Professional Documents

Culture Documents

Product Design Engineering - II Syllabus

Uploaded by

Sudeep UpadhyeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Design Engineering - II Syllabus

Uploaded by

Sudeep UpadhyeCopyright:

Available Formats

1. R. K. Jain, “Engineering Metrology”, Khanna Publications, 17th edition, 1975.

2. K. J. Hume, “Engineering Metrology”, McDonald Publications, 1st edition, 1950.

3. A. W. Judge, “Engineering Precision Measurements”, Chapman and Hall, London, 1957.

4. K. L. Narayana, “Engineering Metrology”, Scitech Publications, 2nd edition.

5. J. F. Galyer, C. R. Shotbolt, “Metrology for Engineers”, Little-hampton Book Services

Ltd., 5th edition, 1969.

6. V. A. Kulkarni, A. K. Bewoor, “Metrology & Measurements”, Tata McGraw Hill Co.

Ltd., 1st edition, 2009.

7. AmitavaMitra, “Fundamental of Quality Control and Improvement”, Wiley Publication.

8. V. A. Kulkarni, A. K. Bewoor, “Quality Control”, Wiley India Publication, 01st August,

2009.

9. Richard S. Figliola, D. E. Beasley, “Theory and Design for Mechanical Measurements”,

Wiley India Publication.

10. E. L. Grant, “Statistical Quality Control”, Tata McGraw Hill Publications.

11. J. M. Juran, “Quality Planning and Analysis”, Tata McGraw Hill Publications.

Product Design Engineering - II

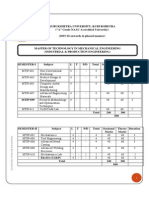

BTID506 PCC 17 Product Design Engineering - II 1-0-2 2 Credits

Teaching Scheme: Examination Scheme:

Lecture-cum-demonstration: 1 hr/week Continuous Assessment: 60 Marks

Design Studio/Practical: 2 hrs/week End Semester Exam: 40 Marks

Pre-requisites:

Product Design Engineering: Part-I, Basic Knowledge of electronics, electrical, computer and

Information Technology

Design Studio/Practical: 2 hrs to develop design sketching and practical skills

Continuous Assessment: Progress through a product design and documentation of

steps in the selected product design

End Semester Assessment: Product Design in Studio with final product

specifications

Course Outcomes: At the end of the course, students will be able to

1.Create prototypes

2. Test the prototypes

3. Understand the product life cycle management

Unit 1: Testing and Evaluation

Prototyping, Design Automation,Product architecture,Prototype testing and evaluation,

Working in multidisciplinary teams, Feedback to design processes, Process safety and

materials,Health and hazard of process operations.

Unit 2: Embedded Engineering- User Interface

Firmware and Hardware Design,UI programming, Algorithm and Logic Development,

Schematic and PCB layout, Testing and Debugging.

Unit 3: Manufacturing

Design models and digital tools, Decision models, Prepare documents for

manufacturing in standard format, Materials and safety data sheet, Final Product

specifications sheet,Detail Engineering Drawings (CAD/CAM programming),

Manufacturing for scale,Design/identification of manufacturing processes.

Unit 4: Environmental Concerns

Product life-cycle management, Disposal of product and waste.

Hands-on Activity Charts for Use of Digital Tools

Hrs.

Activity 1 Prototyping/Assembly 4

Activity 2 Testing and evaluation 3

Activity 3 UI Programming 3

Activity 4 PCB Layout, Testing and debugging 3

Activity 5 CNC Programming 3

Activity 6 CNC Programming with CAM software 3

Activity 7 Product market and Product Specification Sheet 3

Activity 8 Documentation for the product 2

References:

1.Model Curriculum for “Product Design Engineer – Mechanical”, NASSCOM (Ref. ID:

SSC/Q4201, Version 1.0, NSQF Level: 7)

2. Eppinger, S., & Ulrich, K.(2015). Product design and development, McGraw-Hill

Higher Education.

3. Green, W., & Jordan, P. W. (Eds.).(1999), Human factors in product design: current

practice and future trends. CRC Press.

4. Sanders, M. S., & McCormick, E. J. (1993), Human factors in engineering and design.

McGRAW-HILLBook Company.

5. Roozenburg, N. F., &Eekels, J. (1995), Product design: Fundamentals and Methods

(Vol. 2). John Wiley & Sons Inc.

6. Lidwell, W., Holden, K., & Butler, J.(2010), Universal principles of designs, revised

and updated: 125 ways to enhance usability, influence perception, increase appeal,

make better design decisions, and teach through design. Rockport Publication.

Automobile Engineering

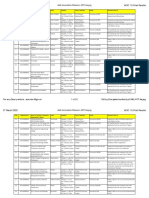

BTMEC506A OEC 2 Automobile Engineering 3-0-0 Audit

Teaching Scheme: Examination Scheme:

Lecture: 3 hrs/week Audit Course

Pre-Requisites: None

Course Outcomes: At the end of the course, students will be able to:

CO1 Identify the different parts of the automobile.

CO2 Explain the working of various parts like engine, transmission, clutch, brakes etc.,

CO3 Demonstrate various types of drive systems.

CO4 Apply vehicle troubleshooting and maintenance procedures.

Analyze the environmental implications of automobile emissions. And suggest

CO5

suitable regulatory modifications.

CO6 Evaluate future developments in the automobile technology.

Mapping of course outcomes with program outcomes

Course Program Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12

CO1 2 1

CO2 1 2 2 1

CO3 1 1 1 1

CO4 2 3 1

CO5 2 1 1 2

CO6 1 2 2

Course Contents:

Unit 1: Introduction

Vehicle specifications, Classifications, Chassis layout, Frame, Main components of

automobile and articulated vehicles; Engine-cylinder arrangements, Power requirements,

Tractive efforts and vehicle performance curves.

Unit 2: Steering and Suspension Systems

Steering system; Principle of steering, Centre point steering, Steeringlinkages, Steering

geometry and wheel alignment, power steering.

Suspension system: its need and types, Independent suspension, coil and leaf springs,

Suspension systems for multi-axle vehicles, troubleshooting and remedies.

Unit 3: Transmission System

Clutch: its need and types, Gearboxes: Types of gear transmission, Shift mechanisms,

Over running clutch, Fluid coupling and torque converters, Transmission universal joint,

Propeller shaft, Front and rear axles types, Stub axles, Differential and its types, Four wheel

drive.

Unit 4: Brakes, Wheels and Tyres

Brake: its need and types: Mechanical, hydraulic and pneumatic brakes, Disc and drum type:

You might also like

- Automotive Electrical & Electronics CourseDocument12 pagesAutomotive Electrical & Electronics CourseSumit VermaNo ratings yet

- Anna University ME Product Design and Development CurriculumDocument10 pagesAnna University ME Product Design and Development Curriculumelango_mm3307No ratings yet

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesRating: 4 out of 5 stars4/5 (4)

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsFrom EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsNo ratings yet

- M.E. Mech (Prod Des & Devp)Document41 pagesM.E. Mech (Prod Des & Devp)Peter PushpanathanNo ratings yet

- Conveyor Belt Design For Bottling Plant of Coca ColaDocument118 pagesConveyor Belt Design For Bottling Plant of Coca Colavivekpattni50% (4)

- Software Engineering: Architecture-driven Software DevelopmentFrom EverandSoftware Engineering: Architecture-driven Software DevelopmentRating: 4.5 out of 5 stars4.5/5 (6)

- MCE 417 Course CompactDocument7 pagesMCE 417 Course CompactKEHINDE BABALOLANo ratings yet

- Mechanical Engineering SyllabusDocument3 pagesMechanical Engineering SyllabusVikram BorkhediyaNo ratings yet

- 18ME62Document263 pages18ME62Action Cut EntertainmentNo ratings yet

- Dit 0401 Software EngineeringDocument1 pageDit 0401 Software Engineeringvictor.wachira2022No ratings yet

- ME403 Production & Operation Management SyllabusDocument6 pagesME403 Production & Operation Management SyllabusGajanan Shankarrao PatangeNo ratings yet

- FALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 14-Jul-2020 SyllabusDocument3 pagesFALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 14-Jul-2020 SyllabusJawa freakNo ratings yet

- 6th Sem - 7 - Mechanical Engineering - 2 PDFDocument39 pages6th Sem - 7 - Mechanical Engineering - 2 PDFfotickNo ratings yet

- ME-406 Manufacturing and DesignDocument2 pagesME-406 Manufacturing and DesignFaraz JamshaidNo ratings yet

- B.E. Automobile Engineering Course DocumentsDocument73 pagesB.E. Automobile Engineering Course Documentssss0987654321No ratings yet

- Product Performance Evaluation using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Performance Evaluation using CAD/CAE: The Computer Aided Engineering Design SeriesNo ratings yet

- L0 MEC205 Zero Lecture UpdatedDocument42 pagesL0 MEC205 Zero Lecture UpdatedJames PrakashNo ratings yet

- Cse3005 Software-Engineering LT 1.0 1 Cse3005Document2 pagesCse3005 Software-Engineering LT 1.0 1 Cse3005vivekparasharNo ratings yet

- Engineering and DesignDocument52 pagesEngineering and DesignsaiNo ratings yet

- Honours CurriculumDocument13 pagesHonours CurriculumJOIJODENo ratings yet

- CIM Course PlanDocument8 pagesCIM Course PlanKamal Vijay Ram R SNo ratings yet

- Automobile Engineering Course DescriptionDocument21 pagesAutomobile Engineering Course DescriptionVpr NaturalsNo ratings yet

- GTU TECHNOLOGICAL UNIVERSITY MACHINE TOOL DESIGNDocument3 pagesGTU TECHNOLOGICAL UNIVERSITY MACHINE TOOL DESIGNDipen RavalNo ratings yet

- SE Software Engineering and Testing at Vidyavardhaka CollegeDocument3 pagesSE Software Engineering and Testing at Vidyavardhaka CollegeELAINE M PAILY CSNo ratings yet

- Ilo PDFDocument18 pagesIlo PDFParnab Shan100% (1)

- Mec531 IntroductionDocument14 pagesMec531 IntroductionMuhammad ZulhilmiNo ratings yet

- Mechanical Engineering Department Scheme of Examination M. Tech. (Product Design and DevelopmentDocument7 pagesMechanical Engineering Department Scheme of Examination M. Tech. (Product Design and Developmentharshottam2977No ratings yet

- Me Manufacturing Curriculum-2Document11 pagesMe Manufacturing Curriculum-2Arun KumarNo ratings yet

- Machine Design NotesDocument349 pagesMachine Design NotesAkshay More100% (1)

- BMM 4623 Mechanical System Design - Rev01 July 31, 2013Document6 pagesBMM 4623 Mechanical System Design - Rev01 July 31, 2013huszsNo ratings yet

- Up and Running with AutoCAD 2012: 2D Drawing and ModelingFrom EverandUp and Running with AutoCAD 2012: 2D Drawing and ModelingRating: 3.5 out of 5 stars3.5/5 (3)

- From Project to Production: The Commonwealth and International Library: Social Administration, Training Economics, and Production DivisionFrom EverandFrom Project to Production: The Commonwealth and International Library: Social Administration, Training Economics, and Production DivisionNo ratings yet

- Precise SyllabusDocument11 pagesPrecise SyllabusDaniel ChapmanNo ratings yet

- GTU Mechanical Engineering Course on Design for ManufacturingDocument3 pagesGTU Mechanical Engineering Course on Design for ManufacturingfalgunNo ratings yet

- Nirma University Institute of Technology School of EngineeringDocument30 pagesNirma University Institute of Technology School of EngineeringKarthikeyanNo ratings yet

- MNIT Jaipur Mechanical Engineering SyllabusDocument9 pagesMNIT Jaipur Mechanical Engineering SyllabusRana SinghNo ratings yet

- Sem 2Document11 pagesSem 2jtsrinivasdownNo ratings yet

- Mp482 Product Development and Design (Careeryuga)Document2 pagesMp482 Product Development and Design (Careeryuga)Subahani HaneefaNo ratings yet

- Model-Driven Software Development: Technology, Engineering, ManagementFrom EverandModel-Driven Software Development: Technology, Engineering, ManagementRating: 4 out of 5 stars4/5 (3)

- Bmee301l Design-Of-Machine-Elements TH 1.0 67 Bmee301lDocument3 pagesBmee301l Design-Of-Machine-Elements TH 1.0 67 Bmee301lKrijayNo ratings yet

- Mee6015 Additive-Manufacturing-Technology Eth 1.0 40 Mee6015Document3 pagesMee6015 Additive-Manufacturing-Technology Eth 1.0 40 Mee6015manoj smNo ratings yet

- Product Lifecycle ManagementDocument38 pagesProduct Lifecycle ManagementManjunatha0% (1)

- 6th Sem - 7 - Mechanical Engineering PDFDocument37 pages6th Sem - 7 - Mechanical Engineering PDFप्रबुद्ध खिलाड़ीNo ratings yet

- Software Quality Assurance: In Large Scale and Complex Software-intensive SystemsFrom EverandSoftware Quality Assurance: In Large Scale and Complex Software-intensive SystemsRating: 5 out of 5 stars5/5 (1)

- Mech Honours Syllabus WEF 2022 23 PAHSUSDocument26 pagesMech Honours Syllabus WEF 2022 23 PAHSUSjeetupatilp7No ratings yet

- Dme Question Bank by Syam Prasad AmmineniDocument22 pagesDme Question Bank by Syam Prasad AmmineniDharmendra SharmaNo ratings yet

- New SME Lab ManualDocument64 pagesNew SME Lab ManualSahil GupteNo ratings yet

- Mec 332 Course Content 2011Document2 pagesMec 332 Course Content 2011WWZNo ratings yet

- Diploma: Uka Tarsadia UniversityDocument5 pagesDiploma: Uka Tarsadia UniversityGira PatelNo ratings yet

- Karanataka State Open University: M Tech in Mechanical (Computer Integrated Manufacturing)Document35 pagesKaranataka State Open University: M Tech in Mechanical (Computer Integrated Manufacturing)nav1278No ratings yet

- Msme BE Mechanical Engineering 2019 Course Structure An 220719 101123-1Document5 pagesMsme BE Mechanical Engineering 2019 Course Structure An 220719 101123-1sonawanepmsNo ratings yet

- V Semster Mechanical Engineering RTMNU NagpurDocument15 pagesV Semster Mechanical Engineering RTMNU NagpurAnand NilewarNo ratings yet

- Sustainable Engineering Products and Manufacturing TechnologiesFrom EverandSustainable Engineering Products and Manufacturing TechnologiesNo ratings yet

- Mec339 - Rapid Prototyping and Reverse Engineering LaboratoryDocument3 pagesMec339 - Rapid Prototyping and Reverse Engineering Laboratorysunilsharma853380No ratings yet

- Uhv Question Set 1Document17 pagesUhv Question Set 1Sudeep UpadhyeNo ratings yet

- DST Monthly Report Highlights Major Science Policy DecisionsDocument18 pagesDST Monthly Report Highlights Major Science Policy DecisionsSudeep UpadhyeNo ratings yet

- Astrology Tuitions Audio Video ContentsDocument69 pagesAstrology Tuitions Audio Video ContentsSudeep UpadhyeNo ratings yet

- The Interplay Between Copyright and Designs in India Wipr AnnualDocument3 pagesThe Interplay Between Copyright and Designs in India Wipr AnnualSudeep UpadhyeNo ratings yet

- Hod Som Spring PHD 2020Document1 pageHod Som Spring PHD 2020Sudeep UpadhyeNo ratings yet

- Study of Mechanical and Tribological Characteristics of Aluminium Alloy Reinforced With Rice Husk AshDocument6 pagesStudy of Mechanical and Tribological Characteristics of Aluminium Alloy Reinforced With Rice Husk AshSudeep UpadhyeNo ratings yet

- EAP ScheduleDocument2 pagesEAP ScheduleSudeep UpadhyeNo ratings yet

- Signature Not Verified: Digitally Signed by MANISH VILAS KULKARNI Date: 2021.05.25 17:58:50 IST Location: Maharashtra-MHDocument1 pageSignature Not Verified: Digitally Signed by MANISH VILAS KULKARNI Date: 2021.05.25 17:58:50 IST Location: Maharashtra-MHSudeep UpadhyeNo ratings yet

- Nakshatra Uttara Bhadrapada (Latter Happy Feet) The Scorching PairDocument5 pagesNakshatra Uttara Bhadrapada (Latter Happy Feet) The Scorching PairANTHONY WRITER100% (2)

- EAP ScheduleDocument2 pagesEAP ScheduleSudeep UpadhyeNo ratings yet

- Nadi Astrology DR B V Raman Part 1Document11 pagesNadi Astrology DR B V Raman Part 1pblsvraman100% (4)

- 27 March 2020 Atal Innovation Mission, NITI Aayog ACIC 1.0 Final ResultsDocument20 pages27 March 2020 Atal Innovation Mission, NITI Aayog ACIC 1.0 Final ResultsSudeep UpadhyeNo ratings yet

- HOW KRISHNAMURTI PADHDHATI PIN POINT THE EVENTSDocument116 pagesHOW KRISHNAMURTI PADHDHATI PIN POINT THE EVENTSanmohiey100% (1)

- Planet and Education - Micro AstrologyDocument2 pagesPlanet and Education - Micro AstrologyShakthidhar RaoNo ratings yet

- InfoDev Mixed Use Incubator Handbook 1 PDFDocument30 pagesInfoDev Mixed Use Incubator Handbook 1 PDFDarwin LimNo ratings yet

- Solapur City Development Corporation Limited: Request For ProposalDocument52 pagesSolapur City Development Corporation Limited: Request For ProposalSudeep UpadhyeNo ratings yet

- Provisional Certificate For COVID-19 Vaccination - 1 Dose: Beneficiary DetailsDocument1 pageProvisional Certificate For COVID-19 Vaccination - 1 Dose: Beneficiary DetailsSudeep UpadhyeNo ratings yet

- Krishneeyam of Sree Krishna Achaarya: PDF-KOSKA-9-2 - 42 Pages - Size 2,769 KB - 5 Jan, 2015Document2 pagesKrishneeyam of Sree Krishna Achaarya: PDF-KOSKA-9-2 - 42 Pages - Size 2,769 KB - 5 Jan, 2015Sudeep UpadhyeNo ratings yet

- A Look Into Pranapada Lagna IIDocument13 pagesA Look Into Pranapada Lagna IIKhoo Hock Leong KhooNo ratings yet

- InfoDev Mixed Use Incubator Handbook 1 PDFDocument30 pagesInfoDev Mixed Use Incubator Handbook 1 PDFDarwin LimNo ratings yet

- Monthly Summary Feb, 21Document13 pagesMonthly Summary Feb, 21Sudeep UpadhyeNo ratings yet

- Format For Submission of Project Proposals Under Technology Interventions For Disabled Elderly (Tide) Programme Core Areas of Funding/Financial Assistance Application ProcedureDocument19 pagesFormat For Submission of Project Proposals Under Technology Interventions For Disabled Elderly (Tide) Programme Core Areas of Funding/Financial Assistance Application ProcedureSudeep UpadhyeNo ratings yet

- UKIERI-DST Call For Proposals 2018-19 - FinalDocument12 pagesUKIERI-DST Call For Proposals 2018-19 - FinalAjay ReyoNo ratings yet

- Science For Equity, Empowerment & Development (Seed) ProgrammeDocument26 pagesScience For Equity, Empowerment & Development (Seed) ProgrammeSudeep UpadhyeNo ratings yet

- SchemeId 1068 CoreSupportProposalformat 2018Document18 pagesSchemeId 1068 CoreSupportProposalformat 2018Sudeep UpadhyeNo ratings yet

- First SDR Platform for 5G Inband D2DDocument2 pagesFirst SDR Platform for 5G Inband D2DSudeep UpadhyeNo ratings yet

- Format For Submission of Proposal For Support: S. No Items Page No(s)Document20 pagesFormat For Submission of Proposal For Support: S. No Items Page No(s)Sudeep UpadhyeNo ratings yet

- Researcher Name:: Project OverviewDocument2 pagesResearcher Name:: Project OverviewSudeep UpadhyeNo ratings yet

- Prototyping PDFDocument8 pagesPrototyping PDFSudeep UpadhyeNo ratings yet

- GM Bluetooth Quick GuideDocument5 pagesGM Bluetooth Quick GuideTin_AmoNo ratings yet

- GNG1105 D Aut2013Document6 pagesGNG1105 D Aut2013oss6000No ratings yet

- Loop Quantum GravityDocument69 pagesLoop Quantum GravityAnderson BernardiNo ratings yet

- Cengel FTFS 6e ISM CH 13Document83 pagesCengel FTFS 6e ISM CH 13Duck FernandoNo ratings yet

- ConMed v. Cosmescu Et. Al.Document28 pagesConMed v. Cosmescu Et. Al.PriorSmartNo ratings yet

- Dekalb White Commercial Management GuideDocument41 pagesDekalb White Commercial Management GuideBanzragch Jamsran88% (8)

- Greenheck Facilities Guide - Locations and Details in Schofield & Mosinee WIDocument1 pageGreenheck Facilities Guide - Locations and Details in Schofield & Mosinee WIRicardo Ruy PeñaNo ratings yet

- LP in ArtsDocument6 pagesLP in ArtsBilindaNo ratings yet

- SHS 2023 Thinking Skills Practice Test QuestionsDocument32 pagesSHS 2023 Thinking Skills Practice Test Questionsvenkatesh113No ratings yet

- Pioneer Deh-X3650uiDocument65 pagesPioneer Deh-X3650uiAllnightlonificationNo ratings yet

- Energy Security IndexDocument13 pagesEnergy Security IndexCarlos AlvarezNo ratings yet

- Headache PAINDocument1 pageHeadache PAINOmarNo ratings yet

- Theme ParkDocument30 pagesTheme ParksassydhineNo ratings yet

- Pokemon Emerald CheatDocument7 pagesPokemon Emerald CheatDimitri Iman P.No ratings yet

- Fire Warden Training: Richard Hagger - ConsultantDocument61 pagesFire Warden Training: Richard Hagger - ConsultantRichard Hagger100% (2)

- Geotechnical Module: Powerful Software Featuring Intuitive WorkflowDocument4 pagesGeotechnical Module: Powerful Software Featuring Intuitive WorkflowMuhammadAviCennaNo ratings yet

- XFGRRRDocument100 pagesXFGRRRAbchoNo ratings yet

- Quiz 2 AnswersDocument6 pagesQuiz 2 Answerselliott.rillstoneNo ratings yet

- Edward Jumper: Willow & Lark 2017 Designed UsingDocument9 pagesEdward Jumper: Willow & Lark 2017 Designed UsingMiraNo ratings yet

- Braithwaite 2017 Complexity Science in Healthcare A White PaperDocument129 pagesBraithwaite 2017 Complexity Science in Healthcare A White PaperFinga Hitam ManiesNo ratings yet

- My Heart Sings Praises - Line UpDocument4 pagesMy Heart Sings Praises - Line UpAnthony JimenezNo ratings yet

- Concepts of ProbabilityDocument32 pagesConcepts of ProbabilityRushina SinghiNo ratings yet

- Yutra 3Document31 pagesYutra 3ကိုနေဝင်းNo ratings yet

- Experiment 7 & 11: Presented By: Group 4Document55 pagesExperiment 7 & 11: Presented By: Group 4Julliane JuanNo ratings yet

- Steel Code Check Theory EnuDocument341 pagesSteel Code Check Theory Enupopaciprian27No ratings yet

- Those Who Serve - Stephen Melillo (Score)Document22 pagesThose Who Serve - Stephen Melillo (Score)Fernando RamiresNo ratings yet

- Signal Sampling, Quantization, Binary Encoding: Oleh Albert SagalaDocument46 pagesSignal Sampling, Quantization, Binary Encoding: Oleh Albert SagalaRamos D HutabalianNo ratings yet

- DC TC 600 L, 01.00, enDocument61 pagesDC TC 600 L, 01.00, enDarkNo ratings yet

- Bai Tap Tieng Anh Lop 8 Unit 7 Environmental Protection Global SuccessDocument8 pagesBai Tap Tieng Anh Lop 8 Unit 7 Environmental Protection Global Successngtrmm1No ratings yet

- B. Inggris Kels IXDocument4 pagesB. Inggris Kels IXANHAS ADVERTISINGNo ratings yet