Professional Documents

Culture Documents

1 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90

Uploaded by

tvwrightOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90

Uploaded by

tvwrightCopyright:

Available Formats

REHS2892-08

30 July 2012

Special Instruction

i04947099 ECM Power Requirements ................................ 19

ECM Negative Battery Connections .................. 19

Electrical Application and ECM Positive Battery Connections ................... 19

Installation Guide for ECM Sensor Common Connections ................. 19

Suppression Of Voltage Transients and Electrical

Petroleum Transmissions Noise ............................................................... 20

EMI/RFI Testing ................................................. 20

SMCS Code: 1408; 3030; 3101; 3168; 4800; 7610; Welding On a Vehicle Equipped With an Electronic

7620 Transmission ................................................... 20

Connectors and Wiring ......................................... 21

Petroleum Transmission Harness and Connector Wiring Guidelines ....... 21

TH48-E70 (S/N: JGC1-Up; KSH1-Up) Harness Recommendations .............................. 21

TH55FT-E70 (S/N: PCJ1-Up) Harness codes .................................................. 22

ECM Connectors ............................................... 22

TH55FT-E90 (S/N: THE1-Up) ECM Connector Part Numbers ......................... 23

Petroleum Power Train Package ECM 70 Terminal Connector Interface Seal ...... 23

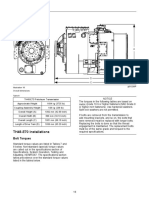

TH48-E70-C27I (S/N: PKZ1-Up) ECM 70 Terminal Connector Allen Screw

TH48-E70-C32I (S/N: PKY1-Up) Torque ............................................................. 24

TH48-E70-C32P (S/N: PKG1-Up) ECM Connector Wire Gauge Size .................... 24

TH55-E70-3512CP (S/N: PNY1-Up; Sealing Plugs .................................................... 24

ECM Pinouts ..................................................... 24

PNZ1-Up) Customer Connector Pinouts ............................ 25

Frac Rig Block Diagram ........................................ 27

Table of Contents Frac Rig Transmission Wiring ............................... 29

Engine Integration Harness Requirements ....... 31

Introduction ........................................................... 2 Integration Harness Wiring and Connections .... 32

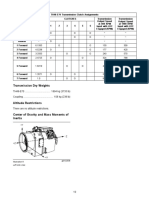

TH48-E70 Transmission References .................... 3 Shifters and Shift Features ................................... 32

TH55 Transmission References ........................... 3 Switch to Ground Shifters ................................. 32

Caterpillar Reference Material .......................... 4 J1939 Based Shifters ........................................ 35

Additional Reference Material ........................... 4 Lever Shifters .................................................... 35

Documents of OEM Interest .............................. 4 Shift Selector (J1939 Interface Option) ............. 36

Product Warranty and Equipment Protection Shift Control Features ....................................... 36

Plans ............................................................... 5 Cold Shift Inhibit ............................................ 36

TH48-E70 Features and Identification .............. 6 Neutral to any Forward Gear ......................... 36

TH55 Features and Identification ...................... 11 Any Forward Gear to Neutral ......................... 36

General Electronic Transmission Operation ......... 13 Quick to Neutral ............................................. 36

Shift Control ...................................................... 13 Forward Gear Downshifts .............................. 36

Speed Limiting .................................................. 14 Forward Gear Upshifts .................................. 36

Torque Limiting .................................................. 14 Park ............................................................... 37

Transmission Speed and Torque Control .......... 14 Transmission Warmup ................................... 37

J1939 Application Layer .................................... 14 Lockup Clutch Control ................................... 38

Requirements of the PROP A (Customer Controller Shift Inhibit Function ...................................... 38

Throttle Interface) ............................................ 16 Monitoring and Protection ..................................... 39

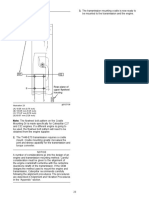

ECM Mechanical Installation ................................ 17 Transmission Monitoring (Dedicated Indicator

ECM External Dimensions ................................ 17 Outputs) ........................................................... 39

ECM Mounting Hardware and Torque ............... 18 Check Transmission Indicator ....................... 39

ECM Environmental Limitations ........................ 18 Warning Indicator ........................................... 40

ECM Wiring Requirements ................................... 18 Shift Inhibit Indicator ...................................... 40

ECM Grounding Requirements ......................... 18 Converter Drive Status Indicator ................... 40

ECM Voltage Requirements .............................. 19 Customer Accessible Sensor Outputs .............. 40

You might also like

- Special Instruction: Mechanical Application and Installation Guide For TH48-E70 Petroleum TransmissionsDocument1 pageSpecial Instruction: Mechanical Application and Installation Guide For TH48-E70 Petroleum TransmissionstvwrightNo ratings yet

- CATengines c15Document161 pagesCATengines c15luis alberto67% (3)

- Eio0000003337 00Document92 pagesEio0000003337 00Doni RandanuNo ratings yet

- LB Aw NM SPT CMT enDocument54 pagesLB Aw NM SPT CMT envulduovlakNo ratings yet

- LB Aw Ns12 SPT CMT enDocument56 pagesLB Aw Ns12 SPT CMT envulduovlakNo ratings yet

- Motores Caterpillar c12 - Compress PDFDocument173 pagesMotores Caterpillar c12 - Compress PDFCirilo PalmaNo ratings yet

- 1599 212 Manual v12-14 E PDFDocument44 pages1599 212 Manual v12-14 E PDFcamarantiNo ratings yet

- BALDOR Serie 5Document48 pagesBALDOR Serie 5Anderson SejasNo ratings yet

- ESAB Origo Mig 4002cw, 4002c, 5002cw, 5002c, 6502cw, 6502c Instruction ManualDocument64 pagesESAB Origo Mig 4002cw, 4002c, 5002cw, 5002c, 6502cw, 6502c Instruction ManualToader MarcuNo ratings yet

- MS-N - Technical CatalogueDocument44 pagesMS-N - Technical CatalogueOle BudiNo ratings yet

- Planning The Cabinet Installation User ManualDocument34 pagesPlanning The Cabinet Installation User ManualYasir AbdooNo ratings yet

- Aristofeed 30 4 Aristofeed 48 4: Service ManualDocument30 pagesAristofeed 30 4 Aristofeed 48 4: Service Manualatual manutencaoNo ratings yet

- Rg510a Manual ServiceDocument68 pagesRg510a Manual Servicelalocisco4209No ratings yet

- Kontaktorer MS-N Teknisk KatalogDocument44 pagesKontaktorer MS-N Teknisk KatalogDraj CahyaNo ratings yet

- Service Manual Ergoselect II enDocument160 pagesService Manual Ergoselect II enwatisnaiNo ratings yet

- Ultra Phoenix - Ultra Phoenix XL PartesDocument52 pagesUltra Phoenix - Ultra Phoenix XL PartesFrost-Center Ar100% (1)

- MSN Cat04 062306 GBDocument44 pagesMSN Cat04 062306 GBAnsure KawaneNo ratings yet

- Uputstvo ABBDocument80 pagesUputstvo ABBSrdjan UzunovicNo ratings yet

- Danfoss Scroll Compressors in Parallel Installation SMSYSZDocument48 pagesDanfoss Scroll Compressors in Parallel Installation SMSYSZNikolas Chionas100% (1)

- Switching Devices - Low Voltage 28.0-1: February 2017Document40 pagesSwitching Devices - Low Voltage 28.0-1: February 2017John Philip BuntalesNo ratings yet

- ACS880-307 - A018 - HW Manual - A - A4Document110 pagesACS880-307 - A018 - HW Manual - A - A4Ravindra S. VyasNo ratings yet

- EN ACS880-37 HW Man B A4Document258 pagesEN ACS880-37 HW Man B A4zain shafiqNo ratings yet

- Kinetix 300 Ethernet/Ip Indexing Servo Drives: User ManualDocument234 pagesKinetix 300 Ethernet/Ip Indexing Servo Drives: User ManualFERMIN ALFARO GARCIANo ratings yet

- Instruction Manual Fisher Fieldvue dvc6200 Sis Digital Valve Controller en 122736Document124 pagesInstruction Manual Fisher Fieldvue dvc6200 Sis Digital Valve Controller en 122736Gangsar DwikaNo ratings yet

- Caddy Tig 1500i-2200i - 0740 800 186 - Serv - ManDocument50 pagesCaddy Tig 1500i-2200i - 0740 800 186 - Serv - ManJunior ÁudioTech100% (1)

- ABB ACS880 FirmwareDocument264 pagesABB ACS880 FirmwareKelley TheisenNo ratings yet

- Esab Arc4000i Tig4000i Mig4000iDocument78 pagesEsab Arc4000i Tig4000i Mig4000iliviucatalinNo ratings yet

- Installation: Transcoding and Rate Adaption Unit Imn:TrauDocument145 pagesInstallation: Transcoding and Rate Adaption Unit Imn:TrauPippo FalcoRossoNo ratings yet

- Fisher™ FIELDVUE™ DVC6200 SIS Digital Valve ControllerDocument116 pagesFisher™ FIELDVUE™ DVC6200 SIS Digital Valve ControllerMohsen HeidariNo ratings yet

- User'S Manual: RG300 and RG400 SeriesDocument64 pagesUser'S Manual: RG300 and RG400 SeriescuervocrowNo ratings yet

- KBVF AC Drive Series (Models 21-26) ManualDocument44 pagesKBVF AC Drive Series (Models 21-26) ManualKBElectronicsincNo ratings yet

- Compresores DanfosDocument56 pagesCompresores DanfosReinaldo GuillenNo ratings yet

- Aplicacion Electrica y Eletronica Caterpillar c10..c12..c15...Document173 pagesAplicacion Electrica y Eletronica Caterpillar c10..c12..c15...Luisa Vanessa Cuero100% (1)

- Danfoss Scroll Compressors: SmsyszDocument56 pagesDanfoss Scroll Compressors: Smsyszjohn-john castañedaNo ratings yet

- Fisher Fieldvue DVC6200 SIS Digital Valve Controller: Instruction ManualDocument116 pagesFisher Fieldvue DVC6200 SIS Digital Valve Controller: Instruction Manualanon_179203922No ratings yet

- Instruction Manual Fisher Fieldvue dvc6200 Sis Digital Valve Controller en 122736Document124 pagesInstruction Manual Fisher Fieldvue dvc6200 Sis Digital Valve Controller en 122736ransekar09No ratings yet

- ESDV Instruction-Manual-Fisher-Fieldvue-Dvc6200-Sis-Digital-Valve-Controller-En-122736Document116 pagesESDV Instruction-Manual-Fisher-Fieldvue-Dvc6200-Sis-Digital-Valve-Controller-En-122736Srinath SriNo ratings yet

- Quantm InspectionDocument64 pagesQuantm InspectionkristiueoNo ratings yet

- Instruction Manual Fisher Fieldvue Dvc6200 Sis Digital Valve Controller en 122736Document116 pagesInstruction Manual Fisher Fieldvue Dvc6200 Sis Digital Valve Controller en 122736Darrin RousseNo ratings yet

- Kinetix 300 Ethernet/Ip Indexing Servo Drives: User ManualDocument234 pagesKinetix 300 Ethernet/Ip Indexing Servo Drives: User ManualPhilip ValencerinaNo ratings yet

- Model 5000 ManualDocument296 pagesModel 5000 ManualExatron Inc.No ratings yet

- Comfort ControllerDocument130 pagesComfort ControllerCarlos TorresNo ratings yet

- Esab PDFDocument66 pagesEsab PDFradomir46No ratings yet

- Esab Caddy Arc-151i A31 803-XxxDocument32 pagesEsab Caddy Arc-151i A31 803-XxxAnonymous nC9gpUWPNo ratings yet

- Driver Information System: SectionDocument68 pagesDriver Information System: Sectionfrank1220uNo ratings yet

- Maneurop® Reciprocating Compressors MT/MTZ: Application GuidelinesDocument42 pagesManeurop® Reciprocating Compressors MT/MTZ: Application GuidelinesIsidro MendozaNo ratings yet

- EN ACS880-37 45 To 400 KW HW E A4 PDFDocument292 pagesEN ACS880-37 45 To 400 KW HW E A4 PDFПламен Бонин100% (1)

- Power Tig 160/200: Service ManualDocument46 pagesPower Tig 160/200: Service Manualsamasca_serbanNo ratings yet

- En ACS880-01 HW Rev M A5 ScreenresDocument270 pagesEn ACS880-01 HW Rev M A5 ScreenresQuy HoangNo ratings yet

- Installation Manual YC YDDocument54 pagesInstallation Manual YC YDIsrael ArceoNo ratings yet

- FRCC PC 015 A7 02-MLM-MLZ-April2015Document52 pagesFRCC PC 015 A7 02-MLM-MLZ-April2015viniciusschwabNo ratings yet

- Caddyt Arc 150i Caddyt Tig 150i Origot Tig 150i: Service ManualDocument66 pagesCaddyt Arc 150i Caddyt Tig 150i Origot Tig 150i: Service Manualr_cristiNo ratings yet

- Eaton ManualDocument32 pagesEaton ManualMario Javier SerranoNo ratings yet

- Tig 3001i SDocument76 pagesTig 3001i ScostelchelariuNo ratings yet

- Ecm - Engine Control System (Mr20dd)Document416 pagesEcm - Engine Control System (Mr20dd)Eliecer Bayona100% (4)

- MEMCMR32CBUMDocument64 pagesMEMCMR32CBUMLuis CribariNo ratings yet

- Enertik Solarriver Tls ManualDocument72 pagesEnertik Solarriver Tls ManualacostaricciNo ratings yet

- Arc 4000i, Mig U4000i, Mig 4000i, Tig 4000i: Aristot OrigotDocument78 pagesArc 4000i, Mig U4000i, Mig 4000i, Tig 4000i: Aristot Origotion suditu100% (1)

- Powerpact™ M-, P-And R-Frame, and Compact™ Ns630B-Ns3200 Circuit BreakersDocument192 pagesPowerpact™ M-, P-And R-Frame, and Compact™ Ns630B-Ns3200 Circuit BreakerscarlocartaNo ratings yet

- 45 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&i GuideDocument1 page45 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&i GuidetvwrightNo ratings yet

- 36 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page36 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 31 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page31 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 33 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page33 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 32 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page32 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 44 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page44 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 41 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page41 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 26 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page26 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 28 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page28 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 23 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page23 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 30 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page30 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 26 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page26 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 27 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page27 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 24 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page24 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 19 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page19 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 25 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page25 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 21 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page21 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 14 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page14 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 17 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page17 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 16 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page16 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 18 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page18 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 11 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page11 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 13 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page13 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 9 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page9 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 12 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page12 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 15 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page15 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 10 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page10 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 7 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page7 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Gauss' Law: F A FADocument14 pagesGauss' Law: F A FAValentina DuarteNo ratings yet

- BS7430 Earthing CalculationDocument14 pagesBS7430 Earthing CalculationgyanNo ratings yet

- Slipform Construction TechniqueDocument6 pagesSlipform Construction TechniqueDivyansh NandwaniNo ratings yet

- Validación Española ADHD-RSDocument7 pagesValidación Española ADHD-RSCristina Andreu NicuesaNo ratings yet

- RV900S - IB - Series 3Document28 pagesRV900S - IB - Series 3GA LewisNo ratings yet

- Plane TrigonometryDocument545 pagesPlane Trigonometrygnavya680No ratings yet

- Harmony Guide DatabaseDocument7 pagesHarmony Guide DatabaseAya SakamotoNo ratings yet

- Gr. 10 Persuasive EssayDocument22 pagesGr. 10 Persuasive EssayZephania JandayanNo ratings yet

- Efektifitas Terapi Musik Klasik Terhadap Penurunan Tingkat HalusinasiDocument9 pagesEfektifitas Terapi Musik Klasik Terhadap Penurunan Tingkat HalusinasiAnis RahmaNo ratings yet

- Stevenson Chapter 13Document52 pagesStevenson Chapter 13TanimNo ratings yet

- Student Workbook: Advance 3Document31 pagesStudent Workbook: Advance 3Damaris VegaNo ratings yet

- Design of AC Chopper Voltage Regulator Based On PIC16F716 MicrocontrollerDocument4 pagesDesign of AC Chopper Voltage Regulator Based On PIC16F716 MicrocontrollerabfstbmsodNo ratings yet

- AZ 103T00A ENU TrainerHandbook PDFDocument403 pagesAZ 103T00A ENU TrainerHandbook PDFlongvietmt100% (2)

- AB-005-2020 Dated 10.09.2020 (SKF-Prestine)Document3 pagesAB-005-2020 Dated 10.09.2020 (SKF-Prestine)AliasgarNo ratings yet

- Climatol GuideDocument40 pagesClimatol GuideFressiaNo ratings yet

- DC Motor: F Bli NewtonDocument35 pagesDC Motor: F Bli NewtonMuhammad TausiqueNo ratings yet

- Chen 2021Document13 pagesChen 2021Aitor UzkudunNo ratings yet

- Florida Motor Fuel Tax Relief Act of 2022Document9 pagesFlorida Motor Fuel Tax Relief Act of 2022ABC Action NewsNo ratings yet

- The Neuroscience of Helmholtz and The Theories of Johannes Muèller Part 2: Sensation and PerceptionDocument22 pagesThe Neuroscience of Helmholtz and The Theories of Johannes Muèller Part 2: Sensation and PerceptionCrystal JenningsNo ratings yet

- The Invisible SunDocument7 pagesThe Invisible SunJay Alfred100% (1)

- TOA Project Presentation (GROUP 5)Document22 pagesTOA Project Presentation (GROUP 5)Khadija ShahidNo ratings yet

- Kimura K.K. (KKK) : Can This Customer Be Saved? - Group D13Document6 pagesKimura K.K. (KKK) : Can This Customer Be Saved? - Group D13Mayuresh GaikarNo ratings yet

- DICKSON KT800/802/803/804/856: Getting StartedDocument6 pagesDICKSON KT800/802/803/804/856: Getting StartedkmpoulosNo ratings yet

- VPZ M BrochureDocument2 pagesVPZ M BrochuresundyaNo ratings yet

- Content Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersDocument18 pagesContent Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersfarhanNo ratings yet

- FS-C8025MFP Release NotesDocument22 pagesFS-C8025MFP Release NotesFirmware SM-SHNo ratings yet

- Assistant Bookkeeper Resume Sample - Best Format - Great Sample ResumeDocument4 pagesAssistant Bookkeeper Resume Sample - Best Format - Great Sample ResumedrustagiNo ratings yet

- TMS320C67x Reference GuideDocument465 pagesTMS320C67x Reference Guideclenx0% (1)

- Hayek - Planning, Science, and Freedom (1941)Document5 pagesHayek - Planning, Science, and Freedom (1941)Robert Wenzel100% (1)

- SL 4001Document2 pagesSL 4001ardiNo ratings yet