Professional Documents

Culture Documents

Analysis of Fiber-Reinforced Polymer Composite Grid Reinforced Concrete Beams

Uploaded by

RajKumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis of Fiber-Reinforced Polymer Composite Grid Reinforced Concrete Beams

Uploaded by

RajKumarCopyright:

Available Formats

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no. 100-S27

Analysis of Fiber-Reinforced Polymer Composite Grid

Reinforced Concrete Beams

by Federico A. Tavarez, Lawrence C. Bank, and Michael E. Plesha

This study focuses on the use of explicit finite element analysis conventional steel or FRP bars. Therefore, the behavior of

tools to predict the behavior of fiber-reinforced polymer (FRP) concrete beams with this type of reinforcement needs to be

composite grid reinforced concrete beams subjected to four-point thoroughly investigated.

bending. Predictions were obtained using LS-DYNA, an explicit

finite element program widely used for the nonlinear transient

analysis of structures. The composite grid was modeled in a discrete OBJECTIVES

manner using beam and shell elements, connected to a concrete The objectives of the present study were: 1) to investigate

solid mesh. The load-deflection characteristics obtained from the the ability of explicit finite element analysis tools to predict

simulations show good correlation with the experimental data. the behavior of composite grid reinforced concrete beams,

Also, a detailed finite element substructure model was developed to including load-deflection characteristics and failure modes;

further analyze the stress state of the main longitudinal reinforce- 2) to evaluate the effect of the shear span-depth ratio in the

ment at ultimate conditions. Based on this analysis, a procedure failure mode of the beams and the stress state of the main

was proposed for the analysis of composite grid reinforced concrete

flexural reinforcement at ultimate conditions; and 3) to

beams that accounts for different failure modes. A comparison of

the proposed approach with the experimental data indicated that

develop an alternate procedure for the analysis of composite grid

the procedure provides a good lower bound for conservative reinforced concrete beams considering multiple failure modes.

predictions of load-carrying capacity.

RESEARCH SIGNIFICANCE

Keywords: beam; composite; concrete; fiber-reinforced polymer; reinforce- The research work presented describes the use of advanced

ment; shear; stress. numerical simulation for the analysis of FRP reinforced

concrete. These numerical simulations can be used effectively

INTRODUCTION to understand the complex behavior and phenomena observed

In recent years, research on fiber-reinforced polymer (FRP) in the response of composite grid reinforced concrete beams. In

composite grids has demonstrated that these products may be as particular, this effort provides a basis for the understanding of

practical and cost-effective as reinforcements for concrete the interaction between the composite grid and the concrete

structures.1-5 FRP grid reinforcement offers several advantages when large flexural-shear cracks are present. As such, alternate

in comparison with conventional steel reinforcement and FRP analysis and design techniques can be developed based on the

reinforcing bars. FRP grids are prefabricated, noncorrosive, and understanding obtained from numerical simulations to ensure

lightweight systems suitable for assembly automation and ideal the required capacity in FRP reinforced concrete structures.

for reducing field installation and maintenance costs. Research

on constructability issues and economics of FRP reinforcement

Background

cages for concrete members has shown the potential of

Several researchers have studied the viability of three-

these reinforcements to reduce life-cycle costs and significantly

dimensional FRP grids to reinforce concrete members.3,5,9,10

increase construction site productivity.6

One specific type of three-dimensional FRP reinforcement is

Three-dimensional FRP composite grids provide a mechanical

constructed from commercially manufactured pultruded FRP

anchorage within the concrete due to intersecting elements, and

profiles (also referred to as FRP grating cages). Figure 1 shows

thus no bond is necessary for proper load transfer. This type of

a schematic of the structural members present in a concrete

reinforcement provides integrated axial, flexural, and shear

beam reinforced with the three-dimensional FRP reinforcement

reinforcement, and can also provide a concrete member with

investigated in this study.

the ability to fail in a pseudoductile manner. Continuing

research is being conducted to fully understand the behavior of A pilot experimental and analytical study was conducted

composite grid reinforced concrete to commercialize its use by Bank, Frostig, and Shapira3 to investigate the feasibility

and gain confidence in its design for widespread structural of developing three-dimensional pultruded FRP grating cages

applications. For instance, there is a need to predict the correct to reinforce concrete beams. Failure of all beams tested occurred

failure mode of composite grid reinforced concrete beams due to rupture of the FRP main longitudinal reinforcement in

where there is significant flexural-shear cracking.7 This type the shear span of the beam. Experimental results also revealed

of information is critical for the development of design that most of the deflection at high loads appeared to occur

guidelines for FRP grid reinforced concrete members. due to localized rotations at large flexural crack widths

Current flexural design methods for FRP reinforced concrete

beams are analogous to the design of concrete beams using ACI Structural Journal, V. 100, No. 2, March-April 2003.

conventional reinforcement.8 The geometrical shape, ductility, MS No. 02-100 received March 27, 2002, and reviewed under Institute publication

policies. Copyright © 2003, American Concrete Institute. All rights reserved, includ-

modulus of elasticity, and force transfer characteristics of FRP ing the making of copies unless permission is obtained from the copyright proprietors.

Pertinent discussion will be published in the January-February 2004 ACI Structural

composite grids, however, are likely to be different than Journal if received by September 1, 2003.

250 ACI Structural Journal/March-April 2003

Federico A. Tavarez is a graduate student in the Department of Engineering Physics

at the University of Wisconsin-Madison. He received his BS in civil engineering from

the University of Puerto Rico-Mayagüez and his MSCE from the University of

Wisconsin. His research interests include finite element analysis, the use of composite

materials for structural applications, and the use of discrete element methods for

modeling concrete damage and fragmentation under impact.

ACI member Lawrence C. Bank is a professor in the Department of Civil and

Environmental Engineering at the University of Wisconsin-Madison. He received his

PhD in civil engineering and engineering mechanics from Columbia University in

1985. He is a member of ACI Committee 440, Fiber Reinforced Polymer Reinforcement.

His research interests include FRP reinforcement systems for structures, progressive

failure of materials and structural systems, and durability of FRP materials.

Fig. 1—Structural members in composite grid reinforced

Michael E. Plesha is a professor in the Engineering Mechanics and Astronautics concrete beam.

Program in the Department of Engineering Physics at the University of Wisconsin-

Madison. He received his PhD from Northwestern University in 1983. His research

interests include finite element analysis, discrete element analysis, dynamics of

geologic media, constitutive modeling of geologic discontinuity behavior, soil structure

interaction modeling, and continuum modeling of jointed saturated rock masses.

developed in the shear span near the load points. The study

concluded that further research was needed to obtain a better

understanding of the stress state in the longitudinal rein-

forcement at failure to predict the correct capacity and failure

modes of the beams.

Further experimental tests on concrete beams reinforced

with three-dimensional FRP composite grids were conducted to

investigate the behavior and performance of the grids when

used to reinforce beams that develop significant flexural-shear

cracking.7 Different composite grid configurations were

designed to study the influence of the FRP grid components

(longitudinal bars, vertical bars, and transverse bars) on the Fig. 2—Deformation due to rotation of rigid bodies.

load-deflection behavior and failure modes. Even though failure

modes of the beams were different depending upon the Numerical analysis of FRP composite grid

characteristics of the composite grid, all beams failed in their reinforced beams

shear spans. Failure modes included splitting and rupture of Implicit finite element methods are usually desirable for

the main longitudinal bars and shear-out failure of the the analysis of quasistatic problems. Their efficiency and

vertical bars. Research results concluded that the design accuracy, however, depend on mesh topology and severity

of concrete beams with composite grid reinforcements must of nonlinearities. In the problem at hand, it would be very

account for failure of the main bars in the shear span. difficult to model the nonlinearities and progressive damage/

A second phase of this experimental research was performed failure using an implicit method, and thus an explicit method

by Ozel and Bank5 to investigate the capacity and failure modes was chosen to perform the analysis.15

of composite grid reinforced concrete beams with different shear Using an explicit finite element method, especially to

span-to-effective depth ratios. Three different shear span- model a quasistatic experiment as the one presented herein,

depth ratios (a/d) were investigated, with values of 3, 4.5, and 6, can result in long run times due to the large number of time

respectively.11 The data obtained from this recently completed steps that are required. Because the time step depends on the

experimental study was compared with the finite element results smallest element size, efficiency is compromised by mesh

obtained in the present study. refinement. The three-dimensional finite element mesh for

Experimental studies have shown that due to the develop- this study was developed in HyperMesh16 and consisted of

ment of large cracks in the FRP-reinforced concrete beams, brick elements to represent the concrete, shell elements to

most of the deformation takes place at a relatively small represent the bottom longitudinal reinforcement, and beam

number of cracks between rigid bodies.12 A schematic of this elements to represent the top reinforcement, stirrups, and

behavior is shown in Fig. 2. As a result, beams with relatively cross rods. Figure 3 shows a schematic of the mesh used for

small shear span-depth ratios typically fail due to rupture of the the models developed. Beams with span lengths of 2300,

main FRP longitudinal reinforcement at large flexural-shear 3050, and 3800 mm were modeled corresponding to shear

cracks, even though they are over-reinforced according to span-depth ratios of 3, 4.5, and 6, respectively. These models

conventional flexural design procedures.5,7,13,14 Due to the are referred to herein as short beam, medium beam, and long

aforementioned behavior for beams reinforced with composite beam, respectively. The cross-sectional properties were

grids, especially those that exhibit significant flexural-shear identical for the three models. As will be seen later, the longi-

cracking, it is postulated that the longitudinal bars in the tudinal bars play an important role in the overall behavior of the

member are subjected to a uniform tensile stress distribution, system, and therefore they were modeled with greater detail

plus a nonuniform stress distribution due to localized rota- than the rest of the reinforcement. The concrete representation

tions at large cracks, which can be of great importance in consisted of 8-node solid elements with dimensions 25 x 25 x

determining the ultimate flexural strength of the beam. The 12.5 mm (shortest dimension parallel to the width of the beam),

present study investigates the stress-state at the flexural- with one-point integration. The mesh discretization was estab-

shear cracks in the main longitudinal bars, using explicit lished so that the reinforcement nodes coincided with the

finite element tools to simulate this behavior and determine concrete nodes. The reinforcement mesh was connected to the

the conditions that will cause failure in the beam. concrete mesh by shared nodes between the concrete and the

ACI Structural Journal/March-April 2003 251

Fig. 3—Finite element model for composite grid reinforced concrete beam.

Fig. 4—Short beam model at several stages in simulation.

reinforcement. As such, a perfect bond is assumed between the Boundary conditions and event simulation time

concrete and the composite grid. To simulate simply supported conditions, the beam was

The two-node Hughes-Liu beam element formulation with supported on two rigid plates made of solid elements. The

2 x 2 Gauss integration was used for modeling the top longi- finite element simulations were displacement controlled,

tudinal bars, stirrups, and cross rods in the finite element which is usually the control method for plastic and nonlinear

models. In this study, each model contains two top longitudinal behavior. That is, a displacement was prescribed on the rigid

bars with heights of 25 mm and thicknesses of 4 mm. The loading plates located on top of the beam. The prescribed

models also have four cross rods and three vertical members displacement was linear, going from zero displacement at t =

at each stirrup location, as shown in Fig. 3. The vertical 0.0 s to 60, 75, and 90 mm at t = 1.0 s for the short, medium,

members have a width of 38 mm and a thickness of 6.4 mm. and long beams, respectively. The corresponding applied

The cross rod elements have a circular cross-sectional load due to the prescribed displacement was then determined

area with a diameter of 12.7 mm. To model the bottom by monitoring the vertical reaction forces at the concrete

longitudinal reinforcement, the four-node Belytschko- nodes in contact with the support elements.

Lin-Tsay shell element formulation was used, as shown The algorithm CONTACT_AUTOMATIC_SINGLE_

in Fig. 3, with two through-the-thickness integration points. SURFACE in LS-DYNA was used to model the contact

252 ACI Structural Journal/March-April 2003

between the supports, load bars, and the concrete beam.

This algorithm automatically generates slave and master

surfaces and uses a penalty method where normal interface

springs are used to resist interpenetration between element

surfaces. The interface stiffness is computed as a function

of the bulk modulus, volume, and face area of the elements

on the contact surface.

The finite element analysis was performed to represent

quasistatic experimental testing. As the time over which the

load is applied approaches the period of the lowest natural

frequency of vibration of the structural system, inertial forces

become more important in the response. Therefore, the load

application time was chosen to be long enough so that inertial

effects would be negligible. The flexural frequency of vibration

was computed analytically for the three beams using conven-

tional formulas for vibration theory. 17 Accordingly, it was

determined that having a load application time of 1.0 s

was sufficiently long so that inertial effects are negligible Fig. 5—Experimental and finite element load-deflection

and the analysis can be used to represent a quasistatic experi- results for short, medium, and long beams.

ment. For the finite element simulations presented in this

study, the CPU run time varied approximately from 22 to

65 h (depending on the length of the beam) for 1.0 s of load

application time on a 600 MHz PC with 512 MB RAM.

Material models

Material Type 72 (MAT_CONCRETE_DAMAGE) in

LS-DYNA was chosen for the concrete representation in the

present study. This material model has been used successfully Fig. 6—Typical failure of composite grid reinforced concrete

for predicting the response of standard uniaxial, biaxial, and beam (Ozel and Bank5).

triaxial concrete tests in both tension and compression. The

formulation has also been used successfully to model the

behavior of standard reinforced concrete dividing walls Table 1—Material properties of FRP bottom bars

subjected to blast loads.18 This concrete model is a plasticity-

Ex 26.7 GPa Xt 266.8 MPa

based formulation with three independent failure surfaces

(yield, maximum, and residual) that change shape depending Ey 14.6 GPa Yt 151.0 MPa

on the hydrostatic pressure of the element. Tensile and Gxy 3.6 GPa Sc 6.9 MPa

compressive meridians are defined for each surface, describing νxy 0.26 Xc 177.9 MPa

the deviatoric part of the stress state, which governs failure in β 0.5 Yc 302.0 MPa

the element. Detailed information about this concrete material

model can be found in Malvar et al.18 The values used in

the input file corresponded to a 34.5 MPa concrete compressive (MAT_RIGID) was used to model the supports and the

strength with a 0.19 Poisson’s ratio and a tensile strength of loading plates.

3.4 MPa. The softening parameters in the model were chosen to

be 15, –50, and 0.01 for uniaxial tension, triaxial tension, and FINITE ELEMENT RESULTS AND DISCUSSION

compression, respectively.19 Graphical representations of the finite element model for

The longitudinal bars were modeled using an orthotropic the short beam at several stages in the simulation are shown

material model (MAT_ENHANCED_COMPOSITE_DAMAGE), in Fig. 4. The lighter areas in the model represent damage

which is material Type 54 in LS-DYNA. Properties used for (high effective plastic strain) in the concrete material model.

this model are shown in Table 1. Because the longitudinal As expected, there is considerable damage in the shear span

bars were drilled with holes for cross rod connections, the of the concrete beam. Figure 4 also shows the behavior of the

tensile strength in the longitudinal direction of the FRP bars composite grid inside the concrete beam. All displacements

was taken from experimental tensile tests conducted on in the simulation graphics were amplified using a factor of 5

notched bar specimens with a 12.7 mm hole to account to enable viewing. Actual deflection values are given in

for stress concentration effects at the cross rod locations. Fig. 5, which shows the applied load versus midspan deflec-

The tensile properties in the transverse direction were tion behavior for the short, medium, and long beams for the

taken from tests on unnotched specimens. 11 Values for experimental and LS-DYNA results, respectively. The

shear and compressive properties were chosen based on jumps in the LS-DYNA curves in the figure represent the

data in the literature. The composite material model uses progressive tensile and shear failure in the concrete elements. As

the Chang/Chang failure criteria. 20 shown in this figure, the ultimate load value from the finite

The remaining reinforcement (top longitudinal bars, stirrups, element model agrees well with the experimental result. The

and cross rods) was modeled using two-noded beam elements model slightly over-predicts the stiffness of the beam, however,

using a linear elastic material model (MAT_ELASTIC) with and under-predicts the ultimate deflection.

the same properties used for the longitudinal direction in the The significant drop in load seen in the load-deflection

bottom FRP longitudinal bars. A rigid material model curves produced in LS-DYNA is caused by failure in the

ACI Structural Journal/March-April 2003 253

Fig. 7—Medium beam model at several stages in simulation.

Fig. 8—Long beam model at several stages in simulation.

longitudinal bars, as seen in Fig. 4. The deformed shape were observed in the short beam, which would imply that this

seen in this figure indicates a peculiar behavior through- model does not exhibit significant flexural-shear damage. For

out the length of the beam. It appears to indicate that after this model, the finite element analysis slightly over-predicted

a certain level of damage in the shear span of the model, both the stiffness and the ultimate load value obtained from

localized rotations occur in the beam near the load points. the experiment. On the other hand, the ultimate deflection

These rotations create a stress concentration that causes was under-predicted. Failure in this model was also caused

the longitudinal bars to fail at those locations. This deflection by rupture of the longitudinal bars at a location near the load

behavior was also observed in the experimental tests. points. In the experimental test, failure was caused by a

Figure 6 shows a typical failure in the longitudinal bars combination of rupture in the longitudinal bars as well as

from the experiments conducted on these beams. 11 As concrete crushing in the compression zone. This compressive

shown in this figure, there is considerable damage in the failure was located near the load points, however, and

shear span of the member. Large shear cracks develop in could have been initiated by cracks formed due to stress

the beam, causing the member to deform in the same concentrations produced by the rigid loading plates. 11

fashion as the one seen in the finite element model. Figure 8 shows the results for the long beam model.

Figure 7 shows the medium beam model at several stages Comparing this simulation with the two previous ones, it

in the simulation. The figure also shows the behavior of the can be seen that this model exhibits the least shear damage,

main longitudinal bars. Comparing this simulation with the as expected. As a result, the longitudinal bars exhibit a

one obtained for the short beam, it can be seen that the shear parabolic shape, which would be the behavior predicted

damage is not as significant as in the previous simulation. using conventional moment-curvature methods based on the

The deflected shape seen in the longitudinal bars shows that curvature of the member. Once again, the stiffness of the

this model does not have the abrupt changes in rotation that beam was slightly over-predicted. However, the ultimate load

254 ACI Structural Journal/March-April 2003

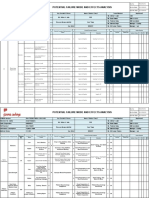

Table 2—Summary of experimental and finite

element results

Tensile force in each

Total load capacity, kN main bar, kN

Finite Finite

Flexural element Flexural element

Beam Experimental analysis analysis analysis analysis

Short 215.7 196.2 215.3 90.7 51.6

Medium 143.2 130.8 161.9 90.7 76.5

Fig. 9—(a) Tensile force in longitudinal bars; and (b) internal Long 108.1 97.9 113.0 90.7 76.5

moment in longitudinal bars.

compression failure mode, which was not the failure

value compares well with the experimental result. Failure in

the model was caused by rupture of the longitudinal bars. mode observed from the experimental tests.

Failure in the experimental test was caused by a compression The curves for the medium beam model and the long beam

failure at a location near one of the load application bars, model, shown in Fig. 9, show that for both cases, the beam

followed by rupture of the main longitudinal bars. Figure 5 shear span-depth ratio was sufficiently large so that the stress

also shows the time at total failure for each beam, which can state in the longitudinal bars would not be greatly affected by the

be related to the simulation stages given in Fig. 4, 7, and 8 shear damage produced in the beam. As such, the ultimate axial

for the short, medium, and long beam, respectively. force obtained in the longitudinal bars for both models was

To investigate the stress state of a single longitudinal bar close to the ultimate axial load that would be predicted by using

at ultimate conditions, the tensile force and the internal conventional methods.

moment of the longitudinal bars at the failed location for the In summary, Table 2 presents the ultimate load capacity

three finite element models was determined, as shown in for the three models, including experimental results, conven-

Fig. 9(a) and (b). It is interesting to note that for the short tional flexural analysis results, and finite element results. As

beam model, the tensile force at failure was approximately shown in this table, conventional flexural analysis under-predicts

51.6 kN, while for the medium beam model and the long the actual ultimate load carried by the beams and a better

beam model the tensile force at failure was approximately ultimate load prediction was obtained using finite element

76.5 kN. On the other hand, the internal moment in the short analysis. The tensile load in the bars was computed (analytically)

beam model was approximately 734 N-m, while the internal

by dividing the experimental moment capacity by the internal

moment was approximately 339 N-m for both the short beam

moment arm computed by using strain compatibility. Although

model and the long beam model. It is clear that the shear

damage in the short beam model causes a considerable the finite element results over-predicted the ultimate load for the

localized effect in the stress state of the longitudinal bars, medium and long beams, the simulations provided a better

which is important to consider for design purposes. understanding of the complex phenomena involved in the

According to Fig. 9(a), the total axial load in the longitudinal behavior of the beams, depending on their shear span-depth

bars for the short beam model produces a uniform stress of ratio. The results for tensile load in the bars reported in this table

130 MPa, which is not enough to fail the element in tension suggest that composite grid reinforced concrete beams

at this location. However, the ultimate internal moment with values of shear span-depth ratio greater than 4.5 can be

produces a tensile stress at the bottom of the longitudinal analyzed by using the current flexural theory.

bars of 141 MPa. The sum of these two components produces It is important to mention that the concrete material model

a tensile stress of 271 MPa. When this value is entered in the parameters that govern the post-failure behavior of the material

Chang/Chang failure criterion for the tensile longitudinal played a key role in the finite element results for the three finite

direction, the strength is exceeded and the elements fail. element models. In the concrete material formulation, the

Using conventional over-reinforced beam analysis formulas, elements fail in an isotropic fashion and, therefore, once an

the tensile force in the longitudinal bars at midspan would element fails in tension, it cannot transfer further shear.

be obtained by dividing the ultimate moment obtained from Because the concrete elements are connected to the reinforce-

the experimental test by the internal moment arm. This ment mesh, this behavior causes the beam to fail prematurely

would imply that there is a uniform tensile force in each as a result of tensile failure in the concrete. Therefore, the

longitudinal bar of 88.1 kN. This tensile force is never parameters that govern the post-failure behavior in the

achieved in the finite element simulation due to considerable concrete material model were chosen so that when an element

shear damage in the concrete elements. As a result of this fails in tension, the element still has the capability to transfer

shear damage in the concrete, the curvature at the center of shear forces and the stresses will gradually decrease to zero.

the beam is not large enough to produce a tensile force in the

Because the failed elements can still transfer tensile stresses,

bars of this magnitude (88.1 kN). The internal moment in the

however, the modifications caused an increase in the stiffness

longitudinal bars shown in Fig. 9(b), however, continues

to develop, resulting in a total failure load comparable to of the beam. In real concrete behavior, when a crack opens,

the experimental result. As mentioned before, the force in there is no tension transfer between the concrete at that

the bars according to the simulation was approximately location, causing the member to lose stiffness as cracking

51.6 kN, which is approximately half the load predicted progresses. Regarding shear transfer, factors such as aggre-

using conventional methods. Therefore, the use of conventional gate interlock and dowel action would contribute to transfer

beam analysis formulas to analyze this composite grid reinforced shear forces in a concrete beam, and tensile failure in the

beam would not only erroneously predict the force in the concrete would not affect the response as directly as in the

longitudinal bars, but it would also predict a concrete finite element model.

ACI Structural Journal/March-April 2003 255

Stress analysis of FRP bars

As discussed previously, failure modes observed in experi-

mental tests performed on composite grid reinforced concrete

beams suggest that the longitudinal bars are subjected to a

uniform tensile stress plus a nonuniform bending stress due

to localized rotations at locations of large cracks. This section

presents a simple analysis procedure to determine the stress

conditions at which the longitudinal bars fail. As a result of this Fig. 10—Failure on FRP bar subjected to pure tension.

analysis, a procedure is presented to analyze/design a composite

grid reinforced concrete beam, considering a nonuniform stress

state in the longitudinal bars.

A more detailed finite element model of a section of the

longitudinal bars was developed in HyperMesh16 using shell

elements, as shown in Fig. 10. A height of 50.8 mm was

specified for the bar model, with a thickness of 4.1 mm. The

length of the bar and the diameter of the hole were 152 and

12.7 mm, respectively. The material formulation and properties

Fig. 11—Failure on FRP bar subjected to pure bending.

were the same as the ones used for the longitudinal bars in the

concrete beam models, with the exception that now the to the nominal strength of the member multiplied by a strength-

unnotched tensile strength of the material (Xt = 521 MPa) was reduction factor φ, as shown in the following equation

used as an input parameter because the hole was incorporated in

the model.

The finite element model was first loaded in tension to φ Mn ≥ Mu (1)

establish the tensile strength of the notched bar. The load

was applied by prescribing a displacement at the end of the For FRP reinforced concrete beams, a compression failure

bar. Figure 10 shows the simulation results for the model at is the preferred mode of failure, and, therefore, the beam

three stages, including elastic deformation and ultimate should be over-reinforced. As such, conventional formulas

failure. As expected, a stress concentration developed on the are used to ensure that the selected cross-sectional area of the

boundary of the hole causing failure in the web of the model, longitudinal bars is sufficiently large to have concrete

followed by ultimate failure of the cross section. A tensile compression failure before FRP rupture. Considering a concrete

strength of 274 MPa was obtained for the model. A value compression failure, the capacity of the beam is computed using

of 267 MPa was obtained from experimental tests con- the following8

ducted on notched bars (tensile strength used in Table 2),

demonstrating good agreement between experimental

M n = A f f f d – ---

and finite element results. a

(2)

A similar procedure was performed to establish the 2

strength of the bar in pure bending. That is, displacements

were prescribed at the end nodes to induce bending in the

model. Figure 11 shows the simulation results for the model Af ff

a = -------------- (3)

at three stages, showing elastic bending and ultimate failure β 1 f c′ b

caused by flexural failure at the tension flange. As shown in

this figure, the width of the top flange was modified to

β1 d – a

prevent buckling in the flange (which was present in the f f = E f ε cu ----------------- (4)

original model). Because buckling would not be present in a a

longitudinal bar due to concrete confinement, it was decided

to modify the finite element model to avoid this behavior. To Experimental tests have shown, however, that there is

maintain an equivalent cross-sectional area, the thickness of a critical value of shear Vscrit in a beam where localized rotations

the flange was increased. A maximum pure bending moment due to large flexural-shear cracks begin to occur. The

of 2.92 kN-m was obtained for the model. ultimate moment in the beam is assumed to be related to

Knowing the maximum force that the bar can withstand in this shear-critical value and it is determined according to

pure tension and pure bending, the model was then loaded at the following equation

different values of tension and moment to cause failure. This

procedure was performed several times to develop a tension-

moment interaction diagram for the bar, as shown in Fig. 12. Mn = n ⋅ ( t ⋅ i e + m ) (5)

The discrete points shown in the figure are combinations of

tensile force and moment values that caused failure in the where n is the number of longitudinal bars. Once the beam has

finite element model. This interaction diagram can be used reached the shear-critical value, it is assumed (conservatively)

to predict what combination of tensile force and moment that the tensile force t, which is the force in each bar at the

would cause failure in the FRP longitudinal bar. shear-critical stage, remains constant and any additional load is

carried by localized internal moment m in the longitudinal

Considerations for design bars. Furthermore, it is assumed that at this stage the concrete

The strength design philosophy states that the flexural is still in its elastic range, and, therefore, the internal moment

capacity of a reinforced concrete member must exceed the arm ie can be determined by equilibrium and elastic strain

flexural demand. The design capacity of a member refers compatibility. The tensile force t in Eq. (5) is computed

256 ACI Structural Journal/March-April 2003

Table 3—Summary of results for three beams using proposed approach

Total load capacity, kN

Experimental

ultimate Theoretical shear Equation for Analytical Tension in each

Beam shear, kN critical, kN moment capacity Experimental Pn = Mn /as main bar, kN

Short 108.1 88.1 Mn = t · ie + m 216 199 70.7

Medium 71.6 88.1 Mn = Af f f (d – a/ 2) 143 131 90.7

Long 54.7 88.1 Mn = Af f f (d – a/2) 109 99 90.7

according to the following equation for a simply supported

beam in four-point bending

crit

Vs ⋅a

t = ---------------------s (6)

ni e

where as is the shear span of the member. The obtained value

for the tension t in each bar is then entered in Eq. (7), which

is the equation for the interaction diagram, to determine the

ultimate internal moment m in Eq. (5) that causes the bar to

fail. In this equation, tmax and mmax are known properties of

the notched composite bar.

m = m max 1 – --------- for t > 0 ; m > 0

t 2

(7)

t max

The aforementioned procedure is a very simplified analysis to

determine the capacity of a composite grid reinforced concrete

beam, and, as can be seen, it depends considerably on the shear- Fig. 12—Tension-moment interaction diagram for longi-

critical value Vscrit established for the beam. This value is tudinal bar.

somewhat difficult to determine. Based on experimental data, a

value given by Eq. (8) (analogous to Eq. (9-1) of ACI to compute the maximum moment that the bar can carry as a

440.1R-01) can be considered to be a lower bound for function of the tensile force acting in the bar. If a specific bar

FRP reinforced beams with shear reinforcement. is always used, however, this difficulty is eliminated, and if

the flexural demand is not exceeded, a higher capacity can be

crit 7 ρf Ef 1 obtained by increasing the number of longitudinal bars in the

Vs = ----------------- --- f ′ bd (8) section. According to the results obtained for the three beams

90 β 1 f c′ 6 c analyzed herein, the proposed procedure will under-predict

the capacity of the composite grid reinforced concrete beam,

where fc′ is the specified compressive strength of the concrete but it will provide a good lower bound for a conservative

in MPa. In summary, the ultimate moment capacity in the beam design. Furthermore, it will ensure that the longitudinal bars

is determined according to one of the following equations will not fail prematurely as a result of the development of

large flexural-shear cracks in the member, and thus the

member will be able to meet and exceed the flexural demand

M n = A f f f d – a--- for V ult < V s

crit

(9)

2 for which it was designed.

CONCLUSIONS

crit

M n = n ⋅ ( t ⋅ i e + m ) for V ult > V s (10) Based on the explicit finite element results and comparison

with experimental data, the following conclusions can be made:

According to Eq. (9), if the ultimate shear force computed 1. Failure in the FRP longitudinal bars occurs due to a

analytically based on conventional theory does not exceed combination of a uniform tensile stress plus a nonuniform

the shear-critical value Vscrit, the moment capacity can be stress caused by localized rotations at large flexural-shear

computed from flexural analysis. On the other hand, if the cracks. Therefore, this failure mode has to be accounted for

computed ultimate shear force is greater than Vscrit, Eq. (10) in the analysis and design of composite grid reinforced concrete

is used. Table 3 presents a summary showing the load capacity beams, especially those that exhibit significant flexural-

for the three beams obtained experimentally and analytically shear cracking;

using the present approach. As shown in this table, the equation 2. The shear span for the medium beam and the long beam

used to determine the flexural capacity depends on the ultimate studied was sufficiently large so that the stress state in the

shear obtained for each beam. longitudinal bars was not considerably affected by shear

As seen in this procedure, the only difficulty in applying damage in the beam. Therefore, the particular failure mode

these formulas is the fact that an equation needs to be determined observed by the short beam model is only characteristic of

ACI Structural Journal/March-April 2003 257

beams with a low shear span-depth ratio. Moreover, according REFERENCES

to the proposed analysis for such systems, both the medium 1. Sugita, M., “NEFMAC—Grid Type Reinforcement,” Fiber-Reinforced-

Plastic (FRP) Reinforcement for Concrete Structures: Properties and

beam and the long beam could be designed using conventional Applications, Developments in Civil Engineering, A. Nanni, ed., Elsevier,

flexural theory because the shear-critical value was never Amsterdam, V. 42, 1993, pp. 355-385.

reached for these beam lengths; 2. Schmeckpeper, E. R., and Goodspeed, C. H., “Fiber-Reinforced

3. Numerical simulations can be used effectively to under- Plastic Grid for Reinforced Concrete Construction,” Journal of Composite

Materials, V. 28, No. 14, 1994, pp. 1288-1304.

stand the complex behavior and phenomena observed in the

3. Bank, L. C.; Frostig, Y.; and Shapira, A., “Three-Dimensional Fiber-

response of composite grid reinforced concrete beams and, Reinforced Plastic Grating Cages for Concrete Beams: A Pilot Study,” ACI

therefore, can be used as a complement to experimental Structural Journal, V. 94, No. 6, Nov.-Dec. 1997, pp. 643-652.

testing to account for multiple failure modes in the design 4. Smart, C. W., and Jensen, D. W., “Flexure of Concrete Beams

of composite grid reinforced concrete beams; and Reinforced with Advanced Composite Orthogrids,” Journal of Aerospace

Engineering, V. 10, No. 1, Jan. 1997, pp. 7-15.

4. The proposed method of analysis for composite grid 5. Ozel, M., and Bank, L. C., “Behavior of Concrete Beams Reinforced

reinforced concrete beams considering multiple failure with 3-D Composite Grids,” CD-ROM Paper No. 069. Proceedings of the

modes will under-predict the capacity of the reinforced 16th Annual Technical Conference, American Society for Composites,

concrete beam, but it will provide a good lower bound for Virginia Tech, Va., Sept. 9-12, 2001.

6. Shapira, A., and Bank, L. C., “Constructability and Economics of FRP

a conservative design. These design considerations will Reinforcement Cages for Concrete Beams,” Journal of Composites for

ensure that the longitudinal bars will not fail prematurely Construction, V. 1, No. 3, Aug. 1997, pp. 82-89.

(or catastrophically) as a result of the development of large 7. Bank, L. C., and Ozel, M., “Shear Failure of Concrete Beams Reinforced

flexural-shear cracks in the member, and thus the member with 3-D Fiber Reinforced Plastic Grids,” Fourth International Symposium on

can develop a pseudoductile failure by concrete crushing, Fiber Reinforced Polymer Reinforcement for Reinforced Concrete Structures,

SP-188, C. Dolan, S. Rizkalla, and A. Nanni, eds., American Concrete

which is more desirable than a sudden FRP rupture. Institute, Farmington Hills, Mich., 1999, pp. 145-156.

8. ACI Committee 440, “Guide for the Design and Construction of

ACKNOWLEDGMENTS Concrete Reinforced with FRP Bars (ACI 440.1R-01),” American Concrete

This work was supported by the National Science Foundation under Institute, Farmington Hills, Mich., 2001, 41 pp.

Grant. No. CMS 9896074. Javier Malvar and Karagozian & Case are 9. Nakagawa, H.; Kobayashi. M.; Suenaga, T.; Ouchi, T.; Watanabe, S.;

thanked for providing information regarding the concrete material formulation and Satoyama, K., “Three-Dimensional Fabric Reinforcement,” Fiber-

used in LS-DYNA. Jim Day, Todd Slavik, and Khanh Bui of Livermore Reinforced-Plastic (FRP) Reinforcement for Concrete Structures: Properties

Software Technology Corporation (LSTC) are also acknowledged for their and Applications, Developments in Civil Engineering, V. 42, A. Nanni, ed.,

assistance in using the finite element software, as well as Strongwell Elsevier, Amsterdam, 1993, pp. 387-404.

Chatfield, MN, for producing the custom composite grids. 10. Yonezawa, T.; Ohno, S.; Kakizawa, T.; Inoue, K.; Fukata, T.; and

Okamoto, R., “A New Three-Dimensional FRP Reinforcement,” Fiber-

Reinforced-Plastic (FRP) Reinforcement for Concrete Structures: Properties

NOTATION and Applications, Developments in Civil Engineering, V. 42, A. Nanni, ed.,

a = depth of equivalent rectangular stress block Elsevier, Amsterdam, 1993, pp. 405-419.

as = length of shear span in reinforced concrete beam 11. Ozel, M., “Behavior of Concrete Beams Reinforced with 3-D

b = width of rectangular cross section Fiber Reinforced Plastic Grids,” PhD thesis, University of Wisconsin-

d = distance from extreme compression fiber to centroid of tension Madison, 2002.

reinforcement 12. Lees, J. M., and Burgoyne, C. J., “Analysis of Concrete Beams with

Ef = modulus of elasticity for FRP bar Partially Bonded Composite Reinforcement,” ACI Structural Journal,

Ex = modulus of elasticity in longitudinal direction of FRP grid material V. 97, No. 2, Mar.-Apr. 2000, pp. 252-258.

Ey = modulus of elasticity in transverse direction of FRP grid material 13. Shehata, E.; Murphy, R.; and Rizkalla, S., “Fiber Reinforced

Polymer Reinforcement for Concrete Structures,” Fourth International

Gxy = shear modulus of FRP grid members

Symposium on Fiber Reinforced Polymer Reinforcement for Reinforced

f ′c = specified compressive strength of concrete

Concrete Structures, SP-188, C. Dolan, S. Rizkalla, and A. Nanni, eds.,

ff = stress in FRP reinforcement in tension American Concrete Institute, Farmington Hills, Mich., 1999, pp. 157-167.

ie = internal moment arm in the elastic range 14. Guadagnini, M.; Pilakoutas, K.; and Waldron, P., “Investigation on

Mn = nominal moment capacity Shear Carrying Mechanisms in FRP RC Beams,” FRPRCS-5, Fibre-

m = internal moment in longitudinal FRP grid bars Reinforced Plastics for Reinforced Concrete Structures, Proceedings of the

n = number of longitudinal FRP grid bars Fifth International Conference, C. J. Burgoyne, ed., V. 2, Cambridge, July

Sc = shear strength of FRP grid material 16-18, 2001, pp. 949-958.

t = tensile force in a longitudinal bar at the shear critical stage 15. Cook, R. D.; Malkus, D. S.; and Plesha, M. E., Concepts and

Vscrit = critical shear resistance provided by concrete in FRP grid rein- Applications of Finite Element Analysis, 3rd Edition, John Wiley &

forced concrete Sons, N.Y., 1989, 832 pp.

Vult = ultimate shear force in reinforced concrete beam 16. Altair Computing, HyperMesh Version 2.0 User’s Manual, Altair

Xc = longitudinal compressive strength of FRP grid material Computing Inc., Troy, Mich., 1995.

Xt = longitudinal tensile strength of FRP grid material 17. Thompson, W. T., and Dahleh, M. D., Theory of Vibration with

Applications, 5th Edition, Prentice Hall, N.J., 1998, 524 pp.

Yc = transverse compressive strength of FRP grid material

18. Malvar, L. J.; Crawford, J. E.; Wesevich, J. W.; and Simons, D., “A

Yt = transverse tensile strength of FRP grid material Plasticity Concrete Material Model for DYNA3D,” International Journal

β = weighting factor for shear term in Chang/Chang failure criterion of Impact Engineering, V. 19, No. 9/10, 1997, pp. 847-873.

β1 = ratio of the depth of Whitney’s stress block to depth to neu- 19. Tavarez, F. A., “Simulation of Behavior of Composite Grid Reinforced

tral axis Concrete Beams Using Explicit Finite Element Methods,” MS thesis, University

εcu = concrete ultimate strain of Wisconsin-Madison, 2001.

ρf = FRP reinforcement ratio 20. Hallquist, J. O., LS-DYNA Keyword User’s Manual, Livermore

νxy = Poisson’s ratio of FRP grid material Software Technology Corporation, Livermore, Calif., Apr. 2000.

258 ACI Structural Journal/March-April 2003

You might also like

- Foundation For Roller Press in A Cement Plant - A Case Study PDFDocument3 pagesFoundation For Roller Press in A Cement Plant - A Case Study PDFRajKumarNo ratings yet

- Material Testing ManualDocument31 pagesMaterial Testing ManualharshNo ratings yet

- Tallchimneyconst00banciala PDFDocument168 pagesTallchimneyconst00banciala PDFRajKumarNo ratings yet

- Concrete Lab Manual, VssutDocument55 pagesConcrete Lab Manual, VssutSatyabrata NayakNo ratings yet

- Manual ConcreteTechDocument72 pagesManual ConcreteTechDharmaraaj RajalinggamNo ratings yet

- Design of Re Inforc 00 BurkDocument90 pagesDesign of Re Inforc 00 BurkdeniNo ratings yet

- 104 s37 PDFDocument9 pages104 s37 PDFRajKumarNo ratings yet

- (PPT) Eurocode 2 Design of Concrete Structures EN1992-1-1 (Walraven)Document173 pages(PPT) Eurocode 2 Design of Concrete Structures EN1992-1-1 (Walraven)Gregory SimmonNo ratings yet

- The Flexural and Shear Design of Deep BeamDocument13 pagesThe Flexural and Shear Design of Deep BeamJONHCENA13No ratings yet

- 100 s64 PDFDocument10 pages100 s64 PDFRajKumarNo ratings yet

- Brick Masonry Walls Book PDFDocument117 pagesBrick Masonry Walls Book PDFPremalatha Jeyaram100% (1)

- Is.2393.2010.pdf-Corter Pin PDFDocument11 pagesIs.2393.2010.pdf-Corter Pin PDFRajKumarNo ratings yet

- Creep and Fatigue Analysis of RC StructuresDocument10 pagesCreep and Fatigue Analysis of RC StructuresLuis RochaNo ratings yet

- Versa-Lok Standard GuideDocument48 pagesVersa-Lok Standard GuideRajKumarNo ratings yet

- Chnical Design Manual: Expanded Metal MeshesDocument36 pagesChnical Design Manual: Expanded Metal MeshesRajKumarNo ratings yet

- Design of Foundation.Document66 pagesDesign of Foundation.gpatil1356No ratings yet

- TeklaStructuresGlossary PDFDocument154 pagesTeklaStructuresGlossary PDFRajKumarNo ratings yet

- Usha Martin Construction Sector NewDocument12 pagesUsha Martin Construction Sector NewRajKumarNo ratings yet

- Lecture6 (CRACKED MOMENT OF INTERTIA)Document38 pagesLecture6 (CRACKED MOMENT OF INTERTIA)RajKumarNo ratings yet

- KR 25HDocument312 pagesKR 25Hjjjhassan100% (1)

- TECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelDocument3 pagesTECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelRaed Naim Khammash100% (1)

- Technical Note TCDocument3 pagesTechnical Note TCewindust3No ratings yet

- Technical Note 016 - Ground Bearing PRDocument3 pagesTechnical Note 016 - Ground Bearing PRAnonymous UebIaD8A8CNo ratings yet

- Technical Note 016Document1 pageTechnical Note 016RajKumarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- PHYCS 324 LAB REPORT Normal Zeeman EffectDocument16 pagesPHYCS 324 LAB REPORT Normal Zeeman EffectSana KhanNo ratings yet

- Greenhoe Et Al-2016-Journal of Polymer Science Part B - Polymer Physics JournalwebsiteDocument7 pagesGreenhoe Et Al-2016-Journal of Polymer Science Part B - Polymer Physics JournalwebsiteMoad BarbariNo ratings yet

- ETABS Shear Wall DesignDocument2 pagesETABS Shear Wall DesignFares ShawadfyNo ratings yet

- Raft FoundationDocument15 pagesRaft FoundationMuniswamaiah Mohan100% (2)

- Spectroscopy: DR - Rosy MallikDocument8 pagesSpectroscopy: DR - Rosy MallikTangudu Tejeswar RaoNo ratings yet

- Somorjai G.a., Li Y. Introduction To Surface Chemistry and CatalysisDocument1,045 pagesSomorjai G.a., Li Y. Introduction To Surface Chemistry and CatalysisIvan100% (1)

- Module and Problem Answers Reinforced Concrete Design 1Document113 pagesModule and Problem Answers Reinforced Concrete Design 1Joseph LantoNo ratings yet

- IGM Additives Product GuideDocument20 pagesIGM Additives Product GuideColoke AdesivosNo ratings yet

- CH 1 Solid State SsnotesDocument29 pagesCH 1 Solid State SsnotesAnonymous 8VJhV1eI2yNo ratings yet

- Convection Heat TransferDocument73 pagesConvection Heat TransferAadil Khan100% (1)

- Further Mechanics 1 Unit Test 5 Elastic Strings and Springs and Elastic Energy Mark SchemeDocument7 pagesFurther Mechanics 1 Unit Test 5 Elastic Strings and Springs and Elastic Energy Mark SchemeGavin Man100% (4)

- 4 FOUNDATION IN ROCK (Compatibility Mode) PDFDocument28 pages4 FOUNDATION IN ROCK (Compatibility Mode) PDFxdhrts54 yNo ratings yet

- MagnetochemistryDocument335 pagesMagnetochemistryMd MaoyafikuddinNo ratings yet

- Astm D4833-07Document4 pagesAstm D4833-07Jluis Ipn100% (1)

- Sample Assignments SDMDocument10 pagesSample Assignments SDMSankar SaroNo ratings yet

- Taperla, NANOTECHNOLOGY Week 10 - 11Document4 pagesTaperla, NANOTECHNOLOGY Week 10 - 11kevin cagud PhillipNo ratings yet

- Direct Shear TestDocument10 pagesDirect Shear TestRuzengulalebih ZEta's-ListikNo ratings yet

- 2013 - Dolomite, Wollastonite and Calcite As Different CaO Sources in Anorthite-Based PorcelainDocument8 pages2013 - Dolomite, Wollastonite and Calcite As Different CaO Sources in Anorthite-Based PorcelainFURY FURIONNo ratings yet

- Temper EmbrittlementDocument13 pagesTemper EmbrittlementAnonymous 5odj1Ic100% (1)

- Passive Layer (EDTA Cleaning)Document7 pagesPassive Layer (EDTA Cleaning)coincoin1No ratings yet

- Chapter 7 PDFDocument60 pagesChapter 7 PDFSurya GusriliawanNo ratings yet

- IKW75N60TDocument13 pagesIKW75N60TY Automation (Jean)No ratings yet

- Iso 9226 1992 PDFDocument8 pagesIso 9226 1992 PDFMario AguillonNo ratings yet

- Ce121 Lec5 BuoyancyDocument18 pagesCe121 Lec5 BuoyancyPetForest Ni JohannNo ratings yet

- Humidification and Air Conditioning: Lecture No. 8Document6 pagesHumidification and Air Conditioning: Lecture No. 8Anonymous UFa1z9XUANo ratings yet

- Scholarships SINGA 2023-06-21-ETDocument128 pagesScholarships SINGA 2023-06-21-ETS RNo ratings yet

- Fmea CastingDocument8 pagesFmea CastingSuraj RawatNo ratings yet

- Buildings 12 00152 v3 SelfcuringDocument27 pagesBuildings 12 00152 v3 Selfcuringraja sekharNo ratings yet

- Fior Illo 2018Document76 pagesFior Illo 2018Anonymous qmuFcaw13No ratings yet