Professional Documents

Culture Documents

Axial Fan TechnicalBulletin Issue4 TighteningOfPinOnBlades March2014 HDK

Uploaded by

Thanaraj SanmughamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Axial Fan TechnicalBulletin Issue4 TighteningOfPinOnBlades March2014 HDK

Uploaded by

Thanaraj SanmughamCopyright:

Available Formats

Technical Bulletin: Issue 4 – March 2014

Recommendation for

tightening of pin on blades

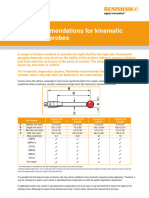

Sectional view of the blade

assembly on Hub

Figure 1

Howden Engineering has reviewed the installation instruction for the pawl and pin

and on the basis of this review they have provided a new installation instruction

for torque of pins to blades.

The pin is used to restrain the pawl,

which is used to position the blade Pin Material Blade material

on the blade pivot (figure 1).

Size SG-iron Aluminum Steel Hastelloy

Howden have revised the existing instruction

which states that all pins are torqued to 60 M22 x 1,5 40 Nm 25 Nm 40 Nm

Nm (44,3 lb.ft). This instruction has been Steel 29,5 lb. ft 18,4 lb. ft 29,5 lb. ft

used since 1992.

M24 x 1,5 50 Nm 30 Nm 50 Nm

The new engineering standard requires Steel 36,9 lb. ft 22,1 lb. ft 36,9 lb. ft

adapting a new differentiating torque M24 x 3 100 Nm 60 Nm 100 Nm

value where the thread dimension and the Steel 73,6 lb. ft 44,3 lb. ft 73,6 lb. ft

blade material is taken in to account. M24 x 3 100 Nm

All pawls and pins must be lubricated with SMO254 73,6 lb. ft

MolyKote GN Paste + prior to mounting and M27 x 1,5 75 Nm 45 Nm 75 Nm

torquing. Steel 55,3 lb. ft 33,2 lb. ft 55,3 lb. ft

The engineering specification is 4239869-0 M35 x 1,5 140 Nm 85 Nm 140 Nm

(figure 2). Steel 103,3 lb. ft 62,7 lb. ft 103,3 lb. ft

M35 x 1,5 140 Nm

SMO254 103,3 lb. ft

BE/HDK 09.01.2014 - 4239869-0

Figure 2

For more information please contact your local Howden office.

This bulletin has been released by:

Howden Denmark ApS, Industrivej 23, DK-4700, Næstved, Denmark

Tel: +45 55 77 62 62 Web: www.howden.com

Email: variax@howden.com

You might also like

- Guidelines Adhd AdultDocument19 pagesGuidelines Adhd AdultJavier Cotobal100% (1)

- Steam Turbine Blade Failure Root Cause Analysis Guide: Place Image HereDocument262 pagesSteam Turbine Blade Failure Root Cause Analysis Guide: Place Image HereThanaraj SanmughamNo ratings yet

- 2015 Nissan Service Maintenance GuideDocument70 pages2015 Nissan Service Maintenance GuideAhmed Almaghrby100% (2)

- Keys To The Ultimate Freedom PDFDocument245 pagesKeys To The Ultimate Freedom PDFdebtru100% (2)

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- Mobile Tower and Mobile Phone Radiation Hazards - Prof Girish Kumar - June 2013Document50 pagesMobile Tower and Mobile Phone Radiation Hazards - Prof Girish Kumar - June 2013Neha Kumar100% (1)

- Tri Cone BitsDocument16 pagesTri Cone BitsPeter ForrestNo ratings yet

- 02) PIPE244.5x6.3 V-BRACE - GUSSET PLT.Document117 pages02) PIPE244.5x6.3 V-BRACE - GUSSET PLT.Asaru Deen100% (1)

- Cat General Torque Specifications PDFDocument48 pagesCat General Torque Specifications PDFAlaudin Awang Xwijaya0% (1)

- Description - Data - Dimensions: Couplings - H, HT Roller Coupling - HS Slipping ClutchDocument12 pagesDescription - Data - Dimensions: Couplings - H, HT Roller Coupling - HS Slipping ClutchJESUSCALVILLO100% (1)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Rebar Join Welding Design (FW - 6mm)Document2 pagesRebar Join Welding Design (FW - 6mm)Utaya Kumar Veelmurugan100% (2)

- ThermallySprayedAbradableCoatings 2012.10Document9 pagesThermallySprayedAbradableCoatings 2012.10Thanaraj SanmughamNo ratings yet

- Bar Bending ScheduleDocument25 pagesBar Bending ScheduleDheeraj Verma100% (1)

- PMP Lite Mock Exam 2 QuestionsDocument16 pagesPMP Lite Mock Exam 2 QuestionsJobin John100% (1)

- Steam Nozzle 1Document47 pagesSteam Nozzle 1Balaji Kalai100% (5)

- Diffusion Make Welding ElectrodeDocument9 pagesDiffusion Make Welding ElectrodeSarah FrazierNo ratings yet

- Glulam Span TableDocument4 pagesGlulam Span TablemartinrorNo ratings yet

- MeasuringDocument4 pagesMeasuringlilikNo ratings yet

- EvolutionTekDatasheet PDFDocument1 pageEvolutionTekDatasheet PDFRobNo ratings yet

- Kapselmutter: Ausgabe/Edition 2005-11Document9 pagesKapselmutter: Ausgabe/Edition 2005-11Ravi VermaNo ratings yet

- RR11 Brochure PDFDocument4 pagesRR11 Brochure PDFel.runitaNo ratings yet

- Mechanical Couplers For Reinforcement SteelDocument17 pagesMechanical Couplers For Reinforcement SteeljerryNo ratings yet

- Grinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataDocument4 pagesGrinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataСергей КолесниковNo ratings yet

- Point Sheave - 1Document2 pagesPoint Sheave - 1Gilney FreitasNo ratings yet

- Grinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataDocument4 pagesGrinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataСергей КолесниковNo ratings yet

- European MarketDocument32 pagesEuropean MarketDejan Simonovic PrivatnoNo ratings yet

- FBRE 07 Fletcher Reo - Mesh Guide North Island V10.00.0322 MRDocument20 pagesFBRE 07 Fletcher Reo - Mesh Guide North Island V10.00.0322 MRhilalNo ratings yet

- 20a Torque CalculationDocument11 pages20a Torque CalculationRiyan EsapermanaNo ratings yet

- Styli Recommendations Leaflet (EN)Document2 pagesStyli Recommendations Leaflet (EN)IlKIn ISmaIlovNo ratings yet

- Cojinetes de Biela y Bancada STD SeleccionDocument5 pagesCojinetes de Biela y Bancada STD SeleccionAlejandro ValenzuelaNo ratings yet

- 1 General Remarks: Original Installation and Maintenance Instructions For Bibby Torque Limiters With ModulesDocument13 pages1 General Remarks: Original Installation and Maintenance Instructions For Bibby Torque Limiters With ModulesAmirmasoudNo ratings yet

- Bi-Metal Tek Screw: Product DatasheetDocument1 pageBi-Metal Tek Screw: Product Datasheetbravo deltafoxNo ratings yet

- Point SheaveDocument2 pagesPoint SheaveGilney FreitasNo ratings yet

- Bulletin-71 - Knockout DimensionsDocument4 pagesBulletin-71 - Knockout DimensionsTinkyTonk86No ratings yet

- AISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1diego AlvarezNo ratings yet

- Hilti CatalogDocument13 pagesHilti CatalogYongHan KwongNo ratings yet

- Expansion Joint Coupling Style 152A: 1.0 Product DescriptionDocument7 pagesExpansion Joint Coupling Style 152A: 1.0 Product DescriptionJuan AliagaNo ratings yet

- Rate Analysis According To DorDocument7 pagesRate Analysis According To DorLamichhane SauravNo ratings yet

- EIG Product Catalogue CABLESDocument36 pagesEIG Product Catalogue CABLESjudarangocaNo ratings yet

- Product Submittals For ProjectDocument46 pagesProduct Submittals For ProjectJavier GarcíaNo ratings yet

- Underground Cable With XLPE Insulation and PVC Sheath: Na2Xy 0624Document2 pagesUnderground Cable With XLPE Insulation and PVC Sheath: Na2Xy 0624Arslan AliNo ratings yet

- Presentation Coupler SystemDocument21 pagesPresentation Coupler SystemPralhad Kore100% (1)

- Advanced Materials For Land Based Gas TurbineDocument26 pagesAdvanced Materials For Land Based Gas TurbineEnary SalernoNo ratings yet

- Beam Connection DesignDocument10 pagesBeam Connection DesignLuqman ZolkibliNo ratings yet

- DisassemblyDocument8 pagesDisassemblyEdson CRNo ratings yet

- Chapter 1.1 With AnswersDocument1 pageChapter 1.1 With AnswersRINA RINANo ratings yet

- MetalisEnergy TechnicalBrochure PDFDocument60 pagesMetalisEnergy TechnicalBrochure PDFAshok SureshNo ratings yet

- SC21B-A Along GL-4 SummaryDocument2 pagesSC21B-A Along GL-4 Summarymhazarath murariNo ratings yet

- Steel Design Shear Block Sample ProblemDocument9 pagesSteel Design Shear Block Sample ProblemJimNo ratings yet

- KCDE Coring in Hole Tools CatalogueDocument80 pagesKCDE Coring in Hole Tools CataloguelingamkumarNo ratings yet

- Machine Design IIDocument3 pagesMachine Design IIRushabh PatelNo ratings yet

- C C C C C C: 3.2.2 Non-Core (Destructive) DrillingDocument14 pagesC C C C C C: 3.2.2 Non-Core (Destructive) DrillingTomas Santiago Hanccoccallo PauccaraNo ratings yet

- Boltmasters Pty LTD Recommended Assembly TorquesDocument9 pagesBoltmasters Pty LTD Recommended Assembly TorquesNavneet SunilNo ratings yet

- HHD - S.Technical - Information - ASSET - DOC - 2331274Document2 pagesHHD - S.Technical - Information - ASSET - DOC - 2331274Hoa Ly TrắngNo ratings yet

- 1B2 - 1 300x400 - Critical: Page 1/2 Legion 5 23/02/2023 23/02/2023 23/02/2023Document2 pages1B2 - 1 300x400 - Critical: Page 1/2 Legion 5 23/02/2023 23/02/2023 23/02/2023Mouris alamamussNo ratings yet

- Sambungan Rafter KolomDocument8 pagesSambungan Rafter Kolomdubin strukturNo ratings yet

- Mesh Product Guide South Island Jul16Document16 pagesMesh Product Guide South Island Jul16Rohn J JacksonNo ratings yet

- 25 Rebar CouplerDocument4 pages25 Rebar CouplerNivedhan GandhiNo ratings yet

- O-Rings - & - Seals - Metric O-Ring & Retaining RingDocument1 pageO-Rings - & - Seals - Metric O-Ring & Retaining RingRoberto MardonesNo ratings yet

- 9865 0171 01 COP SC19 COP SC19X BrochureDocument4 pages9865 0171 01 COP SC19 COP SC19X BrochureАлександр ПравосудовNo ratings yet

- Metric (ISO) Fasteners: Torque SpecificationsDocument3 pagesMetric (ISO) Fasteners: Torque SpecificationsSMKN 6 SAMARINDA PANGESTUNo ratings yet

- Eurocode Calculations For The Aluminium BridgeDocument23 pagesEurocode Calculations For The Aluminium Bridgestromek2006No ratings yet

- Bossard Taptite Self Tapping Screw CatalogueDocument10 pagesBossard Taptite Self Tapping Screw CataloguepmlmkpNo ratings yet

- Pump Installation and Maintenance: Learning OutcomeDocument6 pagesPump Installation and Maintenance: Learning OutcomeMohammed Amin BenharkatNo ratings yet

- Corobore 92008Document168 pagesCorobore 92008Gabriel Espitia MesaNo ratings yet

- Repair of The Steam Turbine Rotor by WeldingDocument38 pagesRepair of The Steam Turbine Rotor by WeldingThanaraj SanmughamNo ratings yet

- Influence of Machining Process On Surface Integrity of Plasma CoatingDocument5 pagesInfluence of Machining Process On Surface Integrity of Plasma CoatingThanaraj SanmughamNo ratings yet

- Dynamic Balancing Machines, Soft-Bearing vs. Hard-BearingDocument3 pagesDynamic Balancing Machines, Soft-Bearing vs. Hard-BearingThanaraj SanmughamNo ratings yet

- AL-Nafeay 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012141Document22 pagesAL-Nafeay 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012141Thanaraj SanmughamNo ratings yet

- It 1 of 11: (12) Patent Application Publication (10) Pub. No.: US 2008/0286459 A1Document6 pagesIt 1 of 11: (12) Patent Application Publication (10) Pub. No.: US 2008/0286459 A1Thanaraj SanmughamNo ratings yet

- Tool Rental Catalogue Page PDF125201993255Document2 pagesTool Rental Catalogue Page PDF125201993255Thanaraj SanmughamNo ratings yet

- United States Patent: Tragesser Et AlDocument7 pagesUnited States Patent: Tragesser Et AlThanaraj SanmughamNo ratings yet

- SF-0015.1 IGT HPT Abradables ENDocument8 pagesSF-0015.1 IGT HPT Abradables ENThanaraj SanmughamNo ratings yet

- TNB REMACO Transportable Lathe Machine Presentation SlidesDocument17 pagesTNB REMACO Transportable Lathe Machine Presentation SlidesThanaraj SanmughamNo ratings yet

- Hidden Errors in Turbine Blade Moment Measurement and How To Avoid ThemDocument24 pagesHidden Errors in Turbine Blade Moment Measurement and How To Avoid ThemThanaraj SanmughamNo ratings yet

- Reusing Screws and Bolts Is A Safety Risk and Decreases Fan ReliabilityDocument3 pagesReusing Screws and Bolts Is A Safety Risk and Decreases Fan ReliabilityThanaraj SanmughamNo ratings yet

- CbM-VIB-M5-05-20 - M5 CID Fan MODAL - Spare BladeDocument2 pagesCbM-VIB-M5-05-20 - M5 CID Fan MODAL - Spare BladeThanaraj SanmughamNo ratings yet

- Operationalisation of Moratorium For Hire-Purchase Loans and Fixed Rate Islamic FinancingDocument2 pagesOperationalisation of Moratorium For Hire-Purchase Loans and Fixed Rate Islamic FinancingThanaraj SanmughamNo ratings yet

- 3MonthWaiver Poster 01Document1 page3MonthWaiver Poster 01Thanaraj SanmughamNo ratings yet

- 9Document16 pages9edmarian0% (1)

- The Paradox of The Duty of Perfection in The Doctrine of Ibn 'Arabi PDFDocument7 pagesThe Paradox of The Duty of Perfection in The Doctrine of Ibn 'Arabi PDFyusuf shaikhNo ratings yet

- Introducing The True Ekklesia of Jesus ChristDocument5 pagesIntroducing The True Ekklesia of Jesus ChristRamil Moreno SumangilNo ratings yet

- How To Represent Geospatial Data in SDMX 20181022Document47 pagesHow To Represent Geospatial Data in SDMX 20181022scorpio1878No ratings yet

- Harsh PatelDocument14 pagesHarsh PatelPradeepNo ratings yet

- SCIDDocument9 pagesSCIDgarimaupadhyay20002No ratings yet

- Week 1Document27 pagesWeek 1Bawa BoyNo ratings yet

- Cirrus HD-OCT RNFL and ONH Analysis ReportDocument4 pagesCirrus HD-OCT RNFL and ONH Analysis ReportSoma AlshokriNo ratings yet

- Sumande - Field Work No.8 - Azimuth Traverse Using Theodolite and TapeDocument10 pagesSumande - Field Work No.8 - Azimuth Traverse Using Theodolite and TapeCedrix SumandeNo ratings yet

- BSC MSC PHD Scholarships by DR Oluseun Ajayi 1673218909 PDFDocument3 pagesBSC MSC PHD Scholarships by DR Oluseun Ajayi 1673218909 PDFInnocent MataazNo ratings yet

- Development of PeriodontiumDocument54 pagesDevelopment of PeriodontiumSachin GargNo ratings yet

- Academic and Occupational English Needs of Tourism and Hotel Management Students Oral Communication Skills in FocusDocument136 pagesAcademic and Occupational English Needs of Tourism and Hotel Management Students Oral Communication Skills in FocusYeneneh WubetuNo ratings yet

- Consider The Rape of The Lock As A Social SatireDocument3 pagesConsider The Rape of The Lock As A Social SatireElena AiylaNo ratings yet

- Acoustic Laster Final-1Document15 pagesAcoustic Laster Final-1Aisha SadiNo ratings yet

- Jurnal 1Document8 pagesJurnal 1Dela Amelia Nur SalehaNo ratings yet

- Reliability & Validity: Nathan A. Thompson PH.DDocument5 pagesReliability & Validity: Nathan A. Thompson PH.DJames SaupanNo ratings yet

- VHDL PaperDocument32 pagesVHDL PaperSajid JanjuaNo ratings yet

- Impact of COVID-19 On Student LifeDocument10 pagesImpact of COVID-19 On Student LifeZunii MalikNo ratings yet

- 1975 - Shen - Science Literacy PDFDocument5 pages1975 - Shen - Science Literacy PDFRoberta Proença0% (1)

- Ishida Checkweigher Scotraco PDFDocument6 pagesIshida Checkweigher Scotraco PDFchrissNo ratings yet

- 9ER1 Question BookletDocument16 pages9ER1 Question BookletCSC TylerNo ratings yet

- MEC Activities TimelineDocument13 pagesMEC Activities TimelineFranz Xavier GarciaNo ratings yet

- Sociologia Şi Ştiinţa Naţiunii În Doctrina Lui Dimitrie GustiDocument35 pagesSociologia Şi Ştiinţa Naţiunii În Doctrina Lui Dimitrie GustiSaveanu RazvanNo ratings yet

- Catalogo PDFGeneratorDocument3 pagesCatalogo PDFGeneratoredwraulNo ratings yet