Professional Documents

Culture Documents

Production Planning and Execution (PP) Case Study - Lecturer Notes

Uploaded by

Toño Gomez BarredaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production Planning and Execution (PP) Case Study - Lecturer Notes

Uploaded by

Toño Gomez BarredaCopyright:

Available Formats

LECTURER NOTES

Production Planning and

Execution (PP)

Case Study – Lecturer Notes

This document is intended to help instructors understand the case study

process and manage the learning process in and outside the classroom.

The main focus lies on prerequisites and common tasks such as testing

and trouble-shooting.

Product MOTIVATION

SAP ERP 6.08 Theoretical lectures explain The main goal of this document is to

Global Bike concepts, principles, and theories help instructors prepare the SAP

through reading and discussion. system for the Production Planning

Level They, therefore, enable students to and Execution case study process

acquire knowledge and gain and to support them trouble-shoot

Instructor

theoretical insights. problems that might occur during the

In contrast, case studies allow course.

Focus them to develop their abilities to

Production Planning and analyze enterprise problems, learn Beside technical and didactic

Execution and develop possible solutions, prerequisites, the lecturer notes list

and make sound decisions. SAP transactions for testing and

Author correcting student results in the SAP

Stefan Weidner The main objective of the Global system. In addition, this document

Michael Boldau Bike case studies in general is for describes common problems and

students to understand the explains their reason and solution.

concept of integration. These

Version descriptive and explanatory case

3.2 studies will allow students to

understand the importance and the

Last Update advantages of integrating

April 2018 enterprise areas using an ERP

system.

© SAP SE / SAP UCC Magdeburg

LECTURER NOTES

Prerequisites

Note Before using this case study in your classroom please make sure that all technical (month-

end closing, user management etc.) and didactic prerequisites are fulfilled. Such prerequisites are

briefly pointed out below. Detailed documentation can be displayed at and downloaded from the

Learning Hub of SAP UA or the UCC web sites.

Technical Prerequisites

The Production Planning and Execution case study is based on a standard

SAP ERP client with the current Global Bike dataset. Before processing the

case study on your own or with your students all general setting should be

checked.

This includes month-end closing in Materials Management (transaction Month-end closing in

MM

MMPV) which is documented on the UCC web sites. MMPV

Note With the current version of the Global Bike client a year-end closing is Year-end closing

not necessary, because it has already been automated or because it is not

needed for the process described in the curriculum material.

User accounts in the SAP system need to be created or unlocked. User management

These student user accounts should end with a three-digit numeric number

(e.g. LEARN-001, LEARN-002 etc.). This number will be represented by

### in the case study and helps differentiate customer accounts, products etc.

In an SAP ERP Global Bike client already exist 1000 user accounts from LEARN-000 to

LEARN-999

LEARN-000 to LEARN-999. These users need to be unlocked. The initial

password for each LEARN-### account is set to tlestart.

tlestart

Transaction ZUSR was developed in the Global Bike client in order to mass ZUSR

maintain SAP user accounts. For a detailed description of this and SAP

standard transactions for user management (SU01 and SU10) please refer to SU01

SU10

the lecturer notes „User Management“ (see: current Introduction to ERP

using Global Bike curriculum chapter 99 – Instructor Tools).

All LEARN-### user accounts have been assigned to the role

Z_UCC_GBI_SCC and have authorizations to use all applicative transactions

in the SAP ERP system. The role allows access to all transactions necessary

for Global Bike exercises and case studies. If you need access to system-

critical transactions, i.e. for development purposes, you may assign the

composite profile SAP_ALL to your student accounts.

It is useful for the instructor to have a user account available for testing that

has the same authorizations as the student accounts. You may use the Instructor account

predefined instructor account LEARN-000 for this purpose. LEARN-000

© SAP SE / SAP UCC Magdeburg Page 2

LECTURER NOTES

Didactic Prerequisites

In order to successfully process this case study, students should be familiar

Navigation

with the navigation in SAP systems, especially the SAP Easy Access menu,

the SAP transaction concept as well as possible documentation and help

options. We highly recommend using the navigation slides and the

navigation course (see: current Introduction to ERP using Global Bike

curriculum chapter 2 – Navigation).

In addition, it has been proven beneficial that students have a thorough

Company background

understanding of the historic background and the enterprise structure of the

Global Bike concern before they start working on the SAP system. For this

purpose we recommend the case study „Global Bike Inc.“ (see: current

Introduction to ERP using Global Bike curriculum chapter 3 – Global

Bike) or the case study „Business Process Analysis 1“ (see: current

Introduction to ERP using Global Bike curriculum chapter 98 – Cross-

Module).

Because the case study is not based on the exercises, it is not necessary to

have processed the PP exercises before you start with the case study.

However, it is recommended.

In order to function properly this case study needs a Global Bike client Global Bike client

version

version that is equal to or higher than the case study version (see cover

page). Please check. If you do not know the client version please use the

transaction ZGBIVERSION within your SAP ERP system or contact your

UCC team.

GBI Mobile App

With Global Bike the App GBI DataViewer was released for all compatible

Android and iOS devices. It can be downloaded through Google Play Store

and Apple Store. The purpose of this app is to show the possibility of

platform-independent support of business processes. Therefore, some task of

the case study can optionally substituted by using the GBI DataViewer App.

Please read the document

Intro_ERP_Using_Global_Bike_mobile_app_(beta) for a more detailed

description of the app. It can be found in the folder 98 Cross-Module of the

Introduction to ERP using Global Bike release.

Please keep in mind that this app is an additional functionality designed by

the UCC Magdeburg and you might encounter a bug. Therefore we kindly

ask you to send any feedback or detailed error descriptions to the following

address: gbi@ucc.ovgu.de

Global Feedback

Do you have any suggestions or feedback about Global Bike? Please send it

to our new email-address gbi@ucc.ovgu.de which is used to gather feedback

globally. All emails will be evaluated by the persons responsible for the

© SAP SE / SAP UCC Magdeburg Page 3

LECTURER NOTES

curriculum bi-weekly. This way your feedback might influence future

releases directly.

Please note that any support requests send to this email-address will be

ignored. Please keep using the common support channels for your support

requests.

© SAP SE / SAP UCC Magdeburg Page 4

LECTURER NOTES

Student Assessment

Note With the transactions listed below you can check and correct master and transactional data

that your students have created during your course.

Master Data

MM02 Change Material

MM03 Display Material

CA02 Change Routing

CA03 Display Routing

Transactional Data

MC82 Change Plan

MC83 Display Plan

MD63 Display Planned Independent Requirements

MD04 Stock/Requirements List

MC01 Logistics Information Library

Global Bike Monitor

We have developed a Global Bike Monitor, which is available for the PP

case study.

A detailed tutorial for this tool is available in the module 99 Instructor Tools

of the current curriculum. You will find the file

Intro_ERP_Using_Global_Bike_Global_Bike_Monitor in the corresponding

folder.

Please keep in mind that this transaction is an additional functionality

designed by the UCC Magdeburg and still in development. Therefore, we

kindly ask you to send any feedback or detailed error descriptions to the

following address: gbi@ucc.ovgu.de

© SAP SE / SAP UCC Magdeburg Page 5

LECTURER NOTES

Result Verification

Note SAP provides several reports for the production process. Two transactions are suitable for

verification of case study results. These two transactions can be used as a starting point for error

tracking.

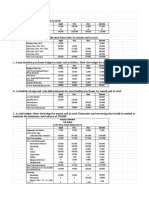

Stock Level Each student should produce a certain amount of red bikes

(DXTR3###) during the case study.

You can verify all stock changes for a range of materials as described below.

Open transaction MC01 which will produce the Logistics Information MC01

Library screen.

Navigate through the following path:

Info Sets ►Logistics info sets ► Warehouse ►Stock analysis (material

view) ► Stock level over time (material view) ► Total stock level over time

(material view) ► Total stock quantity in base unit from material analysis

On following screen enter plant DL00, Material DXTR3000 to DXTR3999 DL00

DXTR3000

and click on (Execute). This will produce the Material Analysis Report: DXTR3999

© SAP SE / SAP UCC Magdeburg Page 6

LECTURER NOTES

Note Your Stock level may have different values depending on your

historical consumption values.

Materials listed in this report indicate that the goods from the production

order (see case study p36) were received into inventory.

© SAP SE / SAP UCC Magdeburg Page 7

LECTURER NOTES

Problem: Error Message during Transfer to Demand Management

Symptom You receive an error message while transferring planning data to Demand

Management.

Reason The master data view MRP 3 of DXTR1### and DXTR2### was not maintained.

Solution Please maintain the necessary data as described below.

Error Message

During transfer of the SOP to Demand Management (case study page 14f.) MC75

you receive the following error message:

The detailed error log available from the menu Goto Error log should

look similar to the screen depicted below:

Solution

Maintain the values for material master view MRP3 of DXTR1### and

DXTR2### described on case study page 3f.

Rerun the SOP transfer from case study page 16f.

Note During the case study only DXTR3### is produced and is not directly

affected by the error described above. If you choose to ignore the error and

proceed with the case study some screens that show the whole product group

will differ from the case study.

© SAP SE / SAP UCC Magdeburg Page 8

LECTURER NOTES

Problem: SOP screen does not show all 12 period columns

Symptom Less than 12 periods are available in the SOP planning screen.

Reason The relative size of your SAP window is too small.

Solution Use the steps below to enter the values

Error Message

While creating the SOP less than 12 periods are displayed. Therefore, you

can’t enter Target days’ supply for all necessary periods.

Solution

Use the icon to navigate through the planning periods.

Alternatively, increase the size of the SAP window and click on . Choose

not to save planning values and then click on

© SAP SE / SAP UCC Magdeburg Page 9

LECTURER NOTES

Solution: PP Challenge

Learning Objective Understand and perform a manufacturing process cycle.

Change Material Master Record

Change your material with transaction MM02. When your material number MM02

ORMN1###

(ORMN1###) is entered in the Material field, click on or press Enter. On

MRP 3

the following screen, please select MRP 3.

Then, press Enter or click on . The following screen will appear.

Find and select the Global Bike manufacturing facility in Dallas (DL00). DL00

Then enter its Finished Goods Stor. Location (FG00). Press Enter or click on FG00

.

In the MRP 3 view, enter Strategy group 40 (Planning with final assembly), 40

1

Consumption mode 1 (Backward consumption only) and Bwd consumption 30

per. 30.

© SAP SE / SAP UCC Magdeburg Page 10

LECTURER NOTES

Click on to save your entries for the Men’s Off Road Bike. Repeat the

ORWN1###

same procedure for the Women’s Off Road Bike. (ORWN1###).

Create Sales and Operation Plan (SOP)

In the transaction MC82 create a sales and operation plan for the product MC82

group Off Road Bicycles. (PG-ORBK###)

Make sure that Product group PG-ORBK### and Plant DL00 are entered. PG-ORBK###

DL00

Then select .

In the Change Rough-Cut Plan screen, enter manually the values for the

sales, starting in two months from today’s date.

Period Sales (amount)

current month + 2 150

current month + 3 175

current month + 4 200

current month + 5 85

current month + 6 90

current month + 7 115

As Target day’s supply enter 5 for each forecasted period (a total of 6 5

months).

In the system menu, select:

Edit ► Create product plan ► Synchronous to sales

Note the change in the Production and in the Stock level lines. The

production plan is created to match the sales forecast.

© SAP SE / SAP UCC Magdeburg Page 11

LECTURER NOTES

Now select in the system menu:

Edit ► Create product plan ► Target day’s supply

Note the impact on the production plan and stock levels. Production levels

are generated to match the sales plus produce enough to put into stock to

meet the target days of supply specifications

Save by clicking on .

Transfer SOP to Demand Management

Start transaction MC75. Follow the instructions as described in the case MC75

PG-ORBK###

study, just change the product group to PG-ORBK###.

Run MPS with MRP

In the transaction MD41 start the Master Production Scheduling with your MD41

ORMN1###

material ORMN1###. Further follow the steps as described in the case

study.

Convert Planned Order into Production Order

In the transaction MD04 proceed as described in the case study, just change MD04

ORMN1###

your material to ORMN1###.

Receive Goods in Inventory

In transaction MIGO you post the goods received of your required raw MIGO

materials in stock.

Choose Goods Receipt and Other. Enter today as Document and Posting today

561

Date, Movement Type 561 (Receipt per initial entry of stock balances into DL00

unr. –use). Plant DL00, and leave Storage Location blank. Then, press Enter

or click on

In the Enter Other Goods Receipts: New Item screen, you can’t use the same

materials as in the case study, because you now plan for material

ORMN1###.

To find out the required materials for ORMN1### you need to take a look at

CS03

the BOM via transaction CS03. Transfer the required materials to the Enter

Goods Receipts: New item screen. For the Off Road Aluminum Wheel

SF00

Assembly (ORWA1###) enter SF00 (Semi-Fin. Goods) and for all the other RM00

500

© SAP SE / SAP UCC Magdeburg Page 12

LECTURER NOTES

materials RM00 (Raw-Materials) as Storage Location. Enter 500 as Quantity

for each material.

Save your goods receipt with and record the material document number.

Then, click on the exit icon to return to the SAP Easy Access screen.

Issue Goods to Production Order

In transaction MIGO advance as described in the case study. MIGO

Confirm Production Completion

In the transaction CO15 confirm the completion of your production, CO15

therefore advance as described in the case study.

Receive Goods from Production Order

In the transaction MIGO advance as described in the case study as well. MIGO

Settle Costs of Production Order

In the transaction KO88 you can settle the costs of the production order as KO88

described in the case study.

© SAP SE / SAP UCC Magdeburg Page 13

You might also like

- Financial Accounting - Accounts Receivable (FI - AR) : Product Motivation PrerequisitesDocument45 pagesFinancial Accounting - Accounts Receivable (FI - AR) : Product Motivation PrerequisitesTuệ Nguyễn Ngọc GiaNo ratings yet

- Unilever Philippines Internal Control and ProceduresDocument2 pagesUnilever Philippines Internal Control and ProceduresNiks Spears100% (1)

- Solution To Operations Management W9Document3 pagesSolution To Operations Management W9Đỗ Nguyễn Anh ThưNo ratings yet

- Cost and Management AccountingDocument12 pagesCost and Management Accountingneha chodryNo ratings yet

- Activity Based Costing ER - NewDocument14 pagesActivity Based Costing ER - NewFadillah LubisNo ratings yet

- Understanding key estimatesDocument7 pagesUnderstanding key estimatesBryan RamosNo ratings yet

- Measuring Financial Position (Balance SheetDocument2 pagesMeasuring Financial Position (Balance SheetjakelakerNo ratings yet

- Running Head: Vertical Integration of Zhangzidao 1Document8 pagesRunning Head: Vertical Integration of Zhangzidao 1DenizNo ratings yet

- SAP Materials Management (MM) : by KmrsoftDocument27 pagesSAP Materials Management (MM) : by Kmrsoftshiblu1983No ratings yet

- Republic of The Philippines Municipality of Binangonan: Mayors PermitDocument2 pagesRepublic of The Philippines Municipality of Binangonan: Mayors PermitAlliah CeñidozaNo ratings yet

- Lesson 7 - Accounting CycleDocument35 pagesLesson 7 - Accounting CycleEyyyNo ratings yet

- Audit Mcqs PDFDocument166 pagesAudit Mcqs PDFBhansali YugalNo ratings yet

- HP's Acquisition of Compaq to Gain Scale and Beat DellDocument4 pagesHP's Acquisition of Compaq to Gain Scale and Beat DellKi-Baek KimNo ratings yet

- ch04.ppt - Income Statement and Related InformationDocument68 pagesch04.ppt - Income Statement and Related InformationAmir ContrerasNo ratings yet

- Chapter 8 - Introduction To Pervasive ControlsDocument18 pagesChapter 8 - Introduction To Pervasive ControlsMark Lawrence Yusi100% (1)

- MANACCDocument3 pagesMANACCminseok kimNo ratings yet

- EAGLE 2018 Annual Report (SEC Form 17-A) PDFDocument208 pagesEAGLE 2018 Annual Report (SEC Form 17-A) PDFRafael Obusan IINo ratings yet

- 1001 It Environments - Stand-Alone Personal ComputersDocument4 pages1001 It Environments - Stand-Alone Personal ComputersiamnumberfourNo ratings yet

- ACC204 Provision and Contingent Liab SeatworkDocument2 pagesACC204 Provision and Contingent Liab SeatworkJudy Ann ImusNo ratings yet

- Consider The Emarpy Appliance Situation in Problem 6 56 If Richard PDFDocument1 pageConsider The Emarpy Appliance Situation in Problem 6 56 If Richard PDFCharlotteNo ratings yet

- Assignment On Chapter 8 Data Warehousing and ManagementDocument13 pagesAssignment On Chapter 8 Data Warehousing and ManagementAnna BelleNo ratings yet

- Financial ManagementDocument3 pagesFinancial Managementgundapola100% (2)

- Hello PDFDocument57 pagesHello PDFMursalin HossainNo ratings yet

- Ch09 Resource Allocation CrashcostDocument25 pagesCh09 Resource Allocation Crashcostndc6105058No ratings yet

- ASSIGNMENT 6.1 (Business Tax)Document5 pagesASSIGNMENT 6.1 (Business Tax)Balasbas KleiserNo ratings yet

- ch#5 of CFDocument2 pagesch#5 of CFAzeem KhalidNo ratings yet

- Problem Set 7 (With Instructions) : Regression StatisticsDocument6 pagesProblem Set 7 (With Instructions) : Regression StatisticsLily TranNo ratings yet

- Case 8-31: April May June QuarterDocument2 pagesCase 8-31: April May June QuarterileviejoieNo ratings yet

- Week 13 SolutionsDocument7 pagesWeek 13 SolutionsStanley RobertNo ratings yet

- Cash InventoriesDocument14 pagesCash InventoriesCharlene GonzalesNo ratings yet

- Your First Assignment in Your New Position As Assistant FinancialDocument2 pagesYour First Assignment in Your New Position As Assistant FinancialAmit PandeyNo ratings yet

- Notes Module 2Document28 pagesNotes Module 2Tejaswini GirishNo ratings yet

- Completing Audit ProceduresDocument7 pagesCompleting Audit ProceduresyebegashetNo ratings yet

- Soal P 7.2, 7.3, 7.5Document3 pagesSoal P 7.2, 7.3, 7.5boba milkNo ratings yet

- The Conversion Cycle: Introduction To Accounting Information Systems, 7eDocument44 pagesThe Conversion Cycle: Introduction To Accounting Information Systems, 7eontykerlsNo ratings yet

- JPMorgan Mission & VisionDocument6 pagesJPMorgan Mission & VisionPuneet Chawla100% (1)

- Feasibility Study, Chapter 3 ..Document6 pagesFeasibility Study, Chapter 3 ..Mahmoud TonopyNo ratings yet

- Hca14 PPT CH07Document39 pagesHca14 PPT CH07Kamlesh ShuklaNo ratings yet

- Chapter 22 (7) Performance Evaluation Using Variances From Standard CostsDocument42 pagesChapter 22 (7) Performance Evaluation Using Variances From Standard CostsJames BarzoNo ratings yet

- Chapter 18-Practice ExsercisesDocument18 pagesChapter 18-Practice ExsercisesThiNo ratings yet

- SD - Case Study - en - v4.1Document51 pagesSD - Case Study - en - v4.1Quynh Nguyen HuongNo ratings yet

- Chapter 6: Project Activity Planning: Learning ObjectivesDocument8 pagesChapter 6: Project Activity Planning: Learning ObjectivesJeng AndradeNo ratings yet

- Module IV: MUS Sampling - Factory Equipment Additions: RequirementsDocument2 pagesModule IV: MUS Sampling - Factory Equipment Additions: RequirementsMukh UbaidillahNo ratings yet

- HWChap 007Document96 pagesHWChap 007hellooceanNo ratings yet

- 409 Chapter 5Document86 pages409 Chapter 5Amber HigginbothamNo ratings yet

- Audit of PPE 1Document2 pagesAudit of PPE 1Raz MahariNo ratings yet

- Duraplast Company Ltd. A) A Data Flow Diagram of The Current SystemDocument6 pagesDuraplast Company Ltd. A) A Data Flow Diagram of The Current SystemNhanha KodjoNo ratings yet

- Financial Reporting in Hyperinflationary EconomiesDocument8 pagesFinancial Reporting in Hyperinflationary EconomiesLakshminarasimman V RaoNo ratings yet

- Ias 2Document4 pagesIas 2mnhammadNo ratings yet

- Erika Co investment property reportingDocument4 pagesErika Co investment property reportingjeams vidalNo ratings yet

- Fundamentals of Assurance ServicesDocument32 pagesFundamentals of Assurance ServicesDavid alfonsoNo ratings yet

- Lower-of-Cost-or-Market Valuation IssuesDocument31 pagesLower-of-Cost-or-Market Valuation Issuesalice123h21No ratings yet

- CH 13Document33 pagesCH 13joyabyssNo ratings yet

- Basic Managerial Accounting Concepts: Seventh EditionDocument92 pagesBasic Managerial Accounting Concepts: Seventh EditionKefas AnugrahNo ratings yet

- Cash Accounts Receivable JournalDocument56 pagesCash Accounts Receivable Journallaale dijaanNo ratings yet

- Intro S4HANA Using Global Bike Notes PP en v3.3Document12 pagesIntro S4HANA Using Global Bike Notes PP en v3.3Gian Carlo LajarcaNo ratings yet

- Intro S4HANA Using Global Bike Notes SD en v3.3Document19 pagesIntro S4HANA Using Global Bike Notes SD en v3.3OliNo ratings yet

- Intro S4HANA Using Global Bike Notes FI Fiori en v3.3Document11 pagesIntro S4HANA Using Global Bike Notes FI Fiori en v3.3Rana GaballahNo ratings yet

- Intro S4HANA Using Global Bike Notes SD en v3.3Document19 pagesIntro S4HANA Using Global Bike Notes SD en v3.3ANTUANETTE MARIBEL ZEVALLOS BALLADARESNo ratings yet

- Top Men's and Women's FragrancesDocument71 pagesTop Men's and Women's FragrancesToño Gomez BarredaNo ratings yet

- Production Planning and Execution (PP) Case Study: Master DataDocument1 pageProduction Planning and Execution (PP) Case Study: Master DataToño Gomez BarredaNo ratings yet

- PP 1: Display Stock/Requirements ListDocument14 pagesPP 1: Display Stock/Requirements ListFrancisco Daniel Tominaga IreyNo ratings yet

- Intro ERP Using GBI Slides PP en v3.1Document62 pagesIntro ERP Using GBI Slides PP en v3.1Miguel Dela CruzNo ratings yet

- Master Data and Transactions for Materials Management Case StudyDocument1 pageMaster Data and Transactions for Materials Management Case StudyPrashant ItankarNo ratings yet

- Materials Management (MM) Case Study - Lecturer Notes: Product MotivationDocument27 pagesMaterials Management (MM) Case Study - Lecturer Notes: Product MotivationToño Gomez BarredaNo ratings yet

- Materials Management (MM) : Curriculum: Introduction To ERP Using Global BikeDocument46 pagesMaterials Management (MM) : Curriculum: Introduction To ERP Using Global BikeToño Gomez BarredaNo ratings yet

- MM 1: Display Purchase Order: Exercise Use The SAP Easy Access Menu in Order To Display A Purchase Time 10 MinDocument10 pagesMM 1: Display Purchase Order: Exercise Use The SAP Easy Access Menu in Order To Display A Purchase Time 10 MinToño Gomez BarredaNo ratings yet

- Materials Management (MM) : Curriculum: Introduction To ERP Using Global BikeDocument46 pagesMaterials Management (MM) : Curriculum: Introduction To ERP Using Global BikeToño Gomez BarredaNo ratings yet

- b2 s1 SpeakingDocument4 pagesb2 s1 SpeakinglilalilakNo ratings yet

- E-18 Why Do Children MisbehaveDocument2 pagesE-18 Why Do Children MisbehaveHermann Dejero LozanoNo ratings yet

- Psthe 1Document111 pagesPsthe 1Angelica RicoNo ratings yet

- Teacher Information FormDocument5 pagesTeacher Information FormdasdmNo ratings yet

- Curriculum Development: Process, Models and FoundationsDocument49 pagesCurriculum Development: Process, Models and FoundationsJhay Phee LlorenteNo ratings yet

- Piaget's Theory of LearningDocument24 pagesPiaget's Theory of LearningMuhammad Salman AhmedNo ratings yet

- Rotman MFEDocument28 pagesRotman MFEfanatik123No ratings yet

- Mega Australian AttackDocument588 pagesMega Australian AttackRajat SharmaNo ratings yet

- Organization and Management Quarter 1: Week 4: Learning Activity SheetDocument5 pagesOrganization and Management Quarter 1: Week 4: Learning Activity SheetHannah Ritch CacaNo ratings yet

- Educational Policy, Anthropology, and The State: Carlos Miñana Blasco and Carolina Arango VargasDocument7 pagesEducational Policy, Anthropology, and The State: Carlos Miñana Blasco and Carolina Arango VargasMaribel MuzadaNo ratings yet

- Math 8-Q3-Module-6Document18 pagesMath 8-Q3-Module-6Tish AcabalNo ratings yet

- Form 2 Lesson Plan on Science and TechnologyDocument3 pagesForm 2 Lesson Plan on Science and TechnologyCnorazimah OmarNo ratings yet

- Lefebvre and SpaceDocument15 pagesLefebvre and SpaceZainab CheemaNo ratings yet

- Facilitation Key ConceptsDocument17 pagesFacilitation Key ConceptsGech DebNo ratings yet

- Graduation and Moving Up Ceremony Program FlowDocument5 pagesGraduation and Moving Up Ceremony Program FlowMICHAEL ANGELO MAYORDO100% (1)

- The Map To Med SchoolDocument10 pagesThe Map To Med SchoolEmerson Augusto100% (1)

- The Impact of Technology On Learning EnvironmnentDocument7 pagesThe Impact of Technology On Learning EnvironmnentAhmad Ali75% (4)

- Math4 q2 Mod9 Changingfractionstolowestterms v.2Document17 pagesMath4 q2 Mod9 Changingfractionstolowestterms v.2Joanna GarciaNo ratings yet

- Curriculum Mapping (MATH 7) First Quarter Week Content Standards Performance Standards Student Assessment Activity/ies Teaching Activities 1Document11 pagesCurriculum Mapping (MATH 7) First Quarter Week Content Standards Performance Standards Student Assessment Activity/ies Teaching Activities 1FairyLeen PitogoNo ratings yet

- Gopal Narayan Singh University PDFDocument2 pagesGopal Narayan Singh University PDFnarendraNo ratings yet

- Ogl 350 Module 1 TBW Assignment 2Document6 pagesOgl 350 Module 1 TBW Assignment 2api-670788105No ratings yet

- PHD Studentship - Predictive Modelling of Small Crack Formation in Superalloys at Cranfield UniversityDocument2 pagesPHD Studentship - Predictive Modelling of Small Crack Formation in Superalloys at Cranfield UniversityOzden IsbilirNo ratings yet

- Entrep Week 1 LAS 1 - 071628Document1 pageEntrep Week 1 LAS 1 - 071628Zenie Jay CardinesNo ratings yet

- 4pm1 02 Rms 20230824Document32 pages4pm1 02 Rms 20230824waliulhasib123No ratings yet

- Bluefield State College - Blue and Gold - Volume X Number 4Document16 pagesBluefield State College - Blue and Gold - Volume X Number 4bluefieldstateNo ratings yet

- A Narrative Report - Community ServiceDocument4 pagesA Narrative Report - Community ServiceASLIMAH50% (2)

- Elementary Teacher Resume ObjectiveDocument1 pageElementary Teacher Resume ObjectiveDolores Mayuga PanchoNo ratings yet

- The Academic Impact of Financial Stress On College StudentsDocument19 pagesThe Academic Impact of Financial Stress On College StudentsZayn LeeNo ratings yet

- Marokko Zeugnisbewertung Dokumente ENDocument5 pagesMarokko Zeugnisbewertung Dokumente ENSuper arabienNo ratings yet

- Detailed Lesson Plan. (Music)Document6 pagesDetailed Lesson Plan. (Music)Yhenyhen Planque87% (67)