Professional Documents

Culture Documents

Manual 02877 723PLUS Hardware Manual

Uploaded by

Milton Andres Leon HernandezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual 02877 723PLUS Hardware Manual

Uploaded by

Milton Andres Leon HernandezCopyright:

Available Formats

Manual 02877 723PLUS Hardware Manual

SYSTEM The following is a general troubleshooting guide for areas to check which may

TROUBLE- present potential difficulties. By making these checks appropriate to your engine/

SHOOTING turbine before contacting Woodward for technical assistance, your system

GUIDE problems can be more quickly and accurately assessed.

Actuators • Is the oil clean?

• Is the oil level normal?

• Does the actuator have the correct hydraulic pressure (if required)?

• Does the actuator have the correct pneumatic pressure (if required)?

• Does the driveshaft rotate (if required), and in the correct direction?

• Is the actuator wiring correct?

• Is the direction of the stroke correct?

• Has the compensation (if so equipped) been adjusted correctly?

• If there is a mechanical governor, are the speed, droop, and load limit

adjusted correctly?

• Is the hydraulic return line free and not clogged?

• Is there back pressure on the hydraulic return line?

• Is the feedback (if any) adjusted correctly and sending the correct signal?

Linkage • Is there slop or lost motion?

• Is there misalignment, binding, or side loading?

• Is there visible wear or scarring?

• Does the linkage move smoothly?

Valves • Does the valve move through it’s proper stroke smoothly?

• Does the valve travel it’s full stroke?

• Can mid-stroke be obtained and held?

• Does the valve fully seat (close) before the governor reaches full

minimum stroke?

• Does the valve fully open before the governor reaches maximum stroke?

• Is the bypass valve(s) (if any) in the proper position?

• If a steam turbine, are there nicks or contamination which allow steam to

pass when the valve is closed?

Woodward Governor Company 33

723PLUS Hardware Manual Manual 02877

Oil/Hydraulic • Is the oil at the proper operating pressure?

System

• Is the oil temperature too high for the type of oil being used?

• Is the oil contaminated?

• Does the actuator have sufficient flow of oil?

• Are the accumulators (if any) charged to the correct pressure?

• Are the filters plugged?

• Is the oil pump operating properly?

Fuel Injection • Are any rack shafts stuck?

Pumps

• Do all rack shafts move through their full stroke smoothly?

• Are all rack shaft settings equal, cylinder to cylinder, as the governor

output shaft is rotated from min to max fuel?

• Are any drain lines clogged?

• Are all injection lines in good condition and free of leaks?

Fuel/Steam • Is the engine/turbine inlet pressure at design specification?

Conditions

• Is the fuel/steam pressure in the proper operating range?

• Are pressure transducers (if any) located close to the engine/turbine?

• Are there any pressure regulating devices or valves which may interfere

with governor operation or proper fuel/steam flow?

Control, Alarm, • Does the governor indicate it is in the correct control mode?

And Fault

• Is the governor issuing any alarms?

Indications

• Are any of the components of the governor indicating hardware faults?

• Does the actuator demand agree with the actual valve position?

• Are any shutdown conditions present?

• Have the control dynamics been tuned to match the system response?

Input Signals • Are all input signals properly scaled?

• Are the inputs free of electrical noise and properly shielded?

• Is the wiring correct?

• Have all field input signals to the control been verified?

• Is the polarity of the signals correct?

34 Woodward Governor Company

Manual 02877 723PLUS Hardware Manual

Output Signals • Are the outputs calibrated?

• Have the actuator drivers been calibrated to the stroke of the fuel injection

pump, fuel valves, or turbine valves?

• Are the output signals free of noise and properly shielded?

• Is the wiring correct?

Transducers • Is the transducer calibrated for the proper range?

• Has it been tested by simulating it’s input and measuring it’s output

signal?

• Does the transducer have power?

• Are the sensing lines feeding the transducer clear of obstructions?

• Are all block, bleed, and bypass valves positioned properly?

Magnetic Pickups • Is the wiring between the speed sensing pickup and the control correct?

And Other Speed

• Are there any grounding problems or worn shields?

Sensing Devices

• Is the signal sufficient (at least 1.5 Vrms)?

• Is the signal a clean sine wave or square wave with no spikes or

distortions?

• Is the MPU head clean and free of oil or metallic particles?

• Is the MPU head free of any nicks or chips?

• Is the MPU or proximity probe correctly aligned with the gear?

• Is the speed sensing probe adjusted to the correct gap?

• Is the speed sensing probe head the correct size for the toothed wheel it is

being used with?

Input Voltage/ • Is the input power within the range of the control’s power supply input?

Power Supplies

• Is the input power free of switching noise or transient spikes?

• Is the power circuit dedicated to the governor only?

• Are the control’s supplies indicating that they are OK?

• Are the control’s supplies outputting the correct voltage?

Woodward Governor Company 35

723PLUS Hardware Manual Manual 02877

Electrical • Are all electrical connections tight and clean?

Connections

• Are all signal wires shielded?

• Are shields continuous from the device to the control?

• Are the shields terminated according to Woodward specifications?

• Are there low voltage signal wires running in the same wiring trays as

high voltage wiring?

• Are the governor’s signal common or grounds not tied to any other

devices?

• Have the signals been checked for electrical noise?

Voltage • Is the voltage regulator working properly?

Regulator

External Devices • Are there external devices the control is dependent on for input signals?

• Are these devices providing the correct signal to the control?

• Is the external device configured or programmed to be compatible with

the control?

36 Woodward Governor Company

You might also like

- On Load Tap ChangersDocument42 pagesOn Load Tap ChangersRama Krishna100% (2)

- Inverter Training 08-BASICDocument91 pagesInverter Training 08-BASICGinguba100% (3)

- Anesthesia MachineDocument55 pagesAnesthesia Machineshikha100% (1)

- MAN K100 Electrical System TGS-TGXDocument236 pagesMAN K100 Electrical System TGS-TGXIrfanKujović92% (51)

- Troubleshooting & Repairing Consumer Electronics Without a SchematicFrom EverandTroubleshooting & Repairing Consumer Electronics Without a SchematicNo ratings yet

- Nissan Sentra 2016Document40 pagesNissan Sentra 2016wilder0l0pezNo ratings yet

- Lecture 10 DC To DC ConvertersDocument68 pagesLecture 10 DC To DC Convertersprabhash anandNo ratings yet

- Calibration Procedure FOR Calipers General: Technical ManualDocument8 pagesCalibration Procedure FOR Calipers General: Technical ManualrcmetrologyNo ratings yet

- Components in LiftDocument2 pagesComponents in LiftDausCR7No ratings yet

- 3516B LocoDocument4 pages3516B LocomarcosNo ratings yet

- Presentation On RIG and CRANESDocument58 pagesPresentation On RIG and CRANESSathya NarayanaNo ratings yet

- Model 70 Classé Audio Inc. Service Manual: Date: August 27, 2007 Model Number: SubjectDocument15 pagesModel 70 Classé Audio Inc. Service Manual: Date: August 27, 2007 Model Number: SubjectVictor TettehNo ratings yet

- How To Achieve Zero AccidentDocument108 pagesHow To Achieve Zero AccidentAjit BhosaleNo ratings yet

- BACKHOE LOADER Pre-Operations ChecklistDocument3 pagesBACKHOE LOADER Pre-Operations Checklistmanny daleonNo ratings yet

- Custody Transfer MeteringDocument57 pagesCustody Transfer MeteringMade Wikan100% (5)

- LY38 Ops Manual PDFDocument36 pagesLY38 Ops Manual PDForlando chullo llave100% (1)

- Maintenance & Troubleshooting: Problem IsolationDocument16 pagesMaintenance & Troubleshooting: Problem IsolationÁgost VitaNo ratings yet

- Engineering Guide PRICEDocument21 pagesEngineering Guide PRICEThiru KumarNo ratings yet

- Inverter Duty MotorDocument6 pagesInverter Duty Motorseshubabu_999No ratings yet

- 7 Types of AbnormalitiesDocument23 pages7 Types of AbnormalitiesBalachandar SathananthanNo ratings yet

- Troubleshooting and Maintenance: in This Chapter...Document16 pagesTroubleshooting and Maintenance: in This Chapter...yohannes tsegayeNo ratings yet

- 12.testing and CommissioningDocument13 pages12.testing and CommissioningShanker PandeyNo ratings yet

- Trouble Shooting Guide For Incremental Encoders: Technical BulletinDocument2 pagesTrouble Shooting Guide For Incremental Encoders: Technical Bulletinjulio cidNo ratings yet

- GTS - Industrial Automation ProfileDocument2 pagesGTS - Industrial Automation Profilerusiru.dpvNo ratings yet

- Best Practices Desaereator 1 PDFDocument34 pagesBest Practices Desaereator 1 PDFWayne GajadharNo ratings yet

- The Six - Fundamental Control Strategies PDFDocument48 pagesThe Six - Fundamental Control Strategies PDFAnonymous AsIbqUNo ratings yet

- Visual Engine Inspection Checklist.: Fuel System Yes No 1 2 3 4 5 6 7 8 9 10Document4 pagesVisual Engine Inspection Checklist.: Fuel System Yes No 1 2 3 4 5 6 7 8 9 10PramodNo ratings yet

- Sequent 24 Installers HandbookDocument15 pagesSequent 24 Installers HandbookrugxNo ratings yet

- 22 Rig Audit PDF AlyDocument10 pages22 Rig Audit PDF AlyKhaled YazidNo ratings yet

- Encoder Troubleshooting GuideDocument2 pagesEncoder Troubleshooting GuidejccNo ratings yet

- Precision Checklist PDFDocument4 pagesPrecision Checklist PDFResianing MaritaNo ratings yet

- Transmicion MerconvDocument8 pagesTransmicion MerconvCesarNo ratings yet

- Hitachi Inverter PDFDocument18 pagesHitachi Inverter PDFFERNSNo ratings yet

- HFVL Trouble Shooting PDFDocument18 pagesHFVL Trouble Shooting PDFFERNSNo ratings yet

- Troubleshooting and Maintenance: in This Chapter...Document18 pagesTroubleshooting and Maintenance: in This Chapter...FERNSNo ratings yet

- AdvHydMotionDesignPractices Paso PDFDocument59 pagesAdvHydMotionDesignPractices Paso PDFPramodVermaNo ratings yet

- LocomotiveDocument27 pagesLocomotiveBlessy MabasaNo ratings yet

- 7mfge25 Maintenance of Electrical Equipment ppt7Document41 pages7mfge25 Maintenance of Electrical Equipment ppt7Athena GrotesqueNo ratings yet

- 62 - 86 - Troubleshoot (2023 - 05 - 04 14 - 43 - 50 UTC)Document3 pages62 - 86 - Troubleshoot (2023 - 05 - 04 14 - 43 - 50 UTC)lwalker1545No ratings yet

- Discussion Group T 14Document1 pageDiscussion Group T 14rodruren01No ratings yet

- Transformer-Operation & InspectionDocument31 pagesTransformer-Operation & InspectionSuresh MishraNo ratings yet

- Indigo Interview QuestionsDocument3 pagesIndigo Interview QuestionsRajesh MNo ratings yet

- InstallationDocument32 pagesInstallationcartarNo ratings yet

- AC Systems TroubleshootingDocument39 pagesAC Systems Troubleshootingkesavaganesan58No ratings yet

- Combined Karcher AR Trouble ShootingDocument18 pagesCombined Karcher AR Trouble ShootingFrancisco Eric CelestinoNo ratings yet

- Control Valve Final Control Element in BriefDocument38 pagesControl Valve Final Control Element in BriefSagar Pawar100% (1)

- Heavy Duty - Fleet Critical Stats Wf27-152aDocument2 pagesHeavy Duty - Fleet Critical Stats Wf27-152ajoshuah171No ratings yet

- Heavy Duty - Fleet Critical Stats Wf27-152aDocument2 pagesHeavy Duty - Fleet Critical Stats Wf27-152ajoshuah171No ratings yet

- Fluid Check Ig Cd4eDocument5 pagesFluid Check Ig Cd4enameNo ratings yet

- Mechatronics 10 3-2-2022Document14 pagesMechatronics 10 3-2-2022Varun VaruNo ratings yet

- E-Series Spare Partkits0407enDocument2 pagesE-Series Spare Partkits0407enChandra NurikoNo ratings yet

- Control Valve TypesDocument46 pagesControl Valve TypesAnderson SiqueiraNo ratings yet

- Codici Avaria EMS II D16Document10 pagesCodici Avaria EMS II D16Claudio CarrettiNo ratings yet

- NB 34AS 5R55W S N Installation GuideDocument8 pagesNB 34AS 5R55W S N Installation GuideCuentas RedproNo ratings yet

- Whirlpool AWG 1112Document16 pagesWhirlpool AWG 1112and andrewNo ratings yet

- Electrical Control System Components Topic 5 - 2Document33 pagesElectrical Control System Components Topic 5 - 2Vedant .ChavanNo ratings yet

- E3. MC-041 Hdraulics and Electro-Hydraulics Training SystemDocument10 pagesE3. MC-041 Hdraulics and Electro-Hydraulics Training Systemmanual imbNo ratings yet

- ATV 71 Installation Manual - ENDocument42 pagesATV 71 Installation Manual - ENFawzi AlzubairyNo ratings yet

- PSG Module IIDocument47 pagesPSG Module IIDr. Srinivas MNo ratings yet

- Pilot Operated Relief Valve NewDocument2 pagesPilot Operated Relief Valve NewNur Syazwani KhalidNo ratings yet

- ICU Ventilation 17nov2022!2!5 Trouble Shooting Guide LP VentilationDocument4 pagesICU Ventilation 17nov2022!2!5 Trouble Shooting Guide LP Ventilationmuhammad.baghdayNo ratings yet

- Maintenance: & Troubleshooting GuideDocument28 pagesMaintenance: & Troubleshooting GuideALBERTO CUEVASNo ratings yet

- TMP XAPRtLDocument17 pagesTMP XAPRtLengmohsen.ramadanhotmail.comNo ratings yet

- 1-1cvjgdf Ys840di Errorcode of Alarm 380500-DeuDocument14 pages1-1cvjgdf Ys840di Errorcode of Alarm 380500-DeuNazar AbbasNo ratings yet

- Overhead CranesDocument50 pagesOverhead CraneshamzanusratNo ratings yet

- Edoc-What Is Automatic Transfer Switch Testing and How Is It DoneDocument9 pagesEdoc-What Is Automatic Transfer Switch Testing and How Is It DoneEl Comedor Benedict100% (1)

- Mini y Notebooks Jonas BrothersDocument4 pagesMini y Notebooks Jonas BrothersCristina MéndezNo ratings yet

- Sluaa 46Document11 pagesSluaa 46ANo ratings yet

- MLX75012Document18 pagesMLX75012Ali AbdoNo ratings yet

- Baschirotto 2006Document7 pagesBaschirotto 2006Roby TristiAantoroNo ratings yet

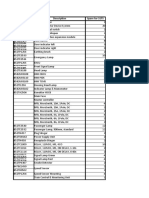

- Material Code Description Spare For 31TSDocument1 pageMaterial Code Description Spare For 31TSBhimantara Yudha PrawiraNo ratings yet

- Arnu 36GT BB4: Btu/h Indoor UnitDocument2 pagesArnu 36GT BB4: Btu/h Indoor UnitMILAGROS DEL CARMEN MENDOZA VELIT0% (1)

- IP Code - Wikipedia PDFDocument25 pagesIP Code - Wikipedia PDFEndhy Wisnu NovindraNo ratings yet

- Emanate White PaperDocument14 pagesEmanate White PapervikydilseNo ratings yet

- Earthing SystemDocument9 pagesEarthing SystemSahiNo ratings yet

- FY Series Digital PID Controller Operation ManualDocument58 pagesFY Series Digital PID Controller Operation ManualRaviKoiralaNo ratings yet

- Small Signal Transistors TO-92 Case (Continued)Document1 pageSmall Signal Transistors TO-92 Case (Continued)roozbehxoxNo ratings yet

- Acer AL1916eDocument40 pagesAcer AL1916eDeyProNo ratings yet

- 501-0623 Magnetic Stimulation Accessories Catalogue Rev 5.7Document52 pages501-0623 Magnetic Stimulation Accessories Catalogue Rev 5.7jmolineteNo ratings yet

- Coa Unit-2Document25 pagesCoa Unit-2PARTEEK RANANo ratings yet

- 45 200kva Triphase Servomotor StabilizerDocument1 page45 200kva Triphase Servomotor StabilizerCristian DorofteiNo ratings yet

- 7525 Lexmark X543-X544-X546.service ManualDocument351 pages7525 Lexmark X543-X544-X546.service ManualMark BeechNo ratings yet

- Electrode Technical ManualDocument11 pagesElectrode Technical ManualBebas Lagi AjaNo ratings yet

- C Ca Cad CL L 1 PDFDocument56 pagesC Ca Cad CL L 1 PDFtayantrungquochpNo ratings yet

- XD 502 4 Page RVD 4 5 22Document4 pagesXD 502 4 Page RVD 4 5 22Ahmed ElsayedNo ratings yet

- Integrated Circuit Fabrication Process Study Notes For ECEDocument9 pagesIntegrated Circuit Fabrication Process Study Notes For ECEkrishnaav100% (1)

- Chap9 PDFDocument50 pagesChap9 PDFpramani90No ratings yet

- Amplitude of The Wave Scattered by An Atom Amplitude of The Wave Scattered by One ElectronDocument3 pagesAmplitude of The Wave Scattered by An Atom Amplitude of The Wave Scattered by One ElectronDesty WulanNo ratings yet