Professional Documents

Culture Documents

Front Axle: Section

Uploaded by

Hakob AdamyanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Front Axle: Section

Uploaded by

Hakob AdamyanCopyright:

Available Formats

TRANSMISSION & DRIVELINE

SECTION FAX FRONT AXLE

B

FAX

E

CONTENTS

2WD NOISE, VIBRATION AND HARSHNESS F

(NVH) TROUBLESHOOTING ........................... 10

SYMPTOM DIAGNOSIS ............................... 3 NVH Troubleshooting Chart ....................................10

G

NOISE, VIBRATION AND HARSHNESS PRECAUTION .............................................. 11

(NVH) TROUBLESHOOTING ............................. 3

NVH Troubleshooting Chart ...................................... 3 PRECAUTIONS ................................................. 11

Precaution for Supplemental Restraint System H

PRECAUTION ............................................... 4 (SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................11

PRECAUTIONS ................................................... 4 Precautions for Drive Shaft ......................................11 I

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- PREPARATION ........................................... 12

SIONER" ................................................................... 4

PREPARATION ................................................. 12 J

PREPARATION ............................................ 5 Special Service Tool ................................................12

Commercial Service Tool ........................................13

PREPARATION ................................................... 5

K

Commercial Service Tool .......................................... 5 PERIODIC MAINTENANCE ........................ 14

PERIODIC MAINTENANCE .......................... 6 FRONT WHEEL HUB AND KNUCKLE ............ 14

Inspection ................................................................14 L

FRONT WHEEL HUB AND KNUCKLE .............. 6

Inspection .................................................................. 6 FRONT DRIVE SHAFT ..................................... 15

Inspection ................................................................15 M

REMOVAL AND INSTALLATION ................ 7

REMOVAL AND INSTALLATION ............... 16

FRONT WHEEL HUB AND KNUCKLE .............. 7

Exploded View .......................................................... 7 FRONT WHEEL HUB AND KNUCKLE ............ 16 N

Removal and Installation ........................................... 7 Exploded View .........................................................16

Inspection .................................................................. 8 Removal and Installation .........................................16

Inspection ................................................................17

SERVICE DATA AND SPECIFICATIONS O

(SDS) ............................................................. 9 FRONT DRIVE SHAFT BOOT .......................... 18

Exploded View .........................................................18

SERVICE DATA AND SPECIFICATIONS Replacement ...........................................................18 P

(SDS) ................................................................... 9

Wheel Bearing ........................................................... 9 FRONT DRIVE SHAFT ..................................... 22

AWD Exploded View .........................................................22

Removal and Installation .........................................23

SYMPTOM DIAGNOSIS .............................. 10 Disassembly and Assembly .....................................23

Inspection ................................................................26

Revision: 2013 February FAX-1 2012 G Sedan

SERVICE DATA AND SPECIFICATIONS SERVICE DATA AND SPECIFICATIONS

(SDS) ........................................................... 28 (SDS) ................................................................. 28

Wheel Bearing ........................................................ 28

Drive Shaft .............................................................. 28

Revision: 2013 February FAX-2 2012 G Sedan

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SYMPTOM DIAGNOSIS > [2WD]

SYMPTOM DIAGNOSIS A

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart INFOID:0000000007467011

B

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

C

NVH in FAX and FSU sections

NVH in WT section

NVH in WT section

NVH in BR section

NVH in ST section

FAX

FAX-7

FAX-6

—

Reference

FRONT AXLE AND FRONT SUSPENSION

G

Improper installation, looseness

H

Wheel bearing damage

Possible cause and SUSPECTED PARTS

Parts interference

ROAD WHEEL

I

STEERING

BRAKE

TIRE

J

Noise × × × × × × × ×

Shake × × × × × × × × K

Vibration × × × × × ×

Symptom FRONT AXLE

Shimmy × × × × × × ×

Judder × × × × × × L

Poor quality ride or handling × × × × ×

×: Applicable

M

Revision: 2013 February FAX-3 2012 G Sedan

PRECAUTIONS

< PRECAUTION > [2WD]

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000007698398

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

Always observe the following items for preventing accidental activation.

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see “SRS AIR BAG”.

• Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

Always observe the following items for preventing accidental activation.

• When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, never use air or electric power tools or strike near the sensor(s) with

a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Revision: 2013 February FAX-4 2012 G Sedan

PREPARATION

< PREPARATION > [2WD]

PREPARATION A

PREPARATION

Commercial Service Tool INFOID:0000000007467013

B

Tool name Description

C

Power tool Loosening bolts and nuts

FAX

E

PBIC0190E

Revision: 2013 February FAX-5 2012 G Sedan

FRONT WHEEL HUB AND KNUCKLE

< PERIODIC MAINTENANCE > [2WD]

PERIODIC MAINTENANCE

FRONT WHEEL HUB AND KNUCKLE

Inspection INFOID:0000000007467014

MOUNTING INSPECTION

Make sure that the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are normal.

WHEEL BEARING INSPECTION

• Move wheel hub and bearing assembly in the axial direction by hand. Make sure there is no looseness of

wheel bearing.

Standard

Axial end play : Refer to FAX-9, "Wheel Bearing".

• Rotate wheel hub and bearing assembly and make sure that is no unusual noise or other irregular condi-

tions. If there is any of irregular conditions, replace wheel hub and bearing assembly.

Revision: 2013 February FAX-6 2012 G Sedan

FRONT WHEEL HUB AND KNUCKLE

< REMOVAL AND INSTALLATION > [2WD]

REMOVAL AND INSTALLATION A

FRONT WHEEL HUB AND KNUCKLE

Exploded View INFOID:0000000007467015

B

FAX

JPDIF0166GB

H

1. Steering knuckle 2. Ball seat 3. Cotter pin

4. Splash guard 5. Wheel hub and bearing assembly

Refer to GI-4, "Components" for symbols in the figure. I

Removal and Installation INFOID:0000000007467016

J

REMOVAL

Wheel Hub and Bearing Assembly

1. Remove tires from vehicle with power tool. K

2. Remove wheel sensor from steering knuckle. Refer to BRC-110, "FRONT WHEEL SENSOR : Exploded

View".

CAUTION: L

Never pull on wheel sensor harness.

3. Remove caliper assembly. Hang caliper assembly in a place where it will not interfere with work. Refer to

BR-48, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Exploded View" (2 piston type), BR-52, M

"BRAKE CALIPER ASSEMBLY (4 PISTON TYPE) : Exploded View" (4 piston type).

CAUTION:

Never depress brake pedal while brake caliper is removed.

N

4. Remove disc rotor. Refer to BR-49, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Removal and

Installation" (2 piston type), BR-53, "BRAKE CALIPER ASSEMBLY (4 PISTON TYPE) : Removal and

Installation" (4 piston type).

O

5. Remove wheel hub and bearing assembly mounting bolts, and then remove splash guard and wheel hub

and bearing assembly from steering knuckle.

Steering Knuckle

P

1. Remove wheel hub and bearing assembly, and then remove splash guard.

2. Remove brake hose bracket. Refer to BR-20, "FRONT : Exploded View".

Revision: 2013 February FAX-7 2012 G Sedan

FRONT WHEEL HUB AND KNUCKLE

< REMOVAL AND INSTALLATION > [2WD]

3. Remove cotter pin (1) of steering outer socket, and then loosen

the nut.

4. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using the ball joint remover.

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover from suddenly coming

off.

5. Remove cotter pin of transverse link and steering knuckle, and

then loosen nut.

6. Separate upper link from steering knuckle. SGIA1183E

7. Separate transverse link from steering knuckle so as not to damage ball joint boot using the ball joint

remover.

CAUTION:

Temporarily tighten the nut to prevent damage to threads and to prevent the ball joint remover

from suddenly coming off.

8. Remove steering knuckle form vehicle.

INSTALLATION

Note the following, and install in the reverse order of the removal.

• Perform the final tightening of each of parts under conditions, which were removed when removing wheel

hub and bearing assembly and steering knuckle.

• Never reuse cotter pin.

Inspection INFOID:0000000007467017

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage. Replace if necessary.

Ball Joint Inspection

Check boots of transverse link and steering outer socket ball joint for breakage, axial play, and torque. Refer to

FSU-6, "Inspection" and ST-33, "2WD : Inspection".

INSPECTION AFTER INSTALLATION

• Check wheel sensor harness for proper connection. Refer to BRC-110, "FRONT WHEEL SENSOR :

Exploded View".

• Check wheel alignment. Refer to FSU-7, "Inspection".

• Adjust neutral position of steering angle sensor. Refer to BRC-9, "ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION : Special Repair Requirement".

Revision: 2013 February FAX-8 2012 G Sedan

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS) [2WD]

SERVICE DATA AND SPECIFICATIONS (SDS) A

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Bearing INFOID:0000000007467018

B

Item Standard

C

Axial end play 0.05 mm (0.002 in) or less

FAX

Revision: 2013 February FAX-9 2012 G Sedan

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SYMPTOM DIAGNOSIS > [AWD]

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart INFOID:0000000007467019

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

Refer to DRIVE SHAFT in this chart.

Refer to FRONT AXLE in this chart.

NVH in FAX and FSU sections

NVH in WT section

NVH in WT section

NVH in BR section

NVH in ST section

FAX-26

FAX-16

FAX-14

—

—

Reference

FRONT AXLE AND FRONT SUSPENSION

Improper installation, looseness

Wheel bearing damage

Joint sliding resistance

Possible cause and SUSPECTED PARTS

Excessive joint angle

Parts interference

ROAD WHEEL

DRIVE SHAFT

FRONT AXLE

STEERING

Imbalance

BRAKE

TIRE

DRIVE Noise × × × × × × × × ×

SHAFT Shake × × × × × × × × ×

Noise × × × × × × × × ×

Shake × × × × × × × × ×

Symptom

FRONT Vibration × × × × × × ×

AXLE Shimmy × × × × × × ×

Judder × × × × × ×

Poor quality ride or handling × × × × ×

×: Applicable

Revision: 2013 February FAX-10 2012 G Sedan

PRECAUTIONS

< PRECAUTION > [AWD]

PRECAUTION A

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT B

PRE-TENSIONER" INFOID:0000000007467020

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along C

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted. FAX

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING: E

Always observe the following items for preventing accidental activation.

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

F

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see “SRS AIR BAG”. G

• Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors. H

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

Always observe the following items for preventing accidental activation. I

• When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, never use air or electric power tools or strike near the sensor(s) with

a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing J

serious injury.

• When using air or electric power tools or hammers, always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

K

Precautions for Drive Shaft INFOID:0000000007467023

• Observe the following precautions when disassembling and assembling drive shaft.

L

• Never disassemble joint sub-assembly because it is non-overhaul parts.

• Perform work in a location which is as dust-free as possible.

• Clean the parts, before disassembling and assembling.

• Prevent the entry of foreign objects during disassembly of the service location. M

• Reassemble disassembled parts carefully in the correct order. If work is interrupted, a clean cover must be

placed over parts.

• Use paper waste. Fabric shop cloths must not be used because of the danger of lint adhering to parts.

N

• Clean disassembled parts (except for rubber parts) with kerosene which shall be removed by blowing with

air or wiping with paper waste.

Revision: 2013 February FAX-11 2012 G Sedan

PREPARATION

< PREPARATION > [AWD]

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000007467024

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.) Description

Tool name

KV40107300 Installing boot band

( − )

Boot band crimping tool

ZZA1229D

KV40107500 Removing drive shaft

( − )

Drive shaft attachment

ZZA1230D

KV38107900 Installing drive shaft

( − )

Protector

a: 32 mm (1.26 in) dia.

PDIA1183J

KV38100500 Installing drive shaft plug

( − )

Drift

a: 80 mm (3.15 in) dia.

b: 60 mm (2.36 in) dia.

ZZA0701D

KV38102200 Installing drive shaft plug

( − )

Drift

a: 90 mm (3.54 in) dia.

b: 31 mm (1.22 in) dia.

ZZA0920D

Revision: 2013 February FAX-12 2012 G Sedan

PREPARATION

< PREPARATION > [AWD]

Commercial Service Tool INFOID:0000000007467025

Tool name Description

Power tool Loosening bolts and nuts B

PBIC0190E FAX

Revision: 2013 February FAX-13 2012 G Sedan

FRONT WHEEL HUB AND KNUCKLE

< PERIODIC MAINTENANCE > [AWD]

PERIODIC MAINTENANCE

FRONT WHEEL HUB AND KNUCKLE

Inspection INFOID:0000000007467026

MOUNTING INSPECTION

Make sure that the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are normal.

WHEEL BEARING INSPECTION

• Move wheel hub and bearing assembly in the axial direction by hand. Make sure there is no looseness of

wheel bearing.

Standard

Axial end play : Refer to FAX-28, "Wheel Bearing".

• Rotate wheel hub and bearing assembly and make sure that is no unusual noise or other irregular condi-

tions. If there is any of irregular conditions, replace wheel hub and bearing assembly.

Revision: 2013 February FAX-14 2012 G Sedan

FRONT DRIVE SHAFT

< PERIODIC MAINTENANCE > [AWD]

FRONT DRIVE SHAFT

A

Inspection INFOID:0000000007467027

• Check drive shaft mounting point and joint for looseness and other damage. B

• Check boot for cracks and other damage.

CAUTION:

Replace entire drive shaft assembly when noise or vibration occurs from drive shaft.

C

FAX

Revision: 2013 February FAX-15 2012 G Sedan

FRONT WHEEL HUB AND KNUCKLE

< REMOVAL AND INSTALLATION > [AWD]

REMOVAL AND INSTALLATION

FRONT WHEEL HUB AND KNUCKLE

Exploded View INFOID:0000000007467028

JPDIF0221GB

1. Steering knuckle 2. Ball seat 3. Cotter pin

4. Splash guard 5. Wheel hub and bearing assembly 6. Wheel hub lock nut

Refer to GI-4, "Components" for symbols in the figure.

Removal and Installation INFOID:0000000007467029

REMOVAL

Wheel Hub and Bearing Assembly

1. Remove tires with power tool.

2. Remove wheel sensor from steering knuckle. Refer to BRC-110, "FRONT WHEEL SENSOR : Exploded

View".

CAUTION:

Never pull on wheel sensor harness.

3. Remove caliper assembly. Hang caliper assembly in a place where it will not interfere with work. Refer to

BR-48, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Exploded View".

CAUTION:

Never depress brake pedal while brake caliper is removed.

4. Remove disc rotor. Refer to BR-49, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Removal and

Installation".

5. Remove cotter pin, then loosen wheel hub lock nut with power tool.

6. Patch wheel hub lock nut with a piece of wood. Hammer the wood to disengage wheel hub and bearing

assembly from drive shaft. Take out the wheel hub lock nut.

CAUTION:

• Never place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for housing (or joint sub-assembly), shaft

and the other parts.

NOTE:

Use a suitable puller, if wheel hub and bearing assembly and drive shaft cannot be separated even after

performing the above procedure.

7. Remove wheel hub and bearing assembly mounting bolts, and then remove splash guard and wheel hub

and bearing assembly from steering knuckle.

Revision: 2013 February FAX-16 2012 G Sedan

FRONT WHEEL HUB AND KNUCKLE

< REMOVAL AND INSTALLATION > [AWD]

Steering Knuckle

1. Remove wheel hub and bearing assembly, and then remove splash guard. A

2. Remove brake hose bracket. Refer to BR-20, "FRONT : Exploded View".

3. Remove cotter pin (1) of steering outer socket, and then loosen

the nut. B

4. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using the ball joint remover.

CAUTION: C

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover from suddenly coming

off. FAX

5. Remove cotter pin of transverse link and steering knuckle, and

then loosen nut.

6. Separate upper link from steering knuckle. SGIA1183E

E

7. Separate transverse link from steering knuckle so as not to damage ball joint boot using the ball joint

remover.

CAUTION:

F

Temporarily tighten the nut to prevent damage to threads and to prevent the ball joint remover

from suddenly coming off.

8. Remove steering knuckle form vehicle.

G

INSTALLATION

Note the following, and install in the reverse order of the removal.

• Perform the final tightening of each of parts under unladen conditions, which were removed when removing H

wheel hub and bearing assembly and steering knuckle.

• Never reuse cotter pin.

Inspection INFOID:0000000007467030 I

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage. Replace if necessary. J

Ball Joint Inspection

Check boots of transverse link and steering outer socket ball joint for breakage, axial play, and torque. Refer to

FSU-37, "Inspection" and ST-43, "AWD : Inspection". K

INSPECTION AFTER INSTALLATION

1. Check the wheel sensor harness for proper connection. Refer to BRC-110, "FRONT WHEEL SENSOR :

Exploded View". L

2. Check the wheel alignment. Refer to FSU-29, "Inspection".

3. Adjust neutral position of steering angle sensor. Refer to BRC-9, "ADJUSTMENT OF STEERING ANGLE

M

SENSOR NEUTRAL POSITION : Special Repair Requirement".

Revision: 2013 February FAX-17 2012 G Sedan

FRONT DRIVE SHAFT BOOT

< REMOVAL AND INSTALLATION > [AWD]

FRONT DRIVE SHAFT BOOT

Exploded View INFOID:0000000007467031

JPDIF0021ZZ

1. Joint sub-assembly 2. Circular clip 3. Boot band

4. Boot 5. Shaft 6. Spider assembly

7. Snap ring 8. Housing 9. Plug

10. Dust shield

A. Left side B. Right side

: Wheel side

: NISSAN genuine grease or an equivalent.

Refer to GI-4, "Components" for symbols not described on the above.

Replacement INFOID:0000000007467032

WHEEL SIDE

1. Remove tires with power tool.

2. Remove wheel sensor from steering knuckle. Refer to BRC-110, "FRONT WHEEL SENSOR : Exploded

View".

CAUTION:

Never pull on wheel sensor harness.

3. Remove brake hose bracket. Refer to BR-20, "FRONT : Exploded View".

4. Remove caliper assembly. Hang caliper assembly a place where it will not interfere with work. Refer to

BR-48, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Exploded View".

CAUTION:

Never depress brake pedal while brake caliper is removed.

5. Remove disc rotor. Refer to BR-49, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Removal and

Installation".

6. Remove cotter pin, then loosen wheel hub lock nut with a power tool.

7. Patch wheel hub lock nut with a piece of wood. Hammer the wood to disengage wheel hub and bearing

assembly from drive shaft. Take out the wheel hub lock nut.

CAUTION:

• Never place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for housing (or joint sub-assembly), shaft

and the other parts.

NOTE:

Revision: 2013 February FAX-18 2012 G Sedan

FRONT DRIVE SHAFT BOOT

< REMOVAL AND INSTALLATION > [AWD]

Use a suitable puller if wheel hub and bearing assembly and drive shaft cannot be separated even after

performing the above procedure. A

8. Remove cotter pin (1) of steering outer socket, and then loosen

the nut.

9. Remove steering outer socket (2) from steering knuckle (3) so B

as not to damage ball joint boot (4) using the ball joint remover.

CAUTION:

Temporarily tighten the nut to prevent damage to threads

C

and to prevent the ball joint remover from suddenly coming

off.

10. Remove cotter pin of transverse link and steering knuckle, and

then loosen nut. FAX

11. Separate transverse link from steering knuckle so as not to dam- SGIA1183E

age ball joint boot using the ball joint remover.

CAUTION: E

Temporarily tighten the nut to prevent damage to threads and to prevent the ball joint remover

from suddenly coming off.

12. Remove drive shaft from wheel hub and bearing assembly. F

13. Remove boot bands, and then remove boot from joint sub-assembly.

14. Screw a drive shaft puller (A) into joint sub-assembly screw part

to a length of 30 mm (1.18 in) or more. Support drive shaft with G

one hand and pull out joint sub-assembly with a sliding hammer

(B) from shaft.

CAUTION: H

• Align a sliding hammer and drive shaft and remove them

by pulling firmly and uniformly.

• If joint sub-assembly cannot be pulled out, try after

removing drive shaft from vehicle. I

JPDIF0022ZZ

J

15. Remove the circular clip (1) from shaft.

16. Remove boot from shaft.

17. Clean the old grease on joint sub-assembly with paper waste. K

18. Fill serration slot joint sub-assembly with NISSAN genuine

grease or equivalent until the serration slot and ball groove

become full to the brim. L

CAUTION:

After applying grease, use a paper waste to wipe off old

grease that has oozed out.

M

19. Install boot and boot bands to shaft. JPDIF0007ZZ

CAUTION:

• Wrap serration on shaft with tape to protect the boot from damage.

• Never reuse boot and boot band. N

20. Remove the tape wrapped around the serration on shaft.

21. Position circular clip on groove at the shaft edge.

CAUTION: O

Never reuse circular clip.

NOTE:

Drive joint inserter is recommended when installing circular clip. P

22. Align both center axles of the shaft edge and joint sub-assembly. Then assemble shaft with circular clip

joint sub-assembly.

Revision: 2013 February FAX-19 2012 G Sedan

FRONT DRIVE SHAFT BOOT

< REMOVAL AND INSTALLATION > [AWD]

23. Install joint sub-assembly (1) to shaft using plastic hammer.

CAUTION:

Confirm that joint sub-assembly is correctly engaged while

rotating drive shaft.

24. Apply the balance of the specified amount of grease into the

boot inside from large diameter side of boot.

Standard

Grease amount : Refer to FAX-28, "Drive Shaft".

JPDIF0011ZZ

25. Install the boot securely into grooves (indicated by “*” marks)

shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (with “*”

mark) on the shaft or joint sub-assembly, boot may come

off. Remove all grease from the surface.

26. To prevent the deformation of the boot, adjust the boot installa-

tion length (L) to the specified value shown below by inserting

the suitable tool into inside of the boot from the large diameter

side of the boot and discharging the inside air.

JPDIF0222ZZ

Standard

Boots installed : Refer to FAX-28, "Drive Shaft".

length (L)

CAUTION:

• If the boot installation length is outside the standard, it may cause breakage of boot.

• Be careful not to touch the inside of the boot with a tip of tool.

27. Secure the large and small ends of the boot with boot bands

using the boot band crimping tool (A) [SST: KV40107300 ( −

)].

JPDIF0012ZZ

NOTE:

Secure boot band so that dimension (M) meets the specification

as shown in the figure.

Dimension (M) : 2.0 – 3.0 mm (0.079 – 0.118 in)

28. Secure joint sub-assembly and shaft, and then make sure that

they are in the correct position when rotating boot. Install them

with boot band when boot installation positions become incor-

rect.

29. Insert drive shaft to wheel hub and bearing assembly, and then

temporarily tighten wheel hub lock nut. DSF0047D

CAUTION:

• The drive shaft is press-fit. When assembling the shaft, never press it, but pull it until fully

seated by tightening the wheel hub lock nut.

• Check that anticorrosive oil is applied to the thread of the drive shaft. If not, apply appropriate oil

such as engine oil.

Revision: 2013 February FAX-20 2012 G Sedan

FRONT DRIVE SHAFT BOOT

< REMOVAL AND INSTALLATION > [AWD]

• If sufficient oil is not applied to the thread of the drive shaft, the wheel hub lock nut may be

seized and the tightening torque reaches the specified limit prematurely. It may cause looseness A

or abnormal noises.

30. Install transverse link to steering knuckle. Refer to FAX-16, "Exploded View".

31. Install steering outer socket to steering knuckle. Refer to ST-34, "AWD : Exploded View". B

32. Install disc rotor. Refer to BR-49, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Removal and Instal-

lation".

33. Install caliper assembly to steering knuckle. Refer to BR-48, "BRAKE CALIPER ASSEMBLY (2 PISTON C

TYPE) : Exploded View".

34. Install brake hose bracket to steering knuckle. Refer to BR-20, "FRONT : Exploded View".

35. Install wheel sensor to steering knuckle. Refer to BRC-110, "FRONT WHEEL SENSOR : Exploded View". FAX

36. Tighten the wheel hub lock nut to the specified torque. Refer to FAX-16, "Exploded View".

37. Install cotter pin.

CAUTION: E

• Never reuse cotter pin.

• Bend it at the root sufficiently to prevent any looseness.

F

Revision: 2013 February FAX-21 2012 G Sedan

FRONT DRIVE SHAFT

< REMOVAL AND INSTALLATION > [AWD]

FRONT DRIVE SHAFT

Exploded View INFOID:0000000007467033

REMOVAL

SDIA3042J

1. Drive shaft (right side) 2. Drive shaft (left side) 3. Cotter pin

Refer to GI section for symbols in the figure.

DISASSEMBLY

JPDIF0021ZZ

1. Joint sub-assembly 2. Circular clip 3. Boot band

4. Boot 5. Shaft 6. Spider assembly

7. Snap ring 8. Housing 9. Plug

10. Dust shield

A. Left side B. Right side

: Wheel side

: NISSAN genuine grease or an equivalent.

Refer to GI-4, "Components" for symbols not described on the above.

Revision: 2013 February FAX-22 2012 G Sedan

FRONT DRIVE SHAFT

< REMOVAL AND INSTALLATION > [AWD]

Removal and Installation INFOID:0000000007467034

A

REMOVAL

Left Side

B

1. Refer to the procedure from 1 to 12 in FAX-18, "Replacement".

2. Remove shock absorber from transverse link with power tool. Refer to FSU-31, "Exploded View".

3. Remove fixing bolts and nuts, and then remove drive shaft from vehicle. C

Right Side

1. Refer to the procedure from 1 to 12 in FAX-18, "Replacement".

FAX

2. Remove shock absorber from transverse link with power tool. Refer to FSU-31, "Exploded View".

3. Remove drive shaft from front final drive.

• Remove drive shaft from front final drive using the drive shaft

attachment (A) [SST: KV40107500 ( − )] and a sliding ham- E

mer (B) while inserting tip of the drive shaft attachment

between housing and front final drive.

CAUTION: F

Never place drive shaft joint at an extreme angle when

removing drive shaft. Also be careful not to overextend

slide joint.

G

JPDIF0004ZZ

INSTALLATION H

Left Side

Install in the reverse order of removal.

I

Right Side

Note the following, and install in the reverse order of removal.

CAUTION:

Always replace front final drive oil seal with new one when installing drive shaft. Refer to DLN-117, J

"RIGHT SIDE : Exploded View".

• Place the protector (A) [SST: KV38107900 ( − )] onto front final

drive to prevent damage to the oil seal while inserting drive shaft. K

Slide drive shaft sliding joint and tap with a hammer to install

securely.

L

JPDIF0023ZZ

N

Disassembly and Assembly INFOID:0000000007467035

DISASSEMBLY

O

Front Final Drive Side

1. Fix shaft with a vise.

CAUTION: P

Protect shaft when fixing with a vise using aluminum or copper plates.

2. Remove boot bands, and then remove boot from housing.

3. Put matching marks on housing and shaft, and then pull out housing from shaft.

CAUTION:

Use paint or similar substance for matching marks. Never scratch the surfaces.

Revision: 2013 February FAX-23 2012 G Sedan

FRONT DRIVE SHAFT

< REMOVAL AND INSTALLATION > [AWD]

4. Put matching marks (A) on the spider assembly and shaft.

CAUTION:

Use paint or similar substance for matching marks. Never

scratch the surfaces.

JPDIF0006ZZ

5. Remove snap ring (1), and then remove spider assembly from

the shaft.

6. Remove boot from the shaft.

7. Remove dust shield from housing. (right side)

8. If plug needs to be removed, move boot to wheel side, and take

it out with a plastic hammer. (left side)

JPDIF0014ZZ

Wheel Side

1. Fix shaft with a vise.

CAUTION:

Protect shaft when fixing with a vise using aluminum or copper plates.

2. Remove boot bands, and then remove boot from joint sub-assembly.

3. Screw the drive shaft puller (A) 30 mm (1.18 in) or more into the

thread of joint sub-assembly, and pull joint sub-assembly with a

sliding hammer (B) from shaft.

CAUTION:

• If joint sub-assembly cannot be removed after five or

more unsuccessful attempts, replace shaft and joint sub

assembly as a set.

• Align sliding hammer and drive shaft and remove them by

pulling directory.

4. Remove circular clip from shaft.

5. Remove boot from shaft. JPDIF0015ZZ

6. Clean old grease on joint sub-assembly with paper waste while

rotating ball cage.

ASSEMBLY

Front Final Drive Side

1. Clean old grease on housing with paper waste.

2. If plug (1) has been removed, use a drift to press in a new one.

(left side)

: Press

A: Drift [SST: KV38100500 ( − )]

B: Drift [SST: KV38102200 ( − )]

3. Install new boot and boot bands to shaft.

CAUTION:

• Wrap serration on shaft with tape to protect boot from

damage. JPDIF0016ZZ

Revision: 2013 February FAX-24 2012 G Sedan

FRONT DRIVE SHAFT

< REMOVAL AND INSTALLATION > [AWD]

• Never reuse boot and boot band.

4. Remove the tape wrapped around the serration on shaft. A

5. To install the spider assembly (1), align it with the matching

marks (A) on the shaft (2) during the removal, and direct the ser-

ration mounting surface (B) to the shaft. B

FAX

JPDIF0017ZZ

6. Secure spider assembly onto shaft with snap ring (1). E

7. Apply the appropriate amount of grease to spider assembly and

sliding surface.

8. Assemble the housing onto spider assembly, and apply the bal- F

ance of the specified amount grease.

Standard G

Grease amount : Refer to FAX-28, "Drive Shaft".

9. Align matching marks painted when housing was removed.

JPDIF0014ZZ H

10. Install boot securely into grooves (indicated by “*” marks) shown

in the figure.

CAUTION:

If grease adheres to the boot mounting surface (with “*” mark) on shaft or housing, boot may I

come off. Remove all grease from the surface.

Right side Left side J

JPDIF0224ZZ JPDIF0223ZZ

N

11. To prevent the deformation of the boot, adjust the boot installation length (L) to the value shown below by

inserting the suitable tool into the inside of boot from the large diameter side of boot and discharging

inside air.

O

Standard

Boots installed length (L) : Refer to FAX-28, "Drive Shaft".

P

CAUTION:

• If the boot installation length is outside the standard, it may cause breakage of boot.

• Be careful not to touch the inside of the boot with the tip of tool.

12. Install new larger and smaller boot bands securely.

Revision: 2013 February FAX-25 2012 G Sedan

FRONT DRIVE SHAFT

< REMOVAL AND INSTALLATION > [AWD]

a. For one-touch clamp band

i. Secure the large and small ends of a boot with new boot bands

as shown in the figure.

PDIA1188J

b. For low profile type band

i. Put boot band in the groove on drive shaft boot. Then fit pawls

( ) into holes to temporary installation.

NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at

first.

SDIA3557E

ii. Pinch projection on the band with suitable pliers to tighten band.

iii. Insert tip of band below end of the pawl.

13. Secure housing and shaft, and then make sure that they are in

the correct position when rotating boot. Install them with new

boot band when the mounting positions become incorrect.

14. Install dust cover to housing. (right side)

CAUTION:

Never reuse dust cover.

SDIA3558E

Wheel Side

For further details on the installation procedure, refer to the installation procedure of “Replacement” for the

drive shaft boot.

Inspection INFOID:0000000007467036

INSPECTION AFTER REMOVAL

• Move joint up/down, left/right, and in the axial directions. Check for motion that is not smooth and for signifi-

cant looseness.

• Check boot for cracks, damage, and leakage of grease.

• Disassemble drive shaft and exchange malfunctioning part if there

is a non-standard condition.

SDIA1163J

INSPECTION AFTER DISASSEMBLY

Revision: 2013 February FAX-26 2012 G Sedan

FRONT DRIVE SHAFT

< REMOVAL AND INSTALLATION > [AWD]

Shaft

Check shaft for runout, cracks, or other damage. Replace if necessary. A

Joint Sub-Assembly (Wheel Side)

Check the following:

• Joint sub-assembly for rough rotation and excessive axial looseness. B

• The inside of the joint sub-assembly for entry of foreign material.

• Joint sub-assembly for compression scars, cracks, and fractures inside of joint sub-assembly.

Replace joint sub-assembly if there are any non-standard conditions of components. C

Housing and Spider assembly (Front Final Drive side)

Replace housing and spider assembly if there is scratching or wear of housing roller contact surface or spider

roller contact surface. FAX

NOTE:

Housing and spider assembly are used in a set.

E

Revision: 2013 February FAX-27 2012 G Sedan

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS) [AWD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Bearing INFOID:0000000007467037

Item Standard

Axial end play 0.05 mm (0.002 in) or less

Drive Shaft INFOID:0000000007467038

Item Standard

Joint Wheel side Front final drive side

Left side 95 – 105 g (3.36 – 3.70 oz)

Grease quantity 77 – 97 g (2.72 – 3.42 oz)

Right side 113 – 123 g (3.99 – 4.33 oz)

Left side 152 mm (5.98 in)

Boots installed length 136 mm (5.35 in)

Right side 158.6 mm (6.24 in)

Revision: 2013 February FAX-28 2012 G Sedan

You might also like

- Front Axle: SectionDocument32 pagesFront Axle: SectionLuis BarriosNo ratings yet

- Front Axle: SectionDocument30 pagesFront Axle: SectionFELIX RASHIANNo ratings yet

- Fax PDFDocument29 pagesFax PDFMaiChiVuNo ratings yet

- Front Axle: SectionDocument32 pagesFront Axle: SectionSlava SlickNo ratings yet

- Front Axle: SectionDocument52 pagesFront Axle: SectionCarlos Tito AmésquitaNo ratings yet

- Fax PDFDocument31 pagesFax PDFMisha KulibaevNo ratings yet

- FAX FRONT AXLE Nissan Pathfinder R52Document32 pagesFAX FRONT AXLE Nissan Pathfinder R52Pablo Marchese HuertaNo ratings yet

- Rear Axle: SectionDocument31 pagesRear Axle: SectionАндрей НадточийNo ratings yet

- Rear Axle: SectionDocument31 pagesRear Axle: SectionOpuNo ratings yet

- Front Axle: SectionDocument28 pagesFront Axle: SectionWilmer Elias Quiñonez HualpaNo ratings yet

- 2014 Nissan Leaf Service Repair Manual (Front Axle)Document32 pages2014 Nissan Leaf Service Repair Manual (Front Axle)Engr Ko VictorNo ratings yet

- Front Suspension: SectionDocument24 pagesFront Suspension: SectionJumadi AlkutsNo ratings yet

- Front Axle: SectionDocument90 pagesFront Axle: SectionH. Yusmira (Kang Otto)No ratings yet

- Front Suspension: SectionDocument24 pagesFront Suspension: SectionederengNo ratings yet

- Front Axle: SectionDocument27 pagesFront Axle: SectionjasleenNo ratings yet

- Front Axle: SectionDocument25 pagesFront Axle: SectiontecnicofigueroaNo ratings yet

- Front Suspension: SectionDocument28 pagesFront Suspension: SectionAgustin Borge GarciaNo ratings yet

- Front Suspension: SectionDocument24 pagesFront Suspension: Sectiongiancarlo sanchezNo ratings yet

- REAR AXLE RaxDocument27 pagesREAR AXLE Raxciro_svNo ratings yet

- Front Suspension Micra k13 NissanDocument68 pagesFront Suspension Micra k13 NissankikaNo ratings yet

- Front Suspension: SectionDocument62 pagesFront Suspension: SectionhuusonbachkhoaNo ratings yet

- Front Axle: SectionDocument27 pagesFront Axle: SectionDiego496No ratings yet

- Front Suspension: SectionDocument26 pagesFront Suspension: SectioncesarNo ratings yet

- Rear Suspension: SectionDocument30 pagesRear Suspension: SectionLíder DieselNo ratings yet

- Front Suspension: SectionDocument27 pagesFront Suspension: SectionProbadorAutomotrizNo ratings yet

- Rear Axle: SectionDocument21 pagesRear Axle: Sectionjair HernandezNo ratings yet

- Front Axle: SectionDocument26 pagesFront Axle: SectionPetter VillarroelNo ratings yet

- Frontier - FSUDocument26 pagesFrontier - FSUIvan A. VelasquezNo ratings yet

- Fsu PDFDocument25 pagesFsu PDFronaldNo ratings yet

- Manual Transaxle: SectionDocument95 pagesManual Transaxle: SectionemenelikNo ratings yet

- Front Axle: SectionDocument137 pagesFront Axle: SectionOpuNo ratings yet

- 2014 Nissan Rogue 40846Document24 pages2014 Nissan Rogue 40846ВладиславГолышевNo ratings yet

- 2014 Nissan Rogue 40846Document24 pages2014 Nissan Rogue 40846ВладиславГолышевNo ratings yet

- Front Suspension: SectionDocument32 pagesFront Suspension: Sectionluis CebergNo ratings yet

- Brake System: SectionDocument128 pagesBrake System: SectionFerri JiNo ratings yet

- Front Suspension: SectionDocument25 pagesFront Suspension: SectionАндрей НадточийNo ratings yet

- Front Suspension FsuDocument29 pagesFront Suspension Fsuciro_svNo ratings yet

- 20 Manual Nissan Sentra 2013Document24 pages20 Manual Nissan Sentra 2013DavidNo ratings yet

- Brake System: SectionDocument47 pagesBrake System: Sectionصالح الدوسريNo ratings yet

- BR PDFDocument47 pagesBR PDFSofyanNo ratings yet

- ST PDFDocument30 pagesST PDFronaldNo ratings yet

- Brake System: SectionDocument36 pagesBrake System: SectionWilmer QuiñonezNo ratings yet

- TM PDFDocument384 pagesTM PDFronaldNo ratings yet

- NissanDocument55 pagesNissanAgustin Borge GarciaNo ratings yet

- Steering System: SectionDocument31 pagesSteering System: SectioncesarNo ratings yet

- RSU Murano 2009Document24 pagesRSU Murano 2009alexNo ratings yet

- Front Suspension: SectionDocument29 pagesFront Suspension: SectionSusana Perez100% (1)

- REAR SUSPENSION 370zDocument19 pagesREAR SUSPENSION 370zjapaxploseNo ratings yet

- Fsu PDFDocument28 pagesFsu PDFMisha KulibaevNo ratings yet

- 9193 2014 Nissan Leaf Service RepairDocument29 pages9193 2014 Nissan Leaf Service RepairEngr Ko VictorNo ratings yet

- Steering System: SectionDocument28 pagesSteering System: SectionАндрей НадточийNo ratings yet

- Transaxle & Transmission: SectionDocument240 pagesTransaxle & Transmission: SectionDiego496No ratings yet

- Brake System: SectionDocument49 pagesBrake System: SectionjasleenNo ratings yet

- Front Suspension: SectionDocument35 pagesFront Suspension: SectionLuis BarriosNo ratings yet

- Fsu PDFDocument22 pagesFsu PDFMaiChiVuNo ratings yet

- Brake System: SectionDocument127 pagesBrake System: SectionLuis GarcíaNo ratings yet

- Front Suspension: SectionDocument21 pagesFront Suspension: SectionWilmer Elias Quiñonez HualpaNo ratings yet

- REAR SUSPENSION RsuDocument27 pagesREAR SUSPENSION Rsuciro_svNo ratings yet

- Brake System (Section BR)Document46 pagesBrake System (Section BR)ramon chilianNo ratings yet

- Technical Analysis from A to Z, 2nd EditionFrom EverandTechnical Analysis from A to Z, 2nd EditionRating: 4.5 out of 5 stars4.5/5 (19)

- Section: Driver ControlsDocument4 pagesSection: Driver ControlsHakob AdamyanNo ratings yet

- Rear Axle: SectionDocument16 pagesRear Axle: SectionHakob AdamyanNo ratings yet

- Exhaust System: SectionDocument6 pagesExhaust System: SectionHakob AdamyanNo ratings yet

- A B D e F G H I J K L M N P oDocument7 pagesA B D e F G H I J K L M N P oHakob AdamyanNo ratings yet

- Charging System: SectionDocument34 pagesCharging System: SectionHakob AdamyanNo ratings yet

- Clutch: SectionDocument24 pagesClutch: SectionHakob AdamyanNo ratings yet

- Who Recommended Hand-Rub FormulationDocument9 pagesWho Recommended Hand-Rub FormulationSaeed Mohammed100% (2)

- Automatic Drive Positioner: SectionDocument207 pagesAutomatic Drive Positioner: SectionHakob AdamyanNo ratings yet

- SFF 8472 (Diagnostic Monitoring Interface)Document39 pagesSFF 8472 (Diagnostic Monitoring Interface)ferchllNo ratings yet

- Wa0009.Document14 pagesWa0009.Pradeep SinghNo ratings yet

- NR Serial Surname Given Name Middlename: Republic of The Philippines National Police CommissionDocument49 pagesNR Serial Surname Given Name Middlename: Republic of The Philippines National Police CommissionKent GallardoNo ratings yet

- Mudbound: Virgil Williams and Dee ReesDocument125 pagesMudbound: Virgil Williams and Dee Reesmohan kumarNo ratings yet

- Café Management System Full and Final ReportDocument18 pagesCafé Management System Full and Final ReportMuhammad Xalman Xhaw100% (3)

- Persian NamesDocument27 pagesPersian NamescekrikNo ratings yet

- Lifetime Prediction of Fiber Optic Cable MaterialsDocument10 pagesLifetime Prediction of Fiber Optic Cable Materialsabinadi123No ratings yet

- Write A Program in C To Check Whether A Entered Number Is Positive, Negative or ZeroDocument10 pagesWrite A Program in C To Check Whether A Entered Number Is Positive, Negative or ZeroSabin kandelNo ratings yet

- KCET MOCK TEST PHY Mock 2Document8 pagesKCET MOCK TEST PHY Mock 2VikashNo ratings yet

- R. K. NarayanDocument9 pagesR. K. NarayanCutypie Dipali SinghNo ratings yet

- Anthem Harrison Bargeron EssayDocument3 pagesAnthem Harrison Bargeron Essayapi-242741408No ratings yet

- The Neuromarketing ConceptDocument7 pagesThe Neuromarketing ConceptParnika SinghalNo ratings yet

- Quanser Active Mass Damper UserManual PDFDocument21 pagesQuanser Active Mass Damper UserManual PDFCHAVEZ MURGA ARTURO ALEJANDRONo ratings yet

- 3RD Last RPHDocument5 pages3RD Last RPHAdil Mohamad KadriNo ratings yet

- 4h Thank You ProofDocument1 page4h Thank You Proofapi-362276606No ratings yet

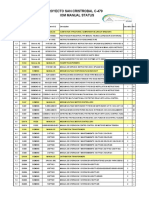

- Proyecto San Cristrobal C-479 Iom Manual StatusDocument18 pagesProyecto San Cristrobal C-479 Iom Manual StatusAllen Marcelo Ballesteros LópezNo ratings yet

- SAi Sankata Nivarana StotraDocument3 pagesSAi Sankata Nivarana Stotrageetai897No ratings yet

- Bed BathDocument6 pagesBed BathKristil ChavezNo ratings yet

- Historical Background of Land Ownership in The PhilippinesDocument2 pagesHistorical Background of Land Ownership in The Philippinesjohn100% (1)

- Promises From The BibleDocument16 pagesPromises From The BiblePaul Barksdale100% (1)

- Jao Vs Court of Appeals G.R. No. 128314 May 29, 2002Document3 pagesJao Vs Court of Appeals G.R. No. 128314 May 29, 2002Ma Gabriellen Quijada-TabuñagNo ratings yet

- Bahaa CVDocument3 pagesBahaa CVbahaa ahmedNo ratings yet

- The Confederation or Fraternity of Initiates (1941)Document82 pagesThe Confederation or Fraternity of Initiates (1941)Clymer777100% (1)

- ISO 9001 QuizDocument4 pagesISO 9001 QuizGVS Rao0% (1)

- Ficha Álvaro y Jesús 3Document8 pagesFicha Álvaro y Jesús 3Alex8mRNo ratings yet

- Solaris Hardening Guide v1Document56 pagesSolaris Hardening Guide v1GusGualdNo ratings yet

- Campos V BPI (Civil Procedure)Document2 pagesCampos V BPI (Civil Procedure)AngeliNo ratings yet

- Nota 4to Parcial ADocument8 pagesNota 4to Parcial AJenni Andrino VeNo ratings yet

- Derichebourg - Universal Registration Document 2020-2021Document256 pagesDerichebourg - Universal Registration Document 2020-2021Abhijeet ShindeNo ratings yet

- 215 Final Exam Formula SheetDocument2 pages215 Final Exam Formula SheetH.C. Z.No ratings yet

- FAR09 Biological Assets - With AnswerDocument9 pagesFAR09 Biological Assets - With AnswerAJ Cresmundo50% (4)