Professional Documents

Culture Documents

MD32-G Operation Manual: Digital-Multifunction Generator Differential Protection Relay Type

Uploaded by

shekooferiahiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MD32-G Operation Manual: Digital-Multifunction Generator Differential Protection Relay Type

Uploaded by

shekooferiahiCopyright:

Available Formats

Doc.

N° MO-0048-ING

MD32-G Rev. 3

Pag. 1 of 25

DIGITAL-MULTIFUNCTION

GENERATOR DIFFERENTIAL

PROTECTION RELAY

TYPE

MD32-G

OPERATION MANUAL

dA> dB> dC> d0>

PROG/ I> B.F. BLOCK

I.R.F. INPUT

MICROELETTRICA SCIENTIFICA

MILANO ITALY

MODE SELECT +

MULTIFUNCTION

GENERATOR

DIFFERENTIAL

RELAY TYPE

-

PROG.

MD32-G

ENTER/RESET

Copyright 1997 Microelettrica Scientifica

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 2 of 25

INDEX

1 General utilization and commissioning directions________________________________ 3

1.1 Storage and transportation________________________________________________________ 3

1.2 Installation____________________________________________________________________ 3

1.3 Electrical connection____________________________________________________________ 3

1.4 Measuring inputs and power supply_________________________________________________ 3

1.5 Outputs loading________________________________________________________________ 3

1.6 Protection earthing______________________________________________________________ 3

1.7 Setting and calibration___________________________________________________________ 3

1.8 Safety protection_______________________________________________________________ 3

1.9 Handling______________________________________________________________________ 3

1.10 Maintenance___________________________________________________________________ 4

1.11 Fault detection and repair________________________________________________________ 4

2 General characteristics and operation__________________________________________ 4

2.1 Power supply__________________________________________________________________ 4

2.2 Differential protection F87TG______________________________________________________ 5

2.2.1 Second Harmonic Restraint_____________________________________________________ 6

2.3 Stator Overcurrent Protection F51G________________________________________________ 6

2.4 Breaker Failure Protection________________________________________________________ 6

2.5 Earth Fault protection F87N/F51G__________________________________________________ 7

2.6 Functions blocking______________________________________________________________ 7

2.7 Characteristics required for C.Ts. __________________________________________________ 8

2.8 Value of the stabilising resistor____________________________________________________ 8

3 Controls and measurements__________________________________________________ 9

4 Signalization_______________________________________________________________ 10

5 Output relays______________________________________________________________ 11

6 Serial communication_______________________________________________________ 11

7 Oscillography records_______________________________________________________ 12

8 Digital inputs_______________________________________________________________ 12

9 Test______________________________________________________________________ 12

10 Keyboard and display operation_______________________________________________ 13

11 Reading of measurements and recorded parameters_____________________________ 14

11.1 ACT. MEAS (Actual measure) __________________________________________________ 14

11.2 MAX VAL (Max val) ________________________________________________________ 14

11.3 LASTTRIP (Last trip) ________________________________________________________ 15

11.4 TRIP NUM (Trip number) ____________________________________________________ 15

12 Reading of programmed settings and relay’s configuration________________________ 15

13 Programming______________________________________________________________ 16

13.1 Programming of functions settings________________________________________________ 16

13.2 Programming the configuration of output relay_______________________________________ 17

14 Manual and automatic test operation__________________________________________ 18

14.1 Mode “TEST PROG” subprogram “W/O TRIP”_______________________________________ 18

14.2 Mode “TEST PROG” subprogram “WhitTRIP”_______________________________________ 18

15 Maintenance_______________________________________________________________ 18

16 Electrical characteristics_____________________________________________________ 19

17 Connection diagram 87G + 87N _______________________________________________ 20

17.1 Connection diagram 87G + 64G__________________________________________________ 20

18 Wiring the serial communication bus__________________________________________ 19

19 Change phase current rated input 1 or 5A______________________________________ 21

20 Direction for pcb’s draw-out and plug-in________________________________________ 22

20.1 Draw-out____________________________________________________________________ 22

20.2 Plug-in______________________________________________________________________ 22

21 Mounting / Overall dimensions________________________________________________ 23

22 Keyboard operational diagram________________________________________________ 24

23 Setting’s form______________________________________________________________ 25

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 3 of 25

1. General utilization and commissioning directions

Always make reference to the specific description of the product and to the Manufacturer's instruction.

Carefully observe the following warnings.

1.1 - STORAGE AND TRANSPORTATION,

must comply with the environmental conditions stated on the product's instruction or by the

applicable IEC standards.

1.2 - INSTALLATION,

must be properly made and in compliance with the operational ambient conditions stated by the

Manufacturer.

1.3 - ELECTRICAL CONNECTION,

must be made strictly according to the wiring diagram supplied with the Product, to its electrical

characteristics and in compliance with the applicable standards particularly with reference to human

safety.

1.4 - MEASURING INPUTS AND POWER SUPPLY,

carefully check that the value of input quantities and power supply voltage are proper and within the

permissible variation limits.

1.5 - OUTPUTS LOADING,

must be compatible with their declared performance.

1.6 - PROTECTION EARTHING

When earthing is required, carefully check its effectiveness.

1.7 - SETTING AND CALIBRATION

Carefully check the proper setting of the different functions according to the configuration of the

protected system, the safety regulations and the co-ordination with other equipment.

1.8 - SAFETY PROTECTION

Carefully check that all safety means are correctly mounted, apply proper seals where required and

periodically check their integrity.

1.9 - HANDLING

Notwithstanding the highest practicable protection means used in designing M.S. electronic circuits,

the electronic components and semiconductor devices mounted on the modules can be seriously

damaged by electrostatic voltage discharge which can be experienced when handling the modules.

The damage caused by electrostatic discharge may not be immediately apparent but the design

reliability and the long life of the product will have been reduced. The electronic circuits reduced by

M.S. are completely safe from electrostatic discharge (8 KV IEC 255.22.2) when housed in their

case; withdrawing the modules without proper cautions expose them to the risk of damage.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 4 of 25

a. Before removing a module, ensure that you are at the same electrostatic potential

as the equipment by touching the case.

b. Handle the module by its front-plate, frame, or edges of the printed circuit board.

Avoid touching the electronic components, printed circuit tracks or connectors.

c. Do not pass the module to any person without first ensuring that you are both at

the same electrostatic potential. Shaking hands achieves equipotential.

d. Place the module on an antistatic surface, or on a conducting surface which is at

the same potential as yourself.

e. Store or transport the module in a conductive bag.

More information on safe working procedures for all electronic equipment can be found

in BS5783 and IEC 147-OF.

1.10 - MAINTENANCE

Make reference to the instruction manual of the Manufacturer ;maintenance must be

carried-out by specially trained people and in strict conformity with the safety regulations.

1.11 - FAULT DETECTION AND REPAIR

Internal calibrations and components should not be altered or replaced.

For repair please ask the Manufacturer or its authorised Dealers.

Misapplication of the above warnings and instruction relieves the Manufacturer of any liability.

2. GENERAL CHARACTERISTICS AND OPERATION

5Amp.

Input currents from system’s CT.s are supplied to two internal

sets of 3 CT.s Dip-switch

An additional CT is used either for Restricted Earth Fault protection or for 5Amp. 1Amp.

Stator Earth Fault current protection (see connection diagrams).

1A 8

Input rated current can be set to 1 of 5A by 7 dip-switches 1B 7

provided on relay’s card. 1C

2A

6

5

2B 4 1

2C 3

Io 2

1

1Amp.

2.1- POWER SUPPLY

The relay can be fitted with two different types of power supply module :

24V(-20%) / 110V(+15%) a.c. 80V(-20%) / 220V(+15%) a.c.

a) - b) -

24V(-20%) / 125V(+20%) d.c. 90V(-20%) / 250V(+20%) d.c.

Before energising the unit check that supply voltage is within the allowed limits.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 5 of 25

2.2 - Differential Protection F87G

The relay performs a percentage biased differential protection of generator or rotating machinery:

Two or three phase internal faults

Restricted Earth Fault

Earth Fault in low-impedance or directly earthed generators.

For each phase the relay measures :

The system frequency component of the value of the vector difference between the currents at

the two winding sides

d x = I1x − I 2x x = A, B, C

I1x + I 2 x

The Generator “Through current” Irx =

2

The operation is based on the comparison of above measurements with the following

programmable levels :

Basic minimum differential pick-up level : d> = (0.02 - 0.2)In, step 0.01In

IR

Percent bias in the zone 0.5 < <P : 1R% = (2-20)%, step 1%

In

IR

Percent bias in the zone >P : 2R% = (5-50)%, step 1%

In

Point of bias slope changement : P = (1.00 - 3.00)

To compensate the differential current produced by errors or saturation of the CTs, the actual

differential current minimum pick-up level Id is dynamically adjusted in function of the actual

Through Current Ir depending on the set percent bias levels 1R%, 2R%.

Fig.1

Id

R% = 100

Is/I 4 IR

Is Id

8 =

In In

2R%

3 Is Id IR 1R%

0,2 ∆IR ∆ld = + ( − 0,5) ⋅

In In In 100

∆lR

0,1

1R% Is Id (P - 0,5 ) 1R% IR 2R%

1 2 = + + ( − P)

∆ld In In 100 In 100

ld/In

Is

d> P ≅8

0 IR/In

In

0,5 1 2 P 3

Is= Effective relay’s operation differential current

Id= Relay set differential current IR= Relay’s through current

The low set differential element operates instantaneously (less than 30ms) when the System frequency

component of measured differential current of any phase exceeds the actual pick-up level Is.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 6 of 25

2.2.1 – Second Harmonic Restraint

Whenever the ratio of the second harmonic component to the system frequency component of the

differential current of any phase exceeds the set level 2H = (0.10-1.00), the operation of the

differential protection element is blocked.

2.3 - Stator Overcurrent Protection F51G

Relays measures the R.M.S. value of the phase currents.

Minimum pick-up level : I> = (0.5-10)In, step 0.01In

Trip time delay (Independent Definite time) : tI> = (0.05-9.99)s, step 0.01s

2.4 - Breaker Failure Protection

tBF = (0.05-1.00)s, step 0.01s

If after the time tBF from tripping of one function (d>, I>, do>) the tripping cause is not removed, a

proper output relay is energized to operate the second opening circuit of the Circuit Breaker

or a back-up breaker.

It is possible to select which protection element controls the Breaker Failure function by

programming the variable:

BF = d, I, do

any combination is possible

BF = - - -

BF = d - -

BF = - I -

BF = - - do

BF = d I -

BF = d - do

BF = d I do

BF = - I do

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 7 of 25

2.5 - Earth Fault protection F87N/F51G

The relays measures the system frequency component only of the current feeding the input

terminals 32-33

Depending upon connection this element can perform:

Restricted Earth Fault Protection (87N)

Neutral current protection (stator earth fault 64G).

The adjustable variables are :

Minimum pick-up level : do> = (0.01 - 1)Ion, step 0.01

(Ion = Rated current of CT feeding input terminals 32-33)

Instantaneous element : t ≤ 30ms

Time delayed element : tdo = (0.05 - 9.99)s, step 0.01

(Same trip level do> as the instantaneous element)

2.6 - Functions Blocking

Any function can be permanently disactivated setting to Dis the relevant variable, or temporarily

blocked via the digital input B1

The operation of the blocking input B1 can be programmed to block (when activated) any of the

relay functions by programming the variable B1.

B1 = d>, I>, do

any combination is possible :

B1 = - - -

B1 = d> - -

B1 = d> - -

B1 = - I> -

B1 = - - do

B1 = d> I> -

B1 = d> - do

B1 = d> I> do

B1 = - I> do

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 8 of 25

2.7 - CHARACTERISTICS REQUIRED FOR C.Ts.

Relay burden on inputs at rated current

Phase inputs : PB = 0.01VA for C.T. 1A; PB = 0.2VA for C.T. 5A

Neutral input : EB = 0.02VA for C.T. 1A; EB = 0.3VA for C.T. 5A

C.T.’s requirements for phase differential protection

Class 5P10 (or better)

Minimum burden 10xPB+(RCT+RL), where:

RCT = Resistance of C.T. secondary winding

RL = Resistance of the loop lead between C.T. and relay plus resistance of the relay

Additional requirements for R.E.F. protection

Minimum Knee-point voltage Vm = 2If(RCT+RL), where If is the maximum expected Earth

Fault current (C.T.’s secondary).

The effective minimum C.T.’s. secondary current that produces relay pick-up is:

Ido = [do>] - 4Im, where:

[do>] = Relay set current

Im = C.T. excitation current at Vm/2.

As a consequence to operate on a Fault Current Ido the relay setting current shall be

[do>] ≤ Ido - 4Im

2.8 - VALUE OF THE STABILISING RESISTOR

- The value of the externally mounted series resistor R is calculated as follows:

Vm/2 − EB/[do >]

R=

[do >]

Continuously variable resistors are normally used:

- for 1A C.T.: (0-200)Ohm 100W rated

- for 5A C.T.: (0-50)Ohm 100W rated

In the unlikely case where the maximum prospective current If during internal Earth Fault can

produce at C.T.’s terminals a voltage Vm = If(R+RTC+RL) >2kV a non linear voltage limiting

device Z is available

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 9 of 25

3. CONTROLS AND MEASUREMENTS

Five key buttons allow for local management of all relay's functions.

A 8-digit high brightness alphanumerical display shows the relevant readings (xxxxxxxx)

(see synoptic table fig.1)

FIG.1

MODE SELECT + - ENTER

ACT MEAS Actual measuremant values

MAX VAL Max. values measured

MEASURES Scanning of

LastTr-X Recording of last five events the menus by

Measurements

display

the key

TRIP NUM N° of tripping for each function “+” “-”

SETTINGS Display of setting

SET DISP

→RELAY

F→ Display of configuration of output relay

Setting Program

display Paramater scanning

by the key

(*) PRO SELECT

SETTINGS Setting of parameters

PROGR Parameter modification

→RELAY

F→ Configuration of output relays by the key “+” “-”

Set Programming

Set validation

by the key ENTER

W/O TRIP Test with operation of signals

TEST PRG only

Test activation

WithTRIP Test with operation of signals and output

Functional Test by the key ENTER

(*) relays

(*) Enabled only if input current is zero

Pressing this button progressively

The + and - buttons are used to

selects between

select the actual measurement or

Measurements Display,

display desired when in

Setting Display, Programming,

Measurements Display or Settings

and Test modes

Display modes. When in Program

MODE SELECT + mode, these buttons increase or

The SELECT button chooses decrease the value of the

which category of values within the displayed setting.

chosen mode to display

-

PROG. When in Program mode, and when

When in Program mode, this

all input currents are zero,

button stores the newly selected

pressing this recessed button

value. If not in Program mode and ENTER/RESET places the relay into active

the relay has tripped, this button

programming mode, allowing any

resets the relay and all output

or all of the relay’s settings to be

contacts. If not tripped, this button

altered.

restores the default display.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 10 of 25

4. SIGNALIZATIONS

Eight signal leds (normally off) are provided:

a b c d

dA> dB> dC> d0>

PROG/ I> B.F. BLOCK

I.R.F. INPUT

e f g h

a) Red LED dA> Illuminated on tripping of differential element phase A (IdA≥[d>])

b) Red LED dB> Illuminated on tripping of differential element phase B (IdB≥[d>])

c) Red LED >

dC> Illuminated on tripping of differential element phase C (IdC≥[d>])

d) Red LED >

d0> Illuminated on tripping of the earth fault element (Io>[do>])

PROG/ Flashing during the programming of the parameters or in case of

e) Yellow LED

I.R.F. Internal Relay Fault

Flashing when the current in any phase exceeds the set level [I>]

f) Red LED I>

Illuminated on trip at the end of time delay tI>

g) Red LED B.F. Illuminated on trip of the Breaker Failure function

BLOCK Flashing when digital input B1 is activated

h) Yellow LED

INPUT

The reset of the leds takes place as follows:

From flashing to off, automatically when the lit-on cause disappears.

From ON to OFF, by "ENTER/RESET" push button only if the tripping cause has disappeared.

In case of auxiliary power supply failure the status of the leds is recorded and reproduced when power

supply is restored.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 11 of 25

5. OUTPUT RELAYS

Five output relays are available (R1, R2, R3, R4, R5)

The relays R1,R2,R3,R4 are normally deenergized (energized on trip): these output relays are user

programmable and any of them can be associated to any of the MD32's functions.

For function do> both instantaneous and time delayed elements are provided.

The reset after tripping of the relays (when tripping cause has been cleared) can be programmed as

Manual or Automatic (Variable RR=Man/Aut).

FRes = Aut : Automatic Reset as soon as pick-up cause has been cleared.

FRes = Man : Reset by ENT/RESET KEY on relay’s front or via serial port

The relay R5, normally energised, is not programmable and is deenergized on:

internal fault

power supply failure

during the programming

6. SERIAL COMMUNICATION

The relays fitted with the serial communication option can be connected via a cable bus or (with proper

adapters) a fiber optic bus for interfacing with a Personal Computer (type IBM or compatible).

All the operations which can be performed locally (for example reading of measured data and changing

of relay’s settings) are also possible via the serial communication interface.

Furthermore the serial port allows the user to read the demand recording data.

The unit has a RS232 / RS485 interface and can be connected either directly to a P.C. via a dedicated

cable or to a RS485 serial bus, thus having many relays to exchange data with a single master P.C.

using the same physical serial line. A RS485/232 converter is available on request.

The communication protocol is MODBUS RTU (only functions 3, 4 and 16 are implemented).

Each relay is identified by its programmable address code (NodeAd) and can be called from the P.C.

A dedicated communication software (MSCOM) for Windows 95/98/NT4 SP3 (or later) is available.

Please refer to the MSCOM instruction manual for more information Microelettrica Scientifica.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 12 of 25

7. OSCILLOGRAPHY RECORDS

The relay continuously records in a buffer the samples of the seven input currents.

The buffer contains samples for approximately 16 periods of each of the seven currents.

Recording is stopped after approximately 8 periods after a trigger signal and the content of the buffer is

stored into memory.

Therefore in the memory are stored the wave forms for 8 cycles before and 8 cycles after the trigger

instant.

The trigger can be operated either internally on tripping of any function programmed d>, I>, Io>, or

externally by activation of the digital input B3.

Selection between the two modes is made by programming the variable TRG = EXT, d>, I>, do>

The last oscillography record is stored; a second record replaces the first.

8. DIGITAL INPUTS

Three inputs active when the relevant terminals are shorted are provided:

B1 (terminals 1 - 2) : For function blocking

B2 (terminals 1 - 3) : Not used

B3 (terminals 1 - 14) : External trigger for oscillography records

9. TEST

Besides the normal "WATCHDOG" and "POWERFAIL" functions, a comprehensive program of self-test

and self-diagnostic provides:

Diagnostic and functional test, with checking of program routines and memory's content, run every

time the aux. power is switched-on: the display shows the type of relay and its version number.

Dynamic functional test run during normal operation every 15 min. (relay's operation is suspended

for less than ≤ 4ms.). If any internal fault is detected, the display shows a fault message, the Led

"PROG/IRF" illuminates and the relay R5 is deenergized.

Complete test activated by the keyboard or via the communication bus either with or without tripping

of the output relays.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 13 of 25

10. KEYBOARD AND DISPLAY OPERATION

All controls can be operated from relay's front or via serial communication bus.

The keyboard includes five hand operable buttons (MODE) - (SELECT) - (+) - (-) - (ENTER/RESET)

plus one indirect operable key (PROG) (see synoptic table a fig.1):

MODE SELECT +

-

PROG.

ENTER/RESET

when operated it enters one of the following operation modes

a) - White key MODE :

indicated on the display :

Reading of all the parameters measured and of those recorded

MEASURES =

in the memory

Reading of the settings and of the configuration of the output

SET DISP =

relays as programmed.

Access to the programming of the settings and of relay

PROG =

configuration.

TEST PROG = Access to the manual test routines.

When operated it selects one of the menus available in the

b) - Green key SELECT :

actual operation MODE

When operated they allow to scroll the different information

c) - Red key “+” AND “-“ :

available in the menu entered by the key SELECT

d) - Yellow key ENTER/RESET : It allows the validation of the programmed settings

- the actuation of test programs

- the forcing of the default display indication

- the reset of signal Leds.

e) - Indirect key • : Enables access to the programming.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 14 of 25

11. READING OF MEASUREMENTS AND RECORDED PARAMETERS

Enter the MODE "MEASURE", SELECT the menus "ACT.MEAS"-"MAX VAL"-"LASTTRIP"-

"TRIP NUM", scroll available information by key "+" or "-" .

11.1 - ACT.MEAS

Actual values as measured during the normal operation. The values displayed are continuously updated.

Display Description

dAxx.xxn System frequency component of differential current of phase A : (0-99.99) per unit of

rated phase input current

dBxx.xxn As above phase B

dCxx.xxn As above phase C

do x.xxn As above residual current Io

1AxxxxxA R.M.S. value of current of phase A of Generator’s side 1: (0-99999) CT’s primary Amp

1BxxxxxA As above phase B

1CxxxxxA As above phase C

2AxxxxxA R.M.S. value of current of phase A of Generator’s side 2: (0-99999) CT’s primary Amp

2BxxxxxA As above phase B

2CxxxxxA As above phase C

11.2 - MAX VAL

Highest values recorded from Breaker closing, (updated any time the breaker closes).

Display Description

dAxx.xxn System frequency component of Differential current of phase A : (0-99.99) per unit of

rated phase input current

dBxx.xxn As above phase B

dCxx.xxn As above phase C

dox.xxxn As above residual current Io

1Axx.xn Current of phase A of side 1 input: (0-99.9) p.u. of phase input current

1Bxx.xn As above phase B of side 1 input

1Cxx.xn As above phase C of side 1 input

2Axx.xn Current of phase A of side 2 input: (0-99.9) p.u. of phase input current

2Bxx.xn As above phase B of side 2 input

2Cxx.xn As above phase C of side 2 input

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 15 of 25

11.3 - LASTTRIP

Display of the function which caused the tripping of the relay plus values of the parameters at the

moment of tripping. The memory contains the records of the last five tripping (FIFO).

Display Description

LastTr-x Indication of the recorded event (x= 0 to 4)

Example: Last event (LastTr -0)

Last but one event (LastTr-1) etc...

Cau:xxxx Function which produced the event being displayed: dA>, dB>, dC>, I>, do>

dAxx.xxn System frequency component of Differential current phase A

dBxx.xxn System frequency component of Differential current phase B

dCxx.xxn System frequency component of Differential current phase C

dox.xxn System frequency component of Residual current Io

1Axxxxn Current phase A of side 1 input

1Bxxxxn As above phase B

1Cxxxxn As above phase C

2Axx.xn Current of phase A of side 2 input

2Bxx.xn As above phase B

2Cxx.xn As above phase C

11.4 - TRIP NUM

Counters of the number of operations for each of the relay’s function.

The memory is non-volatile and can be cancelled only with a secret procedure.

Display Description

dA> xxxx Differential element phase A

dB> xxxx Differential element phase B

dC> xxxx Differential element phase C

do> xxxx Earth fault element

I> xxxx Overcurrent element

12. READING OF PROGRAMMED SETTINGS AND RELAY'S CONFIGURATION

Enter the mode "SET DISP", select the menu "SETTINGS" or "F → RELAY", scroll information available

in the menu by keys "+" or "-".

SETTINGS= values of relay's operation parameters as programmed

F → RELAY= output relays associated to the different functions as programmed.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 16 of 25

13. PROGRAMMING

The relay is supplied with the standard default programming used for factory test. [ Values here below

reported in the “ Display “ column ].

All parameters can be modified as needed in the mode PROG and displayed in the mode SET DISP

Local Programming by the front face key board is enabled only if no input current is detected

(main switch open). Programming via the serial port is always enabled but a password is required to

access the programming mode. The default password is the null string; in the standard application

program for communication “MS-COM” it is also provided an emergency password which can be

disclosed on request only.

As soon as programming is enabled, the Led PRG/IRF flashes and the reclosing lock-out relay R5 is

deenergized. Enter MODE "PROG" and SELECT either "SETTINGS" for programming of parameters

or "F → RELAY" for programming of output relays configuration; enable programming by the indirect

operation key PROG.

The key SELECT now scrolls the available parameters. By the key (+) , (-) the displayed values can be

modified; to speed up parameter's variation press the key SELECT while "+" or "-" are pressed.

Press key "ENTER/RESET" to validate the set values.

13.1 - PROGRAMMING OF FUNCTIONS SETTINGS

In 500 Ap

1In is the name 500 is the Ap is the unit of measure,

of the variable setting default Amps primary.

Mode PROG menu SETTINGS. (Production standard settings here under shown).

Display Description Setting Range Step Units

Fn 50 Hz System frequency 50 - 60 10 Hz

In 500A Rated primary current of CTs 1 - 9999 1 A

Basic minimum pick-up level of low set phase differential

d> 0.15n 0.02-0.2-Dis 0.01 In

element

1R 2% Bias percentage in the zone 0,5<IR<P 2-20 1 %

2R 20% Bias percentage in the zone IR>P 5-50 1 %

P 2.50 Bias slope change point 1.00-3.00 0.01 -

2H0.10d 2nd Harmonic restraint level 0.10-1.00-Dis 0.01 d

I>5.00In Minimum pick-up level of overcurrent element 0.50-8 0.01 In

tI>3.00s Time delay of overcurrent element 0.05-9.99 0.01 s

do> 0.10n Minimum pick-up level of Earth Fault element 0.01-1-Dis 0.01 In

tdo5.00s Time delay of Earth Fault element 0.05-9.99 0.01 s

Selection of element controlling the Breaker Failure function any

BF --I -- d - I - do

combination

tBF 0.25s Breaker Failure time delay 0.05-1.00 0.01 s

Digital input B1 blocks the function selected any

B1 ----do d - I - do

combination

Trigger for oscillography records is Internal (TRG=d>, I>, do>)

TRG d> Ext, d>, I>, do> -

or External via digital input B3.

Identification number for connection on serial communication

NodAd 1 1 - 250 1 -

bus

The setting Dis indicates that the function is disactivated.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 17 of 25

13.2 - PROGRAMMING THE CONFIGURATION OF OUTPUT RELAYS

d> - 2 - 4

This is the name of This dash means The number 2 This dash means The number 4 means

protective element that output relay means that that output relay that output relay 4 will

number 1 is not output relay 2 will number 3 is not operate when this

assigned to this operate when assigned to this element trips

element this element trips element

Mode PROG menu F→RELAY (Production standard settings here under shown).

The key "+" operates as cursor; it moves through the numbers corresponding to the four programmable

relays in the sequence 1,2,3,4,(1= relay R1, etc.) and makes start flashing the information actually

present in the digit. The information present in the digit can be either the number of the relay (if this was

already associated to the function actually on programming) or a dot (-) if the relay was not yet

addressed.

The key "-" changes the existing status from the dot to the relay number or viceversa.

After having programmed all the four relay, press “ ENTER “ to validate the programmed

configuration.

Display Description

d> 1--- Differential element operates relay R1, R2, R3, R4 as programmed

(one or more)

I> ---- Instantaneous Overcurrent element operates relay R1, R2, R3, R4 as programmed

tI> --3- Time delayed Overcurrent element operates relay R1, R2, R3, R4 as programmed

do> -2-- Instantaneous Earth Fault element operates relay R1, R2, R3, R4 as programmed

tdo --3- Time delayed Earth Fault element relay R1, R2, R3, R4 as programmed

tBF ---4 Breaker Failure function relay R1, R2, R3, R4 as programmed

FRes: Aut. Reset of output relays after tripping is:

Aut. = Automatic Man. = Manually key Enter /Reset or via serial bus

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 18 of 25

14. MANUAL AND AUTOMATIC TEST OPERATION

14.1 - Mode "TESTPROG" subprogram "W/O TRIP"

Operation of the yellow key activates a complete test of the electronics and the process routines.

All the leds are lit-on and the display shows (TEST RUN). If the test routine is successfully

completed the display switches-over to the default reading (dAxx.xxn).

If an internal fault is detected, the display shows the fault identification code and the relay R5 is

deenergized. This test can be carried-out even during the operation of the relay without affecting the

relay tripping in case a fault takes place during the test itself.

The display shows (TEST RUN) with the same procedure as for the test with W/O TRIP.

Every 15 min during the normal operation the relay automatically initiates an auto test procedure

(duration ≤ 10ms). If any internal fault is detected during the auto test, the relay R5 is deenergized,

the relevant led is activated and the fault code is displayed.

14.2 - Mode "TESTPROG" subprogram "WithTRIP"

Access to this program is enabled only if the current detected is zero (breaker open).

Pressing the yellow key the display shows "TEST RUN?". A second operation of the yellow key starts

a complete test which also includes the activation of all the output relays.

WARNING

Running the WithTRIP test will operate all of the output relays. Care must be taken to ensure that no

unexpected or harmful equipment operations will occur as a result of running this test.

It is generally recommended that this test be run only in a bench test environment or after all

dangerous output connections are removed.

15. MAINTENANCE

No maintenance is required. Periodically a functional check-out can be made with the test procedures

described under MANUAL TEST chapter. In case of malfunctioning please contact

Microelettrica Scientifica Service or the local Authorised Dealer mentioning the relay's Serial No reported

in the label on relays enclosure.

WARNING

In case of Internal Relay Fault detection, proceed as here-below indicated :

If the error message displayed is one of the following “DSP Err”, “ALU Err” ,”KBD Err” ,”ADC Err”,

switch off power supply and switch-on again. If the message does not disappear send the relay to

Microelettrica Scientifica (or its local dealer) for repair.

If the error message displayed is “E2P Err”, try to program any parameter and then run “W/OTRIP”.

If message disappear please check all the parameters.

If message remains send the relay to Microelettrica Scientifica (or its local dealer) for repair.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 19 of 25

16. ELECTRICAL CHARACTERISTICS

APPROVAZIONI : CE - RINA - File UL e CSA: E202083

REFERENCE STANDARDS IEC 60255 - EN50263 - CE Directive - EN/IEC61000 - IEEE C37

Dielectric test voltage IEC 60255-5 2kV, 50/60Hz, 1 min.

Impulse test voltage IEC 60255-5 5kV (c.m.), 2kV (d.m.) – 1,2/50µs

Climatic tests IEC 68-2-1 - 68-2-2 - 68-2-33

CE EMC Compatibility (EN50081-2 - EN50082-2 - EN50263)

Electromagnetic emission EN55022 IND.ENV.

Radiated electromagnetic field immunity test IEC61000-4-3 level 3 80-1000MHz 10V/m

ENV50204 900MHz/200Hz 10V/m

Conducted disturbances immunity test IEC61000-4-6 level 3 0.15-80MHz 10V

Electrostatic discharge test IEC61000-4-2 level 4 6kV contact / 8kV air

Power frequency magnetic test IEC61000-4-8 1000A/m 50/60Hz

Pulse magnetic field IEC61000-4-9 1000A/m, 8/20µs

Damped oscillatory magnetic field IEC61000-4-10 100A/m, 0.1-1MHz

Electrical fast transient/burst IEC61000-4-4 level 4 2kV, 5kHz

HF disturbance test with damped oscillatory wave (1MHz IEC60255-22-1 class 3 400pps, 2,5kV (m.c.), 1kV (d.m.)

burst test)

Oscillatory waves (Ring waves) IEC61000-4-12 level 4 4kV(c.m.), 2kV(d.m.)

Surge immunity test IEC61000-4-5 level 4 2kV(c.m.), 1kV(d.m.)

Voltage interruptions IEC60255-4-11

Resistance to vibration and shocks IEC60255-21-1 - IEC60255-21-2

CHARACTERISTICS

Accuracy at reference value of influencing factors 2% In for measure

2% +/- 10ms for times

Rated Current In = 1 or 5A - On = 1 or 5A

Current overload 200 A for 1 sec; 10A continuos

Burden on current inputs Phase : 0.01VA at In = 1A; 0.2VA at In = 5A

Neutral : 0.015VA at In = 1A ; 0.35VA at In = 5A

Average power supply consumption 8.5 VA

Output relays rating 5 A; Vn = 380 V

A.C. resistive switching = 1100W (380V max)

make = 30 A (peak) 0,5 sec.

break = 0.3 A, 110 Vcc,

L/R = 40 ms (100.000 op.)

Operation ambient temperature -10°C / +55°C

Storage temperature -25°C / +70°C

Humidity IEC 68-2-3 RH 93% Senza condensa a 40°C

Microelettrica Scientifica S.p.A. - 20089 Rozzano (MI) - Italy - Via Alberelle, 56/68

Tel. (##39) 02 575731 - Fax (##39) 02 57510940

http://www.microelettrica.com e-mail : ute@microelettrica.com

The performances and the characteristics reported in this manual are not binding and can modified at any moment without notice

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 20 of 25

17. CONNECTION DIAGRAM (SCE1492 Rev.3 Standard Output)

17.1 CONNECTION DIAGRAM (SCE1493 Rev.2 Standard Output)

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 21 of 25

18. WIRING THE SERIAL COMMUNICATION BUS (SCE1309 Rev.0)

19. CHANGE PHASE CURRENT RATED INPUT 1 OR 5A

Phase current input can be 1 or 5A (movable jumpers on relay’s card).

5Amp.

Dip-switch

5Amp. 1Amp.

1A 8

1B 7

1C 6

2A 5

2B 4 1

2C 3

Io 2

1

1Amp.

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 22 of 25

20. DIRECTION FOR PCB'S DRAW-OUT AND PLUG-IN

20.1 Draw-out

Rotate clockwise the screws and in the horizontal position of the screws-driver mark.

Draw-out the PCB by pulling on the handle

20.2 Plug-in

Rotate clockwise the screws and in the horizontal position of the screws-driver mark.

Slide-in the card on the rails provided inside the enclosure.

Plug-in the card completely and by pressing the handle to the closed position.

Rotate anticlockwise the screws and with the mark in the vertical position (locked).

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 23 of 25

21. MOUNTING / OVERALL DIMENSIONS

PANEL CUT-OUT 113x142 (LxH)

View of Rear

Terminal Connection

Copyright 1997 - Microelettrica Scientifica S.p.A.

MODE

I=0 I ≠0

(MEASURES) (SETDISP) (PROGR) (TESTPROG)

In programming mode

SEL SEL SEL the output relay R5 SEL

is deenergized

22. KEYBOARD OPERATIONAL DIAGRAM

(LastTrip) (SETTINGS) (F→RELAY)

(LastTrip-1) (SETTINGS) (F→RELAY) 1 (MD32-G)

(ACT MEAS) (MAX VAL) (TRIPNUM) PRG (SelPrg) PRG

(LastTrip-2) 2 (Ver:x.xx)

(EntPrS) (EntPrS)

I=0 I ≠0

(LastTrip-3) +/- +/- 3 (Dtxxxxxx)

(LastTrip-4) SEL ENT SEL ENT

0 Fn xx Hz 0 d> xxxx (UpDwnS) (UpDwnS) (W/O TRIP) (WithTRIP)

1 InxxxxA 1 I> xxxx +/- +/-

+/- +/- +/- +/-

MD32-G

2 d>xxxxn 2 tI> xxxx 0 Fn xx Hz 0 d> xxxx ENT ENT

0 dAxx.xxn 0 dAxx.xxn 0 LastTr-x 0 dA> xxxx 3 1R xx% 3 do> xxxx 1 InxxxxA 1 I> xxxx

1 dBxx.xxn 1 dBxx.xxn 1 Cau:xxxx 1 dB> xxxx 4 2R xx% 4 tdo xxxx 2 d>xxxxn 2 tI> xxxx

2 dCxx.xxn 2 dCxx.xxn 2 dAxx.xxn 2 dC> xxxx 5 P xxxx 5 tBF xxxx 3 1R xx% 3 do> xxxx TESTRUN?

3 do x.xxn 3 do x.xxn 3 dBxx.xxn 3 do> xxxx 6 2Hxxxxd 6 FRes: xxxx 4 2R xx% 4 tdo xxxx

4 1AxxxxxA 4 1AxxxxxA 4 dCxx.xxn 4 I> xxxx 7 I>xxxxIn 5 P xxxx 5 tBF xxxx SEL ENT

5 1BxxxxxA 5 1BxxxxxA 5 do x.xxn 8 tI>xxxxs 6 2Hxxxxd 6 FRes: xxxx

6 1CxxxxxA 6 1CxxxxxA 6 1AxxxxxA 9 do>xxxxn 7 I>xxxxIn

7 2AxxxxxA 7 2AxxxxxA 7 1BxxxxxA 10 tdoxxxxs 8 tI>xxxxs

TEST RUN TEST RUN

8 2BxxxxxA 8 2BxxxxxA 8 1CxxxxxA 11 BFxxxxxx 9 do>xxxxn

9 2CxxxxxA 9 2CxxxxxA 9 2AxxxxxA 12 tBFxxxxs 10 tdoxxxxs 1 msgFAULT 1 msgFAULT

10 2BxxxxxA 13 B1xxxxx 11 BFxxxxxx 2 dAxx.xxn 2 dAxx.xxn

11 2CxxxxxA 14 TRGxxxxx 12 tBFxxxxs

15 NodAdxxx 13 B1xxxxx

14 TRGxxxxx

Rev.

Pag.

15 NodAdxxx

3

24 of 25

Doc. N° MO-0048-ING

Copyright 1997 - Microelettrica Scientifica S.p.A.

Doc. N° MO-0048-ING

MD32-G Rev. 3

Pag. 25 of 25

23. SETTING’S FORM

Date : Number Relay:

RELAY PROGRAMMING

Default Setting Actual Setting

Variable Value Units Description Variable Value Units

Fn 50 Hz System frequency Fn Hz

In 500 A Rated primary current of CTs In A

d> 0.15 n Basic minimum pick-up level of low set phase differential d> n

element

1R 2 % Bias percentage in the zone 0,5<IR<P 1R %

2R 20 % Bias percentage in the zone IR>P 2R %

P 2.50 - Bias slope change point P -

nd

2H 0.10 d 2 Harmonic restraint level 2H d

I> 5.00 In Minimum pick-up level of overcurrent element I> In

tI> 3.00 s Time delay of overcurrent element tI> s

do> 0.10 n Minimum pick-up level of Earth Fault element do> n

tdo 5.00 s Time delay of Earth Fault element tdo s

BF I - Selection of element controlling the Breaker Failure function BF -

tBF 0.25 s Breaker Failure time delay tBF s

B1 do - Digital input B1 blocks the function selected B1 -

TRG d> - Trigger for oscillography records is Internal (TRG=d>, I>, TRG -

do>) or External via digital input B3.

Identification number for connection on serial

NodAd 1 - NodAd -

communication bus

CONFIGURATION OF OUTPUT RELAYS

Default Setting Actual Setting

Protect. Protect.

Output Relays Description Output Relays

Element Element

d> 1 - - - Differential element d>

I> - - - - Instantaneous Overcurrent I>

tI> - - 3 - Time delayed Overcurrent tI>

do> - 2 - - Instantaneous Earth Fault do>

tdo - - 3 - Time delayed Earth Fault tdo

tBF - - - 4 Breaker Failure tBF

FRes: Aut. Reset of output relays after tripping is: FRes:

Aut. = Automatic Man. = Manual

Copyright 1997 - Microelettrica Scientifica S.p.A.

You might also like

- M Im30b00 Eng n49 Ing r0 PDFDocument2 pagesM Im30b00 Eng n49 Ing r0 PDFshekooferiahiNo ratings yet

- Transformer On-Load Tap-Changer Control Relay: M M M M M M MDocument2 pagesTransformer On-Load Tap-Changer Control Relay: M M M M M M MshekooferiahiNo ratings yet

- Operation Manual: Microprocessor Overcurrent and Earth Fault Protection RelayDocument19 pagesOperation Manual: Microprocessor Overcurrent and Earth Fault Protection RelayshekooferiahiNo ratings yet

- Two Phase and Earth Fault Breaker Failure Relay: SettingsDocument2 pagesTwo Phase and Earth Fault Breaker Failure Relay: SettingsshekooferiahiNo ratings yet

- Three-Phase Digital 4-Stage Frequency Relay WITH DF/DT AND DV/DT CONTROLDocument2 pagesThree-Phase Digital 4-Stage Frequency Relay WITH DF/DT AND DV/DT CONTROLshekooferiahiNo ratings yet

- Mo-0126-Ing R0 - Ria123 PDFDocument10 pagesMo-0126-Ing R0 - Ria123 PDFshekooferiahiNo ratings yet

- Mo-0031-Ing R5 - SCM21 PDFDocument25 pagesMo-0031-Ing R5 - SCM21 PDFshekooferiahiNo ratings yet

- K03b-Ing-R2 - Ub0-Atr PDFDocument3 pagesK03b-Ing-R2 - Ub0-Atr PDFshekooferiahiNo ratings yet

- N Din To64 Rfi Ing PDFDocument4 pagesN Din To64 Rfi Ing PDFshekooferiahiNo ratings yet

- Motor Protection Relay: Programmable Input QuantitiesDocument6 pagesMotor Protection Relay: Programmable Input QuantitiesshekooferiahiNo ratings yet

- Percentage Biased Differential Relay For 3-Winding TransformersDocument2 pagesPercentage Biased Differential Relay For 3-Winding TransformersshekooferiahiNo ratings yet

- General Characteristics: Overvoltage Relay For Supervision of CTS' CircuitsDocument2 pagesGeneral Characteristics: Overvoltage Relay For Supervision of CTS' CircuitsshekooferiahiNo ratings yet

- Ndinto64 g28 Ing r4 PDFDocument4 pagesNdinto64 g28 Ing r4 PDFshekooferiahiNo ratings yet

- General Characteristics: Dual Level Current Relays Single, Two, or Three-PhaseDocument2 pagesGeneral Characteristics: Dual Level Current Relays Single, Two, or Three-PhaseshekooferiahiNo ratings yet

- General Characteristics: Overcurrent RelayDocument2 pagesGeneral Characteristics: Overcurrent RelayshekooferiahiNo ratings yet

- Im30deng PDFDocument2 pagesIm30deng PDFshekooferiahiNo ratings yet

- TS03 ING R0 - FMR Ts PDFDocument5 pagesTS03 ING R0 - FMR Ts PDFshekooferiahiNo ratings yet

- A09 Ing R1 PDFDocument2 pagesA09 Ing R1 PDFshekooferiahiNo ratings yet

- A Ub0ato64 A04c EngDocument2 pagesA Ub0ato64 A04c EngshekooferiahiNo ratings yet

- A Ub0atr k3b 89e1 EngDocument3 pagesA Ub0atr k3b 89e1 EngshekooferiahiNo ratings yet

- Product Information DIGSI4 V4 91Document64 pagesProduct Information DIGSI4 V4 91Saqib RasoolNo ratings yet

- Reydisp ManualDocument63 pagesReydisp ManualAmal P RaviNo ratings yet

- J04 Ing R1 PDFDocument2 pagesJ04 Ing R1 PDFshekooferiahiNo ratings yet

- General Characteristics: Dual Level Earth Fault RelayDocument2 pagesGeneral Characteristics: Dual Level Earth Fault RelayshekooferiahiNo ratings yet

- Mo-0031-Ing R5 - SCM21 PDFDocument25 pagesMo-0031-Ing R5 - SCM21 PDFshekooferiahiNo ratings yet

- K03b-Ing-R2 - Ub0-Atr PDFDocument3 pagesK03b-Ing-R2 - Ub0-Atr PDFshekooferiahiNo ratings yet

- Novar: Automatic Power Factor ControlDocument8 pagesNovar: Automatic Power Factor ControlshekooferiahiNo ratings yet

- Mo-0126-Ing R0 - Ria123 PDFDocument10 pagesMo-0126-Ing R0 - Ria123 PDFshekooferiahiNo ratings yet

- Mo-0031-Ing R5 - SCM21 PDFDocument25 pagesMo-0031-Ing R5 - SCM21 PDFshekooferiahiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Generators and Standby Power Systems 2014NECDocument23 pagesGenerators and Standby Power Systems 2014NEChyre_ryeNo ratings yet

- 7SA84 - CatalogDocument4 pages7SA84 - CatalogChung NguyenNo ratings yet

- Transformer Stability Test ReportDocument22 pagesTransformer Stability Test ReportVenkataramanan S100% (12)

- 10 1080@00207217 2019 1625973Document27 pages10 1080@00207217 2019 1625973Clement RajNo ratings yet

- Protection, Monitoring and Control of Shunt ReactorsDocument198 pagesProtection, Monitoring and Control of Shunt Reactorsrodrigocmam100% (3)

- 7SR224 - Argus Complete Technical Manual PDFDocument784 pages7SR224 - Argus Complete Technical Manual PDFnassarkiNo ratings yet

- 1MRK504019-BEN A en Transformer Protection Terminal RET 521-C2 2.3Document23 pages1MRK504019-BEN A en Transformer Protection Terminal RET 521-C2 2.3Robert MihayoNo ratings yet

- Project Report 1 BITS PilaniDocument38 pagesProject Report 1 BITS PilaniGurdeep Singh100% (1)

- Siemens Power Academy Lagos: 2015 Education and Training CatalogueDocument73 pagesSiemens Power Academy Lagos: 2015 Education and Training CatalogueOlanshileNo ratings yet

- 4a9e PDFDocument113 pages4a9e PDFVivekanand TripathiNo ratings yet

- Power Systems Protection Course: Al-Balqa Applied UniversityDocument25 pagesPower Systems Protection Course: Al-Balqa Applied UniversityPIOS CHICKENNo ratings yet

- Analysis and Application of Resistive Superconducting Fault Current Limiters PHD - Thesis - Steven - Blair - April - 2013Document193 pagesAnalysis and Application of Resistive Superconducting Fault Current Limiters PHD - Thesis - Steven - Blair - April - 2013Ahmed58seribegawanNo ratings yet

- MiCOM P122CDocument8 pagesMiCOM P122Cকুররাতুল আইনNo ratings yet

- 230/33Kv Bole Lemi Substation Calculation Note - Protection Relay Setting - 33Kv FeederDocument43 pages230/33Kv Bole Lemi Substation Calculation Note - Protection Relay Setting - 33Kv FeederDebebe TsedekeNo ratings yet

- PL70 current relay data sheetDocument32 pagesPL70 current relay data sheetJuan PerezNo ratings yet

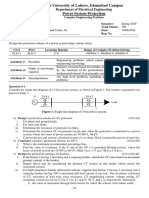

- Complex Engineering Problem - PSP PDFDocument2 pagesComplex Engineering Problem - PSP PDFAMAMA KHAN100% (3)

- Power Systems Protection Course: Al-Balqa Applied UniversityDocument48 pagesPower Systems Protection Course: Al-Balqa Applied UniversityPIOS CHICKENNo ratings yet

- Protecting Power Systems from Faults and FailuresDocument33 pagesProtecting Power Systems from Faults and FailuresmadchoNo ratings yet

- Manual Do Sepam 10 PDFDocument260 pagesManual Do Sepam 10 PDFLucas DoreaNo ratings yet

- PCS-915SC - X - Technical Manual - EN - Overseas General - X - R1.01Document263 pagesPCS-915SC - X - Technical Manual - EN - Overseas General - X - R1.01Kevin Carmona Toral100% (1)

- Difference Between Stub and Teed ProtectionDocument3 pagesDifference Between Stub and Teed ProtectionSellappan Muthusamy25% (4)

- Power System Protection - An OverviewDocument95 pagesPower System Protection - An Overviewardhanareeswaran nNo ratings yet

- Micom P115: Numerical CT and Auxiliary Voltage Powered Overcurrent RelaysDocument4 pagesMicom P115: Numerical CT and Auxiliary Voltage Powered Overcurrent RelaysLa Picarona del PeruNo ratings yet

- Electrical Power System Protection CertificateDocument4 pagesElectrical Power System Protection CertificatenvchinaiNo ratings yet

- Power System Protection Part - 1 DR - Prof.Mohammed TawfeeqDocument59 pagesPower System Protection Part - 1 DR - Prof.Mohammed TawfeeqEngr Zia UR RehmanNo ratings yet

- PCS-902S - X - DataSheet - EN - Overseas General - X - R1.00Document52 pagesPCS-902S - X - DataSheet - EN - Overseas General - X - R1.00Marcio BonfimNo ratings yet

- Power System CH 10 p21Document21 pagesPower System CH 10 p21Anonymous jSTkQVC27bNo ratings yet

- Micom Px30 - Range: Compact Line Differential Protection DeviceDocument8 pagesMicom Px30 - Range: Compact Line Differential Protection DeviceLa Picarona del PeruNo ratings yet

- Induction Motor Faults and ProtectionsDocument2 pagesInduction Motor Faults and ProtectionsMuhammad Ali Khan AwanNo ratings yet

- ABB REC670 1MRK511232 BEN D en Product Guide REC670!1!2 Pre ConfiguredDocument93 pagesABB REC670 1MRK511232 BEN D en Product Guide REC670!1!2 Pre ConfiguredChen ChongNo ratings yet