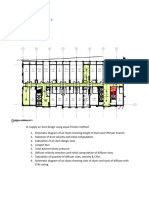

DUCT SIZING

Project: Ninoy Aquino Library and Learning Resources Center (NALLRC)

Name of Area: Second Floor

AIR HANDLING UNIT 2

Covers: T – 16: Server Room 1

T – 16: Server Room 2

T – 17: Lounge

T - 18: Research Lab

T – 19: Jose De Venecia Computer Laboratory

T – 20A: Computer Laboratory Room 1

T – 21: Computer Laboratory Room 2

Total Air Quantity = 14000 CFM

Duct Velocity = 4000 FPM (Recommended)

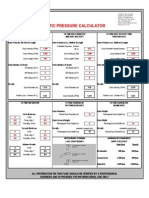

Using the Constant Friction Method

Duct Section Air Quantity CFM Capacity

To A 14000 100%

A-B 9200 66%

B-C 5800 42%

C-D 2400 17%

A-1 4800 34%

1-2 2400 17%

B-3 3400 24%

3-4 972 7%

**All data are obtained and calculated from ASHRAE Manual, Friction Chart.

� C-5 3100 22%

5-6 1600 11%

6-7 800 6%

D-8 2400 17%

8-9 2000 14%

9-10 1000 7%

Using the Constant Friction Merthod:

**All data are obtained and calculated from ASHRAE Manual, Friction Chart.

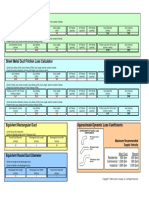

� DIFFUSER SIZING

Room Room BTUH TR CFM No. of Diameter of

No. Description Diffusers DIffuser

T – 16 Server Room 1 26756.21 2.23 1000 1 11.25 in

T – 16 Server Room 2 30.499.44 2.54 1000 1 11.25 in

T – 17 Lounge 9982.765 0.83 400 1 8 in

T -18 Research Lab 52708.18 4.39 1800 1 14 in

T – 19 JDV Computer 44390.38 3.70 1600 2 13.5 in

Lab

T – 20A Comp. Lab 1 102333.814 8.53 3400 1 17.75 in

T – 21 Comp. Lab 2 140142.76 11.68 4800 2 20.25 in

Computations:

T – 16: Server Room 1&2

1 of 1000 cfm diffusers Using 70% blade compensation:

Q = 1000 cfm 67.76

A= =96.8 ¿2

0.70

V = 2125 fpm

Getting diameter using round duct:

Q 1000

A= = =0.47

V 2125 π D2

A=

4

144 ¿2

A=.47 ( 1 ft 2 )

=67.76

D 2=

( 4 ) 96.8 ¿2

π

D=11.10 ∈¿

Use 11.25 in diameter diffuser

T – 17 Lounge:

1of 400 cfm diffusers

Q = 400 cfm Using 70% blade compensation:

V = 1957 fpm 33.12 ¿2 2

A= =47.3 ¿

0.70

Q 400

A= = =0.23 ft 2

V 173 7 Getting diameter using round duct:

144 ¿2 π D2

A=0.23 ft 2 ( 1 ft )

2

=33.12 ¿2 A=

4

( 4 ) 47.3 ¿2

2

D=

π

D=7.76 ∈¿

Use 8 in diameter diffuser

**All data are obtained and calculated from ASHRAE Manual, Friction Chart.

�T - 18 Research Lab:

1 of 1400 cfm diffusers Using 70% blade compensation:

Q = 1800 cfm 105.12 ¿2 2

A= =150.17 ¿

0.70

V = 2375 fpm

Getting diameter using round duct:

Q 1 8 00

A= = =0. 73 ft 2

V 2454 π D2

A=

4

144 ¿2

A=0.73 ft 2 ( 1 ft )

2

=105.12¿ 2

D=2( 4 ) 150.17 ¿ 2

π

D=1 3.33∈¿

Use 13.5 in diameter diffuser

T – 19 JDV Comp. Lab.:

2 of 800 cfm diffusers Using 70% blade compensation:

Q = 800 cfm 56.16 ¿2 2

A= =80.23 ¿

0.70

V = 2050 fpm

Getting diameter using round duct:

Q 800

A= = =0.39 ft 2

V 2 0 50 π D2

A=

4

144 ¿2

A=0.39 ft 2

(

1 ft 2 )

=56.16 ¿2

D 2=

( 4 ) 80.23¿ 2

π

D=1 3.42∈¿

Use 13.5 in diameter diffuser

T – 20A Comp. Lab 1

1 of 3400 cfm diffusers Using 70% blade compensation:

Q = 3400 cfm 168.5 ¿2 2

A= =240.71 ¿

0.70

V = 2886 fpm

Getting diameter using round duct:

Q 600

A= = =1.178 ft 2

V 1957 π D2

A=

4

144 ¿2

A=1.17 ft 2 ( 1 ft )

2

=168.5¿ 2

D 2=

( 4 ) 240.71¿2

π

D=17.62∈¿

Use 17.75 in diameter diffuser

**All data are obtained and calculated from ASHRAE Manual, Friction Chart.

�T – 21: Computer Laboratory 2

2 of 2400 cfm diffusers Using 70% blade compensation:

Q = 2400 cfm 131.04 ¿ 2 2

A= =187.2 ¿

0.70

V = 2646 fpm

Getting diameter using round duct:

Q 2400

A= = =0. 91 ft 2

V 2646 π D2

A=

4

144 ¿2

A=.91 ft2

(

1 ft 2 )

=131.04 ¿ 2

D=2( 4 ) 187.2 ¿2

π

D=20.11∈¿

Use 20.25 in diameter diffuser

LENGTH OF REDUCERS

**All data are obtained and calculated from ASHRAE Manual, Friction Chart.

�Using Concentric Reducers:

L= ( D −D

1

2 )

2

(7)

Diameter Diameter

Reducer No. Ratio Used: LENGTH TO USE

No.1 No.2

1 25.5 22 7 11.2 11.25

2 22 18.25 7 14.875 15

3 18.25 13 7 18.38 18.5

4 17 13 7 14 14

5 15 9.25 7 21.88 22

6 14.5 11.5 7 10.5 10.5

7 11.25 9 7 7.85 8

8 13 12.25 7 2.63 2.75

9 12.25 9.5 7 9.625 9.75

**All data are obtained and calculated from ASHRAE Manual, Friction Chart.