffith, B. T.; Türler, D.; Arasteh, D.; “Surface temperatures of insulating glazing units: infrared

thermography laboratory measurements” ASHRAE transactions 1996, V. 102 PT. 2., internet source for

download: http://gaia.lbl.gov/btech/papers/47373.pdf

[5] internet source for download: http://mvddaq.desy.de/~mvddaq/SC/Tdew.html

[6] Möllmann, K.P.; Vollmer, M.; F. Pinno.; “Night sky radiant cooling – influence on outdoor thermal

imaging analysis” Inframation 2008 Proceedings, ITC 126A 2008-05-14

InfraMation 2008 Proceedings ITC 126 A 2008-05-14

ACKNOWLEDGEMENTS

The authors wish to thank T. Trull for reflection and transmission measurements and T. Dorenburg for

discussions.

ABOUT THE AUTHOR

Frank Pinno studied physics in Potsdam, Germany where he received his PhD (1991) in solid state physics.

Since 1994, he has been employed as a scientific assistant (physics) at the University of Applied Sciences in

Brandenburg, Germany, working in the field of infrared thermal imaging and projects in applied sciences.

Frank is a Certified Level II Thermographer.

K.-P. Möllmann studied physics in Halle and Berlin receiving his PhD in 1983 and Habilitation (1989) in solid

state physics, in particular in the development of HgCdTe infrared detectors. Since 1994 he has been a

professor of physics at the University of Applied Sciences, in Brandenburg, Germany. He has worked in

infrared thermal imaging, pyrometry, thin film and MEMS technology and is a Certified Level II

Thermographer.

Michael Vollmer studied physics in Heidelberg, Germany, receiving a PhD (1986) and Habilitation (1991) in

optical spectroscopy of metal clusters. Since 1994 he has been a professor of physics at the University of

Applied Sciences in Brandenburg/Germany, working in the fields of infrared thermal imaging, spectroscopy,

atmospheric optics, and didactics of physics. He is a certified Level II Thermographer.

InfraMation 2008 Proceedings ITC 126 A 2008-05-14

You might also like

- Shutter LessDocument8 pagesShutter LessMahgul khanNo ratings yet

- Solar Collectors: Solar District Heating GuidelinesDocument15 pagesSolar Collectors: Solar District Heating GuidelinesbonochoppersNo ratings yet

- Electronics 3 Checkbook: The Checkbooks SeriesFrom EverandElectronics 3 Checkbook: The Checkbooks SeriesRating: 5 out of 5 stars5/5 (1)

- Measuring Toxic Gases Using Low-Cost Electrochemical SensorsDocument6 pagesMeasuring Toxic Gases Using Low-Cost Electrochemical SensorsIvan KraljNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Paper - COMSOL Conference 2008 HannoverDocument8 pagesPaper - COMSOL Conference 2008 HannoverDennis van GochNo ratings yet

- 1 s2.0 S0038092X22005679 mmc1Document9 pages1 s2.0 S0038092X22005679 mmc1cristiancobos712No ratings yet

- Module Temperature Estimation Using AnfisDocument12 pagesModule Temperature Estimation Using AnfissakthigokulNo ratings yet

- Antenna Impedance MeasurementsDocument5 pagesAntenna Impedance Measurementsbayman66No ratings yet

- Maldague - Applications of Infrared Thermography in Nondestructive Evaluation PDFDocument23 pagesMaldague - Applications of Infrared Thermography in Nondestructive Evaluation PDFFilipehenriqueNo ratings yet

- Lab 6Document7 pagesLab 6Bhupender SharmaNo ratings yet

- Liebmann - Testing Temperature Uniformity On A Flat-Plate Infrared CalibratorDocument6 pagesLiebmann - Testing Temperature Uniformity On A Flat-Plate Infrared CalibratorCristian MendezNo ratings yet

- Numerical Methods in Termal Zvonko Radmi 2011Document7 pagesNumerical Methods in Termal Zvonko Radmi 2011Zvonko DamnjanovicNo ratings yet

- Determine Coefficient of Thermal Expansion Using Fizeau InterferometerDocument6 pagesDetermine Coefficient of Thermal Expansion Using Fizeau InterferometerABHRANEIL BHATTACHARYANo ratings yet

- Corbell ADocument10 pagesCorbell AИван КосмонавтNo ratings yet

- Sipm: Characterizations, Modelling and Vlsi Front-End Dedicated DevelopmentDocument11 pagesSipm: Characterizations, Modelling and Vlsi Front-End Dedicated DevelopmentNiranjan Kumar PNo ratings yet

- 4 ProbeDocument7 pages4 ProbeSayyed SalmanNo ratings yet

- Procedure: Introduction To SIMULINK AM Modulation and DemodulationDocument15 pagesProcedure: Introduction To SIMULINK AM Modulation and DemodulationypobuleshNo ratings yet

- Calculation of PV Module Angular Losses Using Analytical ModelDocument14 pagesCalculation of PV Module Angular Losses Using Analytical ModelFelipe Aarón KusNo ratings yet

- Models - Heat.cavity Radiation PDFDocument16 pagesModels - Heat.cavity Radiation PDFIsaac Elías Sáez AlfaroNo ratings yet

- Night Sky Radiant Cooling - Influence On Outdoor Thermal Imaging AnalysisDocument18 pagesNight Sky Radiant Cooling - Influence On Outdoor Thermal Imaging AnalysisayviwurbayviwurbNo ratings yet

- Sensor Fault Detection in Building Energy Management SystemsDocument5 pagesSensor Fault Detection in Building Energy Management SystemsAliqpsk AlasadyNo ratings yet

- 0 SolTermDocument49 pages0 SolTermdgil_371591No ratings yet

- Am2c09063 Si 003Document13 pagesAm2c09063 Si 003Neurodynamics (NeuroDynamic Software)No ratings yet

- Stefan Boltzmann DerivationDocument4 pagesStefan Boltzmann DerivationVlado VargasNo ratings yet

- CFD Validation in OECD NEA T-Junction BenchmarkDocument33 pagesCFD Validation in OECD NEA T-Junction BenchmarkMilena RemptoNo ratings yet

- Optical Characterisation of La0 7Sr0 3MnDocument5 pagesOptical Characterisation of La0 7Sr0 3MnbjsimardNo ratings yet

- Validation of Radiation Computations Using Viewfactors and COMSOL's Hemicube ApproachesDocument7 pagesValidation of Radiation Computations Using Viewfactors and COMSOL's Hemicube Approachesindika.pereraNo ratings yet

- EXPERIMENT #1: Investigation of The Dynamic Characteristic of The DSB September 23, 2019Document10 pagesEXPERIMENT #1: Investigation of The Dynamic Characteristic of The DSB September 23, 2019Seth Adriel BaldovinoNo ratings yet

- Solutions For Exercises: Solutions For Exercises For "Introduction To Microsystem Technology: A Guide For Students"Document39 pagesSolutions For Exercises: Solutions For Exercises For "Introduction To Microsystem Technology: A Guide For Students"Mario PajaNo ratings yet

- Feb PeroDocument6 pagesFeb PeroSadaf KhanNo ratings yet

- Modular General Physics 2Document5 pagesModular General Physics 2Annabelle Gauiran-TacadenaNo ratings yet

- Task Description: Principles of Remote SensingDocument7 pagesTask Description: Principles of Remote SensingPabloYmeriNo ratings yet

- T (z, t) = T T is amplitude of the oscillating temperature, z the depth below the surface, λ is theDocument7 pagesT (z, t) = T T is amplitude of the oscillating temperature, z the depth below the surface, λ is theyansyahprasetyoNo ratings yet

- Principle, Advantages, Limitations and Applications of Two-Colour Pyrometers in Thermal ProcessesDocument8 pagesPrinciple, Advantages, Limitations and Applications of Two-Colour Pyrometers in Thermal ProcessesVanbeverNo ratings yet

- Radiatergdfgadgergeg 43trf 34frefDocument10 pagesRadiatergdfgadgergeg 43trf 34frefjack jackNo ratings yet

- TN45 - Thermography and Facades (9 PP)Document9 pagesTN45 - Thermography and Facades (9 PP)Steve MarrNo ratings yet

- 1084-Article Text-4047-1-10-20080721Document7 pages1084-Article Text-4047-1-10-20080721Phạm Hải ĐăngNo ratings yet

- Opto-Electro-Thermal Model of A VCSEL Array Using VHDL-AMSDocument5 pagesOpto-Electro-Thermal Model of A VCSEL Array Using VHDL-AMSalavanthar_tNo ratings yet

- Solar Radiation Modeling and Measurements For Renewable Energy Applications: Data and Model QualityDocument15 pagesSolar Radiation Modeling and Measurements For Renewable Energy Applications: Data and Model QualitymilloteNo ratings yet

- Abdelhakim Zouaki Et Cong Vu Huy EmcaDocument14 pagesAbdelhakim Zouaki Et Cong Vu Huy EmcaLuis Carlos Gonzales FuertesNo ratings yet

- Four ProbeDocument5 pagesFour Probesalman suhailNo ratings yet

- Hall Effect BestDocument8 pagesHall Effect BestSaikat PayraNo ratings yet

- Using Software Gambit 2.0 and Fluent 6.0 For Simulation of Heat Mass Transfer ProblemsDocument11 pagesUsing Software Gambit 2.0 and Fluent 6.0 For Simulation of Heat Mass Transfer ProblemsJasim Al-rubayieNo ratings yet

- Ex1 SolutionDocument6 pagesEx1 SolutionArifiantoNo ratings yet

- Thermal losses in a new CLFR non-evacuated collector cavityDocument6 pagesThermal losses in a new CLFR non-evacuated collector cavityPedro HortaNo ratings yet

- MatLab - Advanced Simulation of Building Systems and Control With SimulinkDocument8 pagesMatLab - Advanced Simulation of Building Systems and Control With SimulinkAlberto Lopez SanchezNo ratings yet

- Lab 1 SolarDocument23 pagesLab 1 SolardanielNo ratings yet

- Mathematical Optimization of Solar Thermal Collectors Efficiency Function Using MATLABDocument5 pagesMathematical Optimization of Solar Thermal Collectors Efficiency Function Using MATLABSantiago Del Rio OliveiraNo ratings yet

- Lab 03 - Earths Temperature SP 22Document13 pagesLab 03 - Earths Temperature SP 22Klutch BoyNo ratings yet

- Monitoring of Grid Tied Photovoltaic System Efficiency in Operating ConditionsDocument4 pagesMonitoring of Grid Tied Photovoltaic System Efficiency in Operating ConditionskubikNo ratings yet

- Landsat DN To KelvinDocument4 pagesLandsat DN To KelvinldsancristobalNo ratings yet

- NEMO2022 KARRAME KhalilDocument5 pagesNEMO2022 KARRAME KhalilMichel CresseauxNo ratings yet

- Air Temperature Measurement Uncertainty Associated To A Mounting Configuration Temperature Sensor-Radiation ShieldDocument9 pagesAir Temperature Measurement Uncertainty Associated To A Mounting Configuration Temperature Sensor-Radiation ShieldMuhammad RidwanNo ratings yet

- tmpC929 TMPDocument13 pagestmpC929 TMPFrontiersNo ratings yet

- Efficiencies of Flat Plate Solar Collectors at Different Flow RatesDocument8 pagesEfficiencies of Flat Plate Solar Collectors at Different Flow Ratesamar m'hammedNo ratings yet

- H&MT Lab Manual.Document47 pagesH&MT Lab Manual.Adil AhmedNo ratings yet

- Science - Abg0291 SMDocument47 pagesScience - Abg0291 SMYong JinNo ratings yet

- Speed Measuring Unit User Manual (ESP-2000-B)Document9 pagesSpeed Measuring Unit User Manual (ESP-2000-B)alexander100% (6)

- Gen4000 Service W455H (Wash Machine)Document100 pagesGen4000 Service W455H (Wash Machine)alexanderNo ratings yet

- MAIHAK Shaft Power Meter MDS 840 Manual V1-1Document80 pagesMAIHAK Shaft Power Meter MDS 840 Manual V1-1alexander100% (2)

- Furuno DS 80 Service ManualDocument52 pagesFuruno DS 80 Service ManualNishant Pandya70% (10)

- Model Number StructureDocument12 pagesModel Number StructurealexanderNo ratings yet

- SRF HRF SSR DanjouxDocument12 pagesSRF HRF SSR Danjouxalexander100% (1)

- DSC 60Document132 pagesDSC 60alexanderNo ratings yet

- BFD-180-570 DN65 GBDocument25 pagesBFD-180-570 DN65 GBalexander100% (3)

- Stem Cell Use in Surgical Treatment of Tennis Elbow-SandickDocument8 pagesStem Cell Use in Surgical Treatment of Tennis Elbow-SandickalexanderNo ratings yet

- Ecdis Ec 1000: With Conning DisplayDocument184 pagesEcdis Ec 1000: With Conning DisplayalexanderNo ratings yet

- DS 30Document148 pagesDS 30alexanderNo ratings yet

- NETA Thermal Testing Criteria for Electrical EquipmentDocument1 pageNETA Thermal Testing Criteria for Electrical EquipmentalexanderNo ratings yet

- IR Theromgraphy in The NFL-GarzaDocument8 pagesIR Theromgraphy in The NFL-GarzaalexanderNo ratings yet

- EC1000 Conning&interfaceDocument198 pagesEC1000 Conning&interfacealexanderNo ratings yet

- IR For Triage in Emergency Medical Services-BrioschiDocument12 pagesIR For Triage in Emergency Medical Services-BrioschialexanderNo ratings yet

- Breast Thermography and Clinical Applications-MostovoyDocument6 pagesBreast Thermography and Clinical Applications-MostovoyalexanderNo ratings yet

- IR Thermography For Wildlife Exposed To Oil-Reese-DeyoeDocument14 pagesIR Thermography For Wildlife Exposed To Oil-Reese-DeyoealexanderNo ratings yet

- Thermography PrimerDocument28 pagesThermography PrimerR. Mega MahmudiaNo ratings yet

- IR Imaging in Engineering Applications - HuntDocument8 pagesIR Imaging in Engineering Applications - HuntalexanderNo ratings yet

- IR NDT On Aeronautical Plastics-Flores-BolarinDocument8 pagesIR NDT On Aeronautical Plastics-Flores-BolarinalexanderNo ratings yet

- IR Benefits-Thinking Outside The Box - BlackDocument12 pagesIR Benefits-Thinking Outside The Box - BlackalexanderNo ratings yet

- Infrared Techniques for Condition Assessment of Isolated Phase Bus DuctDocument6 pagesInfrared Techniques for Condition Assessment of Isolated Phase Bus DuctalexanderNo ratings yet

- High Speed IR For Machinability-Arriola AldamizDocument10 pagesHigh Speed IR For Machinability-Arriola AldamizalexanderNo ratings yet

- Lock in Thermography of Plasma Facing Components-Courtois ADocument12 pagesLock in Thermography of Plasma Facing Components-Courtois AalexanderNo ratings yet

- IR Theromgraphy in The NFL-GarzaDocument8 pagesIR Theromgraphy in The NFL-GarzaalexanderNo ratings yet

- IR Thermography in Sand Minining-BlanchDocument4 pagesIR Thermography in Sand Minining-BlanchalexanderNo ratings yet

- Guess The Real World Emissivity-DeMonteDocument14 pagesGuess The Real World Emissivity-DeMontealexanderNo ratings yet

- Finding Oil Filled Circuit Breaker Resistance With IRDocument8 pagesFinding Oil Filled Circuit Breaker Resistance With IRalexanderNo ratings yet

- Secrets of Bushing Oil Level-GoffDocument8 pagesSecrets of Bushing Oil Level-Goffalexander100% (1)

- Important Mesurements For IR Surveys in SubstationsDocument7 pagesImportant Mesurements For IR Surveys in SubstationsalexanderNo ratings yet

- International Journal of Pressure Vessels and PipingDocument3 pagesInternational Journal of Pressure Vessels and PipingVikas SharmaNo ratings yet

- sr20 Switchingsystems080222Document20 pagessr20 Switchingsystems080222Daniel BholahNo ratings yet

- Airworthiness StandardsDocument15 pagesAirworthiness StandardsJason RossNo ratings yet

- Haas Accessories FlyerDocument12 pagesHaas Accessories FlyerAndrewFranciscoNo ratings yet

- CRM Assignment FrankfinnDocument4 pagesCRM Assignment FrankfinnJyoti Choudhary60% (5)

- Chem 101 Fall17 Worksheet 2Document2 pagesChem 101 Fall17 Worksheet 2mikayla sirovatkaNo ratings yet

- Rock Guitar BookletDocument12 pagesRock Guitar BookletAnthony ChewNo ratings yet

- Best Clinical Embryology Courses in MaduraiDocument8 pagesBest Clinical Embryology Courses in MaduraiVaramreprogenesisNo ratings yet

- Ratan Tata A Great LeaderDocument7 pagesRatan Tata A Great LeaderRoshan MaharjanNo ratings yet

- Lighthouse Institute Mathematics Cala D 2023Document4 pagesLighthouse Institute Mathematics Cala D 2023Kudakwashe RushwayaNo ratings yet

- Content Focus (And Interaction) : Example: Live Lecture (Online or On Campus)Document6 pagesContent Focus (And Interaction) : Example: Live Lecture (Online or On Campus)Dominic LibradillaNo ratings yet

- LPG Cylinder Market Player - Overview (Bangladesh)Document5 pagesLPG Cylinder Market Player - Overview (Bangladesh)ABID REZA KhanNo ratings yet

- 5 - BOSCH I - O ModuleDocument21 pages5 - BOSCH I - O ModuleFELIPE ANGELES CRUZ ROMONo ratings yet

- Donor Selections..Document17 pagesDonor Selections..OmamaNo ratings yet

- NRSG 5800 SyllabusDocument5 pagesNRSG 5800 Syllabusapi-310557802No ratings yet

- Business Math - Interest QuizDocument1 pageBusiness Math - Interest QuizAi ReenNo ratings yet

- Human Factors Cabin CrewDocument18 pagesHuman Factors Cabin CrewMiko Judael TaperlaNo ratings yet

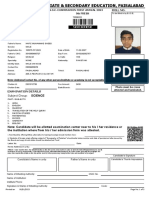

- Roll No. Form No.: Private Admission Form S.S.C. Examination First Annual 2023 9th FRESHDocument3 pagesRoll No. Form No.: Private Admission Form S.S.C. Examination First Annual 2023 9th FRESHBeenish MirzaNo ratings yet

- GCC Lab ManualDocument61 pagesGCC Lab ManualMadhu BalaNo ratings yet

- Measures of Position - Calculating Quartiles Using Different MethodsDocument6 pagesMeasures of Position - Calculating Quartiles Using Different Methodssergio paulo esguerraNo ratings yet

- Membuat Kunci Identifikasi Tipe Perbandingan Kartu Berlubang (Body-Punched Card Key)Document4 pagesMembuat Kunci Identifikasi Tipe Perbandingan Kartu Berlubang (Body-Punched Card Key)Aditya SuryaNo ratings yet

- Business and Tech Mock Exam (8Document11 pagesBusiness and Tech Mock Exam (8Jack PayneNo ratings yet

- Pod Graphics Processor Users GuideDocument71 pagesPod Graphics Processor Users GuideAsmaNo ratings yet

- Statistical Theory and Analysis in Bioassay OverviewDocument11 pagesStatistical Theory and Analysis in Bioassay OverviewEgbuna ChukwuebukaNo ratings yet

- RNYM02-1120A-12Document2 pagesRNYM02-1120A-12bastian silvaNo ratings yet

- Coaching Can Be Defined As The Process of MotivatingDocument5 pagesCoaching Can Be Defined As The Process of MotivatingDaniel DowdingNo ratings yet

- GDRatingDocument13 pagesGDRatingdgzaquinojcNo ratings yet

- Industrial Attachment ReportDocument82 pagesIndustrial Attachment ReportNiyibizi Promesse100% (8)

- Economic and Eco-Friendly Analysis of Solar Power Refrigeration SystemDocument5 pagesEconomic and Eco-Friendly Analysis of Solar Power Refrigeration SystemSiddh BhattNo ratings yet

- Beteq2010 Part 1Document198 pagesBeteq2010 Part 1Zilmar JustiNo ratings yet

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- Advanced Computer-Aided Fixture DesignFrom EverandAdvanced Computer-Aided Fixture DesignRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Introduction to Fly-By-Wire Flight Control SystemsFrom EverandIntroduction to Fly-By-Wire Flight Control SystemsRating: 5 out of 5 stars5/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)