Professional Documents

Culture Documents

Cross Lap Worktop: Project Plan

Uploaded by

Armansyah HakimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cross Lap Worktop: Project Plan

Uploaded by

Armansyah HakimCopyright:

Available Formats

BUILD IT WITH

ROCKLER PROJECT PLAN

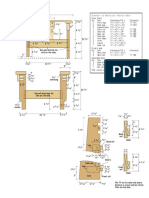

CROSS LAP WORKTOP

Shown on Rockler

Material Mate

Panel Cart and

Shop Stand (56889,

sold separately)

Torsion-box-style BUILD

construction gives

Stock # Item

this tabletop 21797 Baltic Birch Plywood,

strength and rigidity 1/2" x 12" x 60"

35623 Maple, 3/4" x 5" x 24"

without excessive 35385 Maple, 3/4" x 5" x 48"

weight. Building it is 46428 Maple Veneer Plywood,

easy with Rockler’s 1/4" x 24" x 48" QUESTIONS?

56372 Rockler Cross Lap Jig Go to www.rockler.com

innovative Cross Lap 56889 Material Mate Panel Cart or call 800-279-4441

Jig. Just add a stand and Shop Stand (optional)

and you’ve got a

custom work table. All items subject to changes in availability.

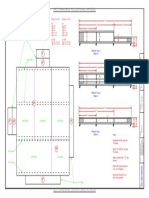

31/4" 1

/2" 31/4"

5

3

/4"

CROSS LAP WORKTOP PARTS

Long

/ " Slats

3

8

3

/4" 3

/4"

(Front View)

1

/4"

2 4

3

Frame Ends/Sides

3

/4" (Front View) 1

1

/4"

41/8" 1

/2" 41/8"

3

/8"

3

/8"

1

/4"

Short Slats

(Front View) 2

31/4" 1

/2" 31/4" 3

5 1

/4"

3

/4"

3

/8"

31/4" 1

/2" 31/4"

5

3

/4"

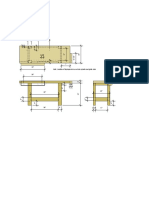

Exploded View

4

3

/4"

41/8" 1

/2"

1 41/8"

4 3

/4"

5

4 /8"

1 1

/2" 4

1

2

3

MATERIAL LIST

TxWxL

1 Plywood face (2) 1/4" x 223⁄4"x 463⁄4"

2 Frame Ends (2) 3/4" x 2" x 231⁄2"

3 Frame Sides (2) 3/4" x 2" x 471⁄2"

4 Long Slats (5) 1/2" x 11⁄2" x 46"

5 Short Slats (9) 1/2" x 11⁄2" x 22"

CROSS LAP WORKTOP | PAGE 2

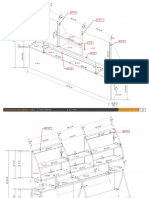

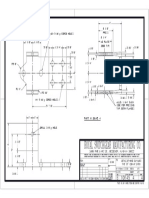

1. SET UP SAW AND MAKE TEST CUTS

Install a dado set in your table saw. Set the width of the dado stack to match the 1/2" thickness of the slats. Set

the cutting height to 3/4", which is half the width of the slats. Make test cuts on scrap pieces to test the fit of

the cross lap joint. Adjust the dado set height and width if the joint is not fitting properly. The pieces should seat

together snugly, and the top and bottom edges should be flush when the joint is assembled.

2. SET INDEXING KEYS ON CROSS LAP JIG

Set the width of the Cross Lap Jig indexing keys to match the thickness of the slats.

CROSS LAP WORKTOP | PAGE 3

d 3. SET JIG FENCE FOR SHORT SLATS

Adjust the jig fence so that the inside edge of the indexing keys is 31⁄4" from the edge of the dado set.

d 4. CUT FIRST NOTCH IN SHORT SLAT

Register the first Short Slat against the inside edge of the indexing keys. Cut the first cross lap notch.

CROSS LAP WORKTOP | PAGE 4

d 5. REPOSITION STOCK, CUT SECOND NOTCH

Position the first notch over the indexing keys and then cut the second notch.

d 6. CUT REMAINING NOTCHES IN SHORT SLATS

Continue to reposition each notch over the indexing keys and cut the remaining notches on the Short Slats. Each

Short Slat gets a total of five cross lap notches.

CROSS LAP WORKTOP | PAGE 5

d 7. SET JIG FENCE FOR LONG SLATS

Reposition the jig fence to cut the notches in the Long Slats. Position the fence so that the inside edge of the

indexing keys is 41⁄8" from the edge of the dado set. Leave the dado set at the same height.

d 8. CUT NOTCHES IN SHORT SLATS

Repeat the same cutting process to cut the nine notches in each Long Slat.

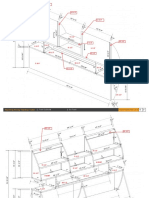

CROSS LAP WORKTOP | PAGE 6

d 9. CUT FRAME PIECES TO WIDTH AND LENGTH

Rip the maple frame parts to 2" wide. The lengths of the frame pieces listed on the materials list is an estimate.

Use your cross lap slats to determine the correct length of your frame pieces. Miter cut one end of each frame

piece. Then place a corresponding cross lap slat on the inside face of the frame piece. Align one end with the inside

of the miter cut (inset) and mark the other end. This mark will be the inside of the miter cut. Miter cut the other

end slightly outside the mark and then check the fit. If it is too long, trim a little off to creep up on the length. Be

careful not to cut the frame parts too short or the miters will not close.

10. CUT RABBETS IN FRAME PIECES

Set up your dado set to 1/4" wide. Attach a sacrificial fence to your table saw fence. Position the dado set flush

with the sacrificial fence. Set the dado set blade height to 3/8". Cut the rabbets in each frame piece.

CROSS LAP WORKTOP | PAGE 7

d 11. GLUE THE CROSS LAP JOINTS

Apply glue to the notches and bring the slats together. Then assemble the frame around the cross lap slats. Check

complete assembly for square by measuring across the diagonals.

12. GLUE PLYWOOD FACES

Attach the mitered frame pieces to the cross lap assembly after the glue has cured. Use a piece of 1/4" plywood

as a spacer to elevate the cross lap assembly, making it easier to align the frame pieces. Apply glue to the ends of

the cross lap slats and to the mitered ends of the frame pieces. Clamp the frame pieces to the cross lap assembly.

Finally, secure the plywood faces to the cross lap frame. Apply glue to the edges of the cross lap slats and along

the rabbets in the frame pieces. Press one plywood piece onto the cross laps. Then flip the assembly and repeat the

glue up for the second plywood face.

CROSS LAP WORKTOP | PAGE 8

d 13. CLAMP PLYWOOD FACES

Clamp the plywood faces, using battens to distribute the pressure across the plywood.

CROSS LAP WORKTOP | PAGE 9

You might also like

- Ball - Backwards and ForwardsDocument108 pagesBall - Backwards and Forwardsg5568g2h100% (1)

- Moonwalk by Michael Jackson - ExcerptDocument11 pagesMoonwalk by Michael Jackson - ExcerptCrown Publishing Group27% (52)

- YAMAHA - Trumpet, Cornet & Flugel Horn SERIAL NUMBER Database Submission FormDocument14 pagesYAMAHA - Trumpet, Cornet & Flugel Horn SERIAL NUMBER Database Submission FormEugenio Tinnirello38% (8)

- Firearms - Blueprint - Sten MK III Sub Machine Gun Receiver BondDocument1 pageFirearms - Blueprint - Sten MK III Sub Machine Gun Receiver Bondanjan971% (14)

- Hardware List: Leveling RiserDocument1 pageHardware List: Leveling Riserkosta vidaliNo ratings yet

- 3-4 Wooden Rabbet Plane Plans by Caleb James 3 - 25 - 13 PDFDocument1 page3-4 Wooden Rabbet Plane Plans by Caleb James 3 - 25 - 13 PDFChrisNo ratings yet

- Web Accessibility HandbookDocument109 pagesWeb Accessibility HandbookArmansyah HakimNo ratings yet

- Music As A Source of Emotion in FilmDocument13 pagesMusic As A Source of Emotion in FilmMarina NikolicNo ratings yet

- 32 Ford CoupeDocument6 pages32 Ford CoupeDominique Voirin0% (1)

- I Can Do That! Woodworking Projects ExportDocument2 pagesI Can Do That! Woodworking Projects ExportAnakin SkywalkerNo ratings yet

- MorrischairDocument1 pageMorrischairjimmer_9No ratings yet

- Golfcaddy PDFDocument1 pageGolfcaddy PDFC BoothNo ratings yet

- Cute Sheep: Sheep Crochet Process Description by Guzel KhairutdinovaDocument14 pagesCute Sheep: Sheep Crochet Process Description by Guzel KhairutdinovaCreative Crochet100% (6)

- JEFFERSON Arts X Crafts CactusDocument5 pagesJEFFERSON Arts X Crafts CactusElizabeth Cruz Muthe100% (1)

- Paddle Blind Thickness Chart Asme Dimensions 11x17Document1 pagePaddle Blind Thickness Chart Asme Dimensions 11x17tekstep7No ratings yet

- Morrischair PDFDocument1 pageMorrischair PDFkosta vidaliNo ratings yet

- Roll Out Bed PlansDocument12 pagesRoll Out Bed PlansAdorjan Sandor Zoltan100% (1)

- Creative Nonfiction Module 2 Week 5 & 6Document8 pagesCreative Nonfiction Module 2 Week 5 & 6Arnold100% (4)

- Primary Eng Paper 1 PDFDocument114 pagesPrimary Eng Paper 1 PDFAgata Dziedzic-KallidouNo ratings yet

- Garrison Rod BinderDocument1 pageGarrison Rod BinderFernando ChaparroNo ratings yet

- 134 Int ST Hilarion School Hallway Hall Plug TN Issued 20211130Document2 pages134 Int ST Hilarion School Hallway Hall Plug TN Issued 20211130api-455371619No ratings yet

- Bar Tool Rack Plan LRDocument7 pagesBar Tool Rack Plan LRbumimanusiaNo ratings yet

- Estructuras: Tale Constructora SacDocument1 pageEstructuras: Tale Constructora SacSA ZNo ratings yet

- Modelos de TejaDocument2 pagesModelos de TejaYessenia LagosNo ratings yet

- Silverware Chest Plan DrawingsDocument1 pageSilverware Chest Plan DrawingsPenis Launcher100% (1)

- LunchRide-Folding Adjustable Ramp PlansDocument18 pagesLunchRide-Folding Adjustable Ramp PlansloganbrewNo ratings yet

- Front Cabinets Iso Front: Wyoming Woody Teardrop TrailerDocument11 pagesFront Cabinets Iso Front: Wyoming Woody Teardrop TrailerFrancois Landry100% (1)

- Front Cabinets Iso Front: Wyoming Woody Teardrop TrailerDocument11 pagesFront Cabinets Iso Front: Wyoming Woody Teardrop TrailerFrancois LandryNo ratings yet

- Kreg Jig Cabinet: Front Brace Left SideDocument10 pagesKreg Jig Cabinet: Front Brace Left SideRodrigo Miranda100% (1)

- مبنى الساحات-Layout1Document1 pageمبنى الساحات-Layout1Kareem Abo SeifNo ratings yet

- Anti Backlash Nut: Sled PartsDocument1 pageAnti Backlash Nut: Sled PartsNando LimaNo ratings yet

- Anti Backlash Nut: Sled PartsDocument1 pageAnti Backlash Nut: Sled PartsZafer ÜlküNo ratings yet

- 2 X 48" Horizontal Grinder Base Plate (Screw/tap/hole) Diagram Plans (Note, Blocks Are Laid Out in 1"x1" Squares) LegendDocument1 page2 X 48" Horizontal Grinder Base Plate (Screw/tap/hole) Diagram Plans (Note, Blocks Are Laid Out in 1"x1" Squares) Legendkkd108No ratings yet

- Prime: Details That Stand OutDocument16 pagesPrime: Details That Stand OutJessica Louraine Byron EugenioNo ratings yet

- Cs PlatformDocument1 pageCs Platformapi-319390606No ratings yet

- Purlin ClipDocument1 pagePurlin Clipanthonyhewitt250No ratings yet

- DYNA FLO - FH1-1-AG (CP10) - ModelDocument1 pageDYNA FLO - FH1-1-AG (CP10) - ModelHernan RomeroNo ratings yet

- Mailbox Bungalow PDFDocument1 pageMailbox Bungalow PDFkosta vidaliNo ratings yet

- BiblioecaDocument1 pageBiblioecaMario Sebastián MartínezNo ratings yet

- Canned Food DispenserDocument9 pagesCanned Food DispenserInteritusdeiNo ratings yet

- Holtzapffel-Style Workbench Drawing by Christopher Schwarz September 2008, Knockdown VersionDocument2 pagesHoltzapffel-Style Workbench Drawing by Christopher Schwarz September 2008, Knockdown VersionRod HyattNo ratings yet

- Bevins Sailing Rig v3Document1 pageBevins Sailing Rig v3Handmade Results TestNo ratings yet

- CW June09 MuskokaDocument1 pageCW June09 MuskokaChris EfstathiouNo ratings yet

- PetersonDocument1 pagePetersonSemelengua LatrabaNo ratings yet

- Sierra de MesaDocument5 pagesSierra de MesaJunior L. SirculiandoNo ratings yet

- Your Leftside Looking at Backside of Hitch Your Rightside Hitch Rightside Hitch LeftsideDocument4 pagesYour Leftside Looking at Backside of Hitch Your Rightside Hitch Rightside Hitch Leftsideapi-3820466No ratings yet

- PS329 - AEP - Trims and Flashings GuideDocument5 pagesPS329 - AEP - Trims and Flashings GuideMirza AliNo ratings yet

- 3 Frame Mini Mating Nuc: Scale - 1" 3"Document3 pages3 Frame Mini Mating Nuc: Scale - 1" 3"WolfgangNo ratings yet

- Base-Mount Ac Motor: Number © 2015 Mcmaster-Carr Supply CompanyDocument1 pageBase-Mount Ac Motor: Number © 2015 Mcmaster-Carr Supply CompanydanishNo ratings yet

- Wall DeskDocument1 pageWall DeskAjay VishwanathNo ratings yet

- CARPINTARIA-MESA DE EXTERIOR (Desenhos) - ShopfixDocument5 pagesCARPINTARIA-MESA DE EXTERIOR (Desenhos) - ShopfixCarlos Ochoa CorreiaNo ratings yet

- Design Aid 6.15.3 Minimum Length of Weld To Develop Full Strength of Bar. Weld Parallel To Bar LengthDocument1 pageDesign Aid 6.15.3 Minimum Length of Weld To Develop Full Strength of Bar. Weld Parallel To Bar LengthbrettNo ratings yet

- Royal Switchgear Manufacturing Co.: PART # 10645-4Document1 pageRoyal Switchgear Manufacturing Co.: PART # 10645-4sagar ramaniNo ratings yet

- We Ride South Bottom PlateDocument1 pageWe Ride South Bottom PlatealbertofrogNo ratings yet

- We Ride South Top PlateDocument1 pageWe Ride South Top PlatealbertofrogNo ratings yet

- TechdwgcyreneDocument1 pageTechdwgcyreneDerek JohnsonNo ratings yet

- Bulkhead BinderDocument114 pagesBulkhead BinderWilliam ProvidoNo ratings yet

- Anuire EditableDocument1 pageAnuire EditableRichard HastingsNo ratings yet

- Ss Stub TypesDocument1 pageSs Stub Typeslambu_ladNo ratings yet

- Standard Dimensions of Spectacle Blind - 8 Blind - EnggCyclopedia PDFDocument12 pagesStandard Dimensions of Spectacle Blind - 8 Blind - EnggCyclopedia PDFMohamed AdelNo ratings yet

- Escritorio PortatilDocument1 pageEscritorio PortatilJorge Luis Rivasplata ZevallosNo ratings yet

- CLI - S - CARLOS-ARC - Proposta de Mudança condensadoras-DETALHES1Document1 pageCLI - S - CARLOS-ARC - Proposta de Mudança condensadoras-DETALHES1mendoncasegundoNo ratings yet

- Y Strainer In Brass Pn 20 Filtration 500 Μm Connections: Female-FemaleDocument2 pagesY Strainer In Brass Pn 20 Filtration 500 Μm Connections: Female-FemalewodrNo ratings yet

- Niagahoster ProCamp - Product IntroductionDocument8 pagesNiagahoster ProCamp - Product IntroductionArmansyah HakimNo ratings yet

- Accessibility Testing Tutorial HandoutsDocument2 pagesAccessibility Testing Tutorial HandoutsArmansyah HakimNo ratings yet

- AccessibilityHeuristics 20190516 FinalDocument2 pagesAccessibilityHeuristics 20190516 FinalArmansyah HakimNo ratings yet

- Modernism and PostmodernismDocument18 pagesModernism and PostmodernismFitra AndanaNo ratings yet

- GiladRatman CatalogueDocument117 pagesGiladRatman CatalogueGabriel Felipe Angel EscobarNo ratings yet

- Colours Show MoodDocument2 pagesColours Show MoodSuraya NordinNo ratings yet

- Koutou Katoa RaDocument1 pageKoutou Katoa RaMariana KapoorNo ratings yet

- ZeebraDocument10 pagesZeebraBallon DopeNo ratings yet

- Heinrich Domnich and The Natural HornDocument4 pagesHeinrich Domnich and The Natural HornredxdevilNo ratings yet

- A Modernist Approach To Eliot (Essay)Document9 pagesA Modernist Approach To Eliot (Essay)Blast ReportNo ratings yet

- À L'Orientale: Francine Giese, Mercedes Volait and Ariane Varela Braga - 978-90-04-41264-4 Via Mcgill UniversityDocument240 pagesÀ L'Orientale: Francine Giese, Mercedes Volait and Ariane Varela Braga - 978-90-04-41264-4 Via Mcgill UniversityHakanBulutNo ratings yet

- Week 4 - National Living TreasuresDocument45 pagesWeek 4 - National Living TreasuresKim DizonNo ratings yet

- A CITY'S DEATH BY FIRE . Derek WalcottDocument5 pagesA CITY'S DEATH BY FIRE . Derek WalcottSehna SerajNo ratings yet

- Sebarkan Wartanya NKB 102Document2 pagesSebarkan Wartanya NKB 102Icha NathaniaNo ratings yet

- Hand Printing: Chloe JacksDocument13 pagesHand Printing: Chloe JackschloejacksNo ratings yet

- February, 1888Document1 pageFebruary, 1888Apreal Jhoy Fernandez67% (3)

- ApostolosCappadona SPACEIMAGEWORD 2013Document19 pagesApostolosCappadona SPACEIMAGEWORD 2013Liane BencuyaNo ratings yet

- ST Takla Org Books Helmy Elkommos Bible Gospel Top HTMLDocument11 pagesST Takla Org Books Helmy Elkommos Bible Gospel Top HTMLAbdulHamid MuhammadNo ratings yet

- Minoru Yamasaki: Grace Henry S1S2 B.Arch Roll No 61017Document32 pagesMinoru Yamasaki: Grace Henry S1S2 B.Arch Roll No 61017Grace HenryNo ratings yet

- MC Wall: Curtain Wall System For Traditional and Semi Structural Curtain Walls With Thermal BreakDocument4 pagesMC Wall: Curtain Wall System For Traditional and Semi Structural Curtain Walls With Thermal BreakSara HusejnovicNo ratings yet

- Elements of Narrative CriticismDocument6 pagesElements of Narrative Criticismcorne.g.zaNo ratings yet

- KONO SUBARASHII SEKAI NI SHUKUFUKU WO - OUCHI NI KAERITAI CHORDS by Misc CarDocument5 pagesKONO SUBARASHII SEKAI NI SHUKUFUKU WO - OUCHI NI KAERITAI CHORDS by Misc CarAditNo ratings yet

- Av Script Star WarsDocument12 pagesAv Script Star Warsapi-691476902No ratings yet

- Assignment No. 5 (Mode of Limited Transposition) - Post Tonal Analysis - Vianny Esquivel FloresDocument1 pageAssignment No. 5 (Mode of Limited Transposition) - Post Tonal Analysis - Vianny Esquivel Floresvianny esquivelNo ratings yet

- Wonders of The World PDFDocument27 pagesWonders of The World PDFRathiarasi RamasamyNo ratings yet