Professional Documents

Culture Documents

All Alloy Aluminium Conductor

Uploaded by

وهيبه بكرOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

All Alloy Aluminium Conductor

Uploaded by

وهيبه بكرCopyright:

Available Formats

AAAC

All Alloy Aluminium Conductor

Other Aluminium products:

AAAC (All aluminium alloy conductor) Aluminium strip

AACSR (All aluminium alloy conductor steel reinforced) Aluminium wire

OPGW (Optic fiber protection overhead conductor) Aluminium alloy wire

ACSR (Aluminium conductor steel reinforced)

Solid sector shaped aluminium conductor

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 1 of 6

AAAC

All Alloy Aluminium Conductor

A2

Value /

Specifications: Installation conditions

Variables

IEC 61089 IEC Wind speed (m/sec) 0.440

IEC 889 IEC Thermal conductivity Air (W m-1 K-1) 0.0264

BS EN 50183 (British) BS Velocity of Air (V) (m/hr.) 16.04

BS EN 50182 (British) BS EN Ambient (°C) 30

ASTM B399 (USA) ASTM Conductor continues maximum operating (°C) 75

CAN/ CSA/C49 & C61089 (Canada) CAN Conductor maximum short circuit temperature (°C) 200

Conductor surface absorbency (0.27-0.95) 0.60

Grease: Solar beam Intensity (W/m²) ID 890

Drop point IP 33 Min 220°C Intensity of Solar sky radiation (W/m²) Id 7.154

Operating temperature - 20°C to 80°C Wind speed (m/s) 0.44

Grease weight is calculated in The stated values are estimated and nominal values.

accordance with EN 50182 Annex B The installer should verify the actual conditions for the

specific location of installation.

Material properties

Aluminium Alloy

Grade 6101 & 6201-T81

Density / Specific gravity Nom. g/cm3 2.703

Tensile strength (hard drawn) Nom. Mpa 110-130

Conductivity Nom. Min. 62.3

Volume resistivity @ 20°C Nom. Ω/mm″.m 0.032227

Coefficient of linier expansion Nom. per °C 23x10-6

Specific heat Nom. KJ/kg/K 0.904

Melt point Nom. °C 658

Chemical properties

Nom. % Max. %

Cu - 0.100

Si 0.50 - 0.9 -

Al Remainder

Si - 0.100

Fe - 0.500

B - 0.060

Other - 0.013

Conductor creep

Details in Annexure A

Sag and tension charts are available on request.

The following information need to be supplied:

• Conductor span lengths

• Maximum design load (45% of UTS is standard)

• Nominal ambient temperature when stringing will take place.

Rev 01: 31/05/2019

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of M-TEC’s knowledge. M-TEC reserves the right to amend this

specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential damages and loss of profits, opportunities or information) arising

from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 2 of 6

AAAC (All Aluminium Conductor)

(A2)

Application:

Specifications:

Bare Overhead transmission lines with high tensile load.

SANS 182-2, BS 215 Construction:

Aluminium Alloy wires stranded, greased or dry up to the 2nd last layer Case 2

or up to the PCD of last layer Case 4 not on outer surface.

All Aluminium conductor Polymeric weather covering (if applicable)

Grease (if applicable) All Aluminium conductor

All Aluminium Alloy Conductor

Specification

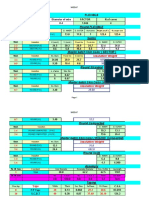

Bending Resistance Current

ber

Conductor Diameter Gross Standard Short #Creep

Size Area mass radius Ω/km Rating circuit

Num

(nominal,

(D) mass length calculated)

Min. (A) rating

Construction and dimensions

dc ac

20°C 75°C (kA.1s)

# mm mm mm² kg/km kg m mm 75°C mm/km

Acacia 7 2.08 6.24 23.8 65.0 334 2 000 187 1.393 1.736 133 3.07 40

Electrical Properties

Almond 7 2.34 7.02 30.1 82.8 370 2 000 211 1.101 1.371 153 3.49 54

CODE 35 7 2.77 8.31 42.2 115.0 434 2 000 249 0.785 0.979 189 4.15 84

Fir 7 2.95 8.85 47.8 131.7 533 2 500 266 0.692 0.863 204 4.46 99

Hazel 7 3.30 9.90 59.9 164.7 533 2 000 297 0.553 0.690 235 5.02 132

Pine 7 3.61 10.83 71.6 196.0 742 2 000 325 0.462 0.576 262 5.51 168

Willow 7 4.04 12.12 89.7 246.9 720 1 500 364 0.369 0.460 302 6.22 224

BS

Oak 7 4.65 13.95 118.9 325.0 1 000 2 000 419 0.279 0.347 359 7.19 323

Mulberry 19 3.18 15.90 150.9 415.2 1 180 2 000 477 0.220 0.274 416 8.19 440

Elm 19 3.76 18.80 211.0 580.5 1 511 2 000 564 0.157 0.196 513 9.77 680

Ash 19 3.48 17.40 180.7 497.3 1 199 2 000 522 0.183 0.228 467 9.00 556

Poplar 37 2.87 20.09 239.4 658.6 1 667 2 000 603 0.138 0.172 513 10.44 801

Sycamore 37 3.23 22.61 303.2 834.2 2 018 2 000 678 0.109 0.136 643 11.82 1 090

Upas 37 3.53 24.71 362.1 996.4 2 343 2 000 741 0.091 0.114 718 12.98 1 373

Yew 37 4.06 28.42 479.0 1318.1 2 327 1 500 853 0.069 0.086 853 15.04 1 974

Modulus

Specification

Coefficient Grease mass PVC insulation

of Elasticity Outer

Conductor of linear UTS calculated Nom.

Initial Final layer 1.6mm 5mm

name expansion

kN/mm² Case 2 Case 4 lay kg/km OD kg/km OD

Nom. x10-6/oC kN kg/km kg/km Nom. mm Nom. mm

Acacia 52.4 61.0 23.00 6.69 - 1.9 RH 60 9 - -

Physical properties

Almond 52.4 61.0 23.00 8.44 - 2.4 RH 66 10 - -

CODE 35 52.4 61.0 23.00 11.86 - 3.4 RH 76 12 - -

Fir 52.4 61.0 23.00 13.40 - 3.8 RH 80 12 - -

Hazel 52.4 61.0 23.00 16.80 - 4.8 RH 88 13 - -

Pine 52.4 61.0 23.00 20.20 - 5.7 RH 95 14 - -

Willow 52.4 61.0 23.00 25.15 - 7.1 RH 105 15 - -

BS

Oak 52.4 61.0 23.00 33.33 - 9.4 RH 119 17 - -

Mulberry 49.7 59.7 23.00 42.29 9.2 18.0 RH 134 19 - -

Elm 49.7 59.7 23.00 59.10 12.9 25.1 RH 156 22 - -

Ash 49.7 59.7 23.00 50.65 11.0 21.5 RH 145 21 - -

Poplar 49.7 59.7 23.00 67.08 22.5 32.9 RH 166 23 599 30

Sycamore 49.7 59.7 23.00 85.00 28.4 41.7 RH 185 26 659 33

Upas 49.7 59.7 23.00 101.50 34.0 49.8 RH 201 28 709 35

Yew 49.7 59.7 23.00 134.20 44.9 65.9 RH (Z) RH 229 32 38

Notes:

Grease and mass must be added as per relevant Case Insulation mass must be added to the conductor mass if relevant.

to conductor mass if greased conductor is required.

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of M-TEC’s knowledge. M-TEC reserves the right to amend this

specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential damages and loss of profits, opportunities or information) arising

from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 3 of 6

AAAC (All Aluminium Conductor)

(A2)

Application:

Specifications:

Bare Overhead transmission lines with high tensile load.

ASTM B232, AS 1220 Construction:

Aluminium Alloy wires stranded, greased or dry up to the 2nd last layer Case 2

or up to the PCD of last layer Case 4 not on outer surface.

All Aluminium conductor Polymeric weather covering (if applicable)

Grease (if applicable) All Aluminium conductor

Construction and dimensions

All Aluminium Alloy Conductor

Specification

Bending Resistance Current

ber

Conductor Diameter Gross Standard Short #Creep

Ω/km

Electrical Properties

Size Area mass radius Rating circuit

Num

(nominal,

(D) mass length calculated)

Min. dc ac (A) rating

(mm/km)

20°C 75°C (kA.1s)

# mm mm mm² kg/km kg m mm 75°C

Azusa 7 3.37 10.11 62.5 171.9 548 2 000 303 0.530 0.661 262 5.14 154

Alliance 7 4.77 14.31 125.1 344.2 1 237 3 000 429 0.265 0.330 395 7.41 381

ASTM

Elgin 19 4.71 23.54 330.6 911.5 1 262 1 000 706 0.100 0.125 739 12.39 1 294

650 37 3.37 23.56 329.2 906.4 2 173 2 000 707 0.101 0.125 789 12.35 1 249

800 37 3.73 26.14 405.2 1115.4 2 591 2 000 784 0.082 0.102 971 13.78 1 636

Greely 37 4.02 28.14 469.6 1294.8 3 046 2 000 844 0.071 0.088 908 14.90 1 982

Modulus

Specification

Coefficient Grease mass Outer PVC insulation

of Elasticity

Conductor of linear UTS calculated Nom.

Physical properties

Initial Final layer 1.6mm 5mm

name expansion Lay

kN/mm² Case 2 Case 4 kg/km OD kg/km OD

direction

Nom. x10-6/oC kN kg/km kg/km Nom. mm Nom. mm

Azusa 49.7 59.7 23.00 18.88 - 5.0 (Z) RH 89 13 - -

Alliance 49.7 59.7 23.00 37.83 - 9.9 (Z) RH 122 18 - -

ASTM

Elgin 49.7 59.7 23.00 96.98 60.41 88.6 (Z) RH 192 27 681 34

650 49.7 59.7 23.00 94.38 30.9 45.3 (Z) RH 192 27 682 34

800 49.7 59.7 23.00 116.14 38.01 55.8 (Z) RH 212 29 743 36

Greely 49.7 59.7 23.00 134.62 44.1 64.6 (Z) RH 227 31 791 38

Notes:

Grease and mass must be added as per relevant Case Insulation mass must be added to the conductor mass if relevant.

to conductor mass if greased conductor is required.

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of M-TEC’s knowledge. M-TEC reserves the right to amend this

specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential damages and loss of profits, opportunities or information) arising

from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 4 of 6

AAAC (All Aluminium Conductor)

(A2)

Application:

Specifications:

Bare Overhead transmission lines with high tensile load.

IEC 60189. Construction:

Aluminium Alloy wires stranded, greased or dry up to the 2nd last layer Case 2

or up to the PCD of last layer Case 4 not on outer surface.

All Aluminium conductor Polymeric weather covering (if applicable)

Grease (if applicable) All Aluminium conductor

All Aluminium Alloy Conductor

Specification

Construction and dimensions

Bending Resistance Current

ber

Conductor Diameter Gross Standard Short #Creep

Size Area mass radius Ω/km Rating circuit

Num

(nominal,

(D) mass length calculated)

Min. dc ac (A) rating

(mm/km)

Electrical Properties

20°C 75°C (kA.1s)

# mm mm mm² kg/km kg m mm 75°C

160 19 3.51 17.55 183.8 506.1 1 372 2 000 527 0.1798 0.2241 355 9.09 609

200 19 3.93 19.65 230.5 634.5 1 629 2 000 590 0.1439 0.1793 513 10.24 814

315 37 3.53 24.71 362.1 998.9 2 358 2 000 741 0.0916 0.1141 671 13.00 1 470

400 37 3.98 27.86 460.3 1268.4 2 897 2 000 836 0.0721 0.0898 829 14.74 2 005

450 37 4.22 29.54 517.5 1426.9 3 214 2 000 886 0.0641 0.0798 987 15.68 2 337

IEC

500 37 4.45 31.15 575.5 1585.5 3 531 2 000 935 0.0577 0.0718 1 145 16.58 2 679

560 61 3.67 33.03 645.3 1778.4 3 917 2 000 991 0.0516 0.0643 1 303 17.61 3 105

630 61 3.89 35.01 725.0 2000.7 4 361 2 000 1050 0.0458 0.0571 1 461 18.73 3 618

710 61 4.13 37.17 817.2 2254.8 4 870 2 000 1115 0.0407 0.0507 1 619 19.94 4 227

800 61 4.38 39.50 921.0 2540.6 5 441 2 000 1185 0.0361 0.0449 1 777 21.23 4 936

Modulus

Specification

Coefficient Grease mass Outer PVC insulation

of Elasticity

Conductor of linear UTS calculated Nom. layer

Initial Final 1.6mm 5mm

name expansion Lay

kN/mm² Case 2 Case 4 kg/km OD kg/km OD

direction

Nom. x10-6/oC kN kg/km kg/km Nom. mm Nom. mm

Physical properties

160 49.7 59.7 23.00 54.32 11.2 21.9 (Z) RH 146 21 538 28

200 49.7 59.7 23.00 67.91 14.1 27.4 (Z) RH 162 23 589 30

315 49.7 59.7 23.00 106.95 11.4 22.1 (Z) RH 201 28 709 35

400 49.7 59.7 23.00 135.81 14.4 28.1 (Z) RH 225 31 785 38

450 49.7 59.7 23.00 152.79 16.2 31.6 (Z) RH 238 33 825 40

IEC

500 49.7 59.7 23.00 169.76 18.1 35.2 (Z) RH 250 34 863 41

560 49.7 59.7 23.00 190.14 12.3 23.9 (Z) RH 265 36 908 43

630 49.7 59.7 23.00 213.90 13.8 26.9 (Z) RH 280 38 955 45

710 49.7 59.7 23.00 241.07 15.6 30.3 (Z) RH 296 40 1007 47

800 49.7 59.7 23.00 271.62 17.5 34.1 (Z) RH 314 43 1062 50

Notes:

Grease and mass must be added as per relevant Case Insulation mass must be added to the conductor mass if relevant.

to conductor mass if greased conductor is required.

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of M-TEC’s knowledge. M-TEC reserves the right to amend this

specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential damages and loss of profits, opportunities or information) arising

from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 5 of 6

Annexure A

Conductor creep

. . . ( )

= × . × × × ×

m = length of conductor span (in mm)

t = time in years (20 years)

T = maximum continues conductor temperature (90°C)

e = Coefficient of linear expansion

σ = Conductor RTS stress in (MPa)

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of

M-TEC’s knowledge. M-TEC reserves the right to amend this specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential

damages and loss of profits, opportunities or information) arising from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 6 of 6

You might also like

- Top 150 Civil Engineer Interview Questions Asked in Top CompaniesDocument17 pagesTop 150 Civil Engineer Interview Questions Asked in Top CompaniesBURDWAN COMMUNITYNo ratings yet

- Ams4945h 2020Document10 pagesAms4945h 2020BauyrzhanNo ratings yet

- IS 2911 Part 1 - Sec 3 - 2010 PDFDocument28 pagesIS 2911 Part 1 - Sec 3 - 2010 PDFSunny RohillaNo ratings yet

- Design of Steel Plate - R0 - 20.04.21Document1 pageDesign of Steel Plate - R0 - 20.04.21Srishti Project ConsultantsNo ratings yet

- Company Logo: Cable Size CalculationDocument7 pagesCompany Logo: Cable Size Calculationahmadgce04No ratings yet

- Aluminium Tubular Busbars For HV SubstatDocument5 pagesAluminium Tubular Busbars For HV Substatasi midobarNo ratings yet

- 33kV & 22kV GIS Specifications PDFDocument15 pages33kV & 22kV GIS Specifications PDFAlauddin khanNo ratings yet

- Sheath Bonding MethodDocument26 pagesSheath Bonding Methodوهيبه بكر100% (1)

- Devices and Methods For Preheating Prewarming Dental Resin CompositesDocument4 pagesDevices and Methods For Preheating Prewarming Dental Resin CompositesMADA100% (1)

- Theorem of Three Moments Modified PDFDocument10 pagesTheorem of Three Moments Modified PDFMahaveer DhakadNo ratings yet

- Durey CastingsDocument28 pagesDurey CastingsAdrian BuicaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Power Mar Bus BarDocument16 pagesPower Mar Bus BarKatty CachagoNo ratings yet

- XSteam Excel v2.6 USDocument4 pagesXSteam Excel v2.6 USWahyu Nugraha100% (1)

- ACSR Rail ZTTDocument6 pagesACSR Rail ZTTAntony Cesar Caballero IbarraNo ratings yet

- TM Cable RequirementDocument96 pagesTM Cable Requirementfaridnor88No ratings yet

- Steel Grating PDFDocument34 pagesSteel Grating PDFhlkhgljkhNo ratings yet

- Lesson Plan in Science IVDocument4 pagesLesson Plan in Science IVPrecilla Ugarte Halago100% (10)

- ACSR LatestDocument12 pagesACSR LatestsohaibNo ratings yet

- YyyDocument2 pagesYyyŽarko MočnikNo ratings yet

- Aoi-01-Eng-2024Document81 pagesAoi-01-Eng-2024Kuldeep ShekhawatNo ratings yet

- 1 4509Document2 pages1 4509Umesh KotadiaNo ratings yet

- Nexans - EAXT ABC Cables With Messenge...Document3 pagesNexans - EAXT ABC Cables With Messenge...mazen zaloudNo ratings yet

- Nexans - Anti Theft Power Cable PVC In...Document5 pagesNexans - Anti Theft Power Cable PVC In...abdulkawi alasharyNo ratings yet

- NF C 33 226 12 20 24 KV CableDocument3 pagesNF C 33 226 12 20 24 KV CableIrvan FauziNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Ica540 72hmiDocument1 pageIca540 72hmiMuhammad JanuardiNo ratings yet

- AC03 Safety (AC03..CS) : Vishay DraloricDocument3 pagesAC03 Safety (AC03..CS) : Vishay Draloricyenassiri278No ratings yet

- PDS - Bohler Q 71 BC (C1)Document1 pagePDS - Bohler Q 71 BC (C1)RaviTeja BhamidiNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- Ul Ag15a1 后乐Document1 pageUl Ag15a1 后乐karthikNo ratings yet

- A12 Appendix 12 Technical ScheduleDocument79 pagesA12 Appendix 12 Technical Scheduleanon_31581079No ratings yet

- FLR6Y-B CablesDocument1 pageFLR6Y-B CablesKristaNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- Belimo FSLF230-S US Datasheet En-UsDocument4 pagesBelimo FSLF230-S US Datasheet En-UsAditya ElangNo ratings yet

- Circuit BreakersDocument60 pagesCircuit Breakerslian tineoNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- Belimo FSNF230 US Datasheet En-UsDocument4 pagesBelimo FSNF230 US Datasheet En-UsENGINEERING- Carlson Innotech CorporationNo ratings yet

- WTA CableDocument1 pageWTA CableVijay KarthikeyanNo ratings yet

- Auto 210 CableDocument1 pageAuto 210 CableVijay KarthikeyanNo ratings yet

- AAAC ConductorsDocument14 pagesAAAC ConductorsDipanku GoswamiNo ratings yet

- Er100s GDocument1 pageEr100s GAhmed Abdel NabiNo ratings yet

- 1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBDocument1 page1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBRodrigo TeodoroNo ratings yet

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Document2 pagesPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazNo ratings yet

- GOLDI - 60GN - Polycrystalline Module: NOCT Irradiance of 800 W/M, Ambient Temperature of 20°C, Wind Speed 1m/secDocument1 pageGOLDI - 60GN - Polycrystalline Module: NOCT Irradiance of 800 W/M, Ambient Temperature of 20°C, Wind Speed 1m/secsuhradamNo ratings yet

- ISO Standards On Mech Test of MetalsDocument1 pageISO Standards On Mech Test of MetalsKiran NikateNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- Am528jxvafh2aa Submittal 230V+HP 03122019Document3 pagesAm528jxvafh2aa Submittal 230V+HP 03122019Luis PaizNo ratings yet

- Jet Fan 300ºc - 4950 CFM - Technical DataDocument4 pagesJet Fan 300ºc - 4950 CFM - Technical DataHidraulica MAB InprosacNo ratings yet

- HT906Z UL CertificationDocument1 pageHT906Z UL CertificationAnimesh Kumar SinghNo ratings yet

- ZALUX Datasheet ACQUEX 030323Document2 pagesZALUX Datasheet ACQUEX 030323hamza.zouikriiNo ratings yet

- 250V RFOU (C) (S102) (Multi Pairs, 1.5 2.5) : DescriptionDocument2 pages250V RFOU (C) (S102) (Multi Pairs, 1.5 2.5) : DescriptionwidiNo ratings yet

- CPE-FR CablesDocument1 pageCPE-FR CablesVijay KarthikeyanNo ratings yet

- Nexans - Medium Hard Drawn Copper Cabl...Document1 pageNexans - Medium Hard Drawn Copper Cabl...hamza salamiNo ratings yet

- Sensata Gigavac Mx16 Series Open Contactors Datash-3077712Document4 pagesSensata Gigavac Mx16 Series Open Contactors Datash-3077712Dragan M.No ratings yet

- 2012 250W AMA Data Sheet 2.2014 PDFDocument2 pages2012 250W AMA Data Sheet 2.2014 PDFChaclis Q. RosaNo ratings yet

- Shanghai Huitian New Material Co LTD: Click To ContinueDocument1 pageShanghai Huitian New Material Co LTD: Click To ContinueAnimesh Kumar SinghNo ratings yet

- 330 Watt Solar PanelDocument2 pages330 Watt Solar PanelSathiya MoorthyNo ratings yet

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocument1 pageBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNo ratings yet

- Pinnacle Alloys E8018 C3Document2 pagesPinnacle Alloys E8018 C3Sajeev SivanandanNo ratings yet

- 08 LisbonDocument1 page08 LisbonElton MelecoNo ratings yet

- Arosta309H EngDocument1 pageArosta309H Engrusf123No ratings yet

- Sabic Chile Ptfe Hoja TecnicaDocument1 pageSabic Chile Ptfe Hoja Tecnicae.vicente.caballeroNo ratings yet

- TDK CD70 B2GA101KYGS Datasheet PDFDocument2 pagesTDK CD70 B2GA101KYGS Datasheet PDFSebastian ChaileNo ratings yet

- Pa 6 GF 30 (En)Document1 pagePa 6 GF 30 (En)Alessandro WeissNo ratings yet

- Pressure TransmitterDocument4 pagesPressure TransmitterKirankumar BoddalaNo ratings yet

- Auto 260 CableDocument1 pageAuto 260 CableVijay KarthikeyanNo ratings yet

- Elerep® 310: ClassificationDocument2 pagesElerep® 310: ClassificationSerhii MishchenkoNo ratings yet

- Schrack Miniature Power PCB RYII & RYII Reflow Solderable: General Purpose Relays PCB RelaysDocument4 pagesSchrack Miniature Power PCB RYII & RYII Reflow Solderable: General Purpose Relays PCB RelaysWilson Rubiano AlfaroNo ratings yet

- Dynamic Thermal Analysis of High-Voltage Power Cable Insulation For Cable Dynamic Thermal RatingDocument12 pagesDynamic Thermal Analysis of High-Voltage Power Cable Insulation For Cable Dynamic Thermal Ratingوهيبه بكرNo ratings yet

- CV-Eng - Wahiba BakerDocument2 pagesCV-Eng - Wahiba Bakerوهيبه بكرNo ratings yet

- CV-Eng - Wahiba BakerDocument2 pagesCV-Eng - Wahiba Bakerوهيبه بكرNo ratings yet

- Zip Password Is '123abc'. ReadmeDocument2 pagesZip Password Is '123abc'. Readmeوهيبه بكرNo ratings yet

- Villa 20-Jawaher-Lansdcaping LayoutDocument1 pageVilla 20-Jawaher-Lansdcaping Layoutوهيبه بكرNo ratings yet

- Drum WEIGHTDocument39 pagesDrum WEIGHTوهيبه بكرNo ratings yet

- Round Flexible: Diameter of Wire Factor N.of Cores 0.4 1.044 4Document51 pagesRound Flexible: Diameter of Wire Factor N.of Cores 0.4 1.044 4وهيبه بكرNo ratings yet

- Low Voltage Aerial Bundled Cable SystemsDocument12 pagesLow Voltage Aerial Bundled Cable Systemsوهيبه بكرNo ratings yet

- Cyme GridDocument3 pagesCyme Gridوهيبه بكرNo ratings yet

- Iso 14001: 2015 Ohsas 18001: 2007Document17 pagesIso 14001: 2015 Ohsas 18001: 2007وهيبه بكرNo ratings yet

- YY PVC Control Flexible CableDocument4 pagesYY PVC Control Flexible Cableوهيبه بكرNo ratings yet

- YY PVC Control Cable (Numbered Cores)Document3 pagesYY PVC Control Cable (Numbered Cores)وهيبه بكرNo ratings yet

- ZMS CABLE LV CAT Ver 2017 PDFDocument42 pagesZMS CABLE LV CAT Ver 2017 PDFوهيبه بكرNo ratings yet

- PVC Insulated Flat Cord H07VVH6-F Acc. To VDE 0281-404: P/N Part Name B (MM) H (MM) Cu (KG/KM) G (KG/KM)Document2 pagesPVC Insulated Flat Cord H07VVH6-F Acc. To VDE 0281-404: P/N Part Name B (MM) H (MM) Cu (KG/KM) G (KG/KM)وهيبه بكرNo ratings yet

- Product Range: Packaging: BasketsDocument2 pagesProduct Range: Packaging: Basketsوهيبه بكرNo ratings yet

- NYY-Flex: Low Voltage Power Cable (0.6/1 KV)Document2 pagesNYY-Flex: Low Voltage Power Cable (0.6/1 KV)وهيبه بكرNo ratings yet

- Principles of Cathodic ProtectionDocument4 pagesPrinciples of Cathodic ProtectionSengAhTuckChekAhNo ratings yet

- 2014MAFord CatalogCountersinksDocument25 pages2014MAFord CatalogCountersinksBeto CovasNo ratings yet

- UBL DEB-E-6-M2-DS-MS3-001-G DataSheet Mechanical Steam Separator Rev.A IFRDocument5 pagesUBL DEB-E-6-M2-DS-MS3-001-G DataSheet Mechanical Steam Separator Rev.A IFRAndi Candra IrawanNo ratings yet

- 3x120 RM 2xSEYFGY (CTS)Document2 pages3x120 RM 2xSEYFGY (CTS)Rakib HasanNo ratings yet

- Piping Coordination System - Butt Welded, Socket Welded and Threaded Symbols FoDocument4 pagesPiping Coordination System - Butt Welded, Socket Welded and Threaded Symbols FoJohan ClpNo ratings yet

- Standard Pipe NipplesDocument1 pageStandard Pipe NippleschadNo ratings yet

- Precision Ceramics: How To Find UsDocument4 pagesPrecision Ceramics: How To Find UsGeorge AcostaNo ratings yet

- Dekoron Cable Product Specification SheetDocument1 pageDekoron Cable Product Specification SheetgrandpaNo ratings yet

- Seminar On Composite Materials in Aerospace ApplicationsDocument20 pagesSeminar On Composite Materials in Aerospace ApplicationsAnketNo ratings yet

- Aalco Aluminium PDFDocument33 pagesAalco Aluminium PDFMihai NedeaNo ratings yet

- Exercise CompDocument6 pagesExercise CompatulsemiloNo ratings yet

- Green Building Material LeedDocument4 pagesGreen Building Material Leeddep_vinNo ratings yet

- Refractory Lining of Blast Furnace PDFDocument11 pagesRefractory Lining of Blast Furnace PDFceng el samiuNo ratings yet

- Catalogue Water Cooled Screw Chiller Cuwd-CDocument15 pagesCatalogue Water Cooled Screw Chiller Cuwd-CBayu SetiaNo ratings yet

- LAY OUT PLAN-Ware House-Structure-RL-1-ModelDocument1 pageLAY OUT PLAN-Ware House-Structure-RL-1-ModelAbid AyubNo ratings yet

- 001 Lca Standard ComponentsDocument4 pages001 Lca Standard ComponentsYUCARIE HIGUCHINo ratings yet

- Nelsondiana Eml4501 Report1Document52 pagesNelsondiana Eml4501 Report1jacksayshiNo ratings yet

- ASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - TaylorDocument7 pagesASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - Taylorsajuhere100% (1)

- Exothermic Welding System: in This SectionDocument66 pagesExothermic Welding System: in This Sectionالمهندس مصطفى عبد المجيدNo ratings yet