Professional Documents

Culture Documents

Handbook Electric Heat Tracing Part V PDF

Uploaded by

Đậu BắpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Handbook Electric Heat Tracing Part V PDF

Uploaded by

Đậu BắpCopyright:

Available Formats

Circuit Monitoring

Circuit Monitoring

If failure of a heater can result in a safety or process

problem, then the heat tracing system may be considered

to be critical to the total process. The temperature control

and circuit monitoring requirements of an application

are defined by the IEC Electric Heat Tracing standards

according to the temperature control types as previously

described, together with the circuit monitoring criticality as

described in the table below.

Desired accuracy of

process temperature control

Is heat tracing a Maintain Maintain Maintain

critical component above a within a within a

of the process? minimum moderate narrow

point Type I band Type II band Type III

Yes = Critical (C) C–I C – II C – III

No = Non-critical (NC) NC – I NC – II NC – III

Process types Temperature Controller with Monitoring

When heat tracing is critical to the process, circuit monitoring

for correct operation is recommended. Malfunction

alarms, and back-up (redundant) heat tracers may also be

considered. Spare or back-up controllers can be specified

to be automatically activated in the event of a fault being

indicated by the monitoring / alarm system. This is sometimes

known as “redundancy”. Back-up heat tracers will maintain

availability and may allow maintenance or repairs to be

performed without a process shutdown.

Page 21 SYSTEM DESIGN – GENERAL

3

Heating Cables - Generic types

There are four generic types of heat tracer

� Parallel Self-Regulating � Series Resistance

� Parallel Constant Power � Skin-Trace

Parallel Self-Regulating

Self-Regulating (or self-limiting) tracers are most popular,

as they can conveniently be cut-to-length and are often

inherently temperature-safe, due to the positive temperature

coefficient heating matrix. Thus temperature control is not

usually needed to provide temperature safety.

Until recently, their availability for only low or moderate

temperatures limited their use. Now though, Heat Trace Ltd.

have pioneered new 3rd generation semi-conductive tracers

able to withstand up to 300ºC energised or power off. So

now, Self-Regulating tracers can fulfil 90% of all applications

within industrial heat tracing – but currently only from Heat

Trace!

Ever since the introduction of self-regulating tracers, the high

currents on start up from cold have created a problem requiring

the need for larger than necessary feed cables and switchgear.

Additionally, safety was compromised, as circuit protection had

Power Output

to be sized in excess of operating currents. Now however, Heat

Trace has made significant reductions in start currents, thereby

improving safety, and reducing distribution costs.

A patented SoftStart device (see illustrations below) having

NTC (negative temperature coefficient) characteristics negates Temperature

the PTC (positive temperature coefficient) of the heating matrix.

Start currents are reduced by about 50% (see Figure below). Heat Trace’s range of self regulating heat tracers

This is further aided by a patented processing method known

as Directional Conductivity. Here the conductive particles within Heat Trace Limited is able to produce self-regulating tracers

the heating matrix are dispersed and distributed in such a way within the following range:

as to control the direction of current flow.

Single phase Self-Regulating tracers are typically limited in 12 - 1000 Volts

circuit length to 100 or 200 metres, and so are used mainly for Up to 300ºC withstand temperature

in-plant applications. However Heat-Trace can now provide Up to 150 W/m

the world’s first 3 phase self-regulating tracer capable of

circuit lengths upto 600m. Datasheets for some of the standard Heat Trace range are

provided, pages 30 - 35 inclusive

Soft Start Device Temperature ranges:

Low

FSLe 85ºC On or Off - up to 31W/m

FSR 85ºC On or Off - up to 40W/m

FSE 100ºC On or Off - up to 60W/m

Inrush Current Trend

Current

MODIFIED CURVE USING

HIgh

SOFTSTART DEVICE FS+ 225ºC On or Off - up to 60W/m

FSS 225ºC On or Off - up to 75W/m

FSU 250ºC On or Off - up to 100W/m

TYPICAL IN-RUSH CHARACTERISTIC FSU+ 275ºC On or Off - up to 125W/m

FOR SELF-REGULATING HEATING CABLE

AFS 300ºC On or Off - up to 150W/m

Time

PRODUCTS AND PRODUCT SELECTION Page 22

4

Heating Cables - Generic types

Parallel Constant Power

Parallel Constant Power (zonal) tracers can be conveniently

cut-to-length, but are less popular than Self-Regulating

heaters, because they often require thermostatic control to

ensure temperature safety, (although sometimes a calculated

temperature-safe stabilised design is possible).

Until recently, all constant power tracers were polymeric,

and so were limited in temperature capability. However, Heat

Trace has patented a parallel resistance, convenient cut-to-

length metal sheathed, mineral insulated (MI) heater having a

withstand temperature of 425 deg. C. This type AHT product

caters for most applications that the new high temperature

Self-Regulating heaters are unable to handle. Thus cut-to-

length parallel tracers are now available for virtually all heat

tracing applications. Parallel heating zones

This is particularly beneficial in the case of instrument lines, Heat Trace’s range of Parallel Constant Power heat

the lengths of which are usually unknown at the design stage tracers

of a project, and which are site run according to convenience.

Heat Trace Limited is able to produce tracers within the

Parallel Constant Power tracers are typically limited in circuit following limitations

length to 100 or 200 metres, and so are used mainly for in-

plant applications Up to 425ºC withstand temperature

Up to 200 W/m

Datasheets of some of the standard Heat Trace range are

provided, pages 36 - 39 inclusive

Temperature ranges:

Medium

MTF 200ºC On or Off - up to 50W/m

EMTF 200ºC On or Off - up to 50W/m

High

PHT 425ºC On or Off - up to 70W/m

AHT 425ºC On or Off - up to 150W/m)

Page 23 PRODUCTS AND PRODUCT SELECTION

4

Heating Cables - Generic types

Series Resistance Tracers

Series Resistance Tracers have to be individually designed

into particular length/load configurations and so are not so

versatile as parallel types.

However, an advantage is that very long circuit lengths are

possible – typically 3 phase ‘Longline’ tracers require electric

supply points only at multi-kilometre intervals. So the major

outlet for series heaters is long pipelines.

Traditionally, metal sheathed, mineral insulated (MI) series

cables were used when process temperatures exceeded the

capability of the more convenient polymeric parallel tracers.

However, the introduction of Heat Trace’s cut-to-length parallel

type AHT MI tracer virtually eliminates the need for series MI

tracers which require skill to terminate and are costly.

Series Resistance Tracers often require temperature controls

to ensure temperature safety.

Heat Trace’s range of series ‘Longline’ heat tracers

Heat Trace Limited is able to produce tracers within the

following limitations

Up to 6.6kV Volts 3 phase

Up to 300ºC withstand temperature

Up to 200 W/m of pipe

Datasheets of some of the standard Heat Trace range are

provided, pages 40 - 43 inclusive

Heating Circuit Configuration

Temperature ranges

A 3 phase circuit configuration comprises either 1 x three foil

Low Medium High Longline heater or 3 x single foil Longline heaters.

HTP3 HTS3F HT/A3F

HTP1 HTS1F HT/A1F

Longline series resistance tracers are for the heating of very

long pipelines, a very competitive option to Skin Trace.

PRODUCTS AND PRODUCT SELECTION Page 24

4

Heating Cables - Generic types

Skin-Trace

Skin-Trace is induction-resistive heat tracing based on skin and

proximity effects of an AC current within a ferromagnetic tube.

The heating element comprises a carbon steel tube into

which is inserted an insulated non-magnetic conductor. The

conductor and the steel tube are connected together at one

end. At the other end an AC voltage is applied between the

conductor and the tube. The relationship of conductor/tube

sizes and voltage determines the output power developed.

The skin effect of the magnetic tube results in the current

being concentrated towards the tube’s inner surface, the

potential to the outside being zero.

Skin-Trace’s advantage is that long circuit lengths are

possible – typically a pipeline of up to 20km may be heated

Depending on the heating power required and the pipeline

from a single electric supply point. So Skin-Trace is most

length, SKIN-TRACE may consist of either one, two, or three,

appropriate for the heating of cross-country pipelines.

heater tubes (see image above).

OPERATING TEMPERATURE -40ºC to +200ºC

POWER SUPPLY up to 3kV AC 50 or 60 Hz

POWER OUTPUT

SKIN-TRACE

heater tube Heat ow Rated power output of one heating element

80

1

2

W/m O u t p u t

60

3

Pipe wall

4

40

� Typically up to 20 km lines heated from one supply point 20

� Robust and reliable system with outputs up to 120W/m 0

0 2 4 6 8 10 12 14 16 18

� Suitable for up to 200ºC operating temperature L e n g t h o f h e a t e d p i p e l i n e , km

� Suitable for use in hazardous areas Rated Power output of one heater tube, W/m

Heater Tube Dimension

1 40mm

2 25mm

3 19mm

4 10mm

Page 25 PRODUCTS AND PRODUCT SELECTION

4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Handbook Electric Heat Tracing Part II PDFDocument5 pagesHandbook Electric Heat Tracing Part II PDFĐậu BắpNo ratings yet

- LPG Technology For Offshore and Mid Scale PlantsDocument22 pagesLPG Technology For Offshore and Mid Scale PlantsĐậu BắpNo ratings yet

- Best Practices For Aspen HYSYSDocument23 pagesBest Practices For Aspen HYSYSfdddddd100% (2)

- Handbook Electric Heat Tracing Part IIIDocument5 pagesHandbook Electric Heat Tracing Part IIIĐậu BắpNo ratings yet

- Handbook Electric Heat Tracing Part V PDFDocument5 pagesHandbook Electric Heat Tracing Part V PDFĐậu BắpNo ratings yet

- M A Haque S M Richardson & G Saville - Blowdown of Pressure Vessels - II Experimental ValidationDocument4 pagesM A Haque S M Richardson & G Saville - Blowdown of Pressure Vessels - II Experimental ValidationĐậu BắpNo ratings yet

- Handbook Electric Heat Tracing Part IIDocument5 pagesHandbook Electric Heat Tracing Part IIĐậu BắpNo ratings yet

- Handbook Electric Heat Tracing Part IIIDocument5 pagesHandbook Electric Heat Tracing Part IIIĐậu BắpNo ratings yet

- Solar Module 'S Catalog Series "MTS"Document14 pagesSolar Module 'S Catalog Series "MTS"Đậu BắpNo ratings yet

- Industrial Heat Tracing System Design and Product Selection GuideDocument5 pagesIndustrial Heat Tracing System Design and Product Selection GuideĐậu BắpNo ratings yet

- THERMAL PROCESSES IN LPG STORAGEDocument4 pagesTHERMAL PROCESSES IN LPG STORAGEĐậu BắpNo ratings yet

- Summit 8800 - Liquid CalculationsDocument9 pagesSummit 8800 - Liquid CalculationsĐậu BắpNo ratings yet

- Solar Brochure 2014Document11 pagesSolar Brochure 2014Đậu BắpNo ratings yet

- Zyme-Flow Decon Technology R6 Promo PDFDocument4 pagesZyme-Flow Decon Technology R6 Promo PDFĐậu BắpNo ratings yet

- Toeic Part 2 - Exercise 01Document3 pagesToeic Part 2 - Exercise 01Đậu BắpNo ratings yet

- Solar Power ProductDocument10 pagesSolar Power ProductĐậu BắpNo ratings yet

- Solar Brochure 2014Document10 pagesSolar Brochure 2014Đậu BắpNo ratings yet

- Hacknao Part VIIDocument5 pagesHacknao Part VIIĐậu BắpNo ratings yet

- Pass The TOEIC Test - ToEIC Word ListDocument11 pagesPass The TOEIC Test - ToEIC Word ListAnue Rathana100% (1)

- Olga Ss Guide PDFDocument30 pagesOlga Ss Guide PDFĐậu BắpNo ratings yet

- Section 18 - UtilitiesDocument5 pagesSection 18 - UtilitiesLeDzungNo ratings yet

- Crude Tower Simulation Using Aspen HYSYSDocument30 pagesCrude Tower Simulation Using Aspen HYSYSĐậu BắpNo ratings yet

- THERMAL PROCESSES IN LPG STORAGEDocument4 pagesTHERMAL PROCESSES IN LPG STORAGEĐậu BắpNo ratings yet

- Storage Handling and Boil-Off of LNG On PDFDocument16 pagesStorage Handling and Boil-Off of LNG On PDFĐậu BắpNo ratings yet

- Crude Tower Simulation Using Aspen HYSYSDocument30 pagesCrude Tower Simulation Using Aspen HYSYSĐậu BắpNo ratings yet

- Calculation Spreadsheet For Gpsa Engineering Data Book, 13Th Edition NomenclatureDocument6 pagesCalculation Spreadsheet For Gpsa Engineering Data Book, 13Th Edition NomenclatureĐậu BắpNo ratings yet

- 1wk Step6Document68 pages1wk Step6dhavaleshNo ratings yet

- CGE Gen PresentationDocument39 pagesCGE Gen PresentationĐậu BắpNo ratings yet

- Toeic VocabularyDocument10 pagesToeic VocabularyĐậu BắpNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pelton Crane OCM OCR Sterilizer Service ManualDocument8 pagesPelton Crane OCM OCR Sterilizer Service ManualWilliam Hernandez100% (1)

- Spare Parts List: LE 10000S Without Electronics dc9201: Leister Process TechnologiesDocument4 pagesSpare Parts List: LE 10000S Without Electronics dc9201: Leister Process TechnologiesAde AdeNo ratings yet

- IDHBIDHE SpecDocument4 pagesIDHBIDHE SpechtanhNo ratings yet

- Electric Water Heater MOU RafcoDocument2 pagesElectric Water Heater MOU RafcoZeeshan YasinNo ratings yet

- N24-Atlantic Water HeatersDocument28 pagesN24-Atlantic Water HeatersPatrick MorcosNo ratings yet

- 166015B-InLineManualwithAtmorLogo1 7-9 PDFDocument2 pages166015B-InLineManualwithAtmorLogo1 7-9 PDFم.محمدولدعليNo ratings yet

- MOV-112F212F MOV-112-212 - MOV-112S2 - 12S MOV SeriesDocument6 pagesMOV-112F212F MOV-112-212 - MOV-112S2 - 12S MOV SeriesВладимир МешочкинNo ratings yet

- Ho EWM 2xxx 3xxx ENV06 General EN PDFDocument70 pagesHo EWM 2xxx 3xxx ENV06 General EN PDFArdo IsküllNo ratings yet

- Automatic Water Heater 94SMSS1Document14 pagesAutomatic Water Heater 94SMSS1Reoeuele Duran CalzitaNo ratings yet

- CFD Applications For Performance Improvement in Power PlantsDocument36 pagesCFD Applications For Performance Improvement in Power Plantsdillipsh123No ratings yet

- Utilization of Electric Power: Module 02: Electric Heating Lec 02: Resistance Heating, Resistance FurnaceDocument11 pagesUtilization of Electric Power: Module 02: Electric Heating Lec 02: Resistance Heating, Resistance FurnaceAbhishek SharmaNo ratings yet

- Immersion Heater Specification Data SheetDocument1 pageImmersion Heater Specification Data SheetEzequiel Guillermo Trejo NavasNo ratings yet

- Extended Surface Heat TransferDocument7 pagesExtended Surface Heat TransferAkay BayatNo ratings yet

- Syl-2362A2 Pid Temperature Controller Instruction ManualDocument5 pagesSyl-2362A2 Pid Temperature Controller Instruction ManualTony GaryNo ratings yet

- Miele w1113 Service ManualDocument67 pagesMiele w1113 Service Manualsteinhansen100% (1)

- Wiring Instructions For Marley 2500 Series Electric Baseboard Heaters XDocument7 pagesWiring Instructions For Marley 2500 Series Electric Baseboard Heaters XTomNo ratings yet

- Electric Duct Heater: Specification and Installation InstructionsDocument8 pagesElectric Duct Heater: Specification and Installation InstructionsDonald VelosoNo ratings yet

- Ieee 1069Document29 pagesIeee 1069Jose Antonio EstofaneroNo ratings yet

- Terumo Sarns 11160 Operator S ManualDocument17 pagesTerumo Sarns 11160 Operator S ManualManigandan DhamodhiranNo ratings yet

- V Guard Electric Water Heaters PDFDocument31 pagesV Guard Electric Water Heaters PDFYOGENDER KUMARNo ratings yet

- Laguna State Polytechnic University: Republic of The Philippines Province of LagunaDocument6 pagesLaguna State Polytechnic University: Republic of The Philippines Province of LagunaLeigh Reyes De ChavezNo ratings yet

- Rheem PROE50 T2 RH95Document2 pagesRheem PROE50 T2 RH95Lovan SoNo ratings yet

- CocoaTown Professional Line PDFDocument14 pagesCocoaTown Professional Line PDFYeshuaMaureraDiazNo ratings yet

- Resistencia CalefactoraDocument18 pagesResistencia CalefactoraTescel SASNo ratings yet

- MP3000 Controller Alarm and Warnings OverviewDocument4 pagesMP3000 Controller Alarm and Warnings OverviewGomesNo ratings yet

- Lupo 1.2 Tdi 3lDocument53 pagesLupo 1.2 Tdi 3lgoopejko100% (2)

- Catalogue Havells Water HeatersDocument60 pagesCatalogue Havells Water HeatersNiravBhalodiyaNo ratings yet

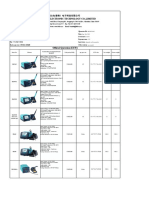

- BAKON Official Quotation for Pulsar Import E.I.R.LDocument5 pagesBAKON Official Quotation for Pulsar Import E.I.R.Lluis palominoNo ratings yet

- Therm o Disc 59T 66T Thermostat BulletinDocument7 pagesTherm o Disc 59T 66T Thermostat BulletinAlberto SanchezNo ratings yet

- Cadet InstructionsDocument9 pagesCadet InstructionsKathyNo ratings yet