Professional Documents

Culture Documents

TMC 132

Uploaded by

handsomekashOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TMC 132

Uploaded by

handsomekashCopyright:

Available Formats

Engineering Manual

Structures

TMC 132

Engineering Manual

MAINTENANCE PLAN – EPPING TO

CHATSWOOD RAIL LINE

STRUCTURES

Version 1.0

Issued July 2010

Owner: Chief Engineer Civil

Approved by: John Stapleton Authorised by: Richard Hitch

A/Principal Engineer Chief Engineer Civil

Technology & Standards

Disclaimer

This document was prepared for use on the RailCorp Network only.

RailCorp makes no warranties, express or implied, that compliance with the contents of this document shall be

sufficient to ensure safe systems or work or operation. It is the document user’s sole responsibility to ensure that the

copy of the document it is viewing is the current version of the document as in use by RailCorp.

RailCorp accepts no liability whatsoever in relation to the use of this document by any party, and RailCorp excludes any liability which arises in

any manner by the use of this document.

Copyright

The information in this document is protected by Copyright and no part of this document may be reproduced, altered, stored or transmitted by

any person without the prior consent of RailCorp

UNCONTROLLED WHEN PRINTED Page 1 of 61

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Document control

Revision Date of Approval Summary of change

1.0 July, 2010 First issue as a RailCorp document

Summary of changes from previous version

Chapter Current Revision Summary of change

Control 1.0 Original Issue

Pages

Ch 1 1.0 Original Issue

Ch 2 1.0 Original Issue

Ch 3 1.0 Original Issue

Ch 4 1.0 Original Issue

Ch 5 1.0 Original Issue

Ch 6 1.0 Original Issue

Ch 7 1.0 Original Issue

App 1 1.0 Original Issue

App 2 1.0 Original Issue

App 3 1.0 Original Issue

© Rail Corporation Page 2 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Contents

Chapter 1 General....................................................................................................................................... 4

C1-1 Purpose....................................................................................................................................... 4

C1-2 Introduction ................................................................................................................................. 4

C1-3 References.................................................................................................................................. 4

C1-4 Definitions, abbreviations and acronyms .................................................................................... 6

Chapter 2 Technical Maintenance Plans .................................................................................................. 7

C2-1 General ....................................................................................................................................... 7

C2-2 Competency ................................................................................................................................ 7

C2-3 Technical maintenance plan user information ............................................................................ 7

Chapter 3 Responsibilities and Authorities ............................................................................................. 8

C3-1 General ....................................................................................................................................... 8

C3-2 Bridge Examiner ......................................................................................................................... 8

C3-3 Structures Manager .................................................................................................................... 8

C3-4 Civil Maintenance Engineer ........................................................................................................ 8

Chapter 4 Description of the system ........................................................................................................ 9

C4-1 Overview ..................................................................................................................................... 9

C4-2 Design parameters.................................................................................................................... 11

C4-3 Description of elements ............................................................................................................ 12

C4-4 Technical data........................................................................................................................... 38

C4-5 Parts list .................................................................................................................................... 38

C4-6 Manufacturers’ technical bulletins and equipment warranties .................................................. 39

C4-7 Drawings ................................................................................................................................... 39

Chapter 5 Examination Requirements.................................................................................................... 41

C5-1 Normal examination requirements............................................................................................ 41

C5-2 Additional examination requirements........................................................................................ 41

C5-3 Hazards..................................................................................................................................... 41

C5-4 Defect limits and responses...................................................................................................... 41

C5-5 Service schedules..................................................................................................................... 42

C5-6 Examination of tunnel lining and waterproofing ........................................................................ 42

C5-7 Examination of Lane Cove River cut & cover tunnel ................................................................ 42

C5-8 Examination of DFF track form ................................................................................................. 43

C5-9 Examination of FST track-form ................................................................................................. 44

C5-10 Examination of tunnel walkway................................................................................................. 44

C5-11 Examination of tunnel drainage channels................................................................................. 45

C5-12 Examination of cross passages ................................................................................................ 45

C5-13 Examination of platform cavern lining....................................................................................... 45

C5-14 Examination of station structural elements ............................................................................... 46

Chapter 6 Maintenance Requirements ................................................................................................... 47

C6-1 Corrective Maintenance ............................................................................................................ 47

Chapter 7 Maintenance Procedures ....................................................................................................... 48

C7-1 General ..................................................................................................................................... 48

C7-2 Removal and/or replacement of FST type A bearings.............................................................. 48

C7-3 Removal and/or replacement of FST type B bearings.............................................................. 49

C7-4 Tunnel walkway ........................................................................................................................ 49

C7-5 Special tools.............................................................................................................................. 50

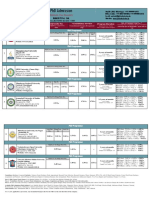

Appendix 1 Technical Maintenance Plan .................................................................................................. 51

Appendix 2 Service Schedules .................................................................................................................. 54

Appendix 3 Examination Reports .............................................................................................................. 59

© Rail Corporation Page 3 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Chapter 1 General

C1-1 Purpose

This document specifies the Technical Maintenance Plan (TMP) for the structures assets of the

Epping to Chatswood Rail Line (ECRL). Structures assets include tunnels, dives, cross passages,

track slabs, drainage channels, walkway, platform caverns, noise attenuation panels, platform

walls.

The Maintenance Plan specifies preventive maintenance tasks which are either not covered in

Engineering Standard ESC 100 - Civil Technical Maintenance Plan or are to be carried out at

frequencies other than those specified in ESC 100. It also specifies some corrective maintenance

tasks. The requirements in ESC 100 apply unless superseded by this TMP.

This document is provided for the use of personnel responsible for programming and implementing

the specified tasks.

The maintenance tasks and minimum frequencies defined in this document are mandatory.

C1-2 Introduction

This manual includes content from, and reference to, the separately published Epping to

Chatswood Rail Line Operations and Maintenance Manuals for the various assets which were

written at the conclusion of the construction as non-updatable documents.

C1-3 References

C1-3.1 RailCorp standards

ESC 100 - Civil Technical Maintenance Plan

ESC 302 - Structures Defect Limits

TMC 001 – Civil Technical Competencies & Engineering Authority

TMC 103 - Maintenance Plan - ECRL

TMC 110 - Structures Service Schedules

TMC 301 - Structures Examination

TMC 302 - Structures Repair

C1-3.2 Other RailCorp documents

Nil

C1-3.3 ECRL documents

PRL-CSA100008 - Concrete Specification

PRL-CSA100013 - Shotcrete Specification

PRL-CSA100016 - Tunnel and Station Waterproofing Specification

PRL-CSD110521 to PRL-CSD110543 – Running Tunnels Tunnel Long Sections

PRL-CSD111518 - Running tunnels M2 shaft: Rectification works. Sheet 1 of 3

PRL-CSD111519 - Running tunnels M2 shaft: Rectification works. Sheet 2 of 3

PRL-CSD111520 - Running tunnels M2 shaft: Rectification works. Sheet 3 of 3

© Rail Corporation Page 4 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

PRL-CSD180003 – Epping Station Drainage Typical Sections

PRL–CSD215618 – Tunnel Sound Absorbent Panels General Arrangement and Details

PRL-CSD219101 - OHW Support and Registration for Tunnel Standard Arrangement

PRL-CSD219102 - OHW Support and Registration for Flat Roof Standard Arrangement

PRL-CSD219103 - Tunnel OHW Support and Registration for Flat Roof Standard Arrangement

PRL-CSD219104 - OHW Support and Registration for Station Caverns - Standard Arrangement

PRL-CSD219105 - OHW Support and Registration for Jet Fan Locations - General Arrangement

PRL-CSR100033 - Design Report for Package R03A – Walkways

PRL-CSR102500 - Technical Design Report – Waterproofing and Lining

PRL-CSR111502 - Design Report for Excavation, Support, Waterproofing and Permanent Lining:

Running Tunnels

PRL-CSR111503 - Design report for running tunnels: M2 shaft, Rectification works

PRL-CSR111700 - Appendix M Design Report Excavation, Support, Waterproofing and Permanent

Lining Running Tunnels

PRL-CSR122001 - Chatswood Cut and Cover and Dive Structure Design Report

PRL-CSR142001 - Lane Cove River Cut and Cover Design Report

PRL-CSR171502 - Design Report – Excavation, Support, Waterproofing and Permanent Lining:

Macquarie University Station Caverns

PRL-CSR181502 - Design Report – Excavation, Support, Waterproofing and Permanent Lining:

Epping Station Caverns, Service Buildings and Transfer Concourse

PRL-CSR192002 - Epping Cut and Cover and Dive Structures Design Report

PRL-CSW219289 - Tunnel Overhead Wiring Mast Support Clamp Protection Fence Layout

PRL-CSY102101-003 - Supplier Manual – Megabolt Rockbolt Datasheets

PRL-CSY102300– Operations & Maintenance Manual Underground Station Structures

PRL-CSY104100 - Rock Bolt Supplier Datasheet

PRL-CSY110200 - Operations & Maintenance Manual Track, Turnouts and Lubricators

PRL-CSY112200 - Operations & Maintenance Manual Tunnel Drainage System

PRL-CSY112210 - Examination Report: ECRL Sumps & Rising Main

PRL-CSY112600 – Operations & Maintenance Manual Tunnels

PRL-CSY112601 - Precast Arch Tunnel Supplier Documentation (Reinforced Earth Company

Technical Manual)

PRL-CSY113200 – Operations & Maintenance Manual Tunnel Cross Passages

PRL-CSY133000 - ECRL Water Treatment Plant Operation and Maintenance Manual

PRL-CSY162504 - Design Report for Design Packages C08B, C10B, C12B, C14B – Buildings and

Structures for: Epping Station, Macquarie Park Station, Macquarie University Station and Delhi

Road Station

© Rail Corporation Page 5 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

PRL-CSY206100 - HV System O&M Manual

PRL-CSY206300 - LV System O&M Manual

PRL-CSY207113 - Jet Fan Operation and Maintenance Manual

PRL-CSY209100 - O & M Manual Overhead Wire System

PRL-CSY216800 - Refer to Tunnel Lighting System Manual

633437 – Operations & Maintenance Manual Corrosion and Strain Monitoring System

CV0486374A - Permanent Way - Track Slab Jacking Plan and Details

C1-4 Definitions, abbreviations and acronyms

The definitions of terms used within this Maintenance Plan are contained in ESC 100.

DFF Direct Fixation Fastener (slab track)

ECRL Epping to Chatswood Rail Line (formerly PRL – Parramatta Rail Link)

FST Floating Slab Track

Platform cavern Lined structure (similar to tunnel structure) containing the track and

platforms at stations

© Rail Corporation Page 6 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Chapter 2 Technical Maintenance Plans

C2-1 General

The maintenance plan specifies maintenance tasks to ensure the Epping to Chatswood Rail Line

(ECRL) remains in a condition commensurate with RailCorp’s safety and reliability objectives.

There are two types of maintenance specified:

− Preventive maintenance

− Corrective maintenance.

C2-1.1 Preventive maintenance

Preventive maintenance is undertaken to keep an item in a specified operating condition through

regular maintenance tasks and through systematic examination to detect and prevent potential

failures. The former of these includes routine servicing and regular scheduled maintenance based

on time or traffic. The latter comprises surveillance examinations, condition monitoring and

functional checks. The Technical Maintenance Plan details periods at which preventive

maintenance is performed.

C2-1.2 Corrective maintenance

Corrective maintenance is undertaken to restore items to a specified condition by repairing or

replacing items. Corrective maintenance is carried out as a result of failures or unsatisfactory

conditions detected during preventive maintenance examinations and checks. Corrective

maintenance tasks are detailed in the TMP.

C2-2 Competency

All maintenance inspection, assessment, monitoring and review functions shall only be carried out

by persons with the competency for the tasks thay are undertaking in accordance with RailCorp

Engineering Manual TMC 001 - Civil Technical Competencies & Engineering Authority and this

manual.

C2-3 Technical maintenance plan user information

Detailed explanation of the TMP table is contained in ESC 100.

© Rail Corporation Page 7 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Chapter 3 Responsibilities and Authorities

C3-1 General

District and Infrastructure Facilities management are responsible for ensuring that the examination,

assessment and repair of the ECRL structures are carried out by competent persons in accordance

with this manual, ESC 100 – Civil Technical Maintenance Plan, and engineering manuals TMC 301

- Structures Examination, TMC 305 – Structures Assessment and TMC 302 - Structures Repair.

No changes can be made to the requirements specified in this maintenance plan without the

approval of the Chief Engineer Civil.

The respective responsibilities of personnel in the implementation of this maintenance plan are

detailed below.

C3-2 Bridge Examiner

The Bridge Examiner is responsible for tasks specified in TMC 301 and for the following additional

detailed examination tasks:

− tunnel cross passages

− platform caverns

− tunnel walkways.

C3-3 Structures Manager

The Structures Manager is responsible for tasks specified in TMC 301 and for arranging the

following additional tasks:

− Additional examination requirements in C5-2.

C3-4 Civil Maintenance Engineer

Civil Maintenance Engineers shall establish and maintain systems to ensure that the requirements

for the completion of safety related tasks specified in ESC 100 are met.

The Civil Maintenance Engineer is responsible for tasks specified in TMC 301 and for the following

additional tasks:

− ensuring that inspection staff are briefed on the requirements of this manual

− ensuring that preventive maintenance and corrective maintenance specified in this

maintenance plan are carried out.

© Rail Corporation Page 8 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Chapter 4 Description of the system

C4-1 Overview

The Epping Chatswood Rail Line (ECRL) is a dual track electrified commuter railway across the

north of Sydney, linking the Main Northern Line at Epping with the North Shore Line at Chatswood.

The ECRL is configured to provide a new train route from Hornsby to the lower North Shore and

Sydney CBD via the North Ryde/Macquarie corridor.

When facing Chatswood the Up line is the tunnel on the left side.

The line includes three new stations at North Ryde (Delhi Road), Macquarie Park and Macquarie

University. In addition, at Epping the existing surface station has been upgraded and new

underground platforms are provided. A new Transport Interchange has been constructed at

Chatswood.

Figure 1 Epping-Chatswood Rail Line (ECRL)

The majority of the ECRL is contained within two tunnels approximately 12 km long between

portals on the northern side of Epping Station and portals on the northern side of Chatswood

Station. The twin circular tunnels are approximately 14m apart. Each tunnel has an internal

diameter of approximately 6.5m and carries a single track.

At a number of locations along the alignment the circular tunnel profile is modified to accommodate

ventilation fans and other system components.

At three locations along the ECRL alignment there are crossovers that allow trains to transfer

between the tunnels.

In addition to the circular tunnels there are short sections of box tunnel constructed by cut and

cover methods. These are located near the portals and under the Lane Cove River.

© Rail Corporation Page 9 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

The tunnel types are detailed in the Tunnels Operations & Maintenance Manual - PRL-

CSY112600.

The open dive structures at each end of the tunnel alignment allow trains to descend from ground

level down to the entry (portal) of the cut and cover tunnel structure. At Epping there are separate

dive structures for both the up and down tracks. At Chatswood there is only one dive structure that

contains both the up and down tracks.

All of the underground track, including the sections of track in the dives and the above ground

section at Chatswood, is non-ballasted and has a concrete track structure. The sections of the

ECRL above ground at Epping have a conventional ballasted track structure.

Two types of concrete track structure are used:

− Rail supported on steel baseplates which are fixed directly to the concrete tunnel invert slab,

called Direct Fixation Fastener (DFF)

− Rail supported on steel baseplates fixed to a floating concrete slab which is held off the invert

slab by elastomeric bearings, called Floating Slab Track (FST). This system is used to reduce

noise and vibration generated by the passage of trains.

The track slabs are detailed in the Track Operations & Maintenance Manual – PRL-CSY110200.

The tunnels intersect with the 4 underground station caverns along the alignment. The station

cavern structures are detailed in the Stations Operations and Maintenance Manual – PRL-

CSY102300.

The tunnels are connected at intervals not exceeding 240m by cross passages. The cross

passages provide access between tunnels. The tunnels are also connected at the three

crossovers, at the platforms of each underground station, and at the Lady Game Drive Service

Facility (LGDSF). Cross passages provide a pedestrian path of minimum 2m width.

The main purpose of the cross passages is to allow passengers and train crew to move from one

tunnel to the other during an underground incident such as a train breakdown or a fire. Cross

passage entrances are protected by sliding self closing fire rated doors that are normally closed but

not locked. With the ventilation system in operation the non incident tunnel provides a place of

relative safety in the event of a fire.

Elevated walkways are provided in the tunnels for the emergency evacuation of passengers and

crew. The walkways run along each tunnel on the side of the tunnel adjacent to the other tunnel

with direct access to the cross passages. The walkways are at approx the same height above rail

as the station platform (1.2m). At each crossover the walkways drop to track level via a set of

stairs, pass through the crossover cavern at rail level and then rise again on the other side of the

cavern.

The walkways provide a minimum envelope of 850 mm wide by 2m tall. As the walkways approach

the stations they connect via a fire door and corridor to the station platform and the emergency fire

stairs to the surface.

Water seeping into the tunnels collects in drains provided on either side of the track and flows

towards sumps located at low points in the tunnels. The water is pumped between the sumps and

from the tunnel using a combination of rising mains and the tunnel drainage system. The water

pumped from the tunnels is treated at the Water Treatment Plant located at the Lady Game Drive

Service Facility (LGDSF) before being discharged into the Lane Cove River.

Two separate lighting systems have been installed in the tunnels: a normal lighting system and an

emergency lighting system. Each system is comprised of fluorescent lights. Emergency lights have

an internal battery and remain illuminated in the event of a power failure.

A tree-structure diagram showing the relationship of this operation and maintenance manual with

other associated operation and maintenance manuals is shown below in Figure 2.

© Rail Corporation Page 10 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 2: Tree-Structure Diagram for Tunnels O & M Manuals

C4-2 Design parameters

C4-2.1 Design information

The design of the tunnel structure and walkway has been carried out in accordance with the

relevant requirements of the Works Brief (CIVSYS contract), RailCorp Standards and Australian

Standards.

The information contained in this section is a summary of information found in the following

documents:

− Tunnel and Station Waterproofing Specification – PRL-CSA100016

− Concrete Specification – PRL-CSA100008

− Shotcrete Specification – PRL-CSA100013

− Design Report for Excavation, Support, Waterproofing and Permanent Lining: Running

Tunnels – PRL-CSR111502

− Design Report for Package R03A – Walkways – PRL-CSR100033.

C4-2.2 Variations from standards

The assets detailed in this maintenance plan were, generally, designed and constructed to earlier

versions of current RailCorp engineering standards. Reference to these old standards has been

replaced with current standards. Where there any be a significant variation from current standards,

this has been cited in the text. Any implications arising from these variations have also been

documented.

C4-2.3 Design speeds

The maximum design speed is 80 km/hr.

© Rail Corporation Page 11 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

C4-2.4 Walkway

The tunnel walkway is installed inside the 200mm lateral extra clearance to the Kinematic Envelope

as specified by RailCorp standards. A Transit Space Operational Infringement Approval (No. TSI

07_009) has been given to permit the Walkway being installed with a minimum clearance to the

Kinematic Envelope of 100mm.

This waiver applies to track slab sections only. A condition of this approval is that warning signs are

attached to the walkway at each tunnel portal, the end of each station platform, each kilometre and

each half kilometre point. No additions or modifications to the walkway are permitted without the

approval of the relevant RailCorp Maintenance Manager.

C4-3 Description of elements

C4-3.1 General

The civil and structural elements of ECRL in this manual are:

− Tunnels

− Track slabs

− Drainage

− Walkway

− Cross passages

− Platform caverns

− Platforms

− Stations

− Noise attenuation panels.

C4-3.2 Tunnels

Figure 3 shows the alignment of the ECRL tunnels and the different types of tunnel structure

existing along the alignment. The different types of tunnel structure used to form the tunnels are:

− Formed concrete lining (circular profile)

− Shotcrete lining (irregular profiles)

− Cut and Cover Crossing under Lane Cove River

− Precast concrete arch segments at M2 construction access shaft

− Cut and Cover Dive Tunnel structure

© Rail Corporation Page 12 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 3: Diagrammatic representation of tunnel structure types along ECRL alignment

© Rail Corporation Page 13 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

C4-3.2.1 Formed concrete & shotcrete tunnel lining structure

The majority of tunnel lining along the alignment is constructed from un-reinforced cast-in-situ

concrete approximately 200mm thick. The concrete was placed in 15m long sections using tunnel

lining forms. This tunnel form has a smooth finish and is circular in profile.

Some sections of the tunnel are shotcrete lined. These sections include station caverns, fan

niches, Epping portal to Epping crossover, Macquarie Park Crossover, Lady Game Drive

Crossover and the soft-ground tunnel approaching the Chatswood portal. This permanent shotcrete

lining is approximately 140mm thick. Permanent rockbolts were installed prior to the shotcrete

lining and anchor the rock above the tunnel excavation and help support the tunnel excavation.

The un-reinforced concrete tunnel lining provides all required support for the tunnel structure. The

lining is designed to resist all loads including the lining self-weight, hydrostatic load on invert, rock

loading and the rail load on the invert. The running tunnel concrete lining is 200mm thick with a 28

day design compressive strength of 32MPa.

The last 180m (approximately) of tunnel at the Chatswood end of the alignment is constructed

through soft shale ground conditions. A combination of steel sets, pipe canopy and shotcrete

structures have been utilised in this area to give the required structural support to the tunnel. In

addition to this structural support, dimple sheet and an additional layer of shotcrete is also installed

to waterproof the tunnel walls.

The tunnel in this area is designed as a drained structure. Sub horizontal drains are installed at 6m

centres along the outside of each tunnel and are angled down and fitted with “U” bends to reduce

clogging from iron precipitating out of solution. The ends of each can be unscrewed for inspection

and cleaning.

For detailed information relating to the Chatswood Soft Ground Tunnel design, refer to Appendix M

Design Report Excavation, Support, Waterproofing and Permanent Lining Running Tunnels – PRL-

CSR111700.

Table 1 details the break-up of formed lining and shotcrete lining for the Epping to Chatswood Rail

Line Tunnels (including through station caverns).

Asset Tunnel Lining Type Length (m)

Formed Concrete Lining 10,073

Shotcrete Lining 2450

M14 TU__12.59UM Lane Cove River Cut & Cover 142

(Upline) Tunnel

M2 Shaft Cut & Cover Tunnel 23

Total Length – Downline 12,688

Formed Concrete Lining 9,958

Shotcrete Lining 2,590

M14 TU__12.59DM Lane Cove River Cut & Cover 135

(Downline) Tunnel

M2 Shaft Cut & Cover Tunnel 23

Total Length – Upline 12,706

Table 1: ECRL Tunnel Lining Details

A HDPE waterproofing membrane (‘dimpled sheet’ membrane) is installed between the excavated

rock surface and the rear face of the concrete lining to waterproof the structure and to drain water

away from the structure. Groundwater can seep between the rock face and the membrane into the

tunnel via weepholes provided in the structure as shown in Figure 4 and Figure 5. Groundwater

(and other water introduced to the tunnel) collects in drainage channels situated on each side of

the concrete track slab and flows towards sumps located at low points in the tunnels. The water is

© Rail Corporation Page 14 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

pumped between the sumps and from the tunnel using a combination of rising mains and the

tunnel drainage system. The water pumped from the tunnels is treated at the Water Treatment

Plant located at the Lady Game Drive Service Facility (LGDSF) before being discharged into the

Lane Cove River.

Waterproofing of the tunnel structure consists of a waterproof membrane between the rock and the

concrete lining. HDPE dimpled sheet is used in ‘drained’ sections of tunnel and PVC plain sheeting

is used in undrained sections of tunnels. Drained sections of tunnel have groundwater inflows less

that 0.1L/s/100m of tunnel. (For more information relating to the break-up of drained and undrained

sections of tunnel, refer to drawings PRL-CSD110521 to PRL-CSD110543.) These waterproofing

measures are sufficient for achieving Grade A waterproofing requirements above rail level (refer

Tunnel and Station Waterproofing Specification – PRL-CSA100016). At approximately rail level

there are weep holes in the lining to allow drainage to occur from the behind the waterproofing

membrane into the tunnel drainage channels (refer Figure 4).

WARNING

A suitably qualified structural engineer should be consulted before any

additional load-bearing fixings are attached to the tunnel lining.

Extreme care should be taken when drilling into the tunnel lining to avoid

punching holes in the waterproofing membrane.

At three locations along the ECRL alignment there are crossovers that allow trains to transfer

between the tunnels. The three cross-over caverns are situated at Epping, Macquarie Park and

Lady Game Drive. Support for the crossover caverns consists of permanent rock bolts and 140mm

thick, 40MPa, steel fibre reinforced shotcrete supported by steel reinforcement ‘spiders’.

Waterproofing is provided by a sprayed waterproofing membrane.

Figure 4: Typical Formed Lining Tunnel Section

© Rail Corporation Page 15 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 5: Shotcrete Tunnel Section at Fan Niche

C4-3.2.2 Lane Cove River cut & cover tunnel structure

A cut and cover tunnel structure is used where the alignment crosses under the Lane Cove River.

The tunnel structure is a reinforced concrete box structure and is designed to withstand all loads

associated with being a completely submerged structure in the poor quality ground conditions

experienced beneath the river. The floor of the structure has been thickened to provide additional

mass to resist buoyancy forces.

Movement joints have been designed to allow movement up to 20mm and also prevent water

ingress into the tunnel.

Corrosion monitoring points are also provided.

Note: it is unclear whether corrosion monitoring instruments were fully installed and commissioned.

The Commissioning Results do not contain any data. Subsequently, some testing has been carried

out by GHD. The final report from TIDC has not yet been received.

For more details relating to the design of the Lane Cove Cut & Cover Tunnel Structure, refer to the

Lane Cove River Cut and Cover Design Report – PRL-CSR142001.

A typical section through the cut and cover tunnel underneath Lane Cove River is shown in Figure

6.

Durability issues

Leaking has been observed at several areas of the tunnel and was investigated by THJV.

© Rail Corporation Page 16 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

The investigation report prepared by THJV’s consultant (GHD) states that testing has

demonstrated that corrosion of the steel in the tunnel walls is imminent or has already commenced

in a significant number of the areas tested. For the areas where corrosion has not yet been

initiated, initiation was predicted to occur within a 20 yr timeframe.

It is unusual for damage of this nature to occur so early in the tunnel's life. Corrosion initiation

would be expected to occur during the latter part (eg 90 years ) of the infrastructure's life, rather

than within the first ten years.

Based on the information provided to date, the design life of parts of the tunnel section under the

aggressive saline environment of the Lane Cove River has been substantially compromised and

does not meet the project durability requirements. The latest GHD Investigation Report (March

2010) states that “in the vicinity of the vertical construction joint, testing has indicated that in 9 out

of 10 cases reinforcement corrosion initiation is imminent (or has already started) and that a loss of

30% of the vertical reinforcement steel is likely to occur within the 100 year design life of the tunnel,

if spalling is not repaired. This is predicted to occur even if the joints are effectively sealed stopping

the saline ground water from entering the tunnel, as a result of the chlorides already present in the

concrete.”

Cracking and spalling of the concrete due to corrosion of the reinforcement is likely to commence

within the next 10 to 20 yrs. Repairs would need to be undertaken several times within the design

life of the tunnel. This is considered to be unacceptable to RailCorp.

The tunnel is critical infrastructure and vital to RailCorp operations. Any repair measures will be

difficult to implement in restricted track access and are likely to be costly. This section of the line

might need to be closed down for extended periods during the repair process, thereby disrupting

train services.

We have not yet received TIDC’s final report (including proposed remedial measures) on this

matter and TIDC has not been able to provide a program for resolving the matter.

Figure 6: Lane Cove Cut & Cover Tunnel Section

© Rail Corporation Page 17 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

C4-3.2.3 Precast concrete arch segments at M2 Construction shaft

During construction of the ECRL there was a construction access shaft located between Delhi

Road and Macquarie Park Station at approximate track chainage 18.620 on the down and 18.630

on the up track. At this location on the finished tunnel alignment there is 23m long section of tunnel

constructed from precast concrete arch segments, backfilled from the surface with selected

granular material which was compacted. These arch segments allowed the shaft above both the up

and down tunnels to be backfilled and reinstated.

Joints between the precast arch segments are taped and sealed with a bitumen tape membrane

and the whole structure was also covered in dimpled sheet before backfilling.

There are drains installed in the backfill at the bottom of the arches that allow any water build-up to

drain into the tunnel.

Overhead wiring, cable trays and other services through this section of tunnel are supported by

ferrules cast into the precast elements.

A section through the precast concrete arch tunnel structure is shown in Figure 7.

WARNING

No drilling into the precast segments shall be permitted. No additional loads

shall be supported by the precast tunnel structure.

The precast concrete arch structure was designed by a specialist subcontractor experienced in this

method of construction. For more information relating to the design of the precast tunnel structure

at the M2 construction shaft, refer to Precast Arch Tunnel Supplier Documentation – PRL-

CSY112601.

Figure 7: Precast Concrete Arch Tunnel Structure

C4-3.2.4 Redesign of M2 arch sections

© Rail Corporation Page 18 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

In late 2008 it was observed that the arches had suffered movement beyond that predicted by the

design model. The extent of the movement was such that the durability of the arches could no

longer be assured. Rectification works were designed and implemented.

Rectification works included:

− Precast concrete arch crack repair to external and internal surfaces

− Crown beam concrete removal and replacement where damage had occurred

− Crown beam concrete crack repair in identified areas

− Joint repair including replacement of backing rod and bandage where required

− Rectification of precast tunnel lining waterproofing system (bandage joints)

− Installation of new shaft drainage system using strip drains

− Placement of concrete backfill (unreinforced) to form of a pair of new arches over the existing

precast arches

− Construction of a drainage layer on top of the new unreinforced concrete arch structure

− Placement of backfill on top of the drainage layer.

Refer to the following documents for full details of the work:

− PRL-CSR111503 (Rev 3) - “Design report for running tunnels:M2 shaft, rectification works”

− Drawing Number PRL-CSD 111518 - “Running tunnels M2 shaft: rectification works. Sheet 1

of 3”

− Drawing Number PRL-CSD 111519 - “Running tunnels M2 shaft: rectification works. Sheet 2

of 3”

− Drawing Number PRL-CSD 111520 - “Running tunnels M2 shaft: rectification works. Sheet 3

of 3”.

C4-3.2.5 Open dive and cut & cover dive structures

The open dive structures and the cut and cover dive structures at each end allow the rail alignment

to drop down below ground level to the location of the tunnel portal.

The dive structures consist of piled reinforced concrete retaining walls (with arched shotcrete infill

between piles) and reinforced concrete invert slabs. In sections of cut and cover tunnel there are

also roof slabs spanning between the retaining wall structures. At Chatswood there are also beams

spanning between the piled walls to provide addition rigidity to the structure.

The piled retaining wall structures are restrained by permanent ground anchors.

Strip drains are provided behind the shotcrete facing to allow water to drain from behind the dive

structure. They drain through weep holes into the dive drains. Subsurface drains are installed

below the invert slab to also assist in draining water away from the structure.

For detailed information relating to the Epping Dive Structures refer to Epping Cut and Cover and

Dive Structures Design Report – PRL-CSR192002. For detailed information relating to the

Chatswood Dive Structure, refer to the Chatswood Cut and Cover and Dive Structure Design

Report – PRL-CSR122001.

A typical dive structure arrangement is shown in Figure 8.

© Rail Corporation Page 19 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 8: Typical Dive Structure (Cut & Cover Dive Tunnel similar)

C4-3.3 Track slabs

C4-3.3.1 Direct Fixation Fastener (DFF)

The DFF track slab consists of a conventional concrete slab track laid directly on the concrete

tunnel invert as shown in Figure 9. Rail is attached to the concrete slab via Delkor Sydney Egg

baseplates and their associated components. The base plates are spaced at 700mm centres under

each rail.

The majority of DFF track-form was constructed using a ‘full top-down’ construction method. In full

top down construction the rail was set and supported on props in the correct position. Baseplates

and all associated components (clips, insulates, screwspikes, ferrules, etc) are clipped to the rail

and then concrete is poured up to the underside of the baseplate. Resulting voids under the

baseplates were then filled with ‘MegaPoxy’ epoxy resin as part of a secondary quality inspection

process.

For the remaining areas of DFF slab (typically shorter sections between sections of FST slabs) a

‘partial top-down’ or ‘drill and grout’ method of construction is used. In this method of construction

the concrete slab is poured first and then holes for the screwspikes and dowels are cored in the top

of the slab. The rail is then set in position and supported by props, and then all associated

components are clipped to the rail, with the screwspikes and dowels extending into the cored

holes. Megapoxy epoxy grout is then pumped into the core holes and allowed to fill the void

between the concrete slab, the screwspikes dowel and the underside of the baseplate.

© Rail Corporation Page 20 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 9: Direct Fixation Fastener Track

C4-3.3.2 Floating Slab Track (FST)

The FST track slab consists of 19.6m long reinforced concrete slabs that are supported on twenty

individual elastomeric pads (bearings). A section through a FST slab is shown in Figure 10. Rail is

attached to the concrete slab via baseplate resilient fastenings and associated components. Please

note that the baseplates for FST is different from those for FST

Figure 10: Floating Slab Track

Holes to house screwspike dowels are cored into the slab and an epoxy grout pad is used beneath

the baseplate pad and around the screwspike dowels to attach the baseplate assemblies to the

slab (‘drill and grout’ construction).

C4-3.3.3 Elastomeric Bearings (FST Trackform)

Type A and Type B Elastomeric Bearings have been designed and manufactured in accordance

with Austroads 1992 Bridge Design Code, Section 4: Bearing and Deck Joints, AS 1523 and BS

6177. For further information, refer to Design Specification for Package R01A Permanent Way

Design – PRL-CSA100040.

© Rail Corporation Page 21 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Bearings were manufactured by Ludowici Rubber & Plastics, refer to C4-5 for further details.

C4-3.4 Drainage system

C4-3.4.1 General

The drainage system in the ECRL tunnel incorporates a network of open drains, pump stations and

rising mains that collect and deliver water to the water treatment plant for treatment. The drainage

network captures the following water sources:

− Seepage flow from tunnels and station caverns;

− Dive structure rainfall runoff and other rainfall runoff ingress;

− Fire suppression system flows; and

− Overflows from station and platform wash down water. (Note: All water used in the stations is

to be captured and disposed of via the station sewerage system).

Dive structure rainfall runoff flows into sumps located inside the tunnel portals at Epping and

Chatswood. Small bund walls approximately 100mm high prevent runoff from bypassing the sump

and flowing down the tunnel. The water collected in the sumps is pumped and discharged into the

local surface stormwater drainage system located at each portal.

All other flows originating between the Chatswood portal and Epping portal are collected in the

trackside drains and then captured in sumps located at low points along the tunnel alignment. The

water is then pumped between the sumps via a series of rising mains and also allowed to flow

under gravity in the trackside drains until it reaches the lowest point on the tunnel alignment, the

sump located near Lady Game Drive Service Facility. From here the water is pumped to the Water

Treatment Plant located on the surface at the Lady Game Drive Service Facility (LGDSF).

Following treatment, the water is discharged to the Lane Cove River.

Water used in the stations for cleaning or other purposes is captured and handled by the stations

drainage system. Any such water that overflows from the platforms and enters the trackside tunnel

drains will be handled by the tunnel drainage system. These additional flows are expected to be

minimal. Litter and trash entering the drainage channels at the stations is captured by trash racks

located in the drains at each end of the station cavern. The trash racks are simple grated frames

that are positioned across the drainage channels.

C4-3.4.2 Trackside tunnel drains

Drainage channels are installed on both sides of the track for the complete length of the ECRL

alignment. In all tunnel structures, the area of tunnel invert between the base of the concrete track

slab and the curved wall of the tunnel is designated as the trackside tunnel drain. These drainage

channels are continuous along the length of both tunnels, including at crossovers where voids in

the slabs allow flow to pass under the turnout tracks.

Trackside tunnel drains are designed with sufficient capacity to allow all groundwater entering the

station caverns and tunnel, along with fire suppression water from one completely open fire hydrant

valve, to drain towards sumps located at low-points along the alignment. The typical groundwater

inflow is expected to be approximately 11 L/s and the flow from one open fire hydrant valve is

expected to be 22 L/s. Through areas of floating track slab, the topping layer of fibre reinforced

concrete has a minimum thickness of 30mm to ensure that, under the flow conditions listed above,

ponding does not occur around the rubber bearings.

Drainage channels are formed between the tunnel walls and the base of concrete track slabs. The

ECRL tunnel has been designed to be a dry tunnel with seepage of 0.1 litres per second per 100

lineal metres of tunnel.

Trash racks are situated in the tunnel drainage channels at each end of the station caverns to

prevent rubbish from the stations being transported through the tunnel.

Tunnel drainage channels are designed to allow all water entering the tunnel (via weepholes or

water used for fire-suppression) to drain towards sumps located at low-points along the alignment.

© Rail Corporation Page 22 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Litter traps are installed at each sump location, on both sides of the track slab in both the up and

down tunnels. Each litter trap contains three baskets to catch the litter. There are a total of 24 litter

traps installed in the tunnel giving a total of 72 litter trap baskets. Water collected in the 4 tunnel

sumps is pumped into the rising main pipework and allowed to flow towards the lowest point on the

alignment beneath Lane Cove River. At this point it is pumped to the surface where it is treated at

the Water Treatment Plant and then released.

In open dives and cut and cover dive sections the drainage channels are recessed into the dive

invert slab and direct flow into the sumps located near the bottom of each dive. The sumps bunded

to minimise storm flows from the open dives entering the tunnel water flowing down the tunnel.

For further detailed information relating to the tunnel drainage system, refer to the ECRL Tunnel

Drainage Manual – PRL-CSY112200.

C4-3.4.3 Tunnel Drainage System - Performance Issues

Several failures have occurred in the drainage system since it was completed. The first

incident was in Oct 2009 when failure of the delivery pipes to both pumps in Sump 5 was reported.

This incident resulted in water levels in the tunnel rising to the level of the bottom of the rail and

nearly resulted in the suspension of train operations. A similar but less severe pipe rupture incident

occurred to both delivery pipes in Sump 2 several months later (Feb 2010). Investigations of the

failures also revealed that certain elements of the pump and pipe installations were not constructed

in accordance with the approved drawings.

After a period of several days of wet weather, and during a storm in Feb 2010, the capacity of

Sump 1, which is located at the Chatswood entrance to the tunnel, was exceeded and water

overflowed into the tunnel drainage system. The water subsequently flowed to the lowest point in

the tunnel and had to be pumped out of the tunnel to the Water Treatment Plant (WTP) at ground

surface level. The increased volume of water that was pumped to the WTP resulted in overloading

the plant. The Feb 2010 storm was not regarded as a particularly severe storm, and certainly well

below the 100 yr Average Return Interval (ARI) event. Therefore there is concern as to why the

existing Sump 1 could not adequately cope with a rainfall event less severe than one that the

design indicated. A more severe rainfall event would have the potential to flood part of the tunnel at

it's lowest point.

These incidents indicate that there may be systemic deficiencies in the design or construction of

the tunnel drainage system. Reliability and durability of the system is paramount in ensuring regular

availability of the tunnel for the passage of trains. The incidents described above indicate the

potential for significant flooding in the tunnel, of a nature that would require line closure, because

there aren't any easy alternative solutions for disposing of large volumes of water to the surface in

a timely manner once part of the drainage system malfunctions.

THJV and TIDC contend that the design is adequate and fit for purpose. However the number and

nature of the incidents point to a potential systemic deficiency in the design. It is considered that a

comprehensive review of the design and construction of the system should be undertaken to

identify any actions required to improve the reliability and durability of the system. A brief has been

prepared as a first step in engaging a consultant to carry out this review.

C4-3.5 Walkway

Elevated walkways are provided in the tunnels providing access for maintenance purposes and for

the emergency evacuation of passengers and crew. The walkways run along each tunnel on the

side of the tunnel adjacent to the other tunnel. The walkway allows access to cross passages and

surface exits at service buildings and stations. At crossovers the walkway drops to track level to

allow access over the crossover.

The tunnel walkway is a modular system consisting of galvanised steel support frames and precast

reinforced concrete deck panels. The walkways have been designed to withstand a maximum load

of 5 kPa (or 10kN point load). 5kPa live load equates to 400kg loading per metre length of 800mm

wide walkway. The modular tunnel walkway system allows for sections of walkway to be readily

adjusted or dismantled for repair, re-coating, or replacement as necessary.

© Rail Corporation Page 23 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

As the walkway infringes transit space (refer to C4-2.4), the walkway has to be closely monitored

during inspections to ensure there is no movement of the concrete panels or the steel frame

towards the track.

In addition, the stability of the walkway is critically dependent on the bolts attaching it to the tunnel

wall. It is imperative that these bolts remain tight

The steel frame of the walkway also supports cable trays used to carry cables for various systems

throughout the tunnel. Galvanised steel handrails, kickplates and access ladders also form part of

the walkway structure. At turnouts the walkway is in-situ concrete cast onto the tunnel invert.

A typical section of tunnel walkway is shown in Figure 11.

WARNING

The walkway deck panels are designed to withstand the load of one drainage

sump pump only. Care should be taken when removing pumps from the

drainage sumps for repair or replacement. Do not place more than one pump on

the walkway at any time. Overloading walkway deck panels may lead to cracking

and failure of the deck panel or supporting frame

Figure 11: Typical Tunnel Walkway Arrangement

© Rail Corporation Page 24 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

C4-3.6 Cross passages

Cross passages link the up and down tunnels at intervals of approximately 240m. Cross passages

provide access between the tunnels. Some cross passages house tunnel services systems and

tunnel drainage sumps.

There are 49 cross passages associated with the ECRL. There are three types of cross passage:

− Standard cross passage

− Service cross passage (nominally every second cross passage)

− Sump cross passages

The main purpose of the cross passages is to allow passengers and train crew to egress from one

tunnel to the other during an underground incident such as a train breakdown or a fire. Cross

passages provide a pedestrian path of minimum 2m width and are protected by self-closing

fireproof doors.

Tunnel cross passage structures have been designed to resist all ground and water loading.

Typically, cross passages are supported by an appropriate excavation shape and shotcrete lining.

The shotcrete lining is typically 140mm thick, with a design strength of 40MPa. A waterproofing

membrane is installed between the excavated rock surface and the rear face of the shotcrete lining

to waterproof the cross passage structure and assist in draining water away from the structure.

At the junction of the cross passage and the tunnel lining structure, a concrete stub connection

forms a lintel beam to provide additional support to the structure. Cross passage dividing walls are

constructed from standard reinforced concrete masonry blockwork with brick ties used to secure

the blockwork to the shotcrete walls. Fireproof sealant is used at interfaces between blockwork and

shotcrete.

Additionally, the service cross passages are provided with separate electrical and communication

rooms (equipment rooms) which house equipment for the operation of the tunnel systems.

Sump cross passages are located at low points along the tunnel alignment and have drainage

sumps and pumps beneath them. These sumps collect water from the tunnel drainage system. The

sumps are covered with metal grates to prevent access. Protection and control systems

associated with the sump pumps are located in the sump cross passage. Refer to Tunnel Drainage

System Manual – PRL-CSY112200.

The walkways which run along each tunnel provide direct access to the cross passages. At cross

passage 1 (Chatswood) and cross passage 16 (Lady Game Drive Service Facility (LGDSF)), there

are access stairs to the surface.

The location of the entrances to the cross passages is highlighted by appropriate signage along the

tunnel walkway. Cross passage entrances are protected by sliding, self-closing, fire rated doors

that are normally closed, but not locked. Operation of a sliding door actuates a switch which in turn

causes the lighting within the cross passage to be illuminated. Cross passages normally contain

one emergency luminare only. Cross passages 48 and 49 due to their length have two emergency

and two normal luminaries. Emergency lights are fitted with an internal battery which allows the

light to remain operable for a period of approximately 2 hours in the event of a power failure.

Normal lights do not have a backup battery. The door switch is monitored by the CCS which turns

off the lights in the cross passage after a predetermined period (nominally 2 hours). Refer to

Tunnel Lighting System Manual – PRL-CSY216800.

For more information relating to Cross Passages, refer to the Cross Passage Operations and

Maintenance Manual – PRL-CSY113200.

C4-3.7 Standard Cross Passage

Standard cross passages provide a safe passage between the tunnels in an emergency. They

contain lights and ventilation for this purpose only.

© Rail Corporation Page 25 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

A cross section of a standard cross passage is shown in Figure 12. An elevation of a standard

cross passage is shown in Figure 13.

Cross Passages 38, 42, 48 & 49 (initially enlarged for construction purposes) have additional

permanent rock bolts installed as part of the structure. These permanent rockbolts help to support

the excavation.

Figure 12: Standard Cross Passage

Figure 13: Standard Cross Passage Elevation

C4-3.8 Service Cross Passages

As well as being an emergency escape passage between the tunnels, service cross passages also

contain electrical and communications equipment rooms. The various system components

(communications equipment, distribution boards, transformers, etc) are housed in these rooms

which are separate to the cross passage thoroughfare. The rooms are fitted with fire suppression

systems in case of fire. Earth electrode access boxes are also installed at service cross passages

(for more information refer to HV System O&M Manual – PRL-CSY206100 and LV System O&M

Manual – PRL-CSY206300)

© Rail Corporation Page 26 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

A cross section of a service cross passage is shown in Figure 14. A plan view showing the layout

of equipment rooms is shown in Figure 15.

Figure 14: Service Cross Passage

Figure 15: Service Cross Passage Plan Layout

C4-3.9 Sump Cross Passages

Sump cross passages are located at low points along the tunnel alignment and have drainage

sumps excavated beneath them that collect the water from the tunnel drainage system. Grated

coverings inside the cross passage prevent access to the sump. Hinged opening panels in the

grates allow access to the sump for removal of the pumps and other maintenance tasks.

Components of the sump pump control systems are located in the sump cross passages, as well

as other tunnel services equipment.

Sump cross passages have additional permanent rock bolts installed as part of the structure.

These permanent rock bolts help to support the excavation.

Figure 16 shows a cross section of cross passage 36 (Sump 5).

© Rail Corporation Page 27 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 16: Sump Cross Passage 36

C4-3.10 Stations

C4-3.10.1 General

Four underground stations are located along the Epping to Chatswood Rail Line route. All four

stations have a number of similarities with regards to form, construction techniques, support,

waterproofing, lining and other structural and architectural elements. Each of the station structures

is considered an individual asset.

A description of the location, form and layout of each station is provided in the following sub-

sections.

Each station structure also includes two service buildings, one connected to each end of the

station. The service buildings provide additional emergency egress routes from the

tunnels/platforms to the surface and also allow access for maintenance personnel. The service

buildings house a range of equipment that is required for the various systems installed in the

stations and tunnels (Refer to section 3 for more details). Hatches with removable precast concrete

covers are built into appropriate floors in each of the service buildings to allow cranes to lift large

pieces of equipment in and out of the buildings. The hatch covers are constructed from parallel

precast concrete planks, recessed into the surrounding floor slab. Procedures for removing these

planks are detailed in section 9.3.1.

C4-3.10.2 Epping Underground Station

Epping Underground station consists of two parallel underground platform caverns (near circular

cross section) linked by four cross passages (rectangular cross-section). The underground station

is located below the surface station at Epping. Two services buildings, one located at the northern

end and one located at the southern end of the station, form part of the underground station

structure. A transfer concourse (to allow commuters to move from the above ground station to the

underground station), escalator shafts and elevator shafts provide direct access from paid areas of

the surface station to the underground station.

An overview of Epping Underground Station access points is shown in Figure 17. Two cross

sections showing the underground station structure are shown in Figures 18 & 19.

© Rail Corporation Page 28 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 17: Epping Underground Station Access Structures

Figure 18: Epping Underground Station Elevation

© Rail Corporation Page 29 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 19: Epping Underground Station Cross Section (Section A)

C4-3.10.3 Macquarie University Station

Macquarie University Station consists of a large cavern (brain-shaped cross section) that

encompasses both rail lines. Stairs, elevators and escalators lead from the centrally located

platform to the elevated concourse area along the northern side of the main station cavern. This

‘paid concourse’ area leads through the ticket turnstiles to an ‘unpaid’ entry concourse area. This

entry concourse is situated in a separate smaller cavern located on the northern side of the main

station cavern. Station entry shafts flank each end of the unpaid concourse cavern and provide

escalator and elevator access from the surface.

Two services buildings immediately adjacent to the station entry shafts, one in the north-west

corner of the station and the other in the north-east corner of the station, also form part of the

underground station structure. Emergency and maintenance access and egress is available via

these service buildings from either end of the main station cavern.

Figure 20: Macquarie University Station Access Structures

© Rail Corporation Page 30 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 21: Macquarie University Station Cross Section

C4-3.10.4 Macquarie Park Station

Macquarie Park Station consists of a large cavern (brain-shaped cross section) that encompasses

both rail lines. Stairs, elevators and escalators lead from the centrally located platform to the

elevated concourse area along the southern side of the main station cavern. This ‘paid concourse’

area above the platforms leads through the ticket turnstiles to an ‘unpaid’ entry concourse area.

This entry concourse is situated in a separate smaller cavern located on the southern side of the

main station cavern. Station entry shafts flank each end of the unpaid concourse cavern and

provide escalator and elevator access from the surface.

Two services buildings also form part of the underground station structure. The East Service

Building is linked to the north-east corner of the main station cavern via the east escape

passageway. The West Service Building is linked to the north-west corner of the main station

cavern via the west escape passageway. Emergency and maintenance access and egress is

available via the service buildings from each end of the main station cavern.

© Rail Corporation Page 31 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 22: Macquarie Park Station Access Structures

Figure 23: Macquarie Park Station Cross Section

C4-3.10.5 North Ryde Station

North Ryde Station consists of a large cavern (brain-shaped cross section) that encompasses both

rail lines. Stairs, elevators and escalators lead from the centrally located platform to the elevated

concourse area along the southern side of the main station cavern. This ‘paid’ concourse area

leads through the ticket turnstiles to an ‘unpaid’ entry concourse area. This entry concourse is

situated in a separate smaller cavern located on the southern side of the main station cavern. A

single station entry shaft is located in the middle of the southern side of the concourse entry cavern

and provides escalator and elevator access from the surface.

Two services buildings also form part of the underground station structure. The East Service

Building is situated adjacent to the south-east corner of the main station cavern and is connected

via short passageways. The West Service Building is situated adjacent to the south-west corner of

the main station cavern and is also connected via short passageways. Emergency and

maintenance access and egress is available via the service buildings from each end of the main

station cavern.

© Rail Corporation Page 32 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Figure 24: North Ryde Station Access Structures

Figure 25: North Ryde Station Cross Section

C4-3.11 Platform caverns

The information contained in this section is a summary of information contained in the various

Station Excavation, Support, Waterproofing and Permanent Lining Design Reports and various

Stations Buildings and Structures Design Reports. For more information, refer to the following

documents:

− Design Report – Excavation, Support, Waterproofing and Permanent Lining: Epping Station

Caverns, Service Buildings and Transfer Concourse – PRL-CSR181502.

− Design Report – Excavation, Support, Waterproofing and Permanent Lining: Macquarie

University Station Caverns – PRL-CSR171502.

− Technical Design Report – Waterproofing and Lining – PRL-CSR102500.

− Design Report for Design Packages C08B, C10B, C12B, C14B – Buildings and Structures for:

Epping Station, Macquarie Park Station, Macquarie University Station and Delhi Road Station

– PRL-CSY162504.

C4-3.11.1 Ground Support

Ground support in the station caverns typically consists of 3.5m long fully grouted CT type bolts

arranged in a 1.5m grid, with additional spot bolts installed as necessary. Permanent rock anchors

installed in the station caverns have a capacity of 300kN ultimate load (186kN working load) and

have been nominally pre-tensioned to between 20kN to 60kN.

© Rail Corporation Page 33 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

Shear deformations of up to 15mm are permissible before re-bolting is required. It is not anticipated

that shear movements and/or surface settlement will continue after station cavern construction is

complete. Likewise, ongoing surface settlement is unlikely to occur.

Rockbolts and rock anchors are protected against corrosion for their design life (100 years) in

accordance with BS808. A number of additional rock bolts have been installed in accessible areas

in each station cavern to allow future over-coring and inspection of rockbolt corrosion if desired.

C4-3.11.2 Waterproofing

The various waterproofing requirements specified in the Works Brief have been met in the design.

Within the station platform caverns, Grade A waterproofing (no leakage, seepage or damp patches)

is provided. Grade B waterproofing (minor damp patches with no visible flow of water) is provided

in emergency passageways and ventilation and cable ducts. Sumps are the only areas designed

for Grade C waterproofing (damp patches and minor seepage).

Due to low predicted groundwater inflows, no further ground treatment was deemed necessary

during construction to ensure the maximum allowable groundwater seepage rate of 0.75L/s from

any 10,000m2 of excavated area (as specified in the Project Deed) was not exceeded.

Waterproofing consists of a sprayed on membrane and/or dimple sheet, with strip drains installed

to transfer water to the bottom of the cavern excavation

C4-3.11.3 Shotcrete cavern lining

The 120mm thick fibre reinforced shotcrete lining is supported by steel reinforcing ‘spiders’ fixed to

the end of the permanent rock bolts. The rockbolt, spider and shot-crete configuration has been

designed to resist the self-weight of the lining, the hydrostatic pressure, loads from rock wedges

situated between the permanent bolts and any loading from secondary fixings attached to the

lining.

WARNING

A suitably qualified structural engineer should be consulted before any

additional secondary fixings are attached to the station cavern shotcrete lining.

Extreme care should be taken when drilling into the shotcrete lining to avoid

punching holes in the waterproofing membrane.

The design of the lining system provides ample drainage capacity behind the final shotcrete lining

to prevent the build-up of hydrostatic loads. Water reaching the drainage layer of the lining

(dimpled sheeting, strip drains), drains under gravity to an underfloor drainage network. The outlets

of drainage from dimpled sheeting and strip drains are submerged to prevent air from entering the

drainage layer. The submerged outlets prevent the oxidisation of iron pyrite dissolved in the

groundwater. Oxidisation may lead to blockages in the strip drains and dimpled sheets.

The shotcrete lining design also exhibits sufficient ductility to allow the lining to crack, yet still

provide sufficient residual strength to prevent failure of the lining structure.

The 180mm (minimum) total thickness of shotcrete lining provides 4 hours fire protection to the

primary cavern support bolts.

The 120mm thick (minimum) final smoothing layer of shotcrete also provides 2 hours fire protection

to the membrane.

C4-3.11.4 Drainage

A subfloor drainage system beneath the platforms and invert collects all seepage water from

behind the station cavern lining and from invert areas. The water travels via drainage pipes and is

discharged into the trackside tunnel drains. The water then travels via the tunnel trackside drains

to drainage sumps located at low points along the tunnel alignment. For information relating to the

tunnel drainage system, refer to the ECRL Tunnel Drainage System Manual – PRL-CSY112200.

© Rail Corporation Page 34 of 61

Issued July 2010 UNCONTROLLED WHEN PRINTED Version 1.0

RailCorp Engineering Manual — Structures

Maintenance Plan – Epping to Chatswood Rail Line Structures TMC 132

The subfloor drainage system consists of 16mm single size gravel and a proprietary drainage mat.

The design provides over-capacity and ensures head build-up below the floor slabs does not occur

over the 100 year design life.

At the north end of Epping Station there is a trackway exhaust passage extending beneath the

upline tracks before ascending vertically into the base of the north services building. There is a

sump constructed at the low-point of the passage. A single-phase submersible drainage pump is