Professional Documents

Culture Documents

K L K L K L: Moisture Barrier (MB) Shell (S) Thermal Liner (TL) 1 MM 1 MM

Uploaded by

Carlos Gonzalez ValarezoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

K L K L K L: Moisture Barrier (MB) Shell (S) Thermal Liner (TL) 1 MM 1 MM

Uploaded by

Carlos Gonzalez ValarezoCopyright:

Available Formats

3.

53 A wire of diameter D

e four ity 25 W/m K having uniform volumetricwalls

heat of

genera- and important

h (10 % hfeatures. % 1000 W/m2 ! K) on the total heater

(c) Calculate the !heat loss from the cylindrical T has an electrical r

s your 3 power requirement, as well as the rate of heat transfer

thetion of 0.3for

canister MW/m is cases.

the four insulated on one side, while the (c) Consider conditions corresponding to a loss flow of 20 A.

other side is exposed to a fluid at 92!C. The convection to the inner surface of the tube and to the fluid.

of coolant at the exposed surface of material A

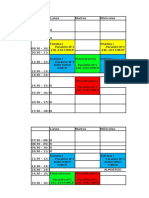

ues of 3.24 A firefighter’s protective

heat transfer clothing,

coefficient referred

between thetowall

as a turnout

and the fluid (a) What is the rate

3.50 A stainless (h " 0). steel Determine (AISIT1304) and Ttube 2 andused plot the to transport

tempera-

t loss coat, isistypically constructed

2 as an ensemble

500 W/m ! K. Determine the maximum of three lay-

temperature length of wire?

a chilledture distributionpharmaceutical throughout hasthean system.inner diameter

ansfer ers separated by

in the wall.air gaps, as shown schematically. unit volume with

of 36 mm and a wall thickness of 2 mm. The pharma-

rence CH003.qxd 3.85 Consider12:26

2/24/11 a planePMcomposite Page 206 wall that is composed of

3.82 Large, cylindrical bales of hay used to feed livestock in ceutical and ambient air are at temperatures of 6!C and (b) If the wire is n

res is three materials (materials A, B, and C are arranged left

the winter

Shell (s) months

Moisture are D " 2

Thermal m in diameter and are 23!C, respectively, while the corresponding inner and large surrou

What to right) of thermal conductivities k " 0.24 W/m ! K,

stored end-to-end barrier (mb)

in long rows. liner (tl)

Microbial energy gener- and outer convection coefficients are A400 W/m2 ! K and what is the te

pared kB " 0.13 2 W/m ! K, and kC " 0.50 W/m ! K. The thick- wire has an em

ation1 mm occurs in 1the hay and can be excessive if the 6 W/m ! K, respectively.

Fire-side mm

kmbthe hay in a too-wet Firefighter nesses of the three sections of the wall are LA " 20 mm, associated with

farmer bales condition. Assuming (a)

L B "What is theand heat LCgain permm. unitAtube length?

ks, Ls k

L tl

13 mm, " 20 contact resistance of may be approx

nven- the thermalmb conductivityLtl of baled hay to be % 2 2

(b)

R$ What" 10 is mthe! K/W heat gain existsperatunit thelengthinterface if a 10-mm-

between form, h # C[(

other k " 0.04 W/m ! K, determine the maximum steady-state 206 t,c Chapter 3 !assilicate One-Dimensional, Steady-State Conduction

Air gap Air gap . 3 thick A

materials layer and of

B, calcium

as well at the insulation

interface between (kins #

W/m7/4 ! K5/4.

e fuel hay temperature for dry hay (q " 1W/m ), moist hay

. 3 . 3 0.050 W/m

materials B and! K) C. isThe applied

left face to the of tube?

the composite wall

eadily (q " 10 W/m ), and wet hay (q " 100 W/m ). Ambient

is insulated, while the right face is exposed to convec- (c) If the wire is co

en be conditionsdimensions

Representative are T! " 0!C andandthermal W/m2 ! K.

h " 25conductivities 3.51

3.74 Superheated

The conditions

outer surface steamofata575!C hollowis routedoffrom

sphere radius a2 boiler to 3.78

tive characterized by h " 10 W/m 2 isTsub-

!rK, ! " Onethickness

modalityand fora dt

ilar to the

jectedturbineto a of an electric

uniform heat power fluxenergyq!2plant

. Theisthrough

inner steel tubes

surface at r1 imbedding

for

3.83theConsider

layers aretheascylindrical

follows. bales of hay in Problem 3.82. 20!C. For Case 1, thermal generated within what areathe small

inn

l cell, (k

is #held 35 at W/m ! K) of 300-mm

a constant .

temperature innerT diameter. 3 and 30-mm within

the the tissue aT

insulation?

It is proposed to utilize the microbial energy generation material A at the rate qA " 5000 s,1W/m . For Case 2,

el cell wall thickness. To reduce heat loss to the surroundings and above

Layerassociated with wet hay to heat (mm) water.kConsider(W/m ! K) a 30-mm thermal

(a)maintain

Develop energy is generated forwithin material Cdistribu- at the 0.9,a and

criticalthe valu

con

rD!

Thickness to . a an expression

safe-to-touch outer thesurface

temperature temperature, a thatexpression

is well remove

diameter, thin-walled tube inserted lengthwise through rate tion

qC " T(r) 5000 in W/m

the 3

.

sphere wall in terms of q! , T , r , r , of pa

ce of layer of calcium silicate insulation (k # 0.10 2W/m s,1 ! K) 1 is 2

to remain at normo

Shell the (s) middle of a cylindrical0.8 bale. The tube carries 0.047 water at and the thermal conductivity of the wall material k. lation thickness

ctivity (a) Determine

applied to the tubes, the maximum while degradation temperatureofwithin the com-

the insulation

Moisture " 20!C(mb)

T!,i barrier with hi " 200 0.55W/m2 ! K. 0.012 Obtain a general ex

d that (b)

is If

reduced the

posite inner

wall

by and

under

wrapping outer it tube

steady-state in a radii

thin are

conditions

sheet r 1 " for

of 50 mm1.

Case

aluminum and 3.54 A 2-mm-diameter

Thermal distribution in the t

avoid (a) liner (tl) the steady-state

Determine 3.5 heat transfer 0.038to the water having r2 " an100

(b) Sketch themm,

emissivity whatofheat

steady-state !# flux

0.20.

temperatureq!2 isThe required air and

distribution to main- wallon 2-mm-thick rubberi

for which heat is di

which per unit length of tube. tain

temperatures

T % the outer

of thesurface

x coordinates power at

for plant

CaseTs,2are " 50#C,

1. 27!C. while the inner the wire/sheath inte

d 2/24/11 12:26 PM Page 199 what heat rate must

r may The air (b) gaps

Plot the between the layers are

radial temperature 1 mm thick,

distribution in the hay, (a) surface is at Ts,1 the " 20#C? The thermal conductivity contact resistance of

(c) Assuming

Sketch the that steady-state inner surface

temperature temperature

distribution for of perature of T % Tc

mitted and heat T(r). is transferred by conduction and radiation ofsteel

aCase the wall tube material is k " to10that W/m of! K. vection heat transfer

2 on thecorresponds

same T % x coordinates the steam

used for Case and 1. 5 mm? The tissue

n 1.5; exchange through thetransfer

stagnant air.water Theper linearized the sheath is 10 W

(c) Plot the heat to the unit length of 3.75 A spherical the convection shell ofcoefficient inner andoutside outer radii the aluminum

ri and ro, mately 0.5 W/m ! K

radiation tube coefficient 3.86 An air heater ismay 2 be fabricated by coiling Nichrome the ambient air is 20

valent for balefor a gap may

diameters of 0.2be m approximated

# D # 2 m. sheet

respectively, is 6 W/m filled! K, withwhat ais heat-generating

the minimum insulation material

k sur- as, hrad ! "(T1 & T2)(T 1 & T 2) ! 4"T avg , where Tavg

2 2 3

wire and passing

thatthickness

provides needed

for a air toinensure

uniform cross

volumetric flow the

that over the wire.

temperature

generation rate tion may not exceed

3.84 Consider

represents the one-dimensional

average temperature conduction of the in surfaces

a plane com- Consider a heater fabricated from wire of diameter D " Conduction

able electrical withpowe Th

mpera- (W/m 3

of )the of qaluminum

. The outerdoes surface not of exceed

the shell 50!C? What is

is exposed to

comprisingposite the wall.gap,Theand outer thesurfaces

radiation arefluxexposedacross to athe fluid at 1 mm, electrical resistivity !e " per 10% 6 meter& !199m, of thermal length of the condu

mall to ! Problems the corresponding heat

a fluid having a temperature T! and a convection coeffi- loss tube

25!C and a convection as q%rad ! hheat transfer coefficient of conductivity k " 25 W/m ! K, and emissivity " " 0.20.

m the gap may be expressed

2

rad (T1 # T2). h. Obtain an expression for the steady-state tem- 3.79 the

cientlength? Theinsulation?

air inside a cha

1000 W/m ! K. The middle wall B experiences uniform The heater is designed to deliver air at a temperature of vectively with hi " 2

(a) Represent the turnout . coat by a thermal circuit, perature distribution T(r) in the shell, expressing your

heat generation qB, while there is no generation in walls T " 50!C under flow conditions that provide a con- having a thermal co

to be labeling

Consider all the thermal

conditions for which resistances.

hotat gases Calculate

at T!,o and ! result in terms of ri, ro, q, h, T!, and the thermal conduc-

!

3.qxd 2/24/11 tabulate A

12:26and C.

PMThe temperatures

Page 198 the interfaces are

2 T1 " vection coefficient of h " 250 W/m2 ! K for the wire. form heat generatio

1700 K261!C the

and cooling thermal resistances per unit area (m ! tivity k of the shell material.

ter to and T2 "air211!C. at T!,i ! 400 K provide outer

Transistor The temperature of the housing that encloses

Tsur

the wire heat generated with

y visi- and K/W) inner for each ofconvection

surface the layers, coefficients

as well as forofthehocon- ! case 3.76 and A spherical tank of 3-m diameter contains a liquified-

through which the air flows is T " 50!C. outside of the cha

5 K). 1000duction

W/m ! Kand

2

andradiation

hi ! 500 T1processes

W/m ! K, 2 in respectively.

the

T2 gaps. Assume If a Ts,c, Pelec

petroleum gas at $ 60#C. Insulation Base plate,

sur

with (k,εa) thermal con-

that a value

0.5-mm-thick of Tavg !

zirconia TBC470 is K mayattached be used to ato 5-mm-

approx- Wire W/m2 ! K, a very th

cov- ductivity of 0.06 W/m ! K and thickness

Interface, Ac

Housing, 250

T mm is

thickimate

T∞, the

Inconel

h radiation resistance of both gaps.

blade wall by means of a metallic bond-

,h

T∞Com- (D, L, ρe, k, ε , Tmax) sur the outer wall to pro

) and applied to the tank to reduce the heat gain.

y thin ment on the relative magnitudes

ing agent, which provides an interfacial thermal resis- of the resistances. W

Enclosure (a) Determine the radial position in the insulation Air

A B C layer

te the tance

(b) For of R" ! 10# 4 m2 ! K/W,

at,cpre-ash-over can the Inconel

fire environment in be main-

which fire- Strip heater, q"o

198 tained at a Chapter temperature

3 ! One-Dimensional,

that q•

is below its

Steady-State

maximum

Conduction at which the temperature is 0#C when the ambient

lating fighters often work, the typical

B radiant heat flux ,h Outside chamber

CH003.qxd 2/24/11air 12:26 temperature PM Page is 20#C208 and the convectionT∞coeffi-

) and allowable

on thevalue of 1250

fire-side of the K?turnout

Radiation coateffects

is 0.25may W/cm be2. ∆ EisAir 2 T∞, o, ho

cient on the outer surface 6

T∞, h W/m ! K.

neglected, and the turbine LA blade2LBmay be Lapproximated C I

What is the outer surface temperature of the turnout (a) Sketch (b) the equivalent

If the insulation thermal circuit corresponding

is pervious to moisture from the

as a plane wall. Plot the temperature distribution with

coat if the innerkAsurface = 25 W/m temperature

•K LA = 30ismm 66!C, a con- to steady-state

If theatmospheric

maximum conditions. air,

allowable In

what variable

conclusions

temperature form,can oflabel

theyouwire reach is

and without the TBC. Are

kC =result

50 W/m

there any limits to the thick- L

dition that would in•KburnLinjury? B = 30 mm appropriate resistances, temperatures,

Tmax " 1200!C, what is the maximum allowable What

about the formation of ice and

in theheat fluxes.

insulation? elec-

ness of the TBC? LC = 20 mm

(b)

(a)Under (a) Sketch the tem

3.25 tricsteady-state

If the air-filled

effect

currentwill conditions

I?aluminum-to-aluminum

ice

If theformation maximum forhave which on the

availableheat chip

interfacegain

voltage to the is

3.31AAparticular

commercial

(a) with

thermal

Assuming grade system

cubical

negligible

involves

freezer, three

3

contactofresistance m objects

on a of

side,

at the inter- heat dissipation

'E LP " 110

is characterized gas?V,How is q$

bywhat an "

c could 30,000

areais the this

of W/m

situation

Acorresponding

! 2 & 10

2

, what # 4 is

be avoided? 2 the

mlengthand L of

T $ x coordina

fixed

has shape

a composite conduction

wall resistances

consisting of an R 1 " 1 K/W,

exterior sheet . 208 chip temperature? Chapter 3 ! cOne-Dimensional, Steady-State Conduction generated withi

wire thatofmay be used may in the heater and thea power

Rof 2 K/W faces,

2 " 6.35-mm-thick and Rdetermine

" 4 K/W,

3 plain

therespectively.

carbon

volumetric heat

steel, an

generation qB 3.77

An objec-

intermediate

a roughness

A transistor, 10which!m, what isbethe maximum

approximated allow-

as hemi- the chamber.

and the thermal conductivity kB. (c) The rating

powerofdissipation

maximum

ablespherical the

heat heater?

allowable

sourceif of Hint:

heat

the In ryour

flux,

surface

radius q$ c,m, solution,

is deter-ofassume

temperature

tive is toofminimize

layer 100-mm-thick the totalcork thermal resistance

insulation, andRtot anasso-

inner o " 0.1 mm, is embed- (b) What are the te

ciated mined

the ded byinTthe

case, constraint

as,c,large

is notsilicon

to exceed that the

85$C?

substrate chip "temperature

(kwithin 125the W/m ! K)but and 3.90 A nuclear

sheet with of a6.35-mm-thick

combination of R 1, R2, and R

aluminum 3. The(2024).

alloy chief negligible temperature variations wire, fuelT(L),

T(0) and elemefo

must not

dissipates exceed 85!C.

heatthe Determine

at desired

a rate q.results, q$

All boundaries for the fore-

engineer

Adhesive is willing

interfaces to invest

between limited the funds insulationto specify and an the (b) The after convection

obtaining coefficient may c,m

beassessincreased theofvalidity

the

by silicon of a steel cladding of th

(c) Determine the va

going areconditions.

maintained Ifatairanisambientused in lieu of the dielec-

alternative

metallic strips material for just

are each one of the

characterized bythree

a thermalobjects;con- subjecting

this assumption. the plate surface to atemperature forced flowofofTair. ! " 27#C, the nuclear fuel at a

strip heater so th

tric liquid,

exceptthe the

foreffectconvection

the top coefficient is reduced by

thetactalternative

resistancematerial of R"t,c ! will

2.5have & 10a thermal

# 4 2

m ! K/W conductiv-

. What is Explore of surface,

increasing which the is well insulated.

coefficient over which adjoins one s

transferred to the

3.87 Consider the composite

approximately an order of magnitude. wall of Example

What is the 3.7. In the

itythethat is twice itscooling

steady-state nominal loadvalue.

thatWhich must be object (1, 2,

maintained the range 4 % h % 200 W/m2 !2K. convection coefficien

Comments

value of q$ section,

for h " temperature

100 W/m ! K? distributions

With air in

cool- the wall (d) If thetheheat gene

orby3)the should be fabricated

refrigerator of the higher

under conditions for whichthermal thecon-

outer c,m o lated, and fuel an

ing,were can determined

significant assuming

improvements

r negligible be contact

realized resistance

by

Silicon while the heat fl

ductivity material to most significantly

and inner surface temperatures are 22$C and # 6$C, decrease R tot ? Poroususing Media o of k ƒ and k s, respectiv

between an materials Aoxide

aluminum and B.circuit Compute board and and/or

plot the tem-

substrate stant, what wou

Hint: Consider two cases, one for which the three ther-

respectively? q paste

mal resistances are arranged in series, and the second by perature

3.34 Ring-poroususing a woods, distributions

conductive such if the

as at thermal

oak, thearechip/board contact inter-

characterized resistance

by is T(0), of theNucleoute

R # 10 "4

m 2

K/W . Steel

3.32for Physicists have determined the theoretical

which the three resistances are arranged in parallel. value of the grains.

face t,for!

The dark

c which R$ grains

! " 10 # 5

consist m 2

! of

K/W? very low-density

t, c 3.80 Consider cylindrica

thermal conductivity of a carbon nanotube to be kcn,T ! material

3.88 that forms

Consider uniform early in the energy

thermal springtime. generation TheT∞sur-

3.28 Two stainless steel plates 10 mm thick are subjected to inside

a a outer surfaces at r1

5000 W/m ! K. rounding lighter-colored wood is of composed of Lhigh- Insulation

contactone-dimensional

pressure of 1 barplane underwall vacuumthickness conditions for with one peratures Ts,1 and T

Contact Resistance

(a) Assuming the actual thermal conductivity of the density material that forms slowly throughout most of

which surface

there isheld an at Ts,1 and

overall the other surface

temperature drop ofinsulated. 100!C heat generation with

carbon nanotube is the same as its theoretical value, the growing season. b

3.26 A composite wall separates combustion gases at across the(a)Obtain

plates.

Find an aWhat

general is the

expression expression

heat

for flux for the the

through

the conduction substrate

plates?

heat fluxtempera-

to the the steady-state, o

find the thermal contact resistance, Rt,c, that exists What is the turecold distribution

temperature

surface and dropand

theacrossevaluate

Wood the

temperaturegrain the

contactofsurface

plane?

(low-density)

the temperature

hot surface Ts,2, of the temperature,

2600!C from a liquid coolant at 100!C, with gas- and

between the carbon nanotube and the top surfaces of the heat source for q " 4 W. . your results with tho

liquid-side convection coefficients of 50 and 1000 3.29 Consider aexpressing your results

plane composite wall that is composed of in terms of k, q , L, and T s,1.

2of the heated and sensing islands in Example 3.4 . (a) Obtain an equatio

W/m ! K. The wall is composed of a 10-mm-thick layer two materials

(b) Compare of thermal the heat conductivities

flux foundkin A "part 0.1(a) W/m with ! Kthe heat T(x) in the nucl

of(b) Using the

beryllium oxidevalue on ofthethe gasthermal

side andcontact resistance

a 20-mm-thick and kB " 0.04 fluxW/m associated! K andwith thicknesses

a plane wall LA " without10 mmenergy and gen- .

terms of q, kƒ, L, b

You might also like

- Understanding The Neher-McGrath Calculation and The Ampacity of ConductorsDocument7 pagesUnderstanding The Neher-McGrath Calculation and The Ampacity of ConductorsbhaskarinvuNo ratings yet

- Average Power-Handling Capability of Microstrip Lines: I.J.Bahland K.C.GuptaDocument4 pagesAverage Power-Handling Capability of Microstrip Lines: I.J.Bahland K.C.Guptatrance 2k17No ratings yet

- R26 Wire Current Density and ResistivityDocument1 pageR26 Wire Current Density and ResistivityTony Maldonado PinzonNo ratings yet

- Control of Uniformity in Rotational Moulding HeatingDocument4 pagesControl of Uniformity in Rotational Moulding HeatingWajidNo ratings yet

- Mmce 1046Document11 pagesMmce 1046YumnaNo ratings yet

- ConductionDocument4 pagesConductionjaibalayyaNo ratings yet

- Rating of Cables On Riser Poles, in Trays, in Tunnels and Shafts-A Review PDFDocument9 pagesRating of Cables On Riser Poles, in Trays, in Tunnels and Shafts-A Review PDFStefanos DiamantisNo ratings yet

- Ejercicios TransferenciaDocument5 pagesEjercicios TransferenciaPablo RuizNo ratings yet

- Design of Planar Power Transformers: A Fast and Easy Method for Layout and Thermal AnalysisDocument16 pagesDesign of Planar Power Transformers: A Fast and Easy Method for Layout and Thermal AnalysisParag RekhiNo ratings yet

- Thermal Design of 25ka Current Injection Transformer (CIT) With Finite Element MethodDocument6 pagesThermal Design of 25ka Current Injection Transformer (CIT) With Finite Element MethodConstantin DorinelNo ratings yet

- Hear Engine Oct-2023Document3 pagesHear Engine Oct-2023Saurabh Kumar ThakurNo ratings yet

- Heat Transfer April2003 NR 320305Document8 pagesHeat Transfer April2003 NR 320305Nizam Institute of Engineering and Technology LibraryNo ratings yet

- HT TUT2 SolutionDocument9 pagesHT TUT2 SolutionAsim UstadNo ratings yet

- Heat P 2019Document5 pagesHeat P 2019JakeNo ratings yet

- 21, Rue D'artois, F-75008 PARIS: CIGRE 2012Document8 pages21, Rue D'artois, F-75008 PARIS: CIGRE 2012Hugh EdwardsNo ratings yet

- 1 s2.0 0020708X85902558 MainDocument4 pages1 s2.0 0020708X85902558 MainasdfNo ratings yet

- Ybco Superconductor Characterization Under Shear StrainDocument4 pagesYbco Superconductor Characterization Under Shear StrainRiddhesh PatelNo ratings yet

- Tutorial 2Document0 pagesTutorial 2xhotdogzxNo ratings yet

- BTech Heat and Mass Transfer Theory Exam QuestionsDocument2 pagesBTech Heat and Mass Transfer Theory Exam QuestionsSuryaNo ratings yet

- Heat Transfer: Lecture 27: Natural ConvectionDocument8 pagesHeat Transfer: Lecture 27: Natural ConvectionDavico MartinezNo ratings yet

- Calculation of Eddy Current Field in The Ascending Flange For The Bushings and Tank Wall of A Large Power TransformerDocument4 pagesCalculation of Eddy Current Field in The Ascending Flange For The Bushings and Tank Wall of A Large Power TransformerDante FilhoNo ratings yet

- 6407 English IranArze PDFDocument6 pages6407 English IranArze PDFkesavaganesan58No ratings yet

- Dimple Jacket Heat Transfer Estimation PDFDocument3 pagesDimple Jacket Heat Transfer Estimation PDFicingrockNo ratings yet

- Ampacity of Cables in Solid Bottom Trays With and Without CoversDocument4 pagesAmpacity of Cables in Solid Bottom Trays With and Without CoversStefanos DiamantisNo ratings yet

- Taller de Problemas de Transferencia de CalorDocument3 pagesTaller de Problemas de Transferencia de CalorAna Karina Suaste EspadasNo ratings yet

- heat transfer homework3-2Document4 pagesheat transfer homework3-2ipns109010010No ratings yet

- Cahill 1990Document8 pagesCahill 1990Triều Huỳnh NhậtNo ratings yet

- ACSR Conductor SelectionDocument12 pagesACSR Conductor SelectionSushant ChauguleNo ratings yet

- Heat Transfer Nov2002 NR 310803Document6 pagesHeat Transfer Nov2002 NR 310803Nizam Institute of Engineering and Technology LibraryNo ratings yet

- HeatTransfer FluidBOOKFrankPInntalsofheatandmasstransfer2007 73Document1 pageHeatTransfer FluidBOOKFrankPInntalsofheatandmasstransfer2007 73SushilGuptaNo ratings yet

- Gauss LawDocument4 pagesGauss Lawp_k_soni_iit_physicsNo ratings yet

- Comparison of Finite-Element and IEC Methods For Cable Thermal Analysis Under Various Operating Environments (Kady2014)Document6 pagesComparison of Finite-Element and IEC Methods For Cable Thermal Analysis Under Various Operating Environments (Kady2014)daegerteNo ratings yet

- Eddy current losses in distribution transformer cover platesDocument6 pagesEddy current losses in distribution transformer cover platesCahya AdinotoNo ratings yet

- Heat Transfer Efficiency of Metal Honeycombs - KopyaDocument10 pagesHeat Transfer Efficiency of Metal Honeycombs - KopyaAli DoğruNo ratings yet

- Chapter2 v2 3 PubfDocument22 pagesChapter2 v2 3 PubfMahmoud AlaaNo ratings yet

- Composites Science and Technology: H. Daniel Wagner, P.M. Ajayan, Karl SchulteDocument7 pagesComposites Science and Technology: H. Daniel Wagner, P.M. Ajayan, Karl SchulteVidhya EVidhyaNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentNripesh PokhrelNo ratings yet

- Ampacidad Elementos FinitosDocument5 pagesAmpacidad Elementos FinitosNicolas MontalvoNo ratings yet

- Thermally-Electrically Tunable Coherent Terahertz Perfect AbsorberDocument4 pagesThermally-Electrically Tunable Coherent Terahertz Perfect AbsorberGergő BárdosNo ratings yet

- Heat Transfer May2004 NR 320305Document8 pagesHeat Transfer May2004 NR 320305Nizam Institute of Engineering and Technology LibraryNo ratings yet

- NIST RSI Thermal Fatigue KellerDocument8 pagesNIST RSI Thermal Fatigue KellerMido KamalNo ratings yet

- Determine Number of Earthing Electrodes Pipes StripsDocument9 pagesDetermine Number of Earthing Electrodes Pipes StripsmerebookNo ratings yet

- Paper 8 - Additional Losses - Damper Winding - Hydrogenerators at Open-Circuit and Load Conditions - Traxler-SamekDocument7 pagesPaper 8 - Additional Losses - Damper Winding - Hydrogenerators at Open-Circuit and Load Conditions - Traxler-SamekNicolás NielsenNo ratings yet

- Heat Transfer From Finned SurfacesDocument81 pagesHeat Transfer From Finned SurfacesIsmail MughalNo ratings yet

- Elec9712-23 - Tutorial 1Document2 pagesElec9712-23 - Tutorial 1Rizanda LeihituNo ratings yet

- Engineering Mechanics Exam QuestionsDocument2 pagesEngineering Mechanics Exam QuestionsAshutosh IndNo ratings yet

- International Communications in Heat and Mass Transfer: S. Eiamsa-Ard, K. Wongcharee, S. SripattanapipatDocument9 pagesInternational Communications in Heat and Mass Transfer: S. Eiamsa-Ard, K. Wongcharee, S. SripattanapipatVenkat Rajesh AnapuNo ratings yet

- Jako201215239617482 PDFDocument5 pagesJako201215239617482 PDFStefano Babai MancinNo ratings yet

- Multiphysics Analysis of Busbars With Various Arrangements Under Short-Circuit Condition - IET JournalsDocument9 pagesMultiphysics Analysis of Busbars With Various Arrangements Under Short-Circuit Condition - IET JournalsfinolhNo ratings yet

- Report On Current Rating For MV LV CablesDocument3 pagesReport On Current Rating For MV LV Cableskunsridhar8901No ratings yet

- Jrproc 1958 286903Document4 pagesJrproc 1958 286903George AcostaNo ratings yet

- Numerical Simulations of Interrupted and Conventional Microchannel Heat SinksDocument12 pagesNumerical Simulations of Interrupted and Conventional Microchannel Heat SinksAnkit LonareNo ratings yet

- Current Distribution in Parallel HTS TapesDocument5 pagesCurrent Distribution in Parallel HTS TapesDante FilhoNo ratings yet

- Unit 3 (C) Pressure MeasurementDocument17 pagesUnit 3 (C) Pressure MeasurementFuzail AhmadNo ratings yet

- Thermal Conductivity Test for Insulating ConcreteDocument5 pagesThermal Conductivity Test for Insulating ConcreteFritz Gerald JimenoNo ratings yet

- 1Neher-McGrath Paper PDFDocument12 pages1Neher-McGrath Paper PDFmordelon468No ratings yet

- New Method For Calculating The Heating of ConductorDocument15 pagesNew Method For Calculating The Heating of ConductorBrent M. GannonNo ratings yet

- Heat and Mass TransferDocument2 pagesHeat and Mass Transferayansiddiqui7700No ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Rating: 4.5 out of 5 stars4.5/5 (5)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Examen Carlos Gonzalez PDFDocument1 pageExamen Carlos Gonzalez PDFCarlos Gonzalez ValarezoNo ratings yet

- Deber 3 Carlos GonzalezDocument7 pagesDeber 3 Carlos GonzalezCarlos Gonzalez ValarezoNo ratings yet

- Scanned Doc by TapScannerDocument1 pageScanned Doc by TapScannerCarlos Gonzalez ValarezoNo ratings yet

- ACU AutoCAD Exam Objectives 2016Document1 pageACU AutoCAD Exam Objectives 2016Felix ReveronNo ratings yet

- TapScanner Document ScanDocument2 pagesTapScanner Document ScanCarlos Gonzalez ValarezoNo ratings yet

- Dibujo2 Presentación1 PDFDocument1 pageDibujo2 Presentación1 PDFCarlos Gonzalez ValarezoNo ratings yet

- Since School: 3rd Course Final Review 1. Make Questions For The Following AnswersDocument4 pagesSince School: 3rd Course Final Review 1. Make Questions For The Following AnswersCarlos Gonzalez ValarezoNo ratings yet

- Coldplay LyricsDocument2 pagesColdplay LyricsCarlos Gonzalez ValarezoNo ratings yet

- Horario 2017aDocument6 pagesHorario 2017aCarlos Gonzalez ValarezoNo ratings yet

- Dibujo2 Presentación1Document1 pageDibujo2 Presentación1Carlos Gonzalez ValarezoNo ratings yet

- Diagrama Electrico 533DDocument2 pagesDiagrama Electrico 533DJordan RaveloNo ratings yet

- Shaper Machine GuideDocument6 pagesShaper Machine GuideChristian John Paul LijayanNo ratings yet

- Mech Micromachining ReportDocument21 pagesMech Micromachining ReportSWAPNALI KHANDARENo ratings yet

- UT (A) - CoE (XI) - Test-05 - Paper-2 - (Code-B) - (2022-24) - Compile (13-10-2022) - (2020-P-2) - (Only Que.)Document13 pagesUT (A) - CoE (XI) - Test-05 - Paper-2 - (Code-B) - (2022-24) - Compile (13-10-2022) - (2020-P-2) - (Only Que.)darling deanNo ratings yet

- Heriot-Watt University - Dubai Campus Pelton Wheel LabDocument8 pagesHeriot-Watt University - Dubai Campus Pelton Wheel LabAbelBayartNo ratings yet

- Spray Drying of Fruit and Vegetable Juices - A ReviewDocument66 pagesSpray Drying of Fruit and Vegetable Juices - A ReviewTantry Eko PutriNo ratings yet

- Introduction To Composite Materials-4 ModuleDocument48 pagesIntroduction To Composite Materials-4 Modulegagan devarajNo ratings yet

- Sencore LC103 Operation and Application ManualDocument65 pagesSencore LC103 Operation and Application ManualXenawise0% (1)

- Carbonate ClassificationDocument5 pagesCarbonate ClassificationArpit UpadhyayNo ratings yet

- Capillary ActionDocument13 pagesCapillary ActionEvelyn HernándezNo ratings yet

- Various Power Generation TechnologiesDocument2 pagesVarious Power Generation TechnologiesPhoon Hee YauNo ratings yet

- BC546B, BC547A, B, C, BC548B, C Amplifier Transistors: NPN SiliconDocument6 pagesBC546B, BC547A, B, C, BC548B, C Amplifier Transistors: NPN SiliconNadia Ayelen GonzalezNo ratings yet

- VSEPRDocument14 pagesVSEPRagraharirajiv33No ratings yet

- Animated ghumster characterDocument61 pagesAnimated ghumster characterramana VemsNo ratings yet

- Use of The Ultrasonic Time of Flight Diffraction (TOFD) TechniqueDocument12 pagesUse of The Ultrasonic Time of Flight Diffraction (TOFD) TechniqueWilson Alexander SantoNo ratings yet

- Volumen FinitoDocument11 pagesVolumen FinitoPablo Villalon DuarteNo ratings yet

- Engineering Mathematics IDocument3 pagesEngineering Mathematics INikash SubediNo ratings yet

- QP D15 De57 PDFDocument3 pagesQP D15 De57 PDFRajashekarBalyaNo ratings yet

- Delta Power Meter DPM Series: Automation For A Changing WorldDocument16 pagesDelta Power Meter DPM Series: Automation For A Changing WorldCarlos Alirio Vera ANo ratings yet

- Hydro Power PlantDocument8 pagesHydro Power PlantShailesh Sankdasariya67% (3)

- Holographic Data StorageDocument9 pagesHolographic Data Storagesamsaswat003No ratings yet

- PLU Civil Engineering Department Midterm Exam ReviewDocument7 pagesPLU Civil Engineering Department Midterm Exam ReviewhaniiramosNo ratings yet

- Toshiba g7 Operation Manual PDFDocument221 pagesToshiba g7 Operation Manual PDFyasseralkadasiNo ratings yet

- Chem 1Document12 pagesChem 1Ellaine NacisNo ratings yet

- MCQ in Differential Calculus (Limits and Derivatives) Part 1 - Math Board ExamDocument13 pagesMCQ in Differential Calculus (Limits and Derivatives) Part 1 - Math Board ExamAF Xal RoyNo ratings yet

- Bhamal Dugwell - EstimateDocument30 pagesBhamal Dugwell - EstimateOm ChauhanNo ratings yet

- Form and Position Tolerances: Tolerance Classes General Tolerances For Straightness and Flatness in MMDocument1 pageForm and Position Tolerances: Tolerance Classes General Tolerances For Straightness and Flatness in MMTrọng NgôNo ratings yet

- Obsolete Product(s) - Obsolete Product(s) : Quad Smart Power Solid State Relay For Complete H-Bridge ConfigurationsDocument33 pagesObsolete Product(s) - Obsolete Product(s) : Quad Smart Power Solid State Relay For Complete H-Bridge Configurationsmarino246No ratings yet

- 20W Photovoltaic Module: Built To LastDocument2 pages20W Photovoltaic Module: Built To LastKushalKallychurnNo ratings yet

- Acid-base titration of aspirinDocument4 pagesAcid-base titration of aspirinZari Sofia Leviste100% (1)