Professional Documents

Culture Documents

7-51-0333 - Details For HOT DIP Galavanised Ladder Type Cable Trays

Uploaded by

ChandrashekharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7-51-0333 - Details For HOT DIP Galavanised Ladder Type Cable Trays

Uploaded by

ChandrashekharCopyright:

Available Formats

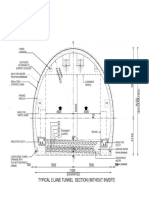

Details for Hot dip Galvanized ladder type DETAILS FOR STANDARD No.

ENGINEERS

cable trays Irg;Uft9g:Ang HOT DIP GALVANISED 7-51-0333 Rev.2

(IANGPAII"' 2\("I'ITE2g) LADDER TYPE CABLE TRAYS

RITerr FleaRUC.3,141.0

SH. 1 OF 3

3000 /11

250 125 125 250 250 250 I 1500 250 250 125

40x15 HORIZONTAL

A -4-1 RUNG (TYP.)

W

[45 45

40

SLOTTED RUNG

MEIMIMUrAMPIELIMINIMPLIMIR

1451

451

100x45 SIDE RUNNER (TYP.)

14 0 HOLE FOR SECTION-AA

12 0 BOLT (TYP.)

LADDER TYPE CABLE TRAY

(w=300/450/600/750)

250

of

10x30 LONG SLOT SLOTTED RUNG

(TYP.) (TYP.)

SLOTTED RUNG SIDE RUNNER

D-07 lc

0 0

0 a) 0 II

1=1MM

11111111111111111

IMAM_

mm411111111

ROUND HEAD BOLT

12 MM DIA

PL.215x90x2 THK.

1301401 75 i 40 P SPLICE PLATES

VIEW B-B SECTION D-D

VIEW C-C

0

N

L--50

BARRIER PLATE

100 HOLE FOR

80 BOLT

(100 MM LONG)

NOTES:-

1 12 DIA ROUND HEAD BOLT WITH WASHERS & NUTS CONFORMING TO

IS 1363 & IS 1367 SHALL BE USED FOR FIXING OF SPLICE PLATE.

7A10> ;14'"A

C)4

2 23.04.13 REVISED AND REISSUED BP FA/RSC UAP/J MS DM

1 11.01.08 REVISED AND REISSUED BP RKS/SSM JMS VC

Rev. Prepared Checked Stds. Committee Stds. Bureau

Date Purpose Convenor Chairman

No. by by

Approved by

Format No. 8-00-0001-F4 Rev.O Copyright EIL - All rights reserved

Page 6320 of 7025

STANDARD No.

DETAILS FOR

/8ifWEIq ENGINEERS

fatalft INDIA LIMITED HOT DIP GALVANISED 7-51-0333 Rev. 2

21E¢15WC613,131171)

"t

(A Go Ind° UndethAing) LADDER TYPE CABLE TRAYS SH. 2 OF 3

125

140 HOLES FOR FIXING

SPLICE PLATE (TYR)

H (Pi')

40x15 MM

RUNG @ 250 C/C

VERTICAL OUTSIDE BEND

HORIZONTAL BEND

125 _1

(TYP)

VERTICAL INSIDE BEND

125

I (np)

W1

s aFM I a I a FA CaINIMIWIEMilaW/ Mi

0

U-)

N

[ W2 J

LEFT HAND REDUCER

W W1

`T' JOINT

W — WIDTH OF CABLE TRAY (300/450/600/750)

W1 — WIDTH OF CABLE TRAY ON ONE SIDE

W2 — WIDTH OF CABLE TRAY ON OTHER SIDE L W2 I

BR— BENDING RADIUS (750/1000/1250)

RIGHT HAND REDUCER

/f"4 ;,e4211

2 23.04.13 REVISED AND REISSUED BP FA/RSC UAP/JMS DM

1 11.01.08 REVISED AND REISSUED BP RKS/SSM JMS VC

Prepared Checked Stds. Committee Stds. Bureau

Rev.

Date Purpose Convenor Chairman

No. by by

Approved by

Format No. 8-00-0001-F4 Rev.O Copyright EIL - All rights reserved

Page 6321 of 7025

STANDARD No.

DETAILS FOR

ENGINEERS

iaPiez INDIA LIMITED HOT DIP GALVANISED 7-51-0333 Rev.2

C61.3917.1) (A Govt of India Undertoking)

LADDER TYPE CABLE TRAYS SH. 3 OF 3

GENERAL NOTES:-

1 THE CABLE TRAYS AND ACCESSORIES SHALL COMPLY WITH LATEST EDITION OF INDIAN STANDARDS

IS: 1363, IS: 1367(PART-13), IS:2629, IS:5986.

2. THE CABLE TRAYS SHALL BE LADDER TYPE PREFABRICATED, HOT DIP GALVANIZED. THE LADDER

TYPE TRAYS SHALL CONSIST OF SIDE RUNNERS & HORIZONTAL RUNGS AS PER DETAILS SHOWN

IN SH. 1 & 2.

3. THE LADDER TYPE TRAYS AND ACCESSORIES SHALL HAVE RIGID WELDED CONSTRUCTION AND

SHALL BE FABRICATED OUT OF 2 mm THICK HOT ROLLED SHEET STEEL. THE RUNGS SHALL

BE WELDED TO THE SIDE RUNNERS.

4. SIDE RUNNERS SHALL BE 100 x 45 mm CHANNEL WITH THE FLANGES FACING INSIDE. RUNGS

SHALL BE 40 x 15 mm SLOTTED CHANNEL TYPE.

5. CABLE TRAYS SHALL BE SUITABLE FOR A CABLE WEIGHT OF 75 kg PER METRE OF RUNNING

LENGTH OF TRAY AND SHALL BE SUPPORTED AT 3 m INTERVALS. IN ADDITION, TRAYS SHALL

BE SUITABLE FOR A POINT LOAD OF 70 kg (EQUIVALENT WEIGHT OF A MAN WORKING ON THE

CABLE TRAY).

6. SIDE RUNNER CHANNELS SHALL BE CONNECTED AT ENDS USING 2 SPLICE PLATES ONE EACH SIDE

AS SHOWN IN SHEET-1.

7. THE SIDE RUNNER WILL ALSO HAVE SUITABLE HOLES AT EVERY METRE FOR CLEATING EARTHING

STRIP. SUITABLE THREADED HOLES SHALL BE PROVIDED ON THE RUNNER TOP AND BOTTOM

FOR SUPPORTING AND FIXING TRAY COVERS WITH SCREWS AT EVERY METRE.

8. HOT DIP GALVANIZING SHALL BE DONE AFTER FABRICATION AS PER THE RELEVANT INDIAN

STANDARD SPECIFICATIONS. THE AMOUNT OF GALVANIZING SHALL BE MINIMUM 610 g/m 2

9. THE TYPE OF CONSTRUCTION SHALL BE SUCH AS TO FACILITATE EASY HANDLING, ASSEMBLY

AND INSTALLATION AT SITE. FOR THE CONSTRUCTION OF CABLE TRAYS THE STANDARD STRAIGHT

LENGTH OF CABLE TRAY SHALL BE 3 METERS UNLESS OTHERWISE SPECIFIED.

10. SPLICE PLATE OF CABLE TRAYS SHALL BE PLACED NOT MORE THAN 750 MM FROM

SUPPORT ANGLE.

11. THE WORKMANSHIP SHALL BE SUCH AS TO ENSURE EASY LAYING OF CABLES WITHOUT CAUSING

DAMAGE TO CABLES. ALL SURFACES SHALL BE FREE FROM DEFECTS SUCH AS BURRS, SHARP

EDGES ETC.

12. THE HARDWARE SHALL CONFORM TO THE RELEVANT INDIAN STANDARD SPECIFICATIONS AND SHALL

BE ABLE TO WITHSTAND THE MAXIMUM LOADING CONDITIONS AS REQUIRED. ALL HARDWARE AND

FITTINGS SHALL BE HARD CHROME OR CADMIUM PLATED. HARDWARE SHALL INCLUDE BOLTS,

NUTS, WASHERS ETC.

13. THE BENDS, TEES, REDUCERS AND DROPPERS SHALL HAVE A BENDING RADIUS AS DESCRIBED

IN THE SCHEDULE OF RATES.

14. THE FOLLOWING TESTS FOR THE AMOUNT OF ZINC COATING SHALL BE CARRIED OUT:

• THICKNESS OF GALVANIZED COATING BY ELCOMETER.

• MASS OF GALVANIZED COATING BY STRIPPING TEST.

• DETERMINATION OF UNIFORMITY OF GALVANIZED COATING.

AN. ^

2 23.04.13 REVISED AND REISSUED BP FA/RSC UAP/JMS DM

1 11.01.08 REVISED AND REISSUED BP RKS/SSM JMS VC

Rev. Prepared Checked Stds. Committee Stds. Bureau

Date Purpose Convenor Chairman

No. by by

Approved by

Format No. 8-00-0001-F4 Rev.O Copyright EIL - All rights reserved

Page 6322 of 7025

You might also like

- EIL 6-51-0051 Rev. 6Document10 pagesEIL 6-51-0051 Rev. 6Manish Sharma100% (1)

- Motor Electric Test RecordDocument1 pageMotor Electric Test RecordArka HatiNo ratings yet

- Rate AnalysisDocument60 pagesRate AnalysisLuojisi CilNo ratings yet

- Miniature Circuit Breaker IEC 60898 Is 8828 Test BenchDocument8 pagesMiniature Circuit Breaker IEC 60898 Is 8828 Test BenchFares NehaouaNo ratings yet

- 1 VentsDocument4 pages1 VentsEugene MicarandayoNo ratings yet

- Kyh1 Sc05 220kv Line Protection Rev-A 04.03.2020 (1) With CommentsDocument50 pagesKyh1 Sc05 220kv Line Protection Rev-A 04.03.2020 (1) With CommentsJayarajan Jayarajan C NNo ratings yet

- Checklist For Transformer Burnt Oil Tank Design & DrawingDocument3 pagesChecklist For Transformer Burnt Oil Tank Design & DrawingRupesh KhandekarNo ratings yet

- DS - 6.6kV HT SWGRDocument22 pagesDS - 6.6kV HT SWGRcherif yahyaoui0% (1)

- Cable Tray Sizing CalculationsDocument6 pagesCable Tray Sizing CalculationsMunir RasheedNo ratings yet

- FEWA LV Capacitor Bank SpecificationsDocument5 pagesFEWA LV Capacitor Bank SpecificationsDEADMANNo ratings yet

- General notes and details for substation constructionDocument1 pageGeneral notes and details for substation constructionA.K.M Shafiq MondolNo ratings yet

- Reference TG - Cable ScheduleDocument21 pagesReference TG - Cable Scheduleerkamlakar2234No ratings yet

- Pilot Cable Specs FewaDocument13 pagesPilot Cable Specs Fewabharat_22nandulaNo ratings yet

- JX NIPPON OIL & GAS LOW VOLTAGE SWITCHBOARD INSPECTIONDocument2 pagesJX NIPPON OIL & GAS LOW VOLTAGE SWITCHBOARD INSPECTIONAmyNo ratings yet

- TB2-SDC - VP114-00QEY-I-M5-DGA-0006 Rev0 PLC Panel Drawing For Compressed Air SystemDocument22 pagesTB2-SDC - VP114-00QEY-I-M5-DGA-0006 Rev0 PLC Panel Drawing For Compressed Air SystemTrong Nguyen VanNo ratings yet

- Contractor QAP for HT Breaker PanelDocument1 pageContractor QAP for HT Breaker Panelmadhu_bedi12No ratings yet

- UDDEHOLM ROYALLOY REFERENCE GUIDEDocument8 pagesUDDEHOLM ROYALLOY REFERENCE GUIDEHarmand HadinataNo ratings yet

- Lightning & Earthing Protection System SpecificationsDocument9 pagesLightning & Earthing Protection System SpecificationsMuhammad Ibad Alam100% (1)

- Motor technical specificationsDocument2 pagesMotor technical specificationsmishtinilNo ratings yet

- Site Acceptance Test Report For MV Panel - J03: Al Hudayriyat Island Tmp4Document6 pagesSite Acceptance Test Report For MV Panel - J03: Al Hudayriyat Island Tmp4Gajendran SriramNo ratings yet

- Conectores BurndyDocument869 pagesConectores BurndyLuiz Azevedo100% (2)

- Milling Time CalculationDocument16 pagesMilling Time CalculationJaka Sembung Bawa GolokNo ratings yet

- Enquiry For HT PANELDocument5 pagesEnquiry For HT PANELPrasenjit MaityNo ratings yet

- Ac Panel Test ReportDocument14 pagesAc Panel Test ReportUtku Can KılıçNo ratings yet

- Cable Tray & Tray Support Drawings PDFDocument14 pagesCable Tray & Tray Support Drawings PDFprabhu85No ratings yet

- AWS D1.1 Code Quick ReviewDocument3 pagesAWS D1.1 Code Quick ReviewDo XuanNo ratings yet

- Ga Drawing For Local Control Panel For Area BF, Hm1, Hm2, LD, CH, Op, SP, SM, Co & RM BuldingDocument16 pagesGa Drawing For Local Control Panel For Area BF, Hm1, Hm2, LD, CH, Op, SP, SM, Co & RM BuldingNitin BihaniNo ratings yet

- Cable Schedule - Instrument - Surfin - Malanpur-R0Document3 pagesCable Schedule - Instrument - Surfin - Malanpur-R0arunpandey1686No ratings yet

- Starting time calculationDocument15 pagesStarting time calculationSankalp MittalNo ratings yet

- Power Cable ScheduleDocument40 pagesPower Cable ScheduleAnupam0103No ratings yet

- Earthing and Lightning Installation Comments ResponseDocument16 pagesEarthing and Lightning Installation Comments Responsebensaadallah ahmedNo ratings yet

- Erection Procedure For Control Battery - LatestDocument12 pagesErection Procedure For Control Battery - LatestAnmohieyNo ratings yet

- Universal Cable (M) Berhad - Bending Radius, Side Wall Pressure and Copper Screen RequirementsDocument1 pageUniversal Cable (M) Berhad - Bending Radius, Side Wall Pressure and Copper Screen RequirementsMuhammad RosliNo ratings yet

- MV Cables Data Sheet - SampleDocument5 pagesMV Cables Data Sheet - SampleAvoor KhanNo ratings yet

- A Study On The Compressive Strength of Concrete With Coconut Shell As Additional AggregateDocument3 pagesA Study On The Compressive Strength of Concrete With Coconut Shell As Additional AggregateNOCHU COME THRUNo ratings yet

- Drawout Type VCB Panel GA DrawingDocument1 pageDrawout Type VCB Panel GA DrawingsaifulNo ratings yet

- Reyes - BT4 - Specification Writing SeatworkDocument11 pagesReyes - BT4 - Specification Writing SeatworkCameron ReyesNo ratings yet

- Architectural Concrete Part 1Document80 pagesArchitectural Concrete Part 1Samuel FuentesNo ratings yet

- 66 - KV - CT - PT - R5 - Metering - Jan - 10 GETCO PDFDocument33 pages66 - KV - CT - PT - R5 - Metering - Jan - 10 GETCO PDFRupesh ChowdaryNo ratings yet

- Fpso - Specifications For Topsides Piping SystemsDocument25 pagesFpso - Specifications For Topsides Piping Systemsdndudc100% (1)

- Instrument Cable SizingDocument2 pagesInstrument Cable Sizingsv_verma100% (1)

- Prok DVs - ACCL - CatalougeDocument3 pagesProk DVs - ACCL - CatalougekapilNo ratings yet

- AICPL DRAWING PROPERTY RIGHTSDocument1 pageAICPL DRAWING PROPERTY RIGHTSsubhankNo ratings yet

- Distribution Board Schedule Db-L&P-Work Shop 1-4 TPN 10: 10A 10A 10A 10A 10A 10A 10A 10A 10A 10A 20A 20ADocument9 pagesDistribution Board Schedule Db-L&P-Work Shop 1-4 TPN 10: 10A 10A 10A 10A 10A 10A 10A 10A 10A 10A 20A 20ANiveeth ChattergyNo ratings yet

- Tariff Metering PanelsDocument2 pagesTariff Metering PanelsSaraswatapalitNo ratings yet

- Inspection and Test Plan: Project NameDocument2 pagesInspection and Test Plan: Project NameehteshamNo ratings yet

- L&T Pushbutton Catalogue Price ListDocument16 pagesL&T Pushbutton Catalogue Price Listfahiyan100% (1)

- PWD Rajasthan Electric BSR 2021Document214 pagesPWD Rajasthan Electric BSR 2021Rajat JangidNo ratings yet

- Trinity Price ListDocument12 pagesTrinity Price Listkirtiraj gehlotNo ratings yet

- Kiosk Earthing CircularDocument1 pageKiosk Earthing CircularsunilgvoraNo ratings yet

- LCP for deluge valvesDocument8 pagesLCP for deluge valvesRana NishithNo ratings yet

- Sfu HandleDocument82 pagesSfu HandlenalasekaranNo ratings yet

- 11 KV 200 Amp 3 Pole AB Switch Technical Specification: ScopeDocument4 pages11 KV 200 Amp 3 Pole AB Switch Technical Specification: ScopeVIKRAM DESAINo ratings yet

- Industrial & Flameproof LCS SpecDocument5 pagesIndustrial & Flameproof LCS SpecAvinash ShuklaNo ratings yet

- 2022-07-14 - D - Approved Tunnel Earthing Plan For Package-3 - MRTDocument25 pages2022-07-14 - D - Approved Tunnel Earthing Plan For Package-3 - MRTBhawani NayakNo ratings yet

- Pressure Transmitter Data SheetDocument2 pagesPressure Transmitter Data Sheetneurolepsia3790No ratings yet

- 7-12-0025 Rev 5Document2 pages7-12-0025 Rev 5cynideNo ratings yet

- Ga Drawing of Indoor Type DB Panel With GTP PDFDocument1 pageGa Drawing of Indoor Type DB Panel With GTP PDFHytech Pvt. Ltd.No ratings yet

- Capacitor Step Size Selection Guidelines in APFC PanelsDocument4 pagesCapacitor Step Size Selection Guidelines in APFC PanelsAditya Pandey100% (1)

- Switchgear Specification For High Voltage Switchgears CT PT BreakerDocument26 pagesSwitchgear Specification For High Voltage Switchgears CT PT BreakerSumit TyagiNo ratings yet

- 33kv Capacitor With Allied EquipmentDocument9 pages33kv Capacitor With Allied EquipmentsbpathiNo ratings yet

- GTP HavellsDocument24 pagesGTP HavellsPradeep GoelNo ratings yet

- Fcma FaqDocument2 pagesFcma FaqSusovan ParuiNo ratings yet

- Pump ChlorineDocument44 pagesPump ChlorineAlexandreCaironiNo ratings yet

- Goel Power Engineers AMF Panel Price-ListDocument1 pageGoel Power Engineers AMF Panel Price-Listrdeepak99100% (1)

- 4 Ammeter Test ReportDocument1 page4 Ammeter Test ReportJayaprakash M PNo ratings yet

- Test Report For: CT Primary Injection TestDocument4 pagesTest Report For: CT Primary Injection TestAhmed FathyNo ratings yet

- Crane Girder -Cr2-y5 보강 부분1 -ModelDocument1 pageCrane Girder -Cr2-y5 보강 부분1 -ModelYanuar IrNo ratings yet

- '2 Lane Without InvertDocument1 page'2 Lane Without InvertShivendra KumarNo ratings yet

- Ce 5Document1 pageCe 5Cyril AleaNo ratings yet

- 2023 PDFDocument12 pages2023 PDFDevesh Kumar PandeyNo ratings yet

- PNS 69-2005Document15 pagesPNS 69-2005Mariel Villaluna0% (1)

- 20BC0049 - 2ND Billing PCMADocument1 page20BC0049 - 2ND Billing PCMARandy Jake Calizo BaluscangNo ratings yet

- Products 2020 03 09 06 19 29Document60 pagesProducts 2020 03 09 06 19 29inabasNo ratings yet

- Civil Engineering Research PDFDocument5 pagesCivil Engineering Research PDFJithu MonNo ratings yet

- Plastic IndustryDocument50 pagesPlastic Industryhelperforeu50% (2)

- D-70 Cupronickel Rev 06Document3 pagesD-70 Cupronickel Rev 06Luis Gustavo AndradeNo ratings yet

- Health Post-Floor PlanDocument21 pagesHealth Post-Floor PlanEng Hinji RudgeNo ratings yet

- Remodeling Garage ConversionDocument3 pagesRemodeling Garage ConversiongarageconversioninfoNo ratings yet

- Assignment On Unit 1-AnsDocument7 pagesAssignment On Unit 1-AnsXyz ZyxNo ratings yet

- METAL WORKING EXTRUSION PROCESSDocument94 pagesMETAL WORKING EXTRUSION PROCESSSajjad0% (1)

- SB-8520 Service Regulator SpecsDocument8 pagesSB-8520 Service Regulator SpecsSantiago UrreaNo ratings yet

- Soil Stabilization Using Sawdust & LimeDocument21 pagesSoil Stabilization Using Sawdust & LimeManas Ranjan Dash100% (1)

- Analysis and ResultDocument3 pagesAnalysis and ResultNur HazwaniNo ratings yet

- Stellram MillingDocument44 pagesStellram Millingdhiraj_forNo ratings yet

- Smart Branch IPBDocument17 pagesSmart Branch IPBRozin AlhaqNo ratings yet

- Presentation - Frame Construction in Concrete SteelDocument23 pagesPresentation - Frame Construction in Concrete SteelOlay KwongNo ratings yet

- MP Module 1Document13 pagesMP Module 1Aryan RaiNo ratings yet

- PSC (3 Unit)Document4 pagesPSC (3 Unit)Padma PinnamreddyNo ratings yet

- U Seal V SeakDocument56 pagesU Seal V SeakMiguelNo ratings yet