Professional Documents

Culture Documents

Rear Axle: Section

Uploaded by

Hakob AdamyanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rear Axle: Section

Uploaded by

Hakob AdamyanCopyright:

Available Formats

TRANSMISSION & DRIVELINE

SECTION RAX REAR AXLE

B

RAX

E

CONTENTS

SYMPTOM DIAGNOSIS ............................... 2 Inspection ................................................................. 6 F

NOISE, VIBRATION AND HARSHNESS REMOVAL AND INSTALLATION ................ 7

(NVH) TROUBLESHOOTING ............................. 2 G

NVH Troubleshooting Chart ...................................... 2

REAR WHEEL HUB AND HOUSING ................ 7

Exploded View .......................................................... 7

PRECAUTION ............................................... 3 Removal and Installation .......................................... 7

Inspection ................................................................. 9 H

PRECAUTIONS ................................................... 3

Precautions for Drive Shaft ....................................... 3 REAR DRIVE SHAFT ........................................ 10

Exploded View .........................................................10

I

PREPARATION ............................................ 4 Removal and Installation .........................................10

Disassembly and Assembly .....................................11

PREPARATION ................................................... 4 Inspection ................................................................15

Special Service Tool ................................................. 4 J

Commercial Service Tool .......................................... 4 SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................ 16

PERIODIC MAINTENANCE .......................... 5 K

SERVICE DATA AND SPECIFICATIONS

REAR WHEEL HUB AND HOUSING ................. 5 (SDS) ................................................................. 16

Inspection .................................................................. 5

Wheel Bearing .........................................................16

L

REAR DRIVE SHAFT .......................................... 6 Drive Shaft ...............................................................16

Revision: 2013 February RAX-1 2012 G Sedan

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SYMPTOM DIAGNOSIS >

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart INFOID:0000000007464039

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

Refer to DRIVE SHAFT in this chart.

Refer to REAR AXLE in this chart.

NVH in RAX and RSU sections.

NVH in DLN section.

NVH in DLN section.

NVH in WT section.

NVH in WT section.

NVH in BR section.

NVH in ST section.

RAX-15

RAX-7

—

—

Reference

REAR AXLE AND REAR SUSPENSION

Improper installation, looseness

Joint sliding resistance

PROPELLER SHAFT

Excessive joint angle

Possible cause and SUSPECTED PARTS Parts interference

DIFFERENTIAL

ROAD WHEEL

DRIVE SHAFT

REAR AXLE

STEERING

Imbalance

BRAKE

TIRE

DRIVE Noise × × × × × × × × × ×

SHAFT Shake × × × × × × × × ×

Noise × × × × × × × × × ×

Shake × × × × × × × × ×

Symptom

Vibration × × × × × × ×

REAR AXLE

Shimmy × × × × × × ×

Judder × × × × × ×

Poor quality ride or handling × × × × ×

×: Applicable

Revision: 2013 February RAX-2 2012 G Sedan

PRECAUTIONS

< PRECAUTION >

PRECAUTION A

PRECAUTIONS

Precautions for Drive Shaft INFOID:0000000007464040

B

• Observe the following precautions when disassembling and assembling drive shaft.

• Never disassemble joint sub-assembly because it is non-overhaul parts.

• Perform work in a location which is as dust-free as possible. C

• Clean the parts, before disassembling and assembling.

• Prevent the entry of foreign objects during disassembly of the service location.

• Reassemble disassembled parts carefully in the correct order. If work is interrupted, a clean cover must be RAX

placed over parts.

• Use paper waste. Fabric shop cloths must not be used because of the danger of lint adhering to parts.

• Clean disassembled parts (except for rubber parts) with kerosene which shall be removed by blowing with

air or wiping with paper waste. E

Revision: 2013 February RAX-3 2012 G Sedan

PREPARATION

< PREPARATION >

PREPARATION

PREPARATION

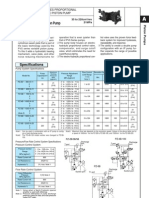

Special Service Tool INFOID:0000000007464041

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.) Description

Tool name

KV40107300 Installing boot band

( − )

Boot band crimping tool

ZZA1229D

Commercial Service Tool INFOID:0000000007464042

Tool name Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: 2013 February RAX-4 2012 G Sedan

REAR WHEEL HUB AND HOUSING

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE A

REAR WHEEL HUB AND HOUSING

Inspection INFOID:0000000007464043

B

MOUNTING INSPECTION

Make sure the mounting conditions (looseness, back lash) of each component and component conditions C

(wear, damage) are normal.

WHEEL BEARING INSPECTION

• Move wheel hub and bearing assembly in the axial direction by hand. Make sure there is no looseness of RAX

wheel bearing.

Standard E

Axial end play : Refer to RAX-16, "Wheel Bearing".

• Rotate wheel hub and bearing assembly and make sure that is no unusual noise or other irregular condi-

tions. If there is any of irregular conditions, replace wheel hub and bearing assembly. F

Revision: 2013 February RAX-5 2012 G Sedan

REAR DRIVE SHAFT

< PERIODIC MAINTENANCE >

REAR DRIVE SHAFT

Inspection INFOID:0000000007464044

• Check drive shaft mounting point and joint for looseness and other damage.

• Check boot for cracks and other damage.

CAUTION:

Replace entire drive shaft assembly when noise or vibration occurs from drive shaft.

Revision: 2013 February RAX-6 2012 G Sedan

REAR WHEEL HUB AND HOUSING

< REMOVAL AND INSTALLATION >

REMOVAL AND INSTALLATION A

REAR WHEEL HUB AND HOUSING

Exploded View INFOID:0000000007464045

B

RAX

JPDIG0178GB

H

1. Ball seat 2. Bushing 3. Cotter pin

4. Axle housing 5. Back plate 6. Anchor block

7. Wheel hub and bearing assembly 8. Spring washer 9. Wheel hub lock nut I

10. Adjusting cap

A. Tightening must be done following

the installation procedure. Refer to J

RAX-7, "Removal and Installation".

Refer to GI-4, "Components" for symbols in the figure.

Removal and Installation INFOID:0000000007464046

K

REMOVAL

L

Wheel Hub and Bearing Assembly

1. Remove tire from vehicle with power tool.

2. Remove caliper assembly. Hang caliper assembly in a place where it will not interfere with work. Refer to M

BR-61, "BRAKE CALIPER ASSEMBLY (1 PISTON TYPE) : Exploded View" (1 piston type), BR-65,

"BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Exploded View" (2 piston type).

CAUTION: N

Never depress brake pedal while brake caliper is removed.

3. Remove disc rotor. Refer to BR-62, "BRAKE CALIPER ASSEMBLY (1 PISTON TYPE) : Removal and

Installation" (1 piston type), BR-66, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Removal and

Installation" (2 piston type). O

4. Remove cotter pin and adjusting cap, then loosen wheel hub lock nut with a power tool.

Revision: 2013 February RAX-7 2012 G Sedan

REAR WHEEL HUB AND HOUSING

< REMOVAL AND INSTALLATION >

5. Put matching mark (A) on drive shaft and wheel hub and bearing

assembly.

JPDIG0121ZZ

6. Patch wheel hub lock nut with a piece of wood. Hammer the wood to disengage wheel hub and bearing

assembly from drive shaft. Take out the wheel hub lock nut and spring washer.

CAUTION:

• Never place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for counterpart such as joint sub-assem-

bly, and other parts.

NOTE:

Use a suitable puller, if the wheel hub and bearing assembly and drive shaft cannot be separated even

after performing the above procedure.

7. Remove cotter pin, then loosen suspension arm mounting nut of axle housing.

8. Remove the wheel hub and bearing assembly.

Axle Housing

1. Remove wheel hub and bearing assembly.

2. Remove parking brake shoe and parking brake cable from back plate. Refer to PB-9, "Exploded View".

3. Remove mounting nuts in stabilizer side of stabilizer connecting rod with power tool. Refer to RSU-33,

"TYPE A : Exploded View" (Type A), RSU-34, "TYPE B : Exploded View" (Type B).

4. Remove axle side nuts and bolts on radius rod. Refer to RSU-25, "TYPE A : Exploded View" (Type A),

RSU-26, "TYPE B : Exploded View" (Type B).

5. Remove coil spring. Refer to RSU-10, "TYPE A : Exploded View" (Type A), RSU-12, "TYPE B : Exploded

View" (Type B).

6. Set suitable jack under axle housing.

7. Remove shock absorber mounting bolts and nuts (axle housing side) with power tool. Refer to RSU-10,

"TYPE A : Exploded View" (Type A), RSU-12, "TYPE B : Exploded View" (Type B).

8. Remove front lower link nuts and bolts (axle housing side), separate front lower link from axle housing.

Refer to RSU-10, "TYPE A : Exploded View" (Type A), RSU-12, "TYPE B : Exploded View" (Type B).

9. Separate suspension arm from axle housing so as not to damage ball joint boot using ball joint remover,

and then remove axle housing from the vehicle.

CAUTION:

• Temporarily tighten nuts to prevent damage to threads and to prevent the ball joint remover from

coming off.

• Never place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for counterpart such as joint sub-assem-

bly, and other parts.

10. Remove anchor block mounting nuts, and then remove anchor block and back plate from axle housing.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Clean the matching surface of wheel hub lock nut and wheel hub and bearing assembly.

CAUTION:

Never apply lubricating oil to these matching surface.

Revision: 2013 February RAX-8 2012 G Sedan

REAR WHEEL HUB AND HOUSING

< REMOVAL AND INSTALLATION >

• Clean the matching surface of drive shaft and wheel hub and bear-

ing assembly. And then apply paste [service parts (440037S000)] A

to surface (A) of joint sub-assembly of drive shaft.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assembly

B

of drive shaft.

Amount paste 1.0 – 3.0 g (0.04 – 0.10 oz)

C

• When installing drive shaft, change the drive shaft and wheel hub

and bearing assembly matching marks put at the removal step by

180 degree. JPDIG0122ZZ

• Use the following torque range for tightening the wheel hub lock RAX

nut.

: 100 – 105 N·m (10 – 11 kg-m, 74 – 77 ft-lb) E

CAUTION:

• Since the drive shaft is assembled by press-fitting, use the tightening torque range for the wheel

hub lock nut. F

• Be sure to use torque wrench to tighten the wheel hub lock nut. Never use a power tool.

NOTE:

Wheel hub lock nut tightening torque does not over torque for avoiding axle noise, and does not less than G

torque for avoiding looseness.

• Perform the final tightening of each of parts under unladen conditions, which were removed when removing

wheel hub and bearing assembly and axle housing.

H

• When installing the spring washer, face the identification paint mark to the wheel hub and bearing assembly

side.

• When installing the adjusting cap, check that there must be no play.

• Never reuse cotter pin, wheel hub lock nut, spring washer, and bushing. I

Inspection INFOID:0000000007464047

J

INSPECTION AFTER REMOVAL

Wheel Hub and Bearing Assembly

Check the wheel hub and bearing assembly for wear, cracks, and damage. Replace if necessary. K

Axle Housing

Check the axle housing for wear, cracks, and damage. Replace if necessary.

Ball Joint Inspection L

Check for boot breakage, axial looseness, and torque of suspension arm ball joint. Refer to RSU-7, "Inspec-

tion".

M

INSPECTION AFTER INSTALLATION

• Check wheel alignment. Refer to RSU-8, "Inspection".

• Adjust neutral position of steering angle sensor. Refer to BRC-9, "ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION : Special Repair Requirement". N

• Adjust parking brake operation (stroke). Refer to PB-3, "PEDAL TYPE : Inspection and Adjustment" (pedal

type), PB-4, "LEVER TYPE : Inspection and Adjustment" (lever type).

O

Revision: 2013 February RAX-9 2012 G Sedan

REAR DRIVE SHAFT

< REMOVAL AND INSTALLATION >

REAR DRIVE SHAFT

Exploded View INFOID:0000000007464048

JPDIG0162GB

1. Housing 2. Snap ring 3. Ball cage/steel ball/inner race as-

sembly

4. Stopper ring 5. Boot band 6. Boot

7. Shaft 8. Circular clip 9. Joint sub-assembly

10. Dust shield

: Wheel side

1: NISSAN genuine grease or an equivalent.

2: Apply paste [service parts (440037S000)].

Refer to GI-4, "Components" for symbols not described on the above.

Removal and Installation INFOID:0000000007464049

REMOVAL

1. Remove tire from vehicle with power tool.

2. Remove cotter pin and adjusting cap, then loosen wheel hub lock nut with power tool.

3. Put matching mark (A) on drive shaft and wheel hub and bearing

assembly.

4. Remove main muffler and center muffler. Refer to EX-5,

"Exploded View".

5. Patch wheel hub lock nut with a piece of wood. Hammer the

wood to disengage wheel hub and bearing assembly from drive

shaft. Take out the wheel hub lock nut and spring washer.

CAUTION:

• Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for JPDIG0121ZZ

counterpart such as joint sub-assembly, and other parts.

NOTE:

Using a suitable puller if the wheel hub and bearing assembly and drive shaft cannot be separated even

after performing the above procedure.

6. Remove mounting bolts between side flange and drive shaft.

INSTALLATION

Revision: 2013 February RAX-10 2012 G Sedan

REAR DRIVE SHAFT

< REMOVAL AND INSTALLATION >

Note the following, and install in the reverse order of removal.

• Clean the matching surface of wheel hub lock nut and wheel hub and bearing assembly. A

CAUTION:

Never apply lubricating oil to these matching surface.

• Clean the matching surface of drive shaft and wheel hub and bear-

B

ing assembly. And then apply paste [service parts (440037S000)]

to surface (A) of joint sub-assembly of drive shaft.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assembly C

of drive shaft.

Amount paste 1.0 – 3.0 g (0.04 – 0.10 oz) RAX

• When installing drive shaft, change the drive shaft and wheel hub

and bearing assembly matching marks put at the removal step by

180 degree. JPDIG0122ZZ

E

• Use the following torque range for tightening the wheel hub lock

nut.

: 100 – 105 N·m (10 – 11 kg-m, 74 – 77 ft-lb) F

CAUTION:

• Since the drive shaft is assembled by press-fitting, use the tightening torque range for the wheel G

hub lock nut.

• Be sure to use torque wrench to tighten the wheel hub lock nut. Never use a power tool.

NOTE:

H

Wheel hub lock nut tightening torque does not over torque for avoiding axle noise, and does not less than

torque for avoiding looseness.

• Perform the final tightening of each of parts under unladen conditions, which were removed when removing

wheel hub and bearing assembly and axle housing. I

• When installing the spring washer, face the identification paint mark to the wheel hub and bearing assembly

side.

• When installing the adjusting cap, check that there must be no play. J

• Never reuse cotter pin, wheel hub lock nut, and spring washer.

Disassembly and Assembly INFOID:0000000007464050

K

DISASSEMBLY

Rear Final Drive Side

L

1. Fix shaft with a vise.

CAUTION:

Protect shaft when fixing with a vise using aluminum or copper plates.

2. Remove boot bands, and then remove boot from housing. M

3. Put matching marks on housing and shaft.

CAUTION:

Use paint or similar substance for matching marks. Never scratch the surface. N

4. Remove stopper ring with suitable tool, and pull out housing.

5. Put matching marks on ball cage/steel ball/inner race assembly

and shaft. O

CAUTION:

Use paint or similar substance for matching marks. Never

scratch the surface. P

SRA249A

Revision: 2013 February RAX-11 2012 G Sedan

REAR DRIVE SHAFT

< REMOVAL AND INSTALLATION >

6. Remove snap ring, then remove ball cage/steel ball/inner race

assembly from shaft.

7. Remove boot from shaft.

SFA514A

Wheel Side

1. Remove dust shield from drive shaft.

2. Fix shaft with a vise.

CAUTION:

Protect shaft when fixing with a vise using aluminum or copper plates.

3. Remove boot bands. Then remove boot from joint sub-assembly.

4. Screw the drive shaft puller (A) 30 mm (1.18 in) or more into the

thread of joint sub-assembly, and pull joint sub-assembly with a

sliding hammer (B) from shaft.

CAUTION:

• If joint sub-assembly cannot be removed after five or

more unsuccessful attempts, replace shaft and joint sub

assembly as a set.

• Align sliding hammer and drive shaft and remove them by

pulling directory.

5. Remove circular clip from shaft.

6. Remove boot from shaft. JPDIF0015ZZ

ASSEMBLY

Rear Final Drive Side

1. Remove old grease on housing with paper paste.

2. Install new boot and boot band to shaft.

CAUTION:

• Wrap serrated part of shaft with tape to protect from damage.

• Never reuse boot and boot band.

3. Remove the tape wrapped around the serrated on shaft.

4. Install ball cage/steel ball/inner race assembly (1) to shaft (2),

and secure them tightly with a snap ring (3).

CAUTION:

Never reuse snap ring.

NOTE:

Align matching marks painted when ball cage/steel ball/inner

race assembly were removed.

5. Apply the appropriate amount of grease onto housing and slid

surface.

NOTE:

Align matching marks painted when housing were removed. JPDIG0004ZZ

Standard

Grease amount : Refer to RAX-16, "Drive

Shaft".

6. Install stopper ring to housing.

7. After installed, pull shaft to check engagement between housing and stopper ring.

Revision: 2013 February RAX-12 2012 G Sedan

REAR DRIVE SHAFT

< REMOVAL AND INSTALLATION >

8. Install boot securely into grooves (indicated by “*” marks) shown

in the figure. A

CAUTION:

If there is grease on boot mounting surfaces (indicated by

“*” marks) of shaft or housing, boot may come off. Remove

B

all grease from the surfaces.

9. To prevent the deformation of the boot, adjust the boot installa-

tion length (L) to the value shown below by inserting the suitable

tool into the inside of boot from the large diameter side of boot C

and discharging inside air.

JPDIF0223ZZ

Standard RAX

Boots installed : Refer to RAX-16, "Drive

length (L) Shaft".

E

CAUTION:

• If the boot installation length is outside the standard, it may cause breakage of boot.

• Be careful not to touch the inside of the boot with the tip of tool.

10. Install new boot bands securely. F

CAUTION:

Never reuse boot band.

a. For one-touch clamp band G

i. Secure large and small ends of boot with new boot bands as

shown in the figure.

H

J

PDIA1188J

b. For low profile type band K

i. Put boot band in the groove on drive shaft boot. Then fit pawls

( ) into holes to temporary installation.

NOTE: L

For the large diameter side, fit projection (A) and guide slit (B) at

first.

M

N

SDIA3557E

ii. Pinch projection on the band with suitable pliers to tighten band. O

iii. Insert tip of band below end of the pawl.

SDIA3558E

Revision: 2013 February RAX-13 2012 G Sedan

REAR DRIVE SHAFT

< REMOVAL AND INSTALLATION >

11. Secure housing and shaft, and then make sure that they are in the correct position when rotating boot.

Install them with new boot band when the mounting positions become incorrect.

Wheel Side

1. Clean old grease on joint sub-assembly with paper waste.

2. Apply the specified amount of grease into joint sub-assembly serration hole until grease begins to ooze

from ball groove and serration hole.

CAUTION:

After applying grease, use a paper waste to wipe off old grease that has oozed out.

3. Install new boot and boot band to shaft.

CAUTION:

• Wrap serrated part of shaft with tape to protect from damage.

• Never reuse boot and boot band.

4. Remove the tape wrapped around the serrated on shaft.

5. Position circular clip on groove at the shaft edge.

CAUTION:

Never reuse circular clip.

NOTE:

Drive joint inserter is recommended when installing circular clip.

6. Align both center axles of the shaft edge and joint sub-assembly. Then assemble shaft with circular clip

joint sub-assembly.

7. Install joint sub-assembly to shaft using plastic hammer.

CAUTION:

Confirm that joint sub-assembly is correctly engaged while

rotating drive shaft.

8. Apply the balance of the specified amount of grease into the

boot inside from large diameter side of boot.

Standard

Grease amount : Refer to RAX-16, "Drive

Shaft". RAC0049D

9. Install the boot securely into grooves (indicated by “*” marks)

shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (with “*”

mark) on the shaft or housing, boot may come off. Remove

all grease from the surfaces.

10. To prevent the deformation of the boot, adjust the boot installa-

tion length (L) to the specified value shown below by inserting

the suitable tool into inside of the boot from the large diameter

side of boot and discharging the inside air.

JPDIF0222ZZ

Standard

Boots installed : Refer to RAX-16, "Drive

length (L) Shaft".

CAUTION:

• If the boot installation length is outside the standard, it may cause breakage of boot.

• Be careful not to touch the inside of the boot with the tip of tool.

Revision: 2013 February RAX-14 2012 G Sedan

REAR DRIVE SHAFT

< REMOVAL AND INSTALLATION >

11. Secure the large and small ends of the boot with boot bands

using the boot band crimping tool (A) [SST: KV40107300 ( − A

)].

PDIA1187J

RAX

NOTE:

Secure boot band so that dimension (M) meets the specification

as shown in the figure. E

Dimension “M” : 1.0 – 4.0 mm (0.039 – 0.157 in)

12. Secure joint sub-assembly and shaft, and then make sure that F

they are in the correct position when rotating boot. Install them

with boot band when boot installation positions become incor-

rect. G

13. Install dust shield to drive shaft.

DSF0047D

H

Inspection INFOID:0000000007464051

INSPECTION AFTER REMOVAL I

• Move joint up/down, left/right, and in the axial direction. Check for any rough movement or significant loose-

ness.

• Check boot for cracks or other damage, and also for grease leak-

age. J

• If a malfunction is found, disassemble drive shaft, and then replace

with new one.

K

RAA0030D

M

Revision: 2013 February RAX-15 2012 G Sedan

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Bearing INFOID:0000000007464052

Item Standard

Axial end play 0.05 mm (0.002 in) or less

Drive Shaft INFOID:0000000007464053

Item Standard

Joint Wheel side Final drive side

Grease quantity 110 – 120 g (3.38 – 4.23 oz) 124 – 134 g (4.37 – 4.73 oz)

Boots installed length 150.68 mm (5.93 in) 155 mm (6.10 in)

Revision: 2013 February RAX-16 2012 G Sedan

You might also like

- Rear Axle: SectionDocument21 pagesRear Axle: Sectionjair HernandezNo ratings yet

- Rear Suspension: SectionDocument13 pagesRear Suspension: SectionjasleenNo ratings yet

- Rear Axle: SectionDocument16 pagesRear Axle: SectionMaiChiVuNo ratings yet

- Front Axle: SectionDocument9 pagesFront Axle: SectionAgustin Borge GarciaNo ratings yet

- TRANSMISSION & DRIVELINE TROUBLESHOOTINGDocument31 pagesTRANSMISSION & DRIVELINE TROUBLESHOOTINGOpuNo ratings yet

- Nissan Titan 13/raxDocument12 pagesNissan Titan 13/raxgiancarlo sanchezNo ratings yet

- Rear Axle: SectionDocument17 pagesRear Axle: SectionLíder DieselNo ratings yet

- Rear Axle: SectionDocument15 pagesRear Axle: SectionederengNo ratings yet

- Rear Suspension: SectionDocument14 pagesRear Suspension: SectiontecnicofigueroaNo ratings yet

- DRIVELINE DIAGNOSISDocument31 pagesDRIVELINE DIAGNOSISАндрей НадточийNo ratings yet

- Fax PDFDocument29 pagesFax PDFMaiChiVuNo ratings yet

- REAR AXLE RaxDocument27 pagesREAR AXLE Raxciro_svNo ratings yet

- Steering System: SectionDocument20 pagesSteering System: SectionJuan Miguel Ossa OspinaNo ratings yet

- Steering System: SectionDocument19 pagesSteering System: SectionNestorNo ratings yet

- Clutch: SectionDocument17 pagesClutch: Sectionjoeldqcgh29No ratings yet

- Rear Axle: SectionDocument8 pagesRear Axle: SectionNestor RosalesNo ratings yet

- 41 Manual Nissan Sentra 2013Document16 pages41 Manual Nissan Sentra 2013DavidNo ratings yet

- PARKING BRAKE SYSTEM PBDocument15 pagesPARKING BRAKE SYSTEM PBciro_svNo ratings yet

- Front Axle: SectionDocument30 pagesFront Axle: SectionFELIX RASHIANNo ratings yet

- TRANSMISSION & DRIVELINE REAR AXLE (RAXDocument9 pagesTRANSMISSION & DRIVELINE REAR AXLE (RAXjoeldqcgh29No ratings yet

- TRANSMISSION & DRIVELINE TROUBLESHOOTING GUIDEThe title "TITLETRANSMISSION & DRIVELINE TROUBLESHOOTING GUIDEDocument32 pagesTRANSMISSION & DRIVELINE TROUBLESHOOTING GUIDEThe title "TITLETRANSMISSION & DRIVELINE TROUBLESHOOTING GUIDEPablo Marchese HuertaNo ratings yet

- Fax PDFDocument16 pagesFax PDFronaldNo ratings yet

- Rear Suspension: SectionDocument23 pagesRear Suspension: SectionederengNo ratings yet

- Front Axle: SectionDocument16 pagesFront Axle: SectionMaiChiVuNo ratings yet

- 9194 2014 Nissan Leaf Service RepairDocument16 pages9194 2014 Nissan Leaf Service RepairEngr Ko VictorNo ratings yet

- Rear Suspension: SectionDocument12 pagesRear Suspension: SectionDudu RodriguesNo ratings yet

- Section: Revision: January 2010 2010 VersaDocument30 pagesSection: Revision: January 2010 2010 VersaemenelikNo ratings yet

- Front Axle: SectionDocument28 pagesFront Axle: SectionHakob AdamyanNo ratings yet

- Front Axle: SectionDocument16 pagesFront Axle: SectionZona Educación Especial ZacapaoaxtlaNo ratings yet

- GW PDFDocument21 pagesGW PDFMaiChiVuNo ratings yet

- Rear Suspension NVH TroubleshootingDocument20 pagesRear Suspension NVH TroubleshootingRifki AwaludinNo ratings yet

- Section: Body InteriorDocument48 pagesSection: Body InteriorCarlos arturo Jimenez marinNo ratings yet

- Manual Transaxle: SectionDocument95 pagesManual Transaxle: SectionemenelikNo ratings yet

- Front Axle: SectionDocument25 pagesFront Axle: SectiontecnicofigueroaNo ratings yet

- Steering System: SectionDocument21 pagesSteering System: SectionDiego496No ratings yet

- Transaxle TransmissionDocument463 pagesTransaxle Transmissionhenry_zambranoNo ratings yet

- Front Axle: SectionDocument52 pagesFront Axle: SectionCarlos Tito AmésquitaNo ratings yet

- Rsu PDFDocument15 pagesRsu PDFMisha KulibaevNo ratings yet

- Direccion AsistidaDocument21 pagesDireccion Asistidaastroboy2666No ratings yet

- (TM) Nissan Manual de Taller Nissan Tiida 2010 en InglesDocument17 pages(TM) Nissan Manual de Taller Nissan Tiida 2010 en InglesLUIS ALFONZONo ratings yet

- Srs Airbag: SectionDocument23 pagesSrs Airbag: SectionNestor RosalesNo ratings yet

- TRANSMISSION & DRIVELINE NVH ISSUESDocument32 pagesTRANSMISSION & DRIVELINE NVH ISSUESSlava SlickNo ratings yet

- Front Axle: SectionDocument26 pagesFront Axle: SectionPetter VillarroelNo ratings yet

- Interior: SectionDocument33 pagesInterior: SectionMax RughfiddNo ratings yet

- Rear Suspension: SectionDocument30 pagesRear Suspension: SectionLíder DieselNo ratings yet

- Glass & Window System: SectionDocument25 pagesGlass & Window System: SectioncesarNo ratings yet

- AIR BAG Frontier 08Document20 pagesAIR BAG Frontier 08Denílson M. GarciaNo ratings yet

- Instrument Panel Nissan NoteDocument26 pagesInstrument Panel Nissan NoteWilmer Elias Quiñonez HualpaNo ratings yet

- Clutch: SectionDocument24 pagesClutch: SectionHakob AdamyanNo ratings yet

- Engine Lubrication System: SectionDocument17 pagesEngine Lubrication System: SectiontecnicofigueroaNo ratings yet

- Front Axle: SectionDocument32 pagesFront Axle: SectionLuis BarriosNo ratings yet

- Srs Airbag: SectionDocument23 pagesSrs Airbag: SectionMaiChiVuNo ratings yet

- TRANSMISSION & DRIVELINE COMPONENTSDocument28 pagesTRANSMISSION & DRIVELINE COMPONENTSWilmer Elias Quiñonez HualpaNo ratings yet

- Rear Suspension: SectionDocument14 pagesRear Suspension: SectionDagoberto MoralesNo ratings yet

- Steering System: SectionDocument20 pagesSteering System: SectionАндрей НегричукNo ratings yet

- Rear Axle Section GuideDocument9 pagesRear Axle Section GuideEngr Ko VictorNo ratings yet

- Rsu PDFDocument13 pagesRsu PDFHarol CastilloNo ratings yet

- Brake SystemDocument41 pagesBrake Systemhenry_zambranoNo ratings yet

- South Africa’s Renewable Energy IPP Procurement ProgramFrom EverandSouth Africa’s Renewable Energy IPP Procurement ProgramNo ratings yet

- Section: Driver ControlsDocument4 pagesSection: Driver ControlsHakob AdamyanNo ratings yet

- Exhaust System: SectionDocument6 pagesExhaust System: SectionHakob AdamyanNo ratings yet

- Quick reference guide for hybrid vehicle systemsDocument7 pagesQuick reference guide for hybrid vehicle systemsHakob AdamyanNo ratings yet

- Front Axle: SectionDocument28 pagesFront Axle: SectionHakob AdamyanNo ratings yet

- Charging System: SectionDocument34 pagesCharging System: SectionHakob AdamyanNo ratings yet

- Clutch: SectionDocument24 pagesClutch: SectionHakob AdamyanNo ratings yet

- Who Recommended Hand-Rub FormulationDocument9 pagesWho Recommended Hand-Rub FormulationSaeed Mohammed100% (2)

- ADP System Manual Section OverviewDocument207 pagesADP System Manual Section OverviewHakob AdamyanNo ratings yet

- SFF 8472 (Diagnostic Monitoring Interface)Document39 pagesSFF 8472 (Diagnostic Monitoring Interface)ferchllNo ratings yet

- Manual of SP-B Pocket Tissue Folding MachineDocument32 pagesManual of SP-B Pocket Tissue Folding MachinenkemgweleolevanelsonNo ratings yet

- Parts Catalogue: CBZ X-TREME (Oct, 2008)Document96 pagesParts Catalogue: CBZ X-TREME (Oct, 2008)Suyash Karnawat0% (1)

- CM20160713 53120 15686 PDFDocument44 pagesCM20160713 53120 15686 PDFNam Anh Trần100% (1)

- Novi Enerji Makina Servis San Mail - Perkins Parts InvoiceDocument2 pagesNovi Enerji Makina Servis San Mail - Perkins Parts InvoiceFlorent A. d'Agoué CADETENo ratings yet

- Auma India Gearbox Catalogue - NewDocument40 pagesAuma India Gearbox Catalogue - NewsrdNo ratings yet

- Factory carburetor setups for GM big and small blocksDocument29 pagesFactory carburetor setups for GM big and small blocksFranziska Kujumdshiev100% (1)

- ZF - Error Code ListDocument56 pagesZF - Error Code ListHenrique88% (16)

- Spare Parts Manual: Engine: ART - NO.: 3CM089308HENDocument28 pagesSpare Parts Manual: Engine: ART - NO.: 3CM089308HENcharlesNo ratings yet

- Engineers Tool CatalogueDocument128 pagesEngineers Tool CatalogueAlvaro RochaNo ratings yet

- Foam Pump Operating and Maintenance ManualDocument16 pagesFoam Pump Operating and Maintenance ManualsaifNo ratings yet

- Craftsman Garden Tractor Owners Manual L0901647 PDFDocument72 pagesCraftsman Garden Tractor Owners Manual L0901647 PDFFrank SnyderNo ratings yet

- All About HidrolicDocument7 pagesAll About Hidrolicpiteng1945100% (3)

- Parts Manual VH4DDocument70 pagesParts Manual VH4DJosé Miguel Sánchez FaríasNo ratings yet

- Repairs BrochureDocument8 pagesRepairs BrochurejerrysohNo ratings yet

- Crane ChecklistDocument3 pagesCrane ChecklistAbdul Rehman SheikhNo ratings yet

- Wagner Hydraulic Cylinder Repair: SectionDocument4 pagesWagner Hydraulic Cylinder Repair: SectionLuis Silva NavarroNo ratings yet

- TMF OPS Construction Fleet Status Per Requisition Original Request 21NOV... (00000003)Document8 pagesTMF OPS Construction Fleet Status Per Requisition Original Request 21NOV... (00000003)Manuel VargasNo ratings yet

- Chapter 3 - Flow Mechanism in The Rotor of A TurbomachineDocument37 pagesChapter 3 - Flow Mechanism in The Rotor of A TurbomachineSiraj Mohammed100% (1)

- 771 772 773seriesvalves-ImDocument4 pages771 772 773seriesvalves-Imza3amNo ratings yet

- Ma TP2 01+Document251 pagesMa TP2 01+Arvind ShuklaNo ratings yet

- Liebherr T282C SpecificationsDocument22 pagesLiebherr T282C Specificationsbas100% (1)

- Altistart 48 CatalogueDocument51 pagesAltistart 48 CataloguerubysultanaNo ratings yet

- Air ConditioningDocument12 pagesAir ConditioningSNo ratings yet

- Parts of Motorcycle EngineDocument12 pagesParts of Motorcycle EngineRj Saneubac Guhabac100% (1)

- Catalago Cummins - Nta855-GDocument45 pagesCatalago Cummins - Nta855-GAnonymous 9fCAFynM78% (9)

- Trans Hyd SysDocument3 pagesTrans Hyd SysRajan Mullappilly100% (1)

- Installation Instructions For Axial Fans For Bathroom, Toilets, Utility Rooms and KitchensDocument2 pagesInstallation Instructions For Axial Fans For Bathroom, Toilets, Utility Rooms and KitchenstylerdurdaneNo ratings yet

- Cat PotenciaDocument12 pagesCat PotenciaGustavo Vargas100% (1)

- Mesb4013 Group 1 Mini Project ReportDocument22 pagesMesb4013 Group 1 Mini Project ReportShahid AmmarNo ratings yet

- Liebert Ds 28 105kw 8 30 Tons System Design ManualDocument234 pagesLiebert Ds 28 105kw 8 30 Tons System Design ManualAlejandro Lopez100% (3)