Professional Documents

Culture Documents

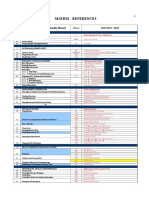

ZOE EX-113.1cross Reference 22000 HACCP

Uploaded by

Sarfraz EPIC Consulting0 ratings0% found this document useful (0 votes)

21 views2 pagesOriginal Title

ZOE EX-113.1cross reference 22000 HACCP

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views2 pagesZOE EX-113.1cross Reference 22000 HACCP

Uploaded by

Sarfraz EPIC ConsultingCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

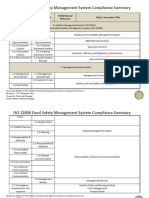

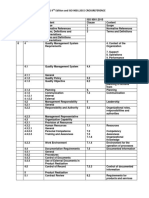

HACCP Management System ISO 22000:2005

Title Document & Reference

5. HACCP System Requirements 7.6 Esthablising the HACCP

plan

5.1 Management Responsibility Quality Manual 5.0 Management responsibility

5.1.1 Food Safety Policy ZOE-EX-106.1 5.2 Food safety policy

5.1.2 Scope of the HACCP System Chapter 6 – HACCP Manual – Sec 2.1 7.6 Establihing HACCP plan

5.1.3 Task, Responsibilities, Authorities GPE-ZOE-EX-105.2 Responsibility and Authority Statements 5.4 Responsibility and

Authorisation

5.1.4 HACCP Team Chapter 6 - HACCP Manual – Sec 2.3 7.3.2 Food safety team

5.1.5 Resources GPE-ZOE-PR-209.1 – Training & HR

GPE-ZOE-PR-205.2 – Management Review 6.0 Resource management

5.1.6 Management Review GPE-ZOE-PR.205.2 Management Review 5.8 Management review

5.2 Product Information 7.3.3 Product Charateristics

5.2.1 Product Charateristics Chapter 6 - HACCP Manual – Sec 2.2

Product Migration Reports, Raw Material Food Contact Statements 7.3.3 Product Charateristics

GPE-ZOE-PR-302.1, 303.2 – Materials Purchasing & Control of Raw Material

5.2.2 Intended Use Chapter 6 - HACCP Manual – Sec 2.7 7.3.4 Intended Use

5.3 Process Information Chapter 6 - HACCP Manual 7.3.5.2 Description of process steps

and control measures

5.3.1 Flow Diagram Chapter 6- HACCP Manual – Sec 2.6 7.3.5.1 Flow Diagram

5.3.2 Layout Chapter 6 - HACCP Manual 7.3.5 Flow diagrams, process

steps and control measures

5.3.3 Control & Verification of Process Information Chapter 6 - HACCP Manual 8.4 Analysis of data

5.4 Pre-Requisite Program GPE-ZOE-PR-601.2 Food Safety Program 7.2 PRP

5.5 Hazard Analysis 7.4.3 Hazard assessment

5.5.1 Hazard Identification Chapter 6 - HACCP Manual – Sec 2.8 7.4.2 Hazard identification and

determination of acceptable

levels

5.5.2 HACCP Analysis (Risk) Chapter 6 - HACCP Manual – Sec 2.8 7.4 HACCP Analysis

5.6 Control Measures 7.4.4 Selection and assessment

of control measures

5.6.1 Specific Control Measures GPE-ZOE-PR-501.3 Process Control 7.4.4 Selection and assessment of

control measures

5.6.2 General Control Measures GPE-ZOE-PR-501.3 Process Control 7.4.4 Selection and assessment of

control measures

5.7 Parameters and Critical Limits

5.7.1 Critical Process & Product Characteristics GPE-ZOE-WI-4110 Internal Specification 200ml 7.2.2 Beoordeling van

GPE-ZOE-WI-4120 Internal Specification 500ml producteisen

5.7.2 Target Values, Action-Limit Values & Critical Limits GPE-ZOE-PR-501.3 Process Control 7.6.3 Determination of critical limits

CP-5110 – Apollo Product Control Plan for ccp’s

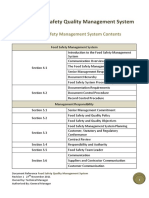

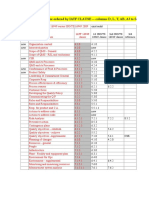

HACCP Management System ISO 22000:2005

Title Document & Reference

5.8 Monitoring & Measuring GPE-ZOE-PR-501.3 Process Control 7.6.5 Actions when monitoring

results exceed critical

limits

5.9 Corrective Action GPE-ZOE-PR-202.2 Corrective & Preventive Action 7.10.2 Corrective actions

5.10 Validation 8.2 Validation of control

measure combinations

5.11 Verification GPE-ZOE-PR-501.3 Process Control, Work Instructions / Test Methods 8.4.2 Evaluation of individual

GPE-ZOE-PR-204.2 Internal Audit verification results

GPE-ZOE-PR-209.1 – Training & HR

GPE-ZOE-PR-208.2 – Customer Complaints

GPE-ZOE-PR-606.2 – Product Recall

GPE-ZOE-PR-206.2 Control of Records

GPE-ZOE-PR.205.3 Management Review

Flow Diagrams – Chapter 6, Sect 2.6 of HACCP Manual

5.12 Documentation & Records 4.2 Documentation

requirements

5.12.1 Document & Document Control GPE-ZOE-PR-201.2 Document Control 4.2.2 Document Control

5.12.2 Records GPE-ZOE-PR-206.2 Control of Records 4.2.3 Control of Records

You might also like

- Comparison of ISO 22000 and BRC Food Issue 7 PDFDocument4 pagesComparison of ISO 22000 and BRC Food Issue 7 PDFLSARAVANAN91100% (1)

- ISO 22000 Food Safety Management System ContentsDocument7 pagesISO 22000 Food Safety Management System ContentsMeg GuzmanNo ratings yet

- Iso22000-Mgmt System Compliance SummaryDocument8 pagesIso22000-Mgmt System Compliance SummaryGidion Jeffri PoerbaNo ratings yet

- Food Safety Management System ContentsDocument22 pagesFood Safety Management System ContentsRocky BisNo ratings yet

- FSSC 2200 Scheme Version 5 - Audit Plan and Risk RatingDocument10 pagesFSSC 2200 Scheme Version 5 - Audit Plan and Risk RatingMidnight Rei100% (1)

- FSSC 22000 Templates IndexDocument11 pagesFSSC 22000 Templates IndexMohammed Imran0% (1)

- Training FSSC 22000 Ver 4.1 DSI & JawamanisDocument37 pagesTraining FSSC 22000 Ver 4.1 DSI & JawamanisFisaNo ratings yet

- ISO 22000 Implementation Package Brochure 2018 PDFDocument25 pagesISO 22000 Implementation Package Brochure 2018 PDFfrmgsNo ratings yet

- Manual HACCP Food SafetyDocument13 pagesManual HACCP Food SafetyDiane Angelique ArceoNo ratings yet

- FSSC 22000 FSMS Implementation Package V5.1 BrochureDocument44 pagesFSSC 22000 FSMS Implementation Package V5.1 BrochureSutha Tamil Nambe100% (1)

- KisdfsdDocument24 pagesKisdfsdrichesNo ratings yet

- 9001-2008 To 9001-2015 To IATF 16949 - Rev1 - 02-17-17Document8 pages9001-2008 To 9001-2015 To IATF 16949 - Rev1 - 02-17-17normalNo ratings yet

- Comparison of ISO220002018 Vs ISO220002005Document4 pagesComparison of ISO220002018 Vs ISO220002005K S Kumara100% (1)

- ISO 9001 Vs ISO 22000Document3 pagesISO 9001 Vs ISO 22000gone4win80% (5)

- DUTCH-Option A Requirements For An HACCPDocument48 pagesDUTCH-Option A Requirements For An HACCPravindrapkadam9423No ratings yet

- ISO 9001:2015 IATF 16949:2016 Correlation Matrix (Gap Analysis) USL International Quality Solutions Consultancy Services For ISO, IRIS, AS, IATFDocument4 pagesISO 9001:2015 IATF 16949:2016 Correlation Matrix (Gap Analysis) USL International Quality Solutions Consultancy Services For ISO, IRIS, AS, IATFKarthikeyan Janarthanan83% (6)

- Comparison of Revised ISO 22000:2018 VS ISO 22000:2005 Food Safety Management System RequirementsDocument5 pagesComparison of Revised ISO 22000:2018 VS ISO 22000:2005 Food Safety Management System RequirementsYogiNo ratings yet

- Comparison of I So 220002018 Vsi So 220002005Document5 pagesComparison of I So 220002018 Vsi So 220002005YogiNo ratings yet

- Bennie Etal NHS 2010 NHS Greater Glasgow and Clyde Acute Pharmacy Redesign ProgramDocument87 pagesBennie Etal NHS 2010 NHS Greater Glasgow and Clyde Acute Pharmacy Redesign ProgramJasminoides GardeniaNo ratings yet

- Comparison of ISO 9001, ISO-DIS 22000, BRC and IFSDocument3 pagesComparison of ISO 9001, ISO-DIS 22000, BRC and IFSJOSE ABAD100% (1)

- Requirements HACCP Versie 3 PDFDocument41 pagesRequirements HACCP Versie 3 PDFsyed zia ul hassanNo ratings yet

- Haccp Manual DocumentsDocument8 pagesHaccp Manual DocumentsHarits As SiddiqNo ratings yet

- QMS Vol. 1 PDFDocument436 pagesQMS Vol. 1 PDFCamilo Jorquera100% (2)

- Comparison of I So 220002018 Vsi So 220002005Document5 pagesComparison of I So 220002018 Vsi So 220002005Rmt Mitro EndroNo ratings yet

- Comparisonof ISO220002018 Vs ISO220002005Document5 pagesComparisonof ISO220002018 Vs ISO220002005SherifNo ratings yet

- Compare ISO 9001 and ISO 13485Document2 pagesCompare ISO 9001 and ISO 13485umarNo ratings yet

- Nominal Cross-References 17025 To 9001 PDFDocument3 pagesNominal Cross-References 17025 To 9001 PDFwhitemithrilNo ratings yet

- Comparison of Revised ISO 22000:2018 VS ISO 22000:2005 Food Safety Management System RequirementsDocument5 pagesComparison of Revised ISO 22000:2018 VS ISO 22000:2005 Food Safety Management System Requirementsmiz baigNo ratings yet

- Comparison of Revised ISO 22000:2018 VS ISO 22000:2005 Food Safety Management System RequirementsDocument5 pagesComparison of Revised ISO 22000:2018 VS ISO 22000:2005 Food Safety Management System RequirementsRegulatory IndaromaNo ratings yet

- Comparison of I So 220002018 Vsi So 220002005Document5 pagesComparison of I So 220002018 Vsi So 220002005Драган ЖивковићNo ratings yet

- FSSC 5 Iso 22000 2018 - SDDocument43 pagesFSSC 5 Iso 22000 2018 - SDdafara groupNo ratings yet

- Iso KlausulDocument16 pagesIso KlausulMelisa HwangNo ratings yet

- Cross Reference Between Iso 22000:2018 and Iso 22000:2005Document6 pagesCross Reference Between Iso 22000:2018 and Iso 22000:2005Anita Ikhwani TrianingrumNo ratings yet

- Iso 22000 Documentation Kit PDFDocument9 pagesIso 22000 Documentation Kit PDFMohammad Mashatleh100% (2)

- Crossreference API Q1 9TH and ISO 9001 2015Document3 pagesCrossreference API Q1 9TH and ISO 9001 2015wachid50583% (6)

- BOSCH7Document14 pagesBOSCH7Georgiana BusuiocNo ratings yet

- Gap Analysis Audit Checklist - IATF 16949Document6 pagesGap Analysis Audit Checklist - IATF 16949PaulaMagalhãesNo ratings yet

- 20 Food Safety ProgramDocument4 pages20 Food Safety ProgramОлександра СеменкоNo ratings yet

- ISO 22000:2018 Food Safety Management System Standard Clause Wise Mandatory Documented Information ListDocument5 pagesISO 22000:2018 Food Safety Management System Standard Clause Wise Mandatory Documented Information ListAnkurNo ratings yet

- Quality Manual qm0492 Iso ts16949 Supplement IDocument20 pagesQuality Manual qm0492 Iso ts16949 Supplement Ix engineeringNo ratings yet

- UNIT 9 ISO 22000:2005 - STRUCTURE: 9.0 ObjectivesDocument13 pagesUNIT 9 ISO 22000:2005 - STRUCTURE: 9.0 Objectivesgsakthivel2008No ratings yet

- FSM 002 Food Safety Quality Manual SummaryDocument8 pagesFSM 002 Food Safety Quality Manual SummaryAliNo ratings yet

- QMS Process IdentificationDocument1 pageQMS Process IdentificationSaravana kumar NagarajanNo ratings yet

- API Spec Q1 Inhouse TrainingDocument14 pagesAPI Spec Q1 Inhouse Trainingachmad100% (2)

- Quality Manual Texas OilfieldDocument34 pagesQuality Manual Texas Oilfieldjaymuscat50% (2)

- IRIS Rev Vs IS022163 Correlation Matrix 1Document6 pagesIRIS Rev Vs IS022163 Correlation Matrix 1Centre For Total Quality ManagementNo ratings yet

- Assured 22000 FSMS Certification Package Brochure 2015Document43 pagesAssured 22000 FSMS Certification Package Brochure 2015Gameel ThabitNo ratings yet

- Quality Manual 9001-2015 06-10-2021Document27 pagesQuality Manual 9001-2015 06-10-2021Geoff EricksonNo ratings yet

- Audit FormDocument6 pagesAudit FormmartinusteddyNo ratings yet

- Comparision ISO 9001 2018 & 2015Document8 pagesComparision ISO 9001 2018 & 2015manish100% (1)

- Quick Reference AS9100 ClauseDocument3 pagesQuick Reference AS9100 ClauseVasudevan GovindarajNo ratings yet

- Supplier Quality Manual - F1555499 - 6 PDFDocument25 pagesSupplier Quality Manual - F1555499 - 6 PDFArjunkNo ratings yet

- HARMAN - Supplier Quality Manual - F1555499 - 6bDocument25 pagesHARMAN - Supplier Quality Manual - F1555499 - 6bMert AtayNo ratings yet

- Iatf UpgradingDocument6 pagesIatf UpgradingAhmad AzrilNo ratings yet

- Surak SlidesDocument18 pagesSurak SlidesAhmed Amine ZIRARNo ratings yet

- ISO 9001 Correlation - MatricesDocument8 pagesISO 9001 Correlation - Matricescaesar bintangNo ratings yet

- PROJECT QUALITY PLAN Rev-00Document33 pagesPROJECT QUALITY PLAN Rev-00shahhassa989% (18)

- Aide-Memoire Inspection Medicinal GasesDocument15 pagesAide-Memoire Inspection Medicinal Gasesmorcos mikhailNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Reheating: Safe MethodDocument2 pagesReheating: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Cooking Safely: Safe MethodDocument2 pagesCooking Safely: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Checking Your MenuDocument2 pagesChecking Your MenuSarfraz EPIC ConsultingNo ratings yet

- Foods That Need Extra Care: Safe MethodDocument2 pagesFoods That Need Extra Care: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Hot Holding PDFDocument2 pagesHot Holding PDFSarfraz EPIC ConsultingNo ratings yet

- Ready-To-Eat Food: Safe MethodDocument2 pagesReady-To-Eat Food: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Cloths: Safe MethodDocument2 pagesCloths: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Reheating: Safe MethodDocument2 pagesReheating: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Freezing: Safe MethodDocument2 pagesFreezing: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Chilling Down Hot Food: Safe MethodDocument2 pagesChilling Down Hot Food: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Ready-To-Eat Food: Safe MethodDocument2 pagesReady-To-Eat Food: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Defrosting: Safe MethodDocument2 pagesDefrosting: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Hot Holding PDFDocument2 pagesHot Holding PDFSarfraz EPIC ConsultingNo ratings yet

- Chilled Storage and Displaying Chilled Food: Safe MethodDocument2 pagesChilled Storage and Displaying Chilled Food: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Audit Program Manager 9k, 14k - Risk Based (14jul2017)Document62 pagesAudit Program Manager 9k, 14k - Risk Based (14jul2017)AliNo ratings yet

- Chilled Storage and Displaying Chilled Food: Safe MethodDocument2 pagesChilled Storage and Displaying Chilled Food: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Your Cleaning Schedule: Safe MethodDocument2 pagesYour Cleaning Schedule: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Clear and Clean As You Go: Safe MethodDocument2 pagesClear and Clean As You Go: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Risk in ISO 9001-2014 (ISO) PDFDocument6 pagesRisk in ISO 9001-2014 (ISO) PDFxyalfaxyNo ratings yet

- Handwashing: Safe MethodDocument2 pagesHandwashing: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- Cleaning Effectively: Safe MethodDocument2 pagesCleaning Effectively: Safe MethodSarfraz EPIC ConsultingNo ratings yet

- How To Use The Audit Program Manager: List The Processes/functional AreasDocument25 pagesHow To Use The Audit Program Manager: List The Processes/functional AreasAliNo ratings yet

- ISO 9001 Process Procedure QPP-061-1 Risks and OpportunitiesDocument5 pagesISO 9001 Process Procedure QPP-061-1 Risks and Opportunitiesimran shaukatNo ratings yet

- Animal Feed Haccp Manual 2006Document5 pagesAnimal Feed Haccp Manual 2006AliNo ratings yet

- Characteristics and Risk Analysis Report - Template v.1.0Document10 pagesCharacteristics and Risk Analysis Report - Template v.1.0Sarfraz EPIC ConsultingNo ratings yet

- Risk Assessment, Mitigation, & Contingency PlanDocument16 pagesRisk Assessment, Mitigation, & Contingency PlanAliNo ratings yet

- List of RisksDocument1 pageList of Risksbudi_alamsyahNo ratings yet

- P-712-A Risk Management: Program Manager and Project TeamDocument3 pagesP-712-A Risk Management: Program Manager and Project TeamAliNo ratings yet

- Blank Risk Matrix, Updated On 31.01.2017.Document9 pagesBlank Risk Matrix, Updated On 31.01.2017.Madhavaram SVNo ratings yet

- Blank Risk Application MatrixDocument1 pageBlank Risk Application MatrixSarfraz EPIC ConsultingNo ratings yet

- Topic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)Document8 pagesTopic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)millerNo ratings yet

- Miso Soup Miso Soup Miso Soup: Ingredients Ingredients IngredientsDocument8 pagesMiso Soup Miso Soup Miso Soup: Ingredients Ingredients IngredientsEllie M.No ratings yet

- Acm Queue PDFDocument12 pagesAcm Queue PDFShubham Anil ShahareNo ratings yet

- E&i QC Inspector Resum and DocumentsDocument24 pagesE&i QC Inspector Resum and DocumentsIrfan 786pakNo ratings yet

- Lite Indicator Admin ManualDocument16 pagesLite Indicator Admin Manualprabakar070No ratings yet

- Granulometry of ClinkerDocument18 pagesGranulometry of ClinkerNael100% (12)

- 1.2.2.5 Packet Tracer - Connecting Devices To Build IoTDocument4 pages1.2.2.5 Packet Tracer - Connecting Devices To Build IoTyayasan dharamabharataNo ratings yet

- Psi Engines Product Sheet PDFDocument2 pagesPsi Engines Product Sheet PDFDaniel DelgadoNo ratings yet

- Form IEPF 2 - 2012 2013FDocument2,350 pagesForm IEPF 2 - 2012 2013FYam ServínNo ratings yet

- rOCKY Dem Manual (010-057)Document48 pagesrOCKY Dem Manual (010-057)eduardo huancaNo ratings yet

- LLB IV Sem GST Unit I Levy and Collection Tax by DR Nisha SharmaDocument7 pagesLLB IV Sem GST Unit I Levy and Collection Tax by DR Nisha Sharmad. CNo ratings yet

- Case Study StarbucksDocument2 pagesCase Study StarbucksSonal Agarwal100% (2)

- MKT STGDocument106 pagesMKT STGAmeya Singh RajputNo ratings yet

- 04 10 ALINT DatasheetDocument2 pages04 10 ALINT DatasheetJoakim LangletNo ratings yet

- I. Level of Barriers in ICT Knowledge, Skills, and Competencies No ICT Knowledge, Skills and Competency Barriers SDA DA N A SADocument2 pagesI. Level of Barriers in ICT Knowledge, Skills, and Competencies No ICT Knowledge, Skills and Competency Barriers SDA DA N A SAMuhamad KhoerulNo ratings yet

- Genstat Release 10.3de (Pc/Windows 7) 28 May 2012 06:35:59Document6 pagesGenstat Release 10.3de (Pc/Windows 7) 28 May 2012 06:35:59Anna Nur HidayatiNo ratings yet

- VISCOLAM202 D20 Acrylic 20 Thickeners 202017Document33 pagesVISCOLAM202 D20 Acrylic 20 Thickeners 202017Oswaldo Manuel Ramirez MarinNo ratings yet

- PCI Secure Software Standard v1 - 0Document67 pagesPCI Secure Software Standard v1 - 0Antonio ClimaNo ratings yet

- Chiba International, IncDocument15 pagesChiba International, IncMiklós SzerdahelyiNo ratings yet

- HOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckDocument3 pagesHOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckRPaivaNo ratings yet

- Fish Siomai RecipeDocument12 pagesFish Siomai RecipeRhyz Mareschal DongonNo ratings yet

- Chemistry For PhotographersDocument184 pagesChemistry For PhotographersBahar ShoghiNo ratings yet

- Macro Economics A2 Level Notes Book PDFDocument33 pagesMacro Economics A2 Level Notes Book PDFMustafa Bilal50% (2)

- Inclusions in Gross IncomeDocument2 pagesInclusions in Gross Incomeloonie tunesNo ratings yet

- Available Online Through: International Journal of Mathematical Archive-4 (12), 2013Document4 pagesAvailable Online Through: International Journal of Mathematical Archive-4 (12), 2013Gwen WalkerNo ratings yet

- Veris Case StudyDocument2 pagesVeris Case StudyPankaj GargNo ratings yet

- Stadium and Club Tours - Senior Tour GuideDocument4 pagesStadium and Club Tours - Senior Tour GuidebizmbuuNo ratings yet

- IFE Level 4 Certificate in Fire InvestigationDocument16 pagesIFE Level 4 Certificate in Fire InvestigationMarlon FordeNo ratings yet

- Mechanical Power FormulaDocument9 pagesMechanical Power FormulaEzeBorjesNo ratings yet

- English Examination 1-Bdsi-XiDocument1 pageEnglish Examination 1-Bdsi-XiHarsuni Winarti100% (1)