Professional Documents

Culture Documents

Intensive, Hands-On Training For Ma Ximum Results: Who Should Attend

Uploaded by

Alex0 ratings0% found this document useful (0 votes)

18 views2 pagesOriginal Title

031348

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views2 pagesIntensive, Hands-On Training For Ma Ximum Results: Who Should Attend

Uploaded by

AlexCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

w w w.swagelok.

com

Who Should At tend

Inte nsi ve,

■ Welders with orbital welding experience who wish to

upgrade their skills or obtain ASME qualification

Ha nds- O n Training

■ Welders without orbital welding experience who would

for Ma x imum Re sults

like to learn the technique

■ Supervisors of orbital welding operations

■ Engineers who design systems that include orbital

welding

■ Quality assurance and quality control personnel

Swagelok, Micro-Fit® Swagelok Company

© 2001, 2003, 2007, 2008 Swagelok Company

Printed in U.S.A., GLI

October 2008, R3

MS-02-139

Course Overview Course Objectives

Four-Day Course Trusted Training From A Respected Source

The four-day course consists of a series of This course will instruct the entry-level orbital Industry has relied on Swagelok® for advanced

lectures and hands-on activities to develop an welder and enhance the welding skill knowledge solutions in fluid handling components for more than

understanding of orbital welding principles. for the experienced orbital welder in the following 60 years. Swagelok welding systems were added to

Upon completion of the program, a theoretical areas: the company’s ever-expanding product line in 1987.

and a practical exam will be administered. A Today, with the global presence of Swagelok, our

certificate of completion will be granted when ■ Basic welding background information support and training complement the premium quality

both exams have been successfully completed. of our products that meet the needs of manufacturers

■ Basic metallurgy for orbital welding

in numerous industries. This training program reflects

An optional day is offered at the end of the four-

■ Tungsten electrodes our commitment to provide the highest quality fluid

day course for participants who wish to test for

system components and services.

ASME Section IX qualification. This can be used ■ Shielding and backing purge gases and

to fulfill QA/QC requirements for the participant’s procedures Because of the complexity of the skills required to con

company. sistently achieve acceptable orbital welds, it is critical

■ Setup and operation of orbital welding that welders obtain up-to-date and accurate training.

Upon completion of the course, students will each equipment The Swagelok approach to learning the theories and

receive a reference workbook, users manual, and

■ Preventive maintenance skills of GTAW orbital welding includes comprehensive

signed certificate of completion.

classroom instruction and valuable hands-on training.

■ Troubleshooting Our four-day course provides:

■ Industry weld specifications

■ An understanding of welding principles

■ Orbital weld evaluation

■ Instructions for setup and operation of the orbital

■ A variety of weld procedures through hands-on welding system

orbital welding experience on applications from

Micro-Fit® fittings to 4 in. diameter tubing ■ Troubleshooting for frequently encountered welding

problems

■ An emphasis on operational issues through hands‑on

Exam Requirements experience

Participants must receive a minimum grade of

80 % to pass the theoretical exam. To pass the

practical exam, participants must demonstrate

the ability to prepare and weld a tubing system

according to a specific drawing without the aid of

a facilitator or peer.

Instructor Qualifications

All program instructors have earned the

qualifications of Certified Weld Inspector (CWI)

and Certified Weld Educator (CWE) and have

a minimum of five years’ experience in orbital

welding instruction.

You might also like

- SOLIDWORKS Simulation 2016: A Tutorial ApproachFrom EverandSOLIDWORKS Simulation 2016: A Tutorial ApproachRating: 5 out of 5 stars5/5 (1)

- Intensive, Hands-On Training For Maximum Results: Who Should AttendDocument2 pagesIntensive, Hands-On Training For Maximum Results: Who Should Attendherysyam1980No ratings yet

- SMAW-Groove Welds With BackingDocument4 pagesSMAW-Groove Welds With BackingKenneth TicodNo ratings yet

- EPTAC DataSheet J-STD-CITDocument1 pageEPTAC DataSheet J-STD-CITnacimdjamelNo ratings yet

- BRO Brochure IHC Training Institute 2017 PDFDocument16 pagesBRO Brochure IHC Training Institute 2017 PDFahsan miaNo ratings yet

- CV For Welding InspectorDocument6 pagesCV For Welding Inspectorkarni MaheshNo ratings yet

- Electrical Machines - Operation & Maintenance: Training OutlineDocument3 pagesElectrical Machines - Operation & Maintenance: Training OutlineYogesh DaundNo ratings yet

- INTCV559 - 72.5 KV Circuit Breakers - v1Document2 pagesINTCV559 - 72.5 KV Circuit Breakers - v1Probal NandyNo ratings yet

- Weld Australia Course Guide IIW IWI S LRDocument4 pagesWeld Australia Course Guide IIW IWI S LRAli TalebiNo ratings yet

- Tuv / Iics 3.1 Certified Welding Inspector Api 577 Welding Inspection & MetallurgyDocument5 pagesTuv / Iics 3.1 Certified Welding Inspector Api 577 Welding Inspection & Metallurgyzulfadli izaraeeNo ratings yet

- Practical Welder Training Courses 2023Document2 pagesPractical Welder Training Courses 2023Winny MokatseNo ratings yet

- PetroSync - Coiled Tubing Operation 2023 Oil Gas TrainingDocument11 pagesPetroSync - Coiled Tubing Operation 2023 Oil Gas TrainingPetro SyncNo ratings yet

- Training Manual for Perkins EnginesDocument18 pagesTraining Manual for Perkins EnginesIK100% (1)

- ASME IX Code - Welding Qualifications - Simplified - Jun10Document3 pagesASME IX Code - Welding Qualifications - Simplified - Jun10Andre AlvesNo ratings yet

- STAMFORD AvK Alternator Technology Centre Service TrainingDocument20 pagesSTAMFORD AvK Alternator Technology Centre Service TrainingGraham Mc KenzieNo ratings yet

- SAE Gear Design Course - C0223 - th003Document194 pagesSAE Gear Design Course - C0223 - th003mirekjanda100% (5)

- Excavator OperatorDocument17 pagesExcavator Operatordwarka prasadNo ratings yet

- Learn Vertical Welding with WPSDocument3 pagesLearn Vertical Welding with WPSFlorinda Gagasa100% (1)

- JKTech Brochure - JKSimMet Training (July2020) FINALDocument2 pagesJKTech Brochure - JKSimMet Training (July2020) FINALjherryNo ratings yet

- Online & Blended IWE Course GuideDocument4 pagesOnline & Blended IWE Course GuideKamal HalawiNo ratings yet

- EWF Qualifications Guideline CatalogueDocument42 pagesEWF Qualifications Guideline Catalogueromanosky11No ratings yet

- Sulfur Recovery Unit VegasDocument2 pagesSulfur Recovery Unit VegasrezaNo ratings yet

- ACS800 Authorized StartupDocument2 pagesACS800 Authorized StartuposcaragNo ratings yet

- Automation Training Catalog 20162Document16 pagesAutomation Training Catalog 20162jmorenoh103No ratings yet

- Address: Professional ProfileDocument3 pagesAddress: Professional ProfileMina RemonNo ratings yet

- Certification Course in Oil & Gas Piping Engineering DesignDocument4 pagesCertification Course in Oil & Gas Piping Engineering DesignRaheel JibranNo ratings yet

- 2020 SKF Malaysia Training HandbookDocument86 pages2020 SKF Malaysia Training HandbookMohamad Hassaidi Abd Hamid100% (1)

- Rigging Lifting 3dayDocument1 pageRigging Lifting 3dayTumwine Rooney.No ratings yet

- Weld Training Solutions: RealweldDocument4 pagesWeld Training Solutions: RealweldNenad MilosevicNo ratings yet

- Customer Courses 2024Document5 pagesCustomer Courses 2024Jasmin PiNo ratings yet

- Brochure IWCP ALL Routes July - 2011Document5 pagesBrochure IWCP ALL Routes July - 2011kumarvizayinNo ratings yet

- Iwi S&CDocument2 pagesIwi S&CbenmedNo ratings yet

- TVL-SMAW 12 - Week 6 - Lesson 1 - Welding Procedure SpecificationDocument10 pagesTVL-SMAW 12 - Week 6 - Lesson 1 - Welding Procedure SpecificationNelPalalonNo ratings yet

- Course Description CHH622 - Rev07Document2 pagesCourse Description CHH622 - Rev07renzo m cuevaNo ratings yet

- UniSim Design Process Modelling FundamentalsDocument2 pagesUniSim Design Process Modelling FundamentalsRoberto BarriosNo ratings yet

- Transformer Manufacturing Training Brochure PDFDocument8 pagesTransformer Manufacturing Training Brochure PDFNammavaru IT100% (1)

- Welding Procedures for Hydroelectric GenerationDocument60 pagesWelding Procedures for Hydroelectric GenerationAnonymous tGFxtqNNo ratings yet

- Welder Level C Program OutlineDocument185 pagesWelder Level C Program OutlineRon Carlo DiosoNo ratings yet

- Thales - Training Catalogue - Point MachinesDocument34 pagesThales - Training Catalogue - Point Machinesmuhammad fahmi arsyadNo ratings yet

- INTCV560—HV Circuit Breakers CourseDocument2 pagesINTCV560—HV Circuit Breakers CourseMarko Maky ZivkovicNo ratings yet

- Iiw Welding GuidelinesDocument95 pagesIiw Welding Guidelinestomychalil100% (2)

- Ball BearingDocument112 pagesBall BearingJyotibaraje Jadhav100% (1)

- C Tech Copper 4.0 One PagerDocument2 pagesC Tech Copper 4.0 One PagerSAMNo ratings yet

- Asme Ix "Welding Qualification": 1 Online TrainingDocument8 pagesAsme Ix "Welding Qualification": 1 Online TrainingIqfal ZulhendriNo ratings yet

- Drive Application Expert TrainingDocument2 pagesDrive Application Expert TrainingGabo2040No ratings yet

- N.B. WIMAL PREMADASA Professional CV (1) 01Document4 pagesN.B. WIMAL PREMADASA Professional CV (1) 01DN PrintNo ratings yet

- Training CatalogDocument35 pagesTraining Catalogkarthikeyan1992No ratings yet

- ASME - Middle-East-Training-Brochure PDFDocument32 pagesASME - Middle-East-Training-Brochure PDFMohamed F MorsyNo ratings yet

- QA/QC Welding Inspector: Category Yrs. Exp. Last UsedDocument3 pagesQA/QC Welding Inspector: Category Yrs. Exp. Last UsedVijayaraman RajendranNo ratings yet

- Standard Service Proposal: Training Courses For Service Technicians and EngineersDocument2 pagesStandard Service Proposal: Training Courses For Service Technicians and Engineersdave chaudhuryNo ratings yet

- CSWIP Welding Inspector Course Info 2024Document2 pagesCSWIP Welding Inspector Course Info 2024joaquim.ventura021No ratings yet

- Injection Moulding Courses BrochureDocument16 pagesInjection Moulding Courses BrochureFa BelNo ratings yet

- Wireline Operations Techniques: Approach Into Slick, Braided & Electrical Line Equipment, Tools & ApplicationsDocument4 pagesWireline Operations Techniques: Approach Into Slick, Braided & Electrical Line Equipment, Tools & ApplicationsJerome LIKIBINo ratings yet

- EWF-544-01, Europski Specialist Za Zavarivanje Čelika Za Armiranje BetonaDocument7 pagesEWF-544-01, Europski Specialist Za Zavarivanje Čelika Za Armiranje BetonaMarija IvanovskaNo ratings yet

- INTCV385 Course on HV/MV switchgear O&MDocument3 pagesINTCV385 Course on HV/MV switchgear O&MPMG Bhuswal ProjectNo ratings yet

- DASH Training ProgramsDocument16 pagesDASH Training ProgramsdashNo ratings yet

- Design Engineering Installation and O M of Rotating Equipments For Process IndustryDocument4 pagesDesign Engineering Installation and O M of Rotating Equipments For Process IndustryAbdul Hamid DjaelaniNo ratings yet

- 2015 Training Handbook PDFDocument124 pages2015 Training Handbook PDFAboo Khan100% (1)

- Advanced Turbomachinery Diagnostics - Online Course W2Document8 pagesAdvanced Turbomachinery Diagnostics - Online Course W2ali shetaNo ratings yet

- ASME Understanding Codes & Stds CourseDocument4 pagesASME Understanding Codes & Stds CourseChandrasekharNo ratings yet

- Pressure Gauges: For Panel Builders PBG SeriesDocument2 pagesPressure Gauges: For Panel Builders PBG SeriesAlexNo ratings yet

- Pressure Gauges: For Panel Builders PBG SeriesDocument2 pagesPressure Gauges: For Panel Builders PBG SeriesAlexNo ratings yet

- Swagelok Welding System: M200 Power SupplyDocument4 pagesSwagelok Welding System: M200 Power SupplyAlexNo ratings yet

- Welding Purge Panel WPP Series: Features and BenefitsDocument2 pagesWelding Purge Panel WPP Series: Features and BenefitsAlexNo ratings yet

- Swagelok Welding System: M200 Power SupplyDocument4 pagesSwagelok Welding System: M200 Power SupplyAlexNo ratings yet

- Gaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsDocument8 pagesGaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsAlexNo ratings yet

- Stream-Select, Switching, and Shutof F Valve Assemblies: T T2 and T2 SeriesDocument8 pagesStream-Select, Switching, and Shutof F Valve Assemblies: T T2 and T2 SeriesAlexNo ratings yet

- Stream Selector System: For Process Analyzer ApplicationsDocument12 pagesStream Selector System: For Process Analyzer ApplicationsAlexNo ratings yet

- Gaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsDocument8 pagesGaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsAlexNo ratings yet

- Stream Selector System: For Process Analyzer ApplicationsDocument12 pagesStream Selector System: For Process Analyzer ApplicationsAlexNo ratings yet

- High-Purity PFA Fine Thread Flare FittingsDocument12 pagesHigh-Purity PFA Fine Thread Flare FittingsAlexNo ratings yet

- Gaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsDocument8 pagesGaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsAlexNo ratings yet

- Gaugeable Chromatograph and Column End Fittings: FeaturesDocument2 pagesGaugeable Chromatograph and Column End Fittings: FeaturesAlexNo ratings yet

- Process Ball Valve Vent Options: E X Ternal and Internal Ball VentsDocument4 pagesProcess Ball Valve Vent Options: E X Ternal and Internal Ball VentsAlexNo ratings yet

- MS 02 131Document4 pagesMS 02 131Renato OliveiraNo ratings yet

- Orbitical WeldingDocument16 pagesOrbitical WeldingchianqiaoNo ratings yet

- PFA Plug Valves: 43 SeriesDocument2 pagesPFA Plug Valves: 43 SeriesAlexNo ratings yet

- Stream-Select, Switching, and Shutof F Valve Assemblies: T T2 and T2 SeriesDocument8 pagesStream-Select, Switching, and Shutof F Valve Assemblies: T T2 and T2 SeriesAlexNo ratings yet

- Orbital Welding System: Micro Weld HeadsDocument4 pagesOrbital Welding System: Micro Weld HeadsAlexNo ratings yet

- 031342Document8 pages031342AlexNo ratings yet

- Swagelok Gas Filters Ultra High PutityDocument4 pagesSwagelok Gas Filters Ultra High PutitytotcsabNo ratings yet

- PDFDocument3 pagesPDFAlexNo ratings yet

- SystemDocument4 pagesSystemAlexNo ratings yet

- PDFDocument2 pagesPDFAlexNo ratings yet

- Process Ball Valve Handle Options: Handle Kits and Factor Y-Installed HandlesDocument6 pagesProcess Ball Valve Handle Options: Handle Kits and Factor Y-Installed HandlesAlexNo ratings yet

- 031310Document3 pages031310AlexNo ratings yet

- SystemDocument4 pagesSystemAlexNo ratings yet

- VCO O-Ring Face Seal FittingsDocument12 pagesVCO O-Ring Face Seal FittingsAlexNo ratings yet

- MS-01-137 Process Ball ValveDocument6 pagesMS-01-137 Process Ball ValveJacques StrappeNo ratings yet

- Orbital Welding of Titanium Pipe For U.S. Navy ShipsDocument3 pagesOrbital Welding of Titanium Pipe For U.S. Navy ShipsaliNo ratings yet

- Designing A CGMP BioprocessDocument5 pagesDesigning A CGMP Bioprocesshareesh13hNo ratings yet

- DW Uhp UsDocument9 pagesDW Uhp UsnotengofffNo ratings yet

- EWF IAB 348r1 17 SV00 E IMORWP Eur Inter Mechanized Orbital Robot Welding Personnel Short VersionDocument14 pagesEWF IAB 348r1 17 SV00 E IMORWP Eur Inter Mechanized Orbital Robot Welding Personnel Short VersiontaichiNo ratings yet

- High Purity Process Piping - Harmonization of ASME Codes and StandardsDocument8 pagesHigh Purity Process Piping - Harmonization of ASME Codes and StandardsLiu Yangtze100% (1)

- Acceptance Criteria For Orbital WeldingDocument11 pagesAcceptance Criteria For Orbital WeldingtinzarmoeNo ratings yet

- Book - Vol.1&2 - BasicsAndQuality - 22junDocument82 pagesBook - Vol.1&2 - BasicsAndQuality - 22junlth770310No ratings yet

- 10.FITOK Company Brochure 160909Document20 pages10.FITOK Company Brochure 160909inglegs75No ratings yet

- Orbital WeldingDocument4 pagesOrbital WeldingDhruv BhatiaNo ratings yet

- CIP Handbook v1 PDFDocument84 pagesCIP Handbook v1 PDFThiagoSilvaOliver100% (4)

- Technology Development in Welding - Orbital Welding: NtroductionDocument6 pagesTechnology Development in Welding - Orbital Welding: NtroductionrubilNo ratings yet

- 4315631175540ceb0e3d478 85539987Document60 pages4315631175540ceb0e3d478 85539987agoyprikitiwNo ratings yet

- Orbital Welding of Stainless Steel WeldingDocument10 pagesOrbital Welding of Stainless Steel WeldingalathekoalaNo ratings yet

- AWS D18 1 D18 1M 2009 PreDocument14 pagesAWS D18 1 D18 1M 2009 PreJeffersonGutiérrez43% (7)

- B Bottontankvalves CAD RattiinoxDocument14 pagesB Bottontankvalves CAD RattiinoxmiliNo ratings yet

- Biopharm Fittings CatalogDocument102 pagesBiopharm Fittings CatalogjamesmarkusNo ratings yet

- Trime C.A: Industrial and Mechanical WorksDocument70 pagesTrime C.A: Industrial and Mechanical WorksJose RomeroNo ratings yet

- Solda Tubo Espelho Technodata Im99 24.13a e T 250 31.03Document51 pagesSolda Tubo Espelho Technodata Im99 24.13a e T 250 31.03Alessandro SergioNo ratings yet

- Sanimatic Sprayball CatalogDocument6 pagesSanimatic Sprayball CatalograjNo ratings yet

- Adaptive Orbital Pipe Welding - Hamidreza LatifiDocument140 pagesAdaptive Orbital Pipe Welding - Hamidreza LatifiMalcolm DiamondNo ratings yet

- SAF 2507™ Super Duplex Weld FittingsDocument8 pagesSAF 2507™ Super Duplex Weld FittingsRoo FaNo ratings yet

- BPE Technical DataDocument5 pagesBPE Technical Datasmtamaskar2277No ratings yet

- Handbook ESAB - MecTIGDocument15 pagesHandbook ESAB - MecTIGRobertoNo ratings yet

- Ofppt CoursDocument17 pagesOfppt CoursAymen HssainiNo ratings yet

- Instrumentation Tubing and Their ConnectionsDocument127 pagesInstrumentation Tubing and Their Connectionsjeeva4384No ratings yet

- SEMINAR ON HYGIENIC PIPING DESIGNDocument18 pagesSEMINAR ON HYGIENIC PIPING DESIGN12101982100% (2)

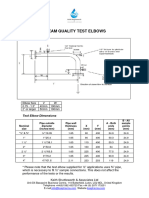

- Test Elbow SpecificationDocument8 pagesTest Elbow Specificationalejandro carmona henaoNo ratings yet

- Welding Hygienic RequirementsDocument5 pagesWelding Hygienic RequirementsZmanNo ratings yet

- Vietz Arcotrac enDocument8 pagesVietz Arcotrac enAlonso Samora ortis100% (1)

- Multiweld BV Orbitaal Stroombron OM 165 CB PDFDocument2 pagesMultiweld BV Orbitaal Stroombron OM 165 CB PDFMarcos AndréNo ratings yet

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsFrom EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNo ratings yet

- Autodesk Inventor | Step by Step: CAD Design and FEM Simulation with Autodesk Inventor for BeginnersFrom EverandAutodesk Inventor | Step by Step: CAD Design and FEM Simulation with Autodesk Inventor for BeginnersNo ratings yet

- Certified Solidworks Professional Advanced Surface Modeling Exam PreparationFrom EverandCertified Solidworks Professional Advanced Surface Modeling Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Contactless Vital Signs MonitoringFrom EverandContactless Vital Signs MonitoringWenjin WangNo ratings yet

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Fusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.From EverandFusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.No ratings yet

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)