0% found this document useful (0 votes)

685 views6 pagesWell Basis of Design Document

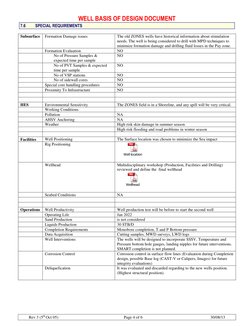

The document provides details for the proposed ZONES 17 development well, including:

1) ZONES field was discovered in 1973 and has since produced over 1.13 TCF from 15 existing wells, 13 of which are currently producing.

2) Key details are given for the proposed ZONES 17 well, including a preferred spud date of December 2011, minimum hole size of 8.5 inches, and total planned depth of 10,028 feet.

3) Requirements are outlined for logging and data collection during drilling of the surface, intermediate, and production holes, prioritizing pressure-volume-temperature and mud logging data.

Uploaded by

Samuel ArevaloCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

685 views6 pagesWell Basis of Design Document

The document provides details for the proposed ZONES 17 development well, including:

1) ZONES field was discovered in 1973 and has since produced over 1.13 TCF from 15 existing wells, 13 of which are currently producing.

2) Key details are given for the proposed ZONES 17 well, including a preferred spud date of December 2011, minimum hole size of 8.5 inches, and total planned depth of 10,028 feet.

3) Requirements are outlined for logging and data collection during drilling of the surface, intermediate, and production holes, prioritizing pressure-volume-temperature and mud logging data.

Uploaded by

Samuel ArevaloCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- General

- Temperature and Formation Data

- Well Program Requirements

- Proposed Formation Tops

- Special Requirements

- Potential Drilling Hazards

- Offset Data

- Supporting Documentation

- Approvals