Professional Documents

Culture Documents

Calibrated Woodward G5 - 23-09-2019 PDF

Uploaded by

Nico FajRiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calibrated Woodward G5 - 23-09-2019 PDF

Uploaded by

Nico FajRiCopyright:

Available Formats

Repair Work Report

Electrical / Mechanical Issues

THIS REPORT MUST BE COMPLETED AFTER INVESTIGATION HAS DONE & SUBMITTED AFTER

ALL HAS FINISHED.

Site: Pekanbaru 50MW In charge by :

Location: Jl. Tanjung Datuk. PLN Teluk Lembu 1. FTS PKU

Date : Sept 24th 2019 2. Maintenance Team

Time : 09:00

Fuel Engine ESN Engine Model Generator Model

Natural Gas 17218 B35:40V20AG2 ABB AMG 1120SM08

DSE

Start date End date Generator ESN Running hour

Sept 24th 2019 Sept 24th 2019 (G#5) 4631675 34452

Trip Blackout Troubleshoot Others

Problem Describe

G#5 (17218)

Summary

· Rack/Load dev high 15.46%

· Bearing and shaft actuator damage

· Bearing rack CYL head B10 damage

· Adjust Admission rack

· Calibration Woodward

oodward (Fuel rack and VTG)

Rack/Load dev high 15.46%

Action

1. Replacement Bearing fuel rack CYL Head B10 with new one

Bearing rack B10

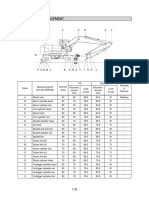

Spare part consumption list

NO Part no Description Qty

1 B00446792 Bearing housing reg. shaft 42mm (new type) 1pc

2. Swapping shaft and bearing actuator form G4 and install to G5

Shaft actuator G5 damage Shaft G4and new bearing ready install to G5

Spare part consumption list

NO Part no Description Qty

1 B00446792 Bearing housing reg. shaft 42mm (new type) 2pcs

Vpower format form / applicable for all troubleshoot issues

3. Adjust Admission Rack

Admission rack

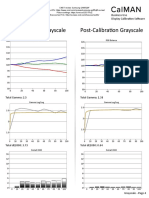

Progress Calibration

Perform fuel rack calibrated by following step by step. The engine is stopped. Starting fuel rack calibrated must

be the Load 50%, 90%, 70%, 30% and 10%.

The function of the calibrated is to match the value of the fuel from HMI to the value average fuel rack on the

Cyl A & B Bank. Fuel rack from HMI must the following average fuel rack A & B Bank.

The way it is with increased mA (MiliAmpere) on HMI for Decreased value fuel rack on HMI. And then

decreased mA on HMI for increased value fuel rack on HMI.

4. Calibrated fuel rack from Woodward

A. Calibrated Load 50% on fuel rack Cyl head

Fuel Rack Position

Before Calibrated After Calibrated

Vpower format form / applicable for all troubleshoot issues

Measurement fuel rack on Cyl Head A-Bank and B-Bank

Before Calibrated After Calibrated

NO A-Bank B-Bank NO A-Bank B-Bank

1 55 45 1 55 45

2 54 51 2 54 51

3 52 50 3 52 50

4 52 51 4 52 51

5 5 49 5 5 49

6 2 50 6 2 50

7 54 52 7 54 52

8 51 51 8 51 51

9 51 53 9 51 53

10 52 50 10 52 50

Average A&B Bank 52.27% Average A&B Bank 51.30%

B. Calibrated Load 90% on fuel rack Cyl head

Fuel Rack Position

Before Calibrated After Calibrated

Vpower format form / applicable for all troubleshoot issues

Measurement fuel rack on Cyl Head A-Bank and B-Bank

Before Calibrated After Calibrated

NO A-Bank B-Bank NO A-Bank B-Bank

1 92 86 1 92 86

2 90 90 2 90 90

3 93 990 3 93 990

4 91 89 4 91 89

5 90 87 5 90 87

6 90 90 6 90 90

7 91 91 7 91 91

8 90 90 8 90 90

9 90 91 9 90 91

10 90 90 10 90 90

Average A&B Bank 91.73% Average A&B Bank 90.03%

C. Calibrated Load 70% on fuel rack Cyl head

Fuel Rack Position

Before Calibrated After Calibrated

Vpower format form / applicable for all troubleshoot issues

Measurement fuel rack on Cyl Head A-Bank and B-Bank

Before Calibrated After Calibrated

NO A-Bank B-Bank NO A-Bank B-Bank

1 72 67 1 72 67

2 71 70 2 71 70

3 72 70 3 72 70

4 72 70 4 72 70

5 70 67 5 70 67

6 70 70 6 70 70

7 73 71 7 73 71

8 71 70 8 71 70

9 70 72 9 70 72

10 73 70 10 73 70

Average A&B Bank 73.20% Average A&B Bank 70.55%

D. Calibrated Load 30% on fuel rack Cyl head

Fuel Rack Position

Before Calibrated After Calibrated

Vpower format form / applicable for all troubleshoot issues

Measurement fuel rack on Cyl Head A-Bank and B-Bank

Before Calibrated After Calibrated

NO A-Bank B-Bank NO A-Bank B-Bank

1 34 26 1 34 26

2 35 30 2 35 30

3 34 32 3 34 32

4 35 33 4 35 33

5 33 30 5 33 30

6 32 32 6 32 32

7 35 31 7 35 31

8 32 31 8 32 31

9 31 32 9 31 32

10 32 30 10 32 30

Average A&B Bank 34.70% Average A&B Bank 32.04%

E. Calibrated Load 10% on fuel rack Cyl head

Fuel Rack Position

Before Calibrated After Calibrated

Vpower format form / applicable for all troubleshoot issues

Measurement fuel rack on Cyl Head A-Bank and B-Bank

Before Calibrated After Calibrated

NO A-Bank B-Bank NO A-Bank B-Bank

1 15 7 14 15 7

2 15 11 17 15 11

3 15 14 13 15 14

4 14 16 13 14 16

5 13 12 14 13 12

6 13 15 13 13 15

7 15 11 15 15 11

8 13 13 12 13 13

9 11 15 10 11 15

10 13 10 10 13 10

Average A&B Bank 15.22% Average A&B Bank 13.06%

5. Calibration VTG from Woodward

Ø VTG Position

VTG Position on HMI 100% VTG Position on IP 0.0%

Vpower format form / applicable for all troubleshoot issues

Ø Rack VTG Position

Rack Position Bank A (-2) Rack Position Bank B (-2)

Ø VTG Position

VTG Position on HMI 0.0% VTG Position on IP 100%

Vpower format form / applicable for all troubleshoot issues

Ø Rack VTG Position

Rack Position Bank A (+4) Rack Position Bank B (+4)

Suggestion

If there is one of the abnormal VTG linkages in Bank A/B linkage we can make linkage adjustment following

the result of the HMI and IP.

Vpower format form / applicable for all troubleshoot issues

OPERATION TEST DATA GAS ENGINE

Site Engine Type Engine S/N Engine RPM Date

PLTMG 50MW B35:40V20AG2 17218 750 23-09-2019

Location Engine Load Gen Load Service Engineer

Pekanbaru 90% 8.457 MW FTS TEAM

Running hrs 34452

Exhaust gas Temp Gas Cooling Water

Cylinder No

A-Bank B-Bank Supply 6.20 Bar 3.0 Bar

HT in o

1 516.9 521.1 Press Main 3.92 Bar 73.5 C

o

2 509.5 508.6 Pre-chamb 3.54 Bar HT Out 81.7 C

o o

3 506.8 507 Temp Eng-inlet 24.1 C LT in 42.7 C

4 514.6 505 Pressure Parameter Temperature Parameter

o

5 501.9 502.4 Charger Air 2.94 Bar Charger Air 57.6 C

o

6 516.9 515.1 Lube oil 3.9 Bar Lube oil 59.7 C

o

7 516.3 519.4 Rocker Arm 2.4 Bar Suction Air 30.9 C

8 522.3 514.9 Crank-case 2.9 Bar Generator

o

9 508.6 516.8 Lube Oil TC-A 1.82 Bar Gen. Bearing D 66.6 C

o

10 511.7 521.9 Lube Oil TC-B 1.84 Bar Gen. Bearing N 66.9 C

o

AVG Exh. Temp. 512.4 513 Oil Mist Level 1 Gen. Wind 1 93.5 C

o

Temp BTC 561.6 557.5 Start Air 27.6 Bar Gen. Wind 2 93.2 C

o o

Dev. A/B 0.6 C Control air 6.4 Bar Gen. Wind 3 93.3 C

Splash Oil Temperature MISC

o o

Crank 1 79.8 C Crank 6 76.9 C VTG 69.95 %

o o

Crank 2 78.4 C Crank 7 77.6 C Rack/Load Dev 0.07 %

o o

Crank 3 77.2 C Crank 8 77.1 C Rack on ECC 74.2 %

o o

Crank 4 77.3 C Crank 9 77.5 C

o o

Crank 5 77.0 C Crank 10 76.0 C

Job. Completion

Reported by Acknowledged by Approved by

Vpower format form / applicable for all troubleshoot issues

Remaks

Ø Each RMS ( Routine Maintenance Service) 2K must calibrate fuel rack.

after calibrated, when the engine is running has a problem at exhaust temperature is high or low.

Recommended for checking 4 items:

1. Check spark plug

2. Check PCC/ bolt valve

3. Check tappet clearance

Check gas supply/orifice

Ø Fuel rack has been calibration with software RR it is suitable between HMI with IP

Ø VTG has been calibration with software RR it is suitable between HMI with IP

Ø Actuator three way valve need to check or have a look what the problem. Because when engine start the

temperature HT out up and down suddenly.

Ø After running test with load 90% engine continue running with system

Conclusion

Not recommended for adjust fuel rack on cyl after has been calibrated, when engine is stop or when engine

running.

Suggestion

Ø Recommended to adjust fuel rack by using peak pressure. By using a tool Kitsler 2516.

Ø When replacement bearing rack and bearing fuel rack are required to Calibrated.

` TYPE FAILURE: Mechanical Faulty Electrical Faulty Others

Repair : YES

Service : YES

Replace Part : YES

Done by Vendor :-

Others :-

Reported by: FTS Team Checked by: FTS Dept Head Acknowledged By

Signed: Signed: Signed:

Date : Date : Date :

Vpower format form / applicable for all troubleshoot issues

Attachment

Adjustment Admission Rack Calibration woodward

HMI woodward Parameters Load

Parameters Exhaust Temperature CYL Head Parameters Pressure system

Vpower format form / applicable for all troubleshoot issues

Parameters Temperature system Load Trend

Vpower format form / applicable for all troubleshoot issues

You might also like

- 2005 Volkswagen New Beetle Aut Transmission 4 Speed 01MDocument270 pages2005 Volkswagen New Beetle Aut Transmission 4 Speed 01MWilmer Huanga100% (3)

- 303-01b Engine TD4Document166 pages303-01b Engine TD4Juraci Diniz100% (1)

- MAN B&W ME Trainee HandoutDocument96 pagesMAN B&W ME Trainee HandoutSorin-Adrian Learschi100% (1)

- HVP 90 Manual EnglishDocument22 pagesHVP 90 Manual EnglishLuis Caba Ramirez87% (15)

- Service Manual Nissan Engine Model PDocument127 pagesService Manual Nissan Engine Model PVirgoNo ratings yet

- Case 2090 2590 Shop ManualDocument10 pagesCase 2090 2590 Shop Manualtheodore100% (55)

- 3784A KXX K4J K4M Clio Motor ManualDocument32 pages3784A KXX K4J K4M Clio Motor ManualDavid NebainNo ratings yet

- B 242Document154 pagesB 242JamalAhmedNo ratings yet

- 1mz FeDocument2 pages1mz FePacaluNo ratings yet

- VATEUD Pilots ManualDocument32 pagesVATEUD Pilots ManualAndreas TzekasNo ratings yet

- Service Manual Nissan Engine Model PDocument10 pagesService Manual Nissan Engine Model Pmichel100% (50)

- fC81047 Cursor9CamshaftTimingforCAMwithEXHAUSTBRAKEJuly2013rev1Document8 pagesfC81047 Cursor9CamshaftTimingforCAMwithEXHAUSTBRAKEJuly2013rev1Victor Pinedo100% (1)

- Parts Catalog For Engine 150 HP - Sea Pro SN 2b482084 - 2b482085 - BakamlaDocument115 pagesParts Catalog For Engine 150 HP - Sea Pro SN 2b482084 - 2b482085 - BakamlaPussarpras KamlaNo ratings yet

- LYC 60294 9 2 Overhaul 76series1975 1996 PDFDocument230 pagesLYC 60294 9 2 Overhaul 76series1975 1996 PDFDAVID WRIGHT100% (2)

- Steering: Section 8B - Hydraulic SteeringDocument18 pagesSteering: Section 8B - Hydraulic Steering이영석No ratings yet

- 1 PM 56K HOURS (The Running Hrs Now Exceeding 9758 HRS) 2 PM 56K HOURS (The Running Hrs Now Exceeding 944 HRS) 3Document2 pages1 PM 56K HOURS (The Running Hrs Now Exceeding 9758 HRS) 2 PM 56K HOURS (The Running Hrs Now Exceeding 944 HRS) 3Zaini SarbiniNo ratings yet

- Production Evaluation Report Highlights Key MetricsDocument102 pagesProduction Evaluation Report Highlights Key MetricsZeeshan KhanNo ratings yet

- 1A Tables v2Document1 page1A Tables v2Itss Mee HadiNo ratings yet

- Comprehensive guide to air-cooled diesel generatorsDocument31 pagesComprehensive guide to air-cooled diesel generatorslliu yunNo ratings yet

- Cat engine cutout test resultsDocument3 pagesCat engine cutout test resultsPILAR MARTINEZ100% (1)

- LUB - BM-B - DS-R3 30litrosDocument3 pagesLUB - BM-B - DS-R3 30litrosHenry SuarezNo ratings yet

- Standing Instructions: EE055-3-3-EOR Final Exam Page1of 6Document6 pagesStanding Instructions: EE055-3-3-EOR Final Exam Page1of 6abdilrhman sulimanNo ratings yet

- CatalogPlacementTestingReport PipingDocument1,055 pagesCatalogPlacementTestingReport Pipingag_f53No ratings yet

- DATA - Mercruiser 3Document12 pagesDATA - Mercruiser 3Bakri danoNo ratings yet

- (TM) Audi Manual de Propietario Audi A8 2006 en InglesDocument354 pages(TM) Audi Manual de Propietario Audi A8 2006 en InglesAlejandro AlvarezNo ratings yet

- Kep 00180-003 201903Document10 pagesKep 00180-003 201903Ronaldo Bandeira RodriguesNo ratings yet

- Technical Service Bulletin: 210-2418 Ed. 4 April 2006 AllDocument7 pagesTechnical Service Bulletin: 210-2418 Ed. 4 April 2006 AllPyro KDNo ratings yet

- MPM 312 01 51Document3 pagesMPM 312 01 51Mousa PetrolNo ratings yet

- Vacuum Pump Tuthill KVAH40 CatologueDocument20 pagesVacuum Pump Tuthill KVAH40 CatologueSamir JadhavNo ratings yet

- RPW Camshaft Spec FileDocument74 pagesRPW Camshaft Spec FileNic RoddaNo ratings yet

- PM of Stage-II MillDocument4 pagesPM of Stage-II MillJoydev GangulyNo ratings yet

- Project Status0Document3 pagesProject Status0AlHussien QadryNo ratings yet

- Design of Valve Lapping Machine For Ic EngineDocument35 pagesDesign of Valve Lapping Machine For Ic EngineIfa75% (4)

- Q12 057 Riello BX Low Nox Manual AddendumDocument22 pagesQ12 057 Riello BX Low Nox Manual AddendumKrystian RosiakNo ratings yet

- MDV-LDocument3 pagesMDV-LCelular Oil Control 05No ratings yet

- 00 General, Technical Data: Engine IdentificationDocument432 pages00 General, Technical Data: Engine IdentificationAngel SotoNo ratings yet

- 2 - Introduction To The ME Engine (June2012v2Document14 pages2 - Introduction To The ME Engine (June2012v2GiovanniJara100% (1)

- Service Bulletin: Teledyne Continental Aircraft Engine Category 3Document4 pagesService Bulletin: Teledyne Continental Aircraft Engine Category 3Kevin ArteagaNo ratings yet

- Catalog SBDocument40 pagesCatalog SBNicho WijayaNo ratings yet

- BOILER STEAM FLOWDocument1 pageBOILER STEAM FLOWzalabiNo ratings yet

- Case Models 385 384 585 685 885 Shop ManualDocument9 pagesCase Models 385 384 585 685 885 Shop Manualsarah100% (44)

- DTC P1349/73 VVT System Malfunction: Wiring DiagramDocument5 pagesDTC P1349/73 VVT System Malfunction: Wiring DiagramAnonymous tWYsgPmNo ratings yet

- LG OLEDB9P CNET Review Calibration ResultsDocument3 pagesLG OLEDB9P CNET Review Calibration ResultsDavid KatzmaierNo ratings yet

- SM - B02 - EJVE pg95Document95 pagesSM - B02 - EJVE pg95Panjang ManaNo ratings yet

- Mercruiser 5.0l Mpi Alpha BravoDocument136 pagesMercruiser 5.0l Mpi Alpha Bravorodrigo catalanNo ratings yet

- 1-3 Alpha LubricatorDocument6 pages1-3 Alpha LubricatorYury Shmyrkin100% (1)

- Altivar 61/71: Migration From ATV78 - ATV61/71 Migration ManualDocument22 pagesAltivar 61/71: Migration From ATV78 - ATV61/71 Migration ManualDhananjay MahakudNo ratings yet

- ATV 2015 OUTLANDER L (Continuously Variable Transmission (CVT) - 450) - Shop Manual - 04cE60AAE - SM51Y015S01 - enDocument22 pagesATV 2015 OUTLANDER L (Continuously Variable Transmission (CVT) - 450) - Shop Manual - 04cE60AAE - SM51Y015S01 - enfe100% (1)

- 2 - Introduction To The ME Engine PDFDocument14 pages2 - Introduction To The ME Engine PDFVikash Khaliyav Yadav50% (2)

- Woosung LOVD 36Document52 pagesWoosung LOVD 36sayeem bikashNo ratings yet

- DG Set Repair Rate ContractDocument17 pagesDG Set Repair Rate Contractboobalan_shriNo ratings yet

- Group 3 Work EquipmentDocument1 pageGroup 3 Work EquipmentTaha RdmanNo ratings yet

- Timing Synchronizing AdjustingDocument6 pagesTiming Synchronizing AdjustingRyan ActonNo ratings yet

- Spare Parts Catalogue: Powerful - Durable - ReliableDocument24 pagesSpare Parts Catalogue: Powerful - Durable - Reliablewillem0% (1)

- ConveyorDocument25 pagesConveyorDodi Iwan SumarnoNo ratings yet

- E90-803-001-001-01 - X 500-2 Brushless - 24v DCDocument20 pagesE90-803-001-001-01 - X 500-2 Brushless - 24v DCAlexNo ratings yet

- Case International 7110 7120 7130 7140 Shop ManualDocument10 pagesCase International 7110 7120 7130 7140 Shop Manualconnie100% (46)

- Form Report Overhaul TM 274 RevDocument14 pagesForm Report Overhaul TM 274 Revsersan darmin100% (1)

- Timing - Calibrate (RENR5012-03)Document5 pagesTiming - Calibrate (RENR5012-03)MichaelMonguiNo ratings yet

- Samsung Q9 CNET CalibrationDocument3 pagesSamsung Q9 CNET CalibrationDavid KatzmaierNo ratings yet

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsFrom EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsNo ratings yet

- Measurement Ignition Timing G6Document3 pagesMeasurement Ignition Timing G6Nico FajRiNo ratings yet

- Calibrated Woodward G5 - 23-09-2019 PDFDocument14 pagesCalibrated Woodward G5 - 23-09-2019 PDFNico FajRiNo ratings yet

- Operating Instructions: Gas Engine 20 V 4000 L32 FBDocument214 pagesOperating Instructions: Gas Engine 20 V 4000 L32 FBNico FajRiNo ratings yet

- List Obat K3Document1 pageList Obat K3Nico FajRiNo ratings yet

- SSRN Id983401Document43 pagesSSRN Id983401LeilaNo ratings yet

- The Role of Molecular Testing in The Differential Diagnosis of Salivary Gland CarcinomasDocument17 pagesThe Role of Molecular Testing in The Differential Diagnosis of Salivary Gland CarcinomasMariela Judith UCNo ratings yet

- Mode D'emploi 2-43 Operating Instructions 44-85 Manual de Instrucciones 86-127Document43 pagesMode D'emploi 2-43 Operating Instructions 44-85 Manual de Instrucciones 86-127Oleksii_ServiceNo ratings yet

- Crestron Teams HardeningDocument20 pagesCrestron Teams HardeningmanishNo ratings yet

- Turbo Plus PDFDocument27 pagesTurbo Plus PDFAnonymous iDJw3bDEW2No ratings yet

- EJN-00625 Installation of Manual Pull Valves in Deluge Systems For SOLPEDocument4 pagesEJN-00625 Installation of Manual Pull Valves in Deluge Systems For SOLPESARAVANAN ARUMUGAMNo ratings yet

- PTL Ls Programme HandbookDocument34 pagesPTL Ls Programme Handbooksalak946290No ratings yet

- Price List 2014: Valid From 01.04.2014, Prices in Euro, Excluding VAT. Previous Price Lists Will Become InvalidDocument106 pagesPrice List 2014: Valid From 01.04.2014, Prices in Euro, Excluding VAT. Previous Price Lists Will Become InvalidarifNo ratings yet

- International Journal of Plasticity: Dong Phill Jang, Piemaan Fazily, Jeong Whan YoonDocument17 pagesInternational Journal of Plasticity: Dong Phill Jang, Piemaan Fazily, Jeong Whan YoonGURUDAS KARNo ratings yet

- Ulliensb PDF 1516040087Document30 pagesUlliensb PDF 1516040087Jose Daniel ArangoNo ratings yet

- CW3 - 4Document2 pagesCW3 - 4Rigel Zabate100% (1)

- Atlantic Revolutions: Ogé Insurrection Inspired Haitian IndependenceDocument18 pagesAtlantic Revolutions: Ogé Insurrection Inspired Haitian IndependenceNiara ChaneyNo ratings yet

- Mechanical Seminar ListDocument9 pagesMechanical Seminar ListalokbdasNo ratings yet

- Manual Flowpet 5GDocument56 pagesManual Flowpet 5GRahkmat DanizarNo ratings yet

- The Spanish-American War (History 70)Document11 pagesThe Spanish-American War (History 70)Tine AtaamNo ratings yet

- UPT Unit 8 Vers ADocument12 pagesUPT Unit 8 Vers AValeria GarciaNo ratings yet

- PRINCIPLES OF MANAGEMENT Model Questions - ADocument4 pagesPRINCIPLES OF MANAGEMENT Model Questions - ALionel MintsaNo ratings yet

- 144-WARA AD 2.1 To AD 2.24 AIRAC AIP AMDT 125 26 JAN 23Document9 pages144-WARA AD 2.1 To AD 2.24 AIRAC AIP AMDT 125 26 JAN 23latsar kusumoNo ratings yet

- Impact On Cocoon Quality Improvement.1Document10 pagesImpact On Cocoon Quality Improvement.1Naveen NtrNo ratings yet

- Zodiac Working Boat MK6HDDocument4 pagesZodiac Working Boat MK6HDdan antonNo ratings yet

- Agreement: /ECE/324/Rev.2/Add.127 /ECE/TRANS/505/Rev.2/Add.127Document29 pagesAgreement: /ECE/324/Rev.2/Add.127 /ECE/TRANS/505/Rev.2/Add.127Mina RemonNo ratings yet

- Nikita Rajput: Anchor/Host/Master of CeremoniesDocument21 pagesNikita Rajput: Anchor/Host/Master of CeremoniesnamanNo ratings yet

- Control unit checks gas burner valve tightness according to EN 1643Document12 pagesControl unit checks gas burner valve tightness according to EN 1643alfredomamutNo ratings yet

- Vodacom Fibre - Application Form CPD - 23 August 2018Document8 pagesVodacom Fibre - Application Form CPD - 23 August 2018Mla Emmanuel ZondoNo ratings yet

- Importance of Communication by ThiruvalluvarDocument7 pagesImportance of Communication by ThiruvalluvarRamavallabhanNo ratings yet

- Space Management Guidelines: Brief SummaryDocument17 pagesSpace Management Guidelines: Brief SummaryMOHD JIDINo ratings yet

- Chapter 6Document53 pagesChapter 6Sam KhanNo ratings yet

- Jurnal Tentang Akuntansi Dengan Metode Kualitatif IDocument8 pagesJurnal Tentang Akuntansi Dengan Metode Kualitatif IAfni FebrianaNo ratings yet

- Champions MindsetDocument48 pagesChampions MindsetDIRECTIA INVATAMINT HINCESTI100% (1)