Professional Documents

Culture Documents

6.4 Mechanical, Electrical, and Plumbing Components: 6.4.3 Pressure Piping

Uploaded by

thilina lakhithaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6.4 Mechanical, Electrical, and Plumbing Components: 6.4.3 Pressure Piping

Uploaded by

thilina lakhithaCopyright:

Available Formats

Available at: http://www.fema.

gov/plan/prevent/earthquake/fema74/

Last Modified: January 2011

6.4 MECHANICAL, ELECTRICAL, AND PLUMBING COMPONENTS

6.4.3 PRESSURE PIPING

6.4.3.4 PIPE RISERS

This category covers pipe risers for pressure piping, that is, vertical runs of pressurized piping

such as those used in multistory buildings. Risers are typically supported by a combination of

wall-mounted supports and additional floor-mounted or roof-mounted supports at the

locations of penetrations. Due to their length, thermal movement may be an important

consideration and seismic restraints must be designed to accommodate the anticipated inter-

story drift and the thermal movement.

TYPICAL CAUSES OF DAMAGE

Pipe risers must be designed to accommodate inter-story drift between adjacent floors,

that is, differential movement between the points of support located on different floors

of the building. If the pipe supports are not designed to accommodate this movement

during an earthquake, the supports may fail or the pipes or pipe joints may fail and leak.

Improperly supported pipes can become dislodged and fall; unbraced risers can sway

and impact adjacent items.

Pipes are vulnerable at penetrations, thus floor and roof penetrations must be

sufficiently oversized to prevent impact. Unrestrained movement of pipes at

penetrations may damage the piping and pipe restraints but may also damage flooring,

ceilings, partitions, insulation, fire-proofing or other architectural finishes. For

insulated risers, the piping insulation may also be damaged if the pipe chafes at the

restraint. If risers are mounted to lightweight partitions, the partitions may be damaged

unless they have been designed and braced to resist the piping loads.

Because risers often involve very long pipe runs, the thermal movement may be

significant. Unless seismic restraints are designed to accommodate thermal movement,

the piping, pipe joints or rigid seismic restraints could be damaged under operating

conditions and fail to perform properly in an earthquake.

Pipe risers in multistory buildings are typically located in utility shafts or pipe chases;

thus, they usually do not pose a significant falling hazard to occupants but riser damage

could cause significant leakage resulting in property losses and business outage.

FEMA E-74 6: Seismic Protection of Nonstructural Components Page 6-247

Available at: http://www.fema.gov/plan/prevent/earthquake/fema74/

Last Modified: January 2011

Damage Examples

Figure 6.4.3.4-1 Movement of unbraced risers damaged ceiling finishes and insulation in the

1994 magnitude-6.7 Northridge Earthquake (Photo courtesy of Mason

Industries).

SEISMIC MITIGATION CONSIDERATIONS

See the general discussion of pipe bracing in Section 6.4.3.1.

Standard steel pipe expands or contracts at a rate of 0.8 inch per 100 feet per 100

degrees Fahrenheit; supports and bracing for tall risers or piping subject to large

temperature variations must be explicitly designed to accommodate thermal movement.

Riser details for chilled water piping may need to accommodate additional insulation.

Riser calculations should be performed assuming the full weight of water is at the

bottom of the pipe riser.

Pipe risers require vertical support (longitudinal restraints) as well as lateral bracing.

Risers are typically supported and braced by a combination of wall-mounted restraints

and floor- or roof-mounted supports or guides at the locations of penetrations. They

FEMA E-74 6: Seismic Protection of Nonstructural Components Page 6-248

Available at: http://www.fema.gov/plan/prevent/earthquake/fema74/

Last Modified: January 2011

may also be supported by hangers located on horizontal branch lines within 24 inches

of the centerline of the riser. Suspended support details are sometimes used at the top

of the riser. The pipes may be rigidly mounted, for instance at the base of the riser, or

mounted with elastomeric pads, sliding guides or vibration isolation. Specially designed

riser clamps are often used to provide vertical support for pipe risers. Isolated piping

should be supported independently from rigidly braced piping; rigid pipe attachments to

lightweight walls may cause vibration problems under operating conditions.

All vertical risers should have lateral restraints at the top and bottom of the riser and at

each intermediate floor at a maximum spacing of 30 foot intervals. When installed as a

riser, nonductile piping, such as no-hub cast iron piping, should include joint stabilizers

where the joints are unsupported between floors.

Pipe penetrations through structural elements such as beams, walls, and slabs must be

coordinated with a structural engineer. Pipe penetrations through nonstructural walls,

architectural finishes or roof membranes must be coordinated with an architect. Riser

penetrations may require thermal insulation, fire proofing, sound proofing or weather

proofing and unless properly detailed, these architectural and safety features may be

compromised during an earthquake. See Section 6.4.3.8 for additional information

about detailing pipe penetrations.

FEMA E-74 6: Seismic Protection of Nonstructural Components Page 6-249

Available at: http://www.fema.gov/plan/prevent/earthquake/fema74/

Last Modified: January 2011

Mitigation Examples

Figure 6.4.3.4-2 Riser supports provide lateral restraint with vertical sliding guides that allow

thermal movement; restraint hardware consisting of tube sections is welded to

either side of pipe (Photo courtesy of Mason Industries).

FEMA E-74 6: Seismic Protection of Nonstructural Components Page 6-250

Available at: http://www.fema.gov/plan/prevent/earthquake/fema74/

Last Modified: January 2011

Figure 6.4.3.4-3 Different schemes for riser supports at floor penetrations with vibration

isolation: first one with restraint hardware welded to pipe, second with two sets

of riser clamps, and third with riser clamp inside the insulation (Photos courtesy

of Mason Industries).

FEMA E-74 6: Seismic Protection of Nonstructural Components Page 6-251

Available at: http://www.fema.gov/plan/prevent/earthquake/fema74/

Last Modified: January 2011

Figure 6.4.3.4-4 Insulated boiler pipe risers with welded lugs (small pipe sections) which travel

vertically in guides providing lateral seismic restraint (Photo courtesy of Eduardo

Fierro, BFP Engineers).

FEMA E-74 6: Seismic Protection of Nonstructural Components Page 6-252

Available at: http://www.fema.gov/plan/prevent/earthquake/fema74/

Last Modified: January 2011

Mitigation Details

Figure 6.4.3.4-5 Wall-mounted pipe riser restraint/support (ER).

FEMA E-74 6: Seismic Protection of Nonstructural Components Page 6-253

Available at: http://www.fema.gov/plan/prevent/earthquake/fema74/

Last Modified: January 2011

Figure 6.4.3.4-6 Riser restraint/support at floor penetrations – variations with pipe clamp,

vibration isolation, and sliding guides (ER).

FEMA E-74 6: Seismic Protection of Nonstructural Components Page 6-254

Available at: http://www.fema.gov/plan/prevent/earthquake/fema74/

Last Modified: January 2011

Figure 6.4.3.4-7 Riser restraint/support at roof penetration – variations with U-bolt or pipe clamp

(ER).

FEMA E-74 6: Seismic Protection of Nonstructural Components Page 6-255

Available at: http://www.fema.gov/plan/prevent/earthquake/fema74/

Last Modified: January 2011

Figure 6.4.3.4-8 Roof penetration with vibration isolation (ER).

FEMA E-74 6: Seismic Protection of Nonstructural Components Page 6-256

You might also like

- Crystal+Essentials a+Beginners+Guide+to+Crystals FINALDocument7 pagesCrystal+Essentials a+Beginners+Guide+to+Crystals FINALGretchenNo ratings yet

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsFrom EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsNo ratings yet

- Financial Analysis and Decision Making PowerpointDocument28 pagesFinancial Analysis and Decision Making Powerpointashvina321No ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Design of MSE Walls at Pile Supported AbutmentsDocument15 pagesDesign of MSE Walls at Pile Supported AbutmentsLjubomir JocicNo ratings yet

- Pile ConstructionDocument177 pagesPile ConstructionWilfredo GuerreroNo ratings yet

- Production RisersDocument3 pagesProduction RisersRakeshKumarNo ratings yet

- Defender 90 110 Workshop Manual 2Document190 pagesDefender 90 110 Workshop Manual 2Jim Brint100% (1)

- Analysis and Design of RCC Retaining Wall To Overcome LandslideDocument9 pagesAnalysis and Design of RCC Retaining Wall To Overcome LandslideIJRASETPublicationsNo ratings yet

- Oliveros, Kyle Gio M. Bspe 5B PTQ Riser SystemsDocument14 pagesOliveros, Kyle Gio M. Bspe 5B PTQ Riser Systemsglenn vincent floresNo ratings yet

- Seismic Technical Guide Seismic Expansion Joints en SC2496Document15 pagesSeismic Technical Guide Seismic Expansion Joints en SC2496carrimonn11No ratings yet

- Earthquake Design and Brick WallsDocument7 pagesEarthquake Design and Brick WallsIftekhar ShadNo ratings yet

- Narrative Report On Reading InterventionDocument5 pagesNarrative Report On Reading InterventionDyelain 199x100% (1)

- Structural DampersDocument78 pagesStructural DampersJithin PayyanurNo ratings yet

- Seismic Base IsolationDocument23 pagesSeismic Base IsolationMia Hussain100% (3)

- Design Aspects For Terrorist Resistant BuildingsDocument48 pagesDesign Aspects For Terrorist Resistant Buildingssanthu256100% (2)

- Estimation of Measurement Uncertainty Printout 2016-2Document94 pagesEstimation of Measurement Uncertainty Printout 2016-2GustavoCaicutoNo ratings yet

- Chapter 8 - Building Types S1/S1A: Steel Moment Frames: 8.1 Description of The Model Building TypeDocument295 pagesChapter 8 - Building Types S1/S1A: Steel Moment Frames: 8.1 Description of The Model Building Typefasih_baqai4252No ratings yet

- Seismic RetrofittingDocument21 pagesSeismic Retrofittinglisan2053No ratings yet

- Reading A02wout AnsDocument4 pagesReading A02wout AnsTavi Nicolae67% (3)

- Seam 325 Prelim Exam ReviewerDocument6 pagesSeam 325 Prelim Exam ReviewerKyle Steven CaymeNo ratings yet

- Autonomy of Art or Dignity of The Artwork? - Agnes HellerDocument20 pagesAutonomy of Art or Dignity of The Artwork? - Agnes HellerProfrFer100% (1)

- Us-Fema-Chapter-6 3 4 1Document13 pagesUs-Fema-Chapter-6 3 4 1mustafaonuronarNo ratings yet

- 6.4.6 Ductwork: 6.4 Mechanical, Electrical, and Plumbing ComponentsDocument10 pages6.4.6 Ductwork: 6.4 Mechanical, Electrical, and Plumbing ComponentslsaishankarNo ratings yet

- Available At: HTTP://WWW - Fema.gov/earthquake-Publications/fema-E-74-Reducing-Risks-Nonstructural-Earthquake-Damage Last Modified: December 2012Document11 pagesAvailable At: HTTP://WWW - Fema.gov/earthquake-Publications/fema-E-74-Reducing-Risks-Nonstructural-Earthquake-Damage Last Modified: December 2012Chelivery CKNo ratings yet

- Ceiling Systems - Lighting Supports - FEMADocument10 pagesCeiling Systems - Lighting Supports - FEMAgunterivNo ratings yet

- FEMA E-74 Part6Document95 pagesFEMA E-74 Part6Davo Duran EugenioNo ratings yet

- 6.4 Mechanical, Electrical, and Plumbing Components: 6.4.9 Light FixturesDocument54 pages6.4 Mechanical, Electrical, and Plumbing Components: 6.4.9 Light Fixturesdyıldırım_4No ratings yet

- 241 260 PDFDocument20 pages241 260 PDFChelivery CKNo ratings yet

- FEMA E-74 Part7Document93 pagesFEMA E-74 Part7Davo Duran EugenioNo ratings yet

- FEMA E-74 Part5Document76 pagesFEMA E-74 Part5Davo Duran EugenioNo ratings yet

- Seismic Response of Nonstructural Components: Part A: Overview of Component Types and BehaviorDocument4 pagesSeismic Response of Nonstructural Components: Part A: Overview of Component Types and Behaviorrmm99rmm99No ratings yet

- Isolator Base DesignDocument9 pagesIsolator Base DesignfazzlieNo ratings yet

- Section 7Document3 pagesSection 7Mohamed AlzainNo ratings yet

- 4.4 Procedures For Lateral-Force-Resisting Systems: 4.4.1 Moment FramesDocument34 pages4.4 Procedures For Lateral-Force-Resisting Systems: 4.4.1 Moment FramesyathiNo ratings yet

- Seismic Arrester DesignDocument14 pagesSeismic Arrester DesignMahendra SuryavanshiNo ratings yet

- Structural Framing SystemDocument20 pagesStructural Framing SystemOdee EbitaNo ratings yet

- New Support Concepts For Hard Rock Mining ApplicationsDocument8 pagesNew Support Concepts For Hard Rock Mining Applicationsadi saputraNo ratings yet

- Restoration Post March 11 2011 EarthquakeDocument12 pagesRestoration Post March 11 2011 EarthquakeErnest0No ratings yet

- Expansion Joints in RoofingDocument10 pagesExpansion Joints in Roofingwaterproofing_bestNo ratings yet

- Hurricane-Proof Building - WikipediaDocument4 pagesHurricane-Proof Building - WikipedialloisjosiahNo ratings yet

- Review of Documents On Seismic Strengthening of Existing BuildingsDocument12 pagesReview of Documents On Seismic Strengthening of Existing Buildingsm7j7a7No ratings yet

- Important AssignmentDocument18 pagesImportant AssignmentrishiNo ratings yet

- Fernandez 10 ADocument14 pagesFernandez 10 AalpegambarliNo ratings yet

- 2 Pier Sections For Bridges in Seismic Regions: Draft Chapter On Sections and Connections, 29/11/2005 1Document12 pages2 Pier Sections For Bridges in Seismic Regions: Draft Chapter On Sections and Connections, 29/11/2005 1Deepak Kr Gupta100% (1)

- Ra7 2011 Res Code 508 PDFDocument5 pagesRa7 2011 Res Code 508 PDFPrisHee YhaRz SalvadorNo ratings yet

- Seismic Restraint of Isolated FloorsDocument5 pagesSeismic Restraint of Isolated FloorsÉmilie RiverinNo ratings yet

- Steelwise WindDocument2 pagesSteelwise Windalberto rosadoNo ratings yet

- Pipe Risers and Their SupportsDocument4 pagesPipe Risers and Their Supportsnaczelny_naczelnikNo ratings yet

- Electrostatic Precipitator: Type EDocument18 pagesElectrostatic Precipitator: Type ELuiz CostaNo ratings yet

- Fema 172part2Document85 pagesFema 172part2Lakeisha RamosNo ratings yet

- Seismic Performance of Ductile Connections Between Precast Beams and Roof ElementsDocument11 pagesSeismic Performance of Ductile Connections Between Precast Beams and Roof ElementsDavidNo ratings yet

- ARMA14 7055 LateralReinf MurphyDocument10 pagesARMA14 7055 LateralReinf Murphy23pr0113No ratings yet

- Seismic Isolation For Strong, Near-Field Earthquake Motions: Victor A ZAYAS and Stanley S LOWDocument6 pagesSeismic Isolation For Strong, Near-Field Earthquake Motions: Victor A ZAYAS and Stanley S LOWmuralihareNo ratings yet

- 1975 R. I. Skinner J. M. Kelly A. J. Heine 1975 - Hysteretic Dampers For Earthquake-Resistant Structures PDFDocument10 pages1975 R. I. Skinner J. M. Kelly A. J. Heine 1975 - Hysteretic Dampers For Earthquake-Resistant Structures PDFSaurabh TakNo ratings yet

- Metal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsDocument5 pagesMetal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsAlvaro MejiaNo ratings yet

- Advanced Earthquake Resistant TechniquesDocument6 pagesAdvanced Earthquake Resistant Techniques153-B RAKSHITHANo ratings yet

- Removable Fire Walls: Modular Concept DescriptionDocument6 pagesRemovable Fire Walls: Modular Concept DescriptionJose Valdez NeyraNo ratings yet

- Introduction To Structural DesignDocument4 pagesIntroduction To Structural DesignaefNo ratings yet

- Structural Materials: Information SheetDocument5 pagesStructural Materials: Information SheetFei XiongNo ratings yet

- Seismic Protection of Plumbing SystemDocument16 pagesSeismic Protection of Plumbing System185412No ratings yet

- Steel Frame Connection Technology of The New Millennium: Satisfying Heightened Performance Expectations With Simplicity and Reliability at Low CostDocument7 pagesSteel Frame Connection Technology of The New Millennium: Satisfying Heightened Performance Expectations With Simplicity and Reliability at Low CostAlfie Angelo ReyesNo ratings yet

- Jitesh ProjectDocument55 pagesJitesh ProjectajayNo ratings yet

- Pipe Riser Support Systems: Mason Industries, IncDocument4 pagesPipe Riser Support Systems: Mason Industries, IncThanhNo ratings yet

- BT5 Prelim ReviewerDocument5 pagesBT5 Prelim ReviewerrealcemackenzieNo ratings yet

- Unit 5 - Construction Technology - WWW - Rgpvnotes.inDocument6 pagesUnit 5 - Construction Technology - WWW - Rgpvnotes.inRitesh Agarwal OYOwalaNo ratings yet

- Mechanics of Rubber Bearings for Seismic and Vibration IsolationFrom EverandMechanics of Rubber Bearings for Seismic and Vibration IsolationNo ratings yet

- Ul Approved Breakaway Duct Connections: Installation Instructions SupplementDocument2 pagesUl Approved Breakaway Duct Connections: Installation Instructions Supplementthilina lakhithaNo ratings yet

- Galvanized Standard Steel PipeDocument1 pageGalvanized Standard Steel Pipethilina lakhithaNo ratings yet

- Valves and Fittings Losses in Equivalent Feet of Pipe: Y-StrainerDocument3 pagesValves and Fittings Losses in Equivalent Feet of Pipe: Y-Strainerthilina lakhithaNo ratings yet

- Code No. 46 & 64 PDFDocument1 pageCode No. 46 & 64 PDFthilina lakhithaNo ratings yet

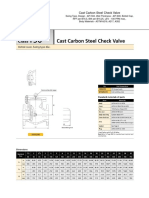

- Carbon Steel Ball Valve: Code # 50 (Aksctk)Document1 pageCarbon Steel Ball Valve: Code # 50 (Aksctk)thilina lakhithaNo ratings yet

- Gate Class 125 Cast Iron: CODE # 75 (125FCWI)Document1 pageGate Class 125 Cast Iron: CODE # 75 (125FCWI)thilina lakhithaNo ratings yet

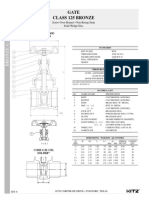

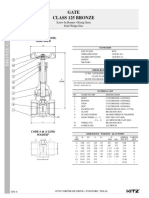

- Gate Class 150 Bronze: CODE # 25 (AK150L) ThreadedDocument1 pageGate Class 150 Bronze: CODE # 25 (AK150L) Threadedthilina lakhithaNo ratings yet

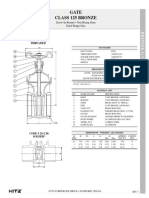

- Gate Class 125 Bronze: CODE # 27 (AKH) ThreadedDocument1 pageGate Class 125 Bronze: CODE # 27 (AKH) Threadedthilina lakhithaNo ratings yet

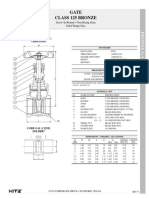

- Gate Class 125 Bronze: CODE # 40 (AK125E) ThreadedDocument1 pageGate Class 125 Bronze: CODE # 40 (AK125E) Threadedthilina lakhithaNo ratings yet

- Gate Class 300 Bronze: CODE # 37 (AK300LU) ThreadedDocument1 pageGate Class 300 Bronze: CODE # 37 (AK300LU) Threadedthilina lakhithaNo ratings yet

- Gate Class 125 Bronze: CODE # 27 (AKH) ThreadedDocument1 pageGate Class 125 Bronze: CODE # 27 (AKH) Threadedthilina lakhithaNo ratings yet

- Code No. 24 44 PDFDocument1 pageCode No. 24 44 PDFthilina lakhithaNo ratings yet

- Code No. 24 44 PDFDocument1 pageCode No. 24 44 PDFthilina lakhithaNo ratings yet

- 150 PDFDocument1 page150 PDFthilina lakhithaNo ratings yet

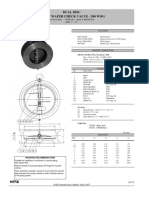

- Dual Disc Silent Wafer Check Valve - 200 Wog: Code No. 7032Document1 pageDual Disc Silent Wafer Check Valve - 200 Wog: Code No. 7032thilina lakhithaNo ratings yet

- No Limitation Min. 18": Pex-A Pipe Support Installations in ASTM E84 ApplicationsDocument1 pageNo Limitation Min. 18": Pex-A Pipe Support Installations in ASTM E84 Applicationsthilina lakhithaNo ratings yet

- Butterfly Valves - 250 Psi: SIZE 2" - 8"Document2 pagesButterfly Valves - 250 Psi: SIZE 2" - 8"thilina lakhithaNo ratings yet

- 13-2-2020revised Screw chiller-1502KWDocument4 pages13-2-2020revised Screw chiller-1502KWthilina lakhithaNo ratings yet

- Class 125 Bronze: Butterfly Valves - 200 PsiDocument1 pageClass 125 Bronze: Butterfly Valves - 200 Psithilina lakhithaNo ratings yet

- I. Contractor Agreed To Submit A Revised Work Programme by 03Document6 pagesI. Contractor Agreed To Submit A Revised Work Programme by 03thilina lakhithaNo ratings yet

- Gate Class 125 Cast Iron: CODE # 73 (125FCLS)Document1 pageGate Class 125 Cast Iron: CODE # 73 (125FCLS)thilina lakhithaNo ratings yet

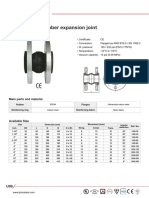

- Single Sphere Rubber Expansion Joint: Main Parts and MaterialDocument1 pageSingle Sphere Rubber Expansion Joint: Main Parts and Materialthilina lakhithaNo ratings yet

- Strainer Class 125 Iron: Y-Pattern - Bolted Cover - Blow-Out-Plug Stainless Steel (304) ScreenDocument1 pageStrainer Class 125 Iron: Y-Pattern - Bolted Cover - Blow-Out-Plug Stainless Steel (304) Screenthilina lakhithaNo ratings yet

- Q669034A - Selection SheetDocument3 pagesQ669034A - Selection Sheetthilina lakhithaNo ratings yet

- Safety Data Sheet According To EEC-Regulation 91/155/EECDocument6 pagesSafety Data Sheet According To EEC-Regulation 91/155/EECANIBALLOPEZVEGANo ratings yet

- 3.1 Mitosis Ans PDFDocument7 pages3.1 Mitosis Ans PDFtess_15No ratings yet

- 1.buying, Having, BeingDocument31 pages1.buying, Having, BeingAmmar AliNo ratings yet

- Kurukh GrammarDocument184 pagesKurukh GrammarBHABANI SHANKAR MINZNo ratings yet

- FS2122-INCOMETAX-01A: BSA 1202 Atty. F. R. SorianoDocument7 pagesFS2122-INCOMETAX-01A: BSA 1202 Atty. F. R. SorianoKatring O.No ratings yet

- Finite Element Analysis of Suction Penetration Seepage Field of Bucket Foundation Platform With Application To Offshore Oilfield DevelopmentDocument9 pagesFinite Element Analysis of Suction Penetration Seepage Field of Bucket Foundation Platform With Application To Offshore Oilfield DevelopmentRayodcNo ratings yet

- Help Utf8Document8 pagesHelp Utf8Jorge Diaz LastraNo ratings yet

- A2 Pe Coursework RugbyDocument6 pagesA2 Pe Coursework Rugbyf67m6abx100% (2)

- Astm A 101Document3 pagesAstm A 101RECEP ÇETİNKAYANo ratings yet

- TErmination Letter-ContractorDocument1 pageTErmination Letter-ContractorBojoNo ratings yet

- vct49xyi-SPEC 2003.12.121Document374 pagesvct49xyi-SPEC 2003.12.121Micu Adrian DanutNo ratings yet

- Javascript: Case Study To Be Used For Hands-On SessionsDocument14 pagesJavascript: Case Study To Be Used For Hands-On SessionsSettiNagarajuNo ratings yet

- Smart School EseiDocument15 pagesSmart School Eseiz89100% (1)

- IT1251 Information Coding TechniquesDocument23 pagesIT1251 Information Coding TechniquesstudentscornersNo ratings yet

- Mid Term Asssignment - The Five Senses - PrimaryDocument5 pagesMid Term Asssignment - The Five Senses - PrimaryPrajna MoodabidriNo ratings yet

- DWDM Equipment-Alcatel 1620Document28 pagesDWDM Equipment-Alcatel 1620Cvenoth Kumar100% (2)

- Chapter OneDocument36 pagesChapter OneJeremiah Alhassan100% (1)

- 100 Patient NamesDocument1 page100 Patient NamesTed anadiloNo ratings yet

- Kafka and NiFIDocument8 pagesKafka and NiFIabhimanyu thakurNo ratings yet

- Effect of Pitting Corrosion On The Mechanical Properties of 316 Grade Stainless SteelDocument6 pagesEffect of Pitting Corrosion On The Mechanical Properties of 316 Grade Stainless SteelAnilNo ratings yet

- Carob (Ceratonia Siliqua) : Synonyms / Common Names / Related TermsDocument7 pagesCarob (Ceratonia Siliqua) : Synonyms / Common Names / Related TermsMonica BotaNo ratings yet

- Using Snap Test Kits Poster enDocument1 pageUsing Snap Test Kits Poster enMoisés RodríguezNo ratings yet