Professional Documents

Culture Documents

3.0 Introduction and Theory'

Uploaded by

Nur Afifah II0 ratings0% found this document useful (0 votes)

9 views2 pagesOriginal Title

intro exp 5

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pages3.0 Introduction and Theory'

Uploaded by

Nur Afifah IICopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

3.0 INTRODUCTION AND THEORY`

Distillation is a process of separating the liquid into a different product by difference of

purity nor temperature through conversion of a liquid into vapor that is subsequently

condensed back into liquid. Distillation is widely used for separating mixtures or product in

industries. Distillation is used to separate liquids from non volatile solids, as in the

separation of alcoholic liquors from fermented materials, or in the separation of two or

more liquids having different boiling points, as in the separation of gasoline, kerosene, and

lubricating oil from crude oil.

Other industrial applications include the processing of such chemical products as

formaldehyde and phenol and the desalination of seawater. The distillation process appears

to have been utilized by the earliest experimentalists. Aristotle(384 – 322bc)

mentionedthat pure water is made by the evaporation of seawater. Pliny the Elder (ad 23 –

79) described a primitive method of condensation in which the oil obtained by heating

rosin is collected on wool placed in the upper part of an apparatus known as a still.

The main purpose of distillation is to separate a mixture by taking advantage of

different substances readiness to become a vapor. If the difference in boiling points

between two substances is great, complete separation may be easily accomplished by a

single-stage distillation. If the boiling points differ only slightly, many re distillations may be

required. If a water and alcohol distillate is returned from the condenser and made to drip

down through along column onto a series of plates, and if the vapor, as it rises to the

condenser, is made to bubble through this liquid at each plate, the vapor and liquid will

interact so that some of the water in the vapor condenses and some of the alcohol in the

liquid vaporizes.

Distillation is that method of heating a liquid, or a liquid-vapor mixture to derive off a

vapor and so collection and condensing this vapor. This case, the product of a distillation

process is limited to an overhead distillate and a bottom, whose compositions differ from

that of the feed. The most common method for chemical separation is distillation which one

of the oldest (Zurich, 2014).

Distillation columns are designed to achieve this separation of components of

different properties efficiently. Even though distillation is one of the most common

separation techniques, it still consumes large amount of energy (during cooling and heating

process). It also contributes to more than 50% plant of operating costs. To separate the

components of mixtures, a group of operations is done based on the transfer of the material

from the homogeneous phase to another. These methods utilize differences in vapor

pressure or solubility, not like purely mechanical separation which involves density or

particle size (Sencan, 2).

Distillation had two principal methods. The first method is the production of vapor by

boiling the liquid mixture to be separated. So, the boiled liquid mixture went through

condensing the vapors without allowed any liquid to return to the still in connect with the

vapors. Secondly, the back of condensate part to the still under such conditions that this

returning liquid is brought into intimate connect with the vapors on their way to the

condenser. These methods may be conducted as a continuous process or as a batch process.

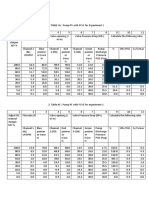

Figure 2 : Bubble Cap Distillation Column

But each distillation column will used different type

of packing.Examples of commonpacking that were used in industries are packed columnand

bubble cap.There were other type of pack or tray such as propak,heli- pak,ceramicsaddles,w

ire mesh and specialized structured packing.Bubble-cap tray is device or packing that was

mounted in a rectifying column that concentrates the alcohol. Vapor from the still pot rises

into the column and enters a pipe on the bottom of the tray. The cap forces the vapor into

the liquid sitting on top of the tray. Some of the vapor condenses overflows the weir on the

tray and falls down the column. Some of the alcohol in the liquid vaporizes creating a higher

concentration of alcohol and rises further in the column where the process is repeated at

the net bubble cap tray. The cap shave slots to break up and reduce bubble size.

You might also like

- Oil and Gas DictionaryDocument47 pagesOil and Gas DictionaryMakutenko Makutenko100% (4)

- Simple DistillationDocument2 pagesSimple DistillationHarvey A. JuicoNo ratings yet

- Techniques of Separation Distillation: Created by Lakshay 9DDocument11 pagesTechniques of Separation Distillation: Created by Lakshay 9DLakshay ChauhanNo ratings yet

- A Guide to Perfume Production - A Selection of Vintage Articles on the Methods and Ingredients of PerfumeryFrom EverandA Guide to Perfume Production - A Selection of Vintage Articles on the Methods and Ingredients of PerfumeryRating: 5 out of 5 stars5/5 (2)

- Assignment CPP Jan 2020 PDFDocument5 pagesAssignment CPP Jan 2020 PDFNur Afifah IINo ratings yet

- Chlorine Institute Manual 2000Document68 pagesChlorine Institute Manual 2000Misael RamírezNo ratings yet

- DistillationDocument3 pagesDistillationAndreaNo ratings yet

- DistilationDocument11 pagesDistilationMuhammad HusseinNo ratings yet

- Introduction About Distillation ColumnDocument24 pagesIntroduction About Distillation ColumneliasNo ratings yet

- Liquid Surface Boiling Oil Crude Oil Aristotle Evaporation Pliny The Elder CondensationDocument2 pagesLiquid Surface Boiling Oil Crude Oil Aristotle Evaporation Pliny The Elder CondensationM AhmadNo ratings yet

- Distillation in Chemical ProccesDocument2 pagesDistillation in Chemical ProccesFebrian Rifkhi FahrizalNo ratings yet

- Literatur Modul 5 - Kesetimbangan FasaDocument18 pagesLiteratur Modul 5 - Kesetimbangan Fasasherilyn pagarintanNo ratings yet

- Hydrodynamics of Sieve Tray Distillation Column Using CFD SimulationDocument3 pagesHydrodynamics of Sieve Tray Distillation Column Using CFD SimulationShivam RathourNo ratings yet

- Tugas 2 Destilasi FixDocument2 pagesTugas 2 Destilasi FixVira YunizaNo ratings yet

- Basic Distillation ProcessDocument6 pagesBasic Distillation ProcessAmeerRashidNo ratings yet

- Definition:: DistillationDocument2 pagesDefinition:: DistillationAirah De JesusNo ratings yet

- Distillation Written ReportDocument18 pagesDistillation Written ReportMaRiz BalitaanNo ratings yet

- History: Government Polytechnic Jalna Atmospheric DistillationDocument11 pagesHistory: Government Polytechnic Jalna Atmospheric DistillationMs. YMPNo ratings yet

- Distillation Column: PrincipleDocument3 pagesDistillation Column: PrincipleShivam RathourNo ratings yet

- Introduction and Theory Buble CapDocument5 pagesIntroduction and Theory Buble CapAness ZulaikhaNo ratings yet

- Basic Operations Distillation & Filtration: Dr. George Georgiadis PHDDocument71 pagesBasic Operations Distillation & Filtration: Dr. George Georgiadis PHDgeorgiadisgNo ratings yet

- Refining Process (ARCHANA COMPLETE REFINING STUFF)Document96 pagesRefining Process (ARCHANA COMPLETE REFINING STUFF)Mahesh sinhaNo ratings yet

- Refining Process (ARCHANA COMPLETE REFINING STUFF)Document96 pagesRefining Process (ARCHANA COMPLETE REFINING STUFF)Mahesh sinhaNo ratings yet

- Distillation ColumnDocument5 pagesDistillation ColumnaimanjamelNo ratings yet

- Presented By: Anas SaleemDocument21 pagesPresented By: Anas SaleemAnas Saleem100% (2)

- 1.0 1.1 Experimental BackgroundDocument13 pages1.0 1.1 Experimental Backgroundpanteraa60No ratings yet

- Reflux: The Reflux System in A Typical Industrial Distillation ColumnDocument4 pagesReflux: The Reflux System in A Typical Industrial Distillation ColumnMohammed AliraqiNo ratings yet

- DistillationDocument4 pagesDistillationManoj KhanalNo ratings yet

- DistillationDocument18 pagesDistillationHannah CokerNo ratings yet

- Operation Distilation Tools OkeDocument75 pagesOperation Distilation Tools Okeali budiantoNo ratings yet

- Group 3Document31 pagesGroup 3vdfbhgNo ratings yet

- RefluxDocument5 pagesRefluxFranco Salerno100% (1)

- Process and Significance of DistillationDocument11 pagesProcess and Significance of DistillationSiddiquer Rehman SidNo ratings yet

- Mass Transfer: Unit OperationDocument4 pagesMass Transfer: Unit OperationazibanjumNo ratings yet

- Boiling Point and DistillationDocument21 pagesBoiling Point and Distillationشهد إيادNo ratings yet

- Distillation: Different Boiling Points Into The Gas PhaseDocument2 pagesDistillation: Different Boiling Points Into The Gas PhaseMika PelagioNo ratings yet

- Lyrics of I Believe I Can Fly - Erik SantosDocument3 pagesLyrics of I Believe I Can Fly - Erik SantosRaz MahariNo ratings yet

- Literature Review of FYPDocument7 pagesLiterature Review of FYPRiethanelia UsunNo ratings yet

- Distillation Basics: Dharmsinh Desai UniversityDocument20 pagesDistillation Basics: Dharmsinh Desai UniversityGilles DakouriNo ratings yet

- Distillation: DefinitionDocument4 pagesDistillation: DefinitionFareez IzwanNo ratings yet

- Distillation Application in PetroleumDocument46 pagesDistillation Application in Petroleumamirthalingam_b671No ratings yet

- Design of Fractionation Columns: August 2014Document35 pagesDesign of Fractionation Columns: August 2014Arbaz KhanNo ratings yet

- Fractional DistillationDocument5 pagesFractional DistillationLê LộcNo ratings yet

- Chapter OneDocument23 pagesChapter OneAyuob ElsharefNo ratings yet

- Laboratory Report DistillationDocument3 pagesLaboratory Report DistillationQueenie Luib MapoyNo ratings yet

- Simple Distillation: Raoult's LawDocument4 pagesSimple Distillation: Raoult's LawPerry Z. ZafeNo ratings yet

- Chapter OneDocument27 pagesChapter OneAyuob ElsharefNo ratings yet

- DisstilationDocument6 pagesDisstilationMustafa KhanNo ratings yet

- Applied DISTILLATION ADDEDDocument7 pagesApplied DISTILLATION ADDEDSidra YousafNo ratings yet

- Lab 2 - Distillation Column CompleteDocument18 pagesLab 2 - Distillation Column CompleteHadiChan100% (1)

- Periodic Table of The ElementsDocument36 pagesPeriodic Table of The ElementsJayakaran PachiyappanNo ratings yet

- 1.1 Distillation and Its BackgroundDocument32 pages1.1 Distillation and Its BackgroundAhmed ElsakaanNo ratings yet

- Fractional DistillationDocument17 pagesFractional DistillationSubash KumarNo ratings yet

- Experiment 6 - DistillationDocument5 pagesExperiment 6 - DistillationRohit BiswasNo ratings yet

- DistillationDocument5 pagesDistillationMa. Lilian Jem MonteroNo ratings yet

- Experiment 6Document24 pagesExperiment 6Ahmed SameerNo ratings yet

- MSP Unit-1Document117 pagesMSP Unit-1Jeya BharathiNo ratings yet

- Lab Report 4 Group 4Document19 pagesLab Report 4 Group 42023389329No ratings yet

- Project (Unit 1) Heriberto Jasso Pérez: "Distillation Process"Document9 pagesProject (Unit 1) Heriberto Jasso Pérez: "Distillation Process"fridda ovalleNo ratings yet

- 2.02 DistillationDocument2 pages2.02 DistillationAsto AtongNo ratings yet

- Fse DistillationDocument5 pagesFse DistillationShannel Audrey BadlisNo ratings yet

- Design of Fraction at I On ColumnDocument35 pagesDesign of Fraction at I On Columnprasad_vjtiNo ratings yet

- Types of Distillation 13CH56Document25 pagesTypes of Distillation 13CH56Talal Ashraf0% (1)

- Exp 1 Prepare Buffer SolnDocument4 pagesExp 1 Prepare Buffer SolnLaila FaeizahNo ratings yet

- Batch ReactorDocument28 pagesBatch ReactorNur Afifah IINo ratings yet

- Lab Manual CPPDocument51 pagesLab Manual CPPNur Afifah IINo ratings yet

- Naoh + Et (Ac) Na (Ac) + EtohDocument2 pagesNaoh + Et (Ac) Na (Ac) + EtohNur Afifah IINo ratings yet

- Lab Manual CPPDocument51 pagesLab Manual CPPNur Afifah IINo ratings yet

- Result CPPDocument3 pagesResult CPPNur Afifah IINo ratings yet

- Result Baru ProcessDocument3 pagesResult Baru ProcessNur Afifah IINo ratings yet

- Exp 5-Thermocouple RTD MeasurementDocument11 pagesExp 5-Thermocouple RTD MeasurementMemey LaNo ratings yet

- Business Plan Template Business Plan ExampleDocument6 pagesBusiness Plan Template Business Plan ExamplewernerNo ratings yet

- Density Measurement and Calibration Experiment System SE302Document3 pagesDensity Measurement and Calibration Experiment System SE302Nur Afifah IINo ratings yet

- BL4S Results 2021Document2 pagesBL4S Results 2021Sadika AkhterNo ratings yet

- Science Reviewer 3rd GradingDocument7 pagesScience Reviewer 3rd GradingSean Irvin MirandaNo ratings yet

- Science Class EightDocument16 pagesScience Class EightMuhammad UmarNo ratings yet

- Material Safety Data Sheet Hdpe: Section 1 - Chemical Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet Hdpe: Section 1 - Chemical Product and Company IdentificationruksfarhanNo ratings yet

- Welding F22 To F91 (09MAR2018)Document2 pagesWelding F22 To F91 (09MAR2018)Juan Shuna100% (2)

- WellLock Resin Rigless Micro Channel Remediation H011331Document1 pageWellLock Resin Rigless Micro Channel Remediation H011331bagus918No ratings yet

- Improvement of Biocomposite Properties Based Tapioca Starch and Sugarcane Bagasse Cellulose NanofibersDocument7 pagesImprovement of Biocomposite Properties Based Tapioca Starch and Sugarcane Bagasse Cellulose Nanofibersyasin AhmedNo ratings yet

- P Block Elements (Q.B) 13thDocument6 pagesP Block Elements (Q.B) 13thRaju SinghNo ratings yet

- BiochemistryDocument16 pagesBiochemistryLeila JoieNo ratings yet

- Eye Drops PreparationDocument1 pageEye Drops PreparationJai MurugeshNo ratings yet

- Development of Shade Continuity and Wash-Fastness Properties of Reactive Dyed Cellulosic Fabrics .Document4 pagesDevelopment of Shade Continuity and Wash-Fastness Properties of Reactive Dyed Cellulosic Fabrics .Rezaul Karim TutulNo ratings yet

- SSI AFD270 9in DiscDiff 012210Document2 pagesSSI AFD270 9in DiscDiff 012210Chris HdezNo ratings yet

- Le Ngoc Lieu - Chapter 1 - DehydrationDocument117 pagesLe Ngoc Lieu - Chapter 1 - DehydrationThuỳ TrangNo ratings yet

- Jarit CV Catalog NS1888 04 08 PDFDocument285 pagesJarit CV Catalog NS1888 04 08 PDFFabian Andres GiraldoNo ratings yet

- Microbial Cell FactoriesDocument11 pagesMicrobial Cell FactoriesthemarkmirNo ratings yet

- Kobel CoDocument4 pagesKobel CoCesar ZarateNo ratings yet

- Pump Cutaways and Drawings: Material CodesDocument11 pagesPump Cutaways and Drawings: Material CodesSalomón ContrerasNo ratings yet

- PPIIDocument1,106 pagesPPIIVineeta SharmaNo ratings yet

- Major Plant of NirmaDocument3 pagesMajor Plant of NirmaAnndy TrivediNo ratings yet

- R.1.47.01 Atlas Rupture DiscDocument2 pagesR.1.47.01 Atlas Rupture DiscSmita RojatkarNo ratings yet

- EN - Op.2 - EEE EXP4 - Semi Conductors - LecturesDocument82 pagesEN - Op.2 - EEE EXP4 - Semi Conductors - LecturesImmaculee BITWAGEBWA VERONIQUENo ratings yet

- Journal of Radiation Research and Applied Sciences: Abdullah Al Naim, Nisrin Alnaim, Sobhy S. Ibrahim, S.M. MetwallyDocument7 pagesJournal of Radiation Research and Applied Sciences: Abdullah Al Naim, Nisrin Alnaim, Sobhy S. Ibrahim, S.M. MetwallySarifatul HidayahNo ratings yet

- Yunus 2014Document10 pagesYunus 2014La Ode Muhamad RusliNo ratings yet

- Manual 21 MTO-1Document73 pagesManual 21 MTO-1Abhay RajputNo ratings yet

- Filter DataDocument6 pagesFilter DataJohnNo ratings yet

- Stepan: Bio-Terge As-90 BeadsDocument2 pagesStepan: Bio-Terge As-90 BeadsJerily Alzate TapiasNo ratings yet

- June 2012 (v2) QP - Paper 2 CIE Chemistry A-LevelDocument12 pagesJune 2012 (v2) QP - Paper 2 CIE Chemistry A-LevelNoor ZahraNo ratings yet