Professional Documents

Culture Documents

150Z Spec & Accessories

Uploaded by

shady yehiaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

150Z Spec & Accessories

Uploaded by

shady yehiaCopyright:

Available Formats

High-Pressure Plunger Pump Type 150 Z

Mounting space

211 133 615 Discharge

250

100 95 60°-Konus 9.5 deep

M12x17 deep

322

331

55

255

162

65

73

445 41 346 41

268 304 83 665 82,5

572 1057

All dimensions in mm Oil sight glass Suction IG 1 1/2

Thread ”M“ as per DIN 13/ISO 261 Connection for Oil cooling G 1/2

Thread ”G“ as per DIN ISO 228/1

왘 Installation variations

Ø50k6 Key 14x72 per

Technical data: DIN 6885 Page1

450

100

왘 Oil capacity: approx. 9 l

Mounting space

왘 Weight: approx. 311 kg net

380

445

495

475

왘 Stroke: 95 mm / 3.74 inch

왘 Inlet pressure required: 3 – 8 bar / 45 – 115 psi

왘 Rod force: 40 kN

Ø19

Performance Chart Pump Type 150 Z

Plunger Gear ratio Crank Required Nominal flow rate Max. permissible

diameter Pinion shaft (Rpm) shaft drive USG IMPG operating pressure

(mm) 1,500 1,800 2,100 (Rpm) (kW) pm pm l/min (psi / bar)

4.57 460 96 9.25 7.70 35

3.69 487 101 9.77 8.14 37

4.57 393 82 7.93 6.60 30

P 19 2.96 506 106 10.30 8.58 39 21,750 / 1,500

3.69 406 85 8.19 6.82 31

4.57 328 68 6.60 5.50 25

4.57 460 89 10.30 8.58 39

3.69 487 93 10.83 9.02 41

4.57 393 75 8.72 7.26 33

P 20 2.96 506 98 11.36 9.46 43 18,100 / 1,250

3.69 406 77 8.98 7.48 34

4.57 328 62 7.13 5.94 27

4.57 460 86 12.42 10.34 47

3.69 487 91 13.21 11.00 50

4.57 393 73 10.57 8.80 40

P 22 2.96 506 95 13.74 11.44 52 14,500 / 1,000

3.69 406 77 11.10 9.24 42

4.57 328 62 8.98 7.48 34

4.57 460 92 17.70 14.74 67

3.69 487 97 18.76 15.62 71

4.57 393 79 15.32 12.76 58

P 26 2.96 506 101 19.55 16.28 74 10,900 / 750

3.69 406 82 15.85 13.20 60

4.57 328 66 12.68 10.56 48

4.57 460 93 23.78 19.80 90

3.69 487 99 25.10 20.90 95

4.57 393 80 20.34 16.94 77

P 30 2.96 506 103 26.15 21.78 99 8,300 / 570

3.69 406 82 20.87 17.38 79

4.57 328 67 16.91 14.08 64

4.57 460 93 32.49 27.06 123

3.69 487 99 34.34 28.60 130

4.57 393 80 27.74 23.10 105

P 35 2.96 506 103 35.93 29.92 136 6,090 / 420

3.69 406 83 28,79 23.98 109

4.57 328 67 23.25 19.36 88

HG SERIES

Hand-Held Zero Thrust

Control Gun

Pressures from 10,000 - 15,000 PSI

Easy

Cartridge

Diffuser Tube Assembly Overhaul Wafer Tee Inlet

1/2" NPT

Model HGZT-15K Adjustable

Hand Grip

Zero-Thrust

Trigger

Control Gun Safety

Part #3102115005 Latch

Designed for underwater or topside use where balance is critical.

The equal forward and backward thrust allows the operator to be in balance.

Constructed of stainless steel for corrosion resistance.

Vertical inlet connection for underwater use. Adjustable hand grip.

Features 60 second cartridge overhaul.

Weighs only 16 Lbs. (7.26 Kg) 10-15 KPSI (800-1050 Bar)

60 Second Cartridge Overhaul

REMOVE ALIGN LOBE ON CARTRIDGE ASSEMBLY REPLACE

WITH GROOVE IN CARTRIDGE CARTRIDGE AND

CARTRIDGE ADAPTER

ADAPTER AND TURN

COUNTERCLOCKWISE TO

INSTALL IN BLOCK

UNLOCK AND REMOVE.

STEP 1 STEP 2 STEP 3

PRV

Pressure Regulating Valve

Pressures from 15,000 - 20,000 PSI

PRV-15K #77800020 Adjuster

Handle

PRV-20K #77800032

PRV FLOW-THROUGH INSTALLATION

PRV with Lock

Dump Nut

Tube.

PRV PARALLEL INSTALLATION

(Recommended)

Outlet

PRV Body Inlet

(1/2" NPT

Female - 15K)

or

(9/16" MP

Dump Port Autoclave

(1/2" NPT Female) Female - 20K)

Application/Features:

The Gardner Denver Water Jetting Systems Pressure Regulating Valve (PRV) is designed primarily for use on fixed-

speed pumps (e.g. electric motor pumps) as a means of controlling the system pressure. The PRV can be used either

in a parallel system or in a “flow through” system arrangement. The PRV is a “needle-type” valve which allows excess

flow to be released from the system and recirculated back to the pump. Water flow is controlled by turning the adjuster

handle on top of the PRV. The hoses attach to the inlet/outlet in the valve body. Overhaul of the Pressure Regulating

Valve is easy and takes only a few minutes with the PRV Overhaul Kit, and may be done without removing the PRV from

the system. It is essential that a pressure gauge is utilized for adjusting system pressure using the PRV.

You might also like

- Case 580 M Series 2 Parts ManualDocument2,146 pagesCase 580 M Series 2 Parts ManualEduardo Ariel Bernal86% (21)

- S5-42 DatasheetDocument2 pagesS5-42 Datasheetchillin_in_bots100% (1)

- Pelton Wheel Experiment Performance AnalysisDocument5 pagesPelton Wheel Experiment Performance AnalysisCaleb KreegerNo ratings yet

- Feller Bunch ErsDocument139 pagesFeller Bunch ErsJhonald Lanz LossadaNo ratings yet

- Pump DrawingDocument1 pagePump DrawingOcta RioNo ratings yet

- Vemag Robot 500 Spec SheetDocument2 pagesVemag Robot 500 Spec SheetTorben Richard PedersenNo ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Case 2090 2590 Shop ManualDocument10 pagesCase 2090 2590 Shop Manualtheodore100% (55)

- Datasheet-Motor 12V With EncoderDocument5 pagesDatasheet-Motor 12V With EncoderRoger VicenteNo ratings yet

- Flyer Robot EPX Series E 06.2015 13 PDFDocument8 pagesFlyer Robot EPX Series E 06.2015 13 PDFIulia CostacheNo ratings yet

- Motoman Mh5L: General Purpose and Handling With The MH-seriesDocument2 pagesMotoman Mh5L: General Purpose and Handling With The MH-seriesFrancisco HermidaNo ratings yet

- Bronze Gate Valve - 175GLBDocument2 pagesBronze Gate Valve - 175GLBNguyễn Thành ChungNo ratings yet

- 02 01Document1 page02 01kinna.04.1991No ratings yet

- SX310 PTT 2000kgDocument1 pageSX310 PTT 2000kgCedric ChatonNo ratings yet

- Electric Stationary CompressorDocument1 pageElectric Stationary Compressorlalji halaiNo ratings yet

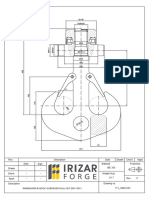

- RAMSHORN B-HOOK SUSPENSION No.10-P DIN 15411Document1 pageRAMSHORN B-HOOK SUSPENSION No.10-P DIN 15411JosePeterPintoNo ratings yet

- AE MD-144 Series 530W-550W: Ae Half Large CellDocument2 pagesAE MD-144 Series 530W-550W: Ae Half Large CelltasoNo ratings yet

- Solar Module German Brand AE MD-530W-550W-144Document2 pagesSolar Module German Brand AE MD-530W-550W-144Theofilus JusniNo ratings yet

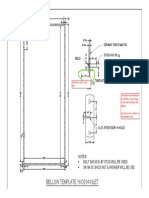

- Bellow Template Yko014 InletDocument1 pageBellow Template Yko014 InletjabNo ratings yet

- Euro Klim AteDocument5 pagesEuro Klim Atewesam allabadiNo ratings yet

- EE Fueling SheetsDocument20 pagesEE Fueling SheetsOrlando GomezNo ratings yet

- MH5 E Web 05Document2 pagesMH5 E Web 05hdjose62No ratings yet

- Z59 Siemens GearboxDocument1 pageZ59 Siemens GearboxShivanand RamachandranNo ratings yet

- 5k OhmDocument1 page5k Ohmartur.damascenoNo ratings yet

- T1 - (Ø12 - 4 NOS.) : 4 Nos Holes Ø22 Thru. On 360 P.C.D. EquispacedDocument1 pageT1 - (Ø12 - 4 NOS.) : 4 Nos Holes Ø22 Thru. On 360 P.C.D. EquispacedDhilipkumar GNo ratings yet

- APACHE H15 MkIV SUBWOOFER SPECS AND CONTACTDocument1 pageAPACHE H15 MkIV SUBWOOFER SPECS AND CONTACTIrvanda ENVIOUSNo ratings yet

- Series: Static Three Wheel RollerDocument2 pagesSeries: Static Three Wheel RollerFahri Alvian NoorNo ratings yet

- Z29 Siemens GearboxDocument1 pageZ29 Siemens GearboxShivanand RamachandranNo ratings yet

- Product Information: Pyroshield® Syn Open Gear GreaseDocument4 pagesProduct Information: Pyroshield® Syn Open Gear GreaseRoberto Alfaro EspinozaNo ratings yet

- ZOOMLION ZD220 (S) - 3 Crawler BulldozerDocument2 pagesZOOMLION ZD220 (S) - 3 Crawler BulldozerShoaib MahmudNo ratings yet

- Solenoid Valve, Metal, NAMUR: ConstructionDocument4 pagesSolenoid Valve, Metal, NAMUR: ConstructionEdmar Vilela de SouzaNo ratings yet

- pds SEI 50_18 GBDocument2 pagespds SEI 50_18 GBrose.devineNo ratings yet

- Tubing Cutter Replacement WheelsDocument1 pageTubing Cutter Replacement WheelsKTNo ratings yet

- Hiab 330 5Document2 pagesHiab 330 5ndamota76No ratings yet

- MAG Pneumatic Grease Lubricator: FeaturesDocument1 pageMAG Pneumatic Grease Lubricator: FeaturesDmitry DauhalNo ratings yet

- Flyer Robot Mh5sii-F Mh5lsii-F e 07.2018Document4 pagesFlyer Robot Mh5sii-F Mh5lsii-F e 07.2018Pravin RajNo ratings yet

- Sketch 1Document1 pageSketch 1Hariprasad CNo ratings yet

- Epx Series DatasheetDocument8 pagesEpx Series DatasheetAlexandr TcacencoNo ratings yet

- 6351 1500 WebDocument1 page6351 1500 Webmohamed bakryNo ratings yet

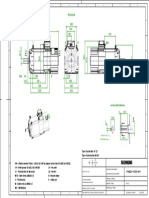

- Asynchron-Servomotor front viewDocument1 pageAsynchron-Servomotor front viewHemraj SonarNo ratings yet

- SK22 - 90LP/4: Date Name Drawn SystemDocument1 pageSK22 - 90LP/4: Date Name Drawn Systemsun sampleNo ratings yet

- Series: Static Three Wheel RollerDocument2 pagesSeries: Static Three Wheel Rolleragus yuliantoNo ratings yet

- Flyer Robot GP180 E 11.2020Document2 pagesFlyer Robot GP180 E 11.2020pruma.ruNo ratings yet

- Industrial Robot Motoman Up50 Robotforum RuDocument2 pagesIndustrial Robot Motoman Up50 Robotforum RuTrí ChốtNo ratings yet

- Bellows Cylinders EB/EBS: 2007/03 - Subject To Change - Products 2007Document14 pagesBellows Cylinders EB/EBS: 2007/03 - Subject To Change - Products 2007Kyriakos MichalakiNo ratings yet

- Specs Flightcase Boxes L XLDocument18 pagesSpecs Flightcase Boxes L XLapi-652055634No ratings yet

- 11 Cylinder Serie 51 SL - 0608Document2 pages11 Cylinder Serie 51 SL - 0608Ivana DincicNo ratings yet

- QGCIS-ASA-VD-212Document1 pageQGCIS-ASA-VD-212workshop13.asaNo ratings yet

- SZ 50-55 100 hp-730 Rpm-ModelDocument1 pageSZ 50-55 100 hp-730 Rpm-ModelmzakriasesNo ratings yet

- Technical Details ENDocument5 pagesTechnical Details ENhenk.schepers01No ratings yet

- Z49 Siemens GearboxDocument1 pageZ49 Siemens GearboxShivanand RamachandranNo ratings yet

- HM 350-4Document12 pagesHM 350-4Mohan CharanchathNo ratings yet

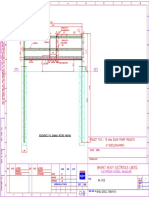

- DIESEL DAY TANK (5 m3 CAPACITY)Document1 pageDIESEL DAY TANK (5 m3 CAPACITY)Abdur RehmanNo ratings yet

- Aloa Led GHM EclatecDocument3 pagesAloa Led GHM EclatecsumozaabNo ratings yet

- Plain Diffuser LKA: DimensionsDocument11 pagesPlain Diffuser LKA: DimensionsadigetoNo ratings yet

- Edur Vbu Series Dimensions 1Document1 pageEdur Vbu Series Dimensions 1Mohammad HosseinNo ratings yet

- General Technical Versions: Motor Terminal BoxesDocument1 pageGeneral Technical Versions: Motor Terminal Boxesmazumdar_satyajitNo ratings yet

- Raghanesdhsa SCB Model - pdf2Document1 pageRaghanesdhsa SCB Model - pdf21382aceNo ratings yet

- GA BRS 3x3 (R0)Document1 pageGA BRS 3x3 (R0)sandhya dollyekkaNo ratings yet

- 12AYM-WGT Marine Propulsion Diesel Engine Dimensions and SpecsDocument1 page12AYM-WGT Marine Propulsion Diesel Engine Dimensions and Specsghyd artiagaNo ratings yet

- ISO 9001 AIR-OIL COOLERSDocument6 pagesISO 9001 AIR-OIL COOLERSsuresh muthuramanNo ratings yet

- Hino 500 Boom CylinderDocument2 pagesHino 500 Boom CylinderTruck TrailerNo ratings yet

- DS421 Cabolt MachineDocument2 pagesDS421 Cabolt MachineEfrain MendozaNo ratings yet

- 045 - WS-BM7Document1 page045 - WS-BM7sivagnanam sNo ratings yet

- Detail Tangki Air PanasDocument1 pageDetail Tangki Air PanasBe25 jh08No ratings yet

- GL XX Mobil Vactra Oil Numbered SeriesDocument2 pagesGL XX Mobil Vactra Oil Numbered Seriesshady yehiaNo ratings yet

- GL XX Mobil DTE 20 SeriesDocument3 pagesGL XX Mobil DTE 20 SeriesdpomahNo ratings yet

- Transolac Aluminium HR: Product DescriptionDocument3 pagesTransolac Aluminium HR: Product Descriptionshady yehiaNo ratings yet

- BS - EN - 12021 - Estandar Pureza AireDocument3 pagesBS - EN - 12021 - Estandar Pureza AireTECNOSUBNo ratings yet

- Practical Machinery Vibration Analysis and Predictive MaintenanceDocument3 pagesPractical Machinery Vibration Analysis and Predictive MaintenanceSafrul EfendiNo ratings yet

- Engine mechanical guideDocument204 pagesEngine mechanical guidehectorgonzalezm100% (6)

- RT 8908LL Ingles PDFDocument254 pagesRT 8908LL Ingles PDFFernandoNo ratings yet

- FINITE ELEMENT BOOK AUTHOR INDEXDocument25 pagesFINITE ELEMENT BOOK AUTHOR INDEXJorge Luis Chino CelisNo ratings yet

- Tucson 2010Document92 pagesTucson 2010edi100% (1)

- Edr 01 Dec 2018Document21 pagesEdr 01 Dec 2018AMALENDU PAULNo ratings yet

- MotorDocument2 pagesMotorKeLvinLazyBoyNo ratings yet

- Refrigeration and Air-ConditioningDocument24 pagesRefrigeration and Air-ConditioningKumar SahebNo ratings yet

- Specification Sheet: Pour Point of Crude Oils - Procedure BDocument3 pagesSpecification Sheet: Pour Point of Crude Oils - Procedure BMiguelNo ratings yet

- Drilling HydraulicsDocument36 pagesDrilling HydraulicsSohaib RashidNo ratings yet

- Hy Hybc5210pro Despiece Es enDocument6 pagesHy Hybc5210pro Despiece Es enJuan ArdevolNo ratings yet

- 04 Feedback Control 1Document26 pages04 Feedback Control 1ibekaputraNo ratings yet

- Mathematics: Wednesday 17 January 2024Document28 pagesMathematics: Wednesday 17 January 2024t.a.qafarovNo ratings yet

- 6180J PDFDocument620 pages6180J PDFCarlos Eduardo100% (1)

- PT. PUTRA SEJATI WELL TEST SUMMARYDocument18 pagesPT. PUTRA SEJATI WELL TEST SUMMARYAditya FathurachmanNo ratings yet

- HDH Desalination PDFDocument20 pagesHDH Desalination PDFDianita Citra Dewi100% (1)

- OHB Manual PDFDocument68 pagesOHB Manual PDFLuis Angel Huaratazo HuallpaNo ratings yet

- Manual For Design of Concrete Structures ICE 2002 PDFDocument95 pagesManual For Design of Concrete Structures ICE 2002 PDFsitheeqNo ratings yet

- Cooling Hyundai ScoupeDocument19 pagesCooling Hyundai ScoupeCanelo BalbinNo ratings yet

- MF1547Engine PDFDocument83 pagesMF1547Engine PDFAhmad Ali Nursahidin100% (1)

- Recommended Tap Drill SizesDocument4 pagesRecommended Tap Drill SizesJason-chungNo ratings yet

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- Lecture 01 PDFDocument7 pagesLecture 01 PDFNuta Marius AlexandruNo ratings yet

- Forces in Equilibrium on Inclined PlanesDocument16 pagesForces in Equilibrium on Inclined PlanesPauling ChiaNo ratings yet

- SuzukiDocument170 pagesSuzukiSebastian Ruiz PeraltaNo ratings yet