Professional Documents

Culture Documents

Track PDF

Uploaded by

Vijay HatkarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Track PDF

Uploaded by

Vijay HatkarCopyright:

Available Formats

700CK series

Track drive gearmotors

Integrated design will result into the best possible axial piston hydraulic motors, developed in

product combination. cooperation with KAYABA.

Extreme compactness, lightweight, efficiency and Available for machines in the 1.5 to 100 Ton class

smooth operation are the key features of the range.

700CK series track drives, powered by integrated

Type Torque [Nm]

700 C2 K 1200

700-2C2 K 1900

701 C2 K 2500

702 C2 K 3500

704 C2 K 5000

705 C2 K 9000

706 C3 K 18000

707 C3 K 26000

709 C3 K 30000

710 C3 K 36000

713 C2 K 45000

713 C3 K 60000

715 C3 K 85000

716 C3 K 100000

718 C3 K 180000

720 C3 K 220000

700CK series

Torque Range Hydraulic motors

1200 ... 220000 Nm KAYABA hydraulic motors, fixed and dual displacement, complete

with counterbalance valve.

Machine weight

1.5 up 100 Ton Motor options

Pressure relief valves, shockless type

Gear Ratios Anticavitation valve

20 ... 120

Brake

Key Features Hydraulically released failsafe parking brake automatically operated

Rotating output flange with large PCD suitable for sprocket; by main pressure

Rugged design; High torque capacity; High load capacity; Mechanical

lifetime seals; Compact design

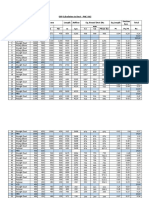

Type Motor Max. Max. 2 speed control Parking brake Range Weight Approx. weight

displacement pressure flow min. pressure torque of ratios of machine

max/min bar l/min bar Nm 1: Kg ton

700 C2 K 12-5.5 210 20 6 25 32-41 20 1.6

700-2C2 K 18-9 210 30 6 25 30-42 25 2

701 C2 K 18-11.6 250 35 6 25 30-53 25 3

702 C2 K 26.3-13.4 250 45 6 40 37-53 35 4

704 C2 K 33.8-19 250 60 6 40 45-53 60 5.5

705 C2 K 50.9-25.4 320 92 6 50 24-53 70 7

706 C3 K 50-25 300 75 6 50 68-128 80 8-10

707 C3 K 87-50 300 120 10 240 46-109 140 10-12

709 C3 K 87-50 300 160 10 400 53-123 225 13-20

710 C3 K 170-96 300 240 10 400 49-69 230 20-25

713 C2 K 170-96 300 230 10 400 55 280 25-29

713 C3 K 230-120 345 310 10 400 60-75 300 29-37

715 C3 K 230-340 345 370 10 400 62-82 380 37-50

716 C3 K 340 345 420 10 2000 75 500 50-60

718 C3 K 340 345 500 10 2000 85-106 850 60-80

720 C3 K 340 345 500 10 2000 120 1000 up to 120

D7 D8 L4

A A

R/G Ps

B

D4

D5

D6

D1

D2

D3

T

B

T

L2 L3

Ps

L1

Type D1 D2 D3 D4 D5 D6 D7 D8 L1 L2 L3 L4 A-B T Ps

700 C2 K 175 155 140 140 155 175 M10x1.5 n°8 M10x1.5 n°8 202 45 93 40 1/4" 1/4" 1/4"

700-2C2 K 190 170 150 160 180 200 M10x1.5 n°8 M10x1.5 n°8 223 40 108 39 3/8" 1/4" 1/4"

701 C2 K 215 192 165 190 215 240 M12x1.75 n°9 M12x1.75 n°9 300 50 125 45 1/2" 1/4" 1/4"

702 C2 K 215 192 165 204 232 255 M12x1.75 n°9 M12x1.75 n°9 285 70 115 45 1/2" 1/4" 1/4"

704 C2 K 264 240 200 230 262 286 M14x2 n°9 M14x2 n°9 345 68 167 46 1/2" 3/8" 1/4"

705 C2 K 268 244 210 230 260 286 M14x2 n°12 M14x2 n°12 340 75 144 50 1/2" 3/8" 1/4"

706 C3 K 308 280 246 280 330 370 M16x2 n°20 M16x2 n°12 412 100 193 50 1/2" 3/8" 1/4"

707 C3 K 350 320 280 300 340 370 M16x2 n°16 M16x2 n°20 440 91 210 84 3/4" 1/2" 1/4"

709 C3 K 350 320 280 300 340 370 M16x2 n°16 M16x2 n°20 470 91 240 84 3/4" 1/2" 1/4"

710 C3 K 375 340 300 330 370 400 M16x2 n°30 M16x2 n°30 455 99.5 243 84 3/4" 1/2" 1/4"

713 C2 K 375 340 300 350 400 435 M16x2 n°30 M20x2.5 n°16 500 91 253 84 3/4" 1/2" 1/4"

713 C3 K 480 440 380 410 455 490 M24x3 n°18 M20x2.5 n°24 570 100 278 90 1" 1/2" 1/4"

715 C3 K 500 460 420 460 510 550 M20x2.5 n°24 M20x2.5 n°24 605 130 315 90 1" 1/2" 1/4"

716 C3 K 500 460 420 460 500 548 M24x3 n°24 M18x1.5 n°36 663 165 308 118 1" 3/4" 1/4"

718 C3 K 570 510 450 576 626 670 M24x3 n°30 M24x3 n°30 730 170 350 118 1" 3/4" 1/4"

720 C3 K 650 600 480 610 680 735 M30x3.5 n°30 M24x3.5 n°24 800 170 370 118 1" 3/4" 1/4"

Bonfiglioli Riduttori S.p.A. tel: +39 051 647 3111 TR_DAT_700CK_STD_ENG_R00_0

Via Giovanni XXIII, 7/A fax: +39 051 647 3126

40012 Lippo di Calderara di Reno bonfiglioli@bonfiglioli.com

Bologna (Italy) www.bonfiglioli.com

You might also like

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Bell B20D Super Truck AdtDocument559 pagesBell B20D Super Truck AdthendriNo ratings yet

- RANGE ROVER SPORT Electrical ReferenceDocument1,157 pagesRANGE ROVER SPORT Electrical ReferenceGeorge Sibiya100% (1)

- Warrior 2100 Operations Manual Revision 3.0 (English)Document394 pagesWarrior 2100 Operations Manual Revision 3.0 (English)Daniel Bianchini100% (1)

- HAVAL H6 Service Manual PreviewDocument2,913 pagesHAVAL H6 Service Manual PreviewEmg Sai100% (2)

- Fordf 2502005 1Document2 pagesFordf 2502005 1horacio sanchezNo ratings yet

- Grader presentation-OPT-latestDocument34 pagesGrader presentation-OPT-latestJack SonNo ratings yet

- ZF 2000 Series: Product DetailsDocument4 pagesZF 2000 Series: Product DetailsJhonAlexRiveroNo ratings yet

- Progressing Cavity Pump (PCP) - Huaming EnergyDocument3 pagesProgressing Cavity Pump (PCP) - Huaming EnergyKevin XuNo ratings yet

- ZF 665 Series: Product DetailsDocument4 pagesZF 665 Series: Product DetailsJhonAlexRiveroNo ratings yet

- 3000/4000 Hydraulics ChartDocument32 pages3000/4000 Hydraulics Chartabdelhadi houssinNo ratings yet

- Line and Base: Pw1100G-JMDocument16 pagesLine and Base: Pw1100G-JMGenaro Rodriguez100% (1)

- NPD1 Training - PTPL - Smart Modular Gearbox - Apr 2020 PDFDocument20 pagesNPD1 Training - PTPL - Smart Modular Gearbox - Apr 2020 PDFShyam J Vyas0% (1)

- User Manual of S-Type Ram BOPDocument26 pagesUser Manual of S-Type Ram BOPhebert perezNo ratings yet

- Serp3816-35 Vol I CdmasterDocument708 pagesSerp3816-35 Vol I CdmasterJuan Felipe Garza GNo ratings yet

- AC Switches DC Switches: Click To ViewDocument32 pagesAC Switches DC Switches: Click To ViewY.a. OoiNo ratings yet

- CalculationReport PDFDocument10 pagesCalculationReport PDFFikret DavudovNo ratings yet

- P360 CB8x4MHZ Specifications Four Axle Tipper Truck DimensionsDocument4 pagesP360 CB8x4MHZ Specifications Four Axle Tipper Truck DimensionsSteven Frye100% (1)

- 7 Series PDFDocument2 pages7 Series PDFVijay HatkarNo ratings yet

- Sany Crane-Brochure STC900T5-212030Document45 pagesSany Crane-Brochure STC900T5-212030Victor CastroNo ratings yet

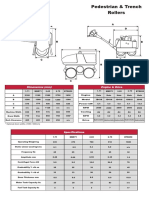

- Pedestrian & Trench Rollers: Engine & Drive Dimensions (MM)Document4 pagesPedestrian & Trench Rollers: Engine & Drive Dimensions (MM)MuhaiminNo ratings yet

- 700CK series track drive gearmotorsDocument2 pages700CK series track drive gearmotorsvijayNo ratings yet

- 700CK PDFDocument2 pages700CK PDFVijay HatkarNo ratings yet

- Ходовые редукторы Bonfiglioli серии 700C (гусеничные)Document10 pagesХодовые редукторы Bonfiglioli серии 700C (гусеничные)MortariosNo ratings yet

- DOCUMENTTITLE Technical specificationsDocument1 pageDOCUMENTTITLE Technical specificationsABELARDO PINANo ratings yet

- Travel Drives - Bonfiglioli Seriws 700CDocument1 pageTravel Drives - Bonfiglioli Seriws 700CČika DekiNo ratings yet

- SKF Quiet Running Deep Groove Ball BearingsDocument4 pagesSKF Quiet Running Deep Groove Ball BearingsvietkhamNo ratings yet

- Поворотные редукторы Bonfiglioli серий 700T, 700TK - англDocument4 pagesПоворотные редукторы Bonfiglioli серий 700T, 700TK - англOlivier SangwaNo ratings yet

- 6B5.9-C (CPR252)Document2 pages6B5.9-C (CPR252)Dennis K ThomasNo ratings yet

- HNK - H BorerDocument26 pagesHNK - H Boreragri.mariadasNo ratings yet

- Urdc SicherungenDocument82 pagesUrdc SicherungenTang Soo YeowNo ratings yet

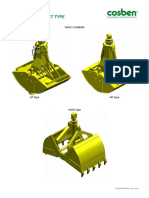

- Clamshell Bucket Type: Twice CylindersDocument3 pagesClamshell Bucket Type: Twice CylindersTran Trong PhuNo ratings yet

- Daily Maint November Site LGG 2023Document701 pagesDaily Maint November Site LGG 2023Arry Eko pristiwantoNo ratings yet

- Impact CrusherDocument2 pagesImpact CrusherAhmed El-sheshtawyNo ratings yet

- ZF 360 Series: Product DetailsDocument4 pagesZF 360 Series: Product DetailsjhprimamudaNo ratings yet

- Bonfiglioli WinchDocument1 pageBonfiglioli WinchJames EddiebondNo ratings yet

- Cofialt 3 5 7 15 KV 200cDocument2 pagesCofialt 3 5 7 15 KV 200cVictor CarvalhoNo ratings yet

- BOYANG BOYARD R134A DC Rotary Compressor CatalogueDocument2 pagesBOYANG BOYARD R134A DC Rotary Compressor CatalogueChaminda KumaraNo ratings yet

- Hydraulic Attachment Tools: Demolition, Waste Management and Earth-MovingDocument48 pagesHydraulic Attachment Tools: Demolition, Waste Management and Earth-MovingmiquelNo ratings yet

- Wuxy Trummy CatalogDocument4 pagesWuxy Trummy CatalogMartin RomeroNo ratings yet

- Rendering Rotary Cooker Ver. 1.3Document2 pagesRendering Rotary Cooker Ver. 1.3TG-MachinesNo ratings yet

- Enclosed Switch CatalogueDocument28 pagesEnclosed Switch CatalogueSteveMateNo ratings yet

- Mordaza Epiroc Cc1700 UDocument2 pagesMordaza Epiroc Cc1700 URodolfo Cuadra CanalesNo ratings yet

- Lesson 2Document13 pagesLesson 2mostafa smtNo ratings yet

- Performance Curve Notes: Viking Universal Seal PumpsDocument2 pagesPerformance Curve Notes: Viking Universal Seal PumpsErick GoyesNo ratings yet

- DS-ZF_400_A gear box for volvo penta d13Document4 pagesDS-ZF_400_A gear box for volvo penta d131380485No ratings yet

- End Truck DataDocument1 pageEnd Truck DataErc Nunez VNo ratings yet

- Brushless Aircraft Motor Cross Reference ChartDocument2 pagesBrushless Aircraft Motor Cross Reference ChartOlavo PastoreNo ratings yet

- Quifer Ductile Iron Technical CatalogueDocument5 pagesQuifer Ductile Iron Technical CatalogueSergei KurpishNo ratings yet

- Series 800: Hydraulic Cable Winches - Standard FeaturesDocument6 pagesSeries 800: Hydraulic Cable Winches - Standard Featurespaolita_mahecha1265No ratings yet

- Summary Machine Program Inspection Report: Model Unit C/N Engine GR256 Model S/NDocument8 pagesSummary Machine Program Inspection Report: Model Unit C/N Engine GR256 Model S/NJoko WahonoNo ratings yet

- Vet Load SchedDocument3 pagesVet Load SchedkyananthonyNo ratings yet

- Premier Series Piston Pumps Technical SpecificationsDocument40 pagesPremier Series Piston Pumps Technical SpecificationsDamNo ratings yet

- Wire Rope HoistDocument2 pagesWire Rope HoistNikhil BhattNo ratings yet

- Industrial Batteries: System Solutions For RailwaysDocument8 pagesIndustrial Batteries: System Solutions For RailwaysDavid MonederoNo ratings yet

- Single Phase Jet Monoblocs Performance Chart: Texmo IndustriesDocument7 pagesSingle Phase Jet Monoblocs Performance Chart: Texmo IndustriesSDE TXNNo ratings yet

- Brosur ITU - Split Modular R410A Aug-2016Document6 pagesBrosur ITU - Split Modular R410A Aug-2016Yudhi YudadmokoNo ratings yet

- Sl-A 7 8 9 10 12 EngDocument2 pagesSl-A 7 8 9 10 12 Engska-techNo ratings yet

- LatihanafrgtthtDocument8 pagesLatihanafrgtthtAndi ayuNo ratings yet

- AMHma ManualDocument2 pagesAMHma ManualSheikh ShoaibNo ratings yet

- Centrifugal Monoset Pumps GuideDocument4 pagesCentrifugal Monoset Pumps GuidemallinathaNo ratings yet

- Application Deep Well Turbine Pumps: Product Introduction 2361.1x/01-10G3Document4 pagesApplication Deep Well Turbine Pumps: Product Introduction 2361.1x/01-10G3FawadNo ratings yet

- Industrial Batteries - Network Power Sonnenschein Solar Safe Storage Capacity For Renewable Energy. SpecificationsDocument4 pagesIndustrial Batteries - Network Power Sonnenschein Solar Safe Storage Capacity For Renewable Energy. Specificationssebax123No ratings yet

- Weight Bridge Exit RampDocument12 pagesWeight Bridge Exit RampSasanka SekharNo ratings yet

- Bomba Gould Sumergible para Aguas NegrasDocument4 pagesBomba Gould Sumergible para Aguas NegrasNick OchoaNo ratings yet

- Esp CalculationDocument3 pagesEsp CalculationDpnsHomeNo ratings yet

- ZF 665a Data SheetDocument4 pagesZF 665a Data Sheetluisdavid01No ratings yet

- Screenshot 2022-10-24 at 12.57.56 PMDocument12 pagesScreenshot 2022-10-24 at 12.57.56 PMARSALANNo ratings yet

- Crane Duty Motors ChartDocument9 pagesCrane Duty Motors ChartAnil KumarNo ratings yet

- Full Line Brochure 7-2021Document32 pagesFull Line Brochure 7-2021PrudzNo ratings yet

- Large Diameter Excavations For Personal Engineering Geologic InspectionDocument9 pagesLarge Diameter Excavations For Personal Engineering Geologic InspectionVijay HatkarNo ratings yet

- Exploring soil conditions and geology with portable drilling rigs and excavated trenchesDocument11 pagesExploring soil conditions and geology with portable drilling rigs and excavated trenchesVijay HatkarNo ratings yet

- Rigs 12Document11 pagesRigs 12Vijay HatkarNo ratings yet

- Drilling Challenges in Sticky Clayey SiltDocument11 pagesDrilling Challenges in Sticky Clayey SiltVijay HatkarNo ratings yet

- Examples of Various Kinds ofDocument11 pagesExamples of Various Kinds ofVijay HatkarNo ratings yet

- Js200 Travel Gearbox New TypeDocument3 pagesJs200 Travel Gearbox New TypeManuel felipe PalmaNo ratings yet

- Powerline SeriesDocument3 pagesPowerline SeriesELWAN NAOVAL HAPID ALFANA -No ratings yet

- Pressure Die Casting - Al - NewDocument17 pagesPressure Die Casting - Al - Newhardeep SinghNo ratings yet

- PCM Operation Basic TrainingDocument33 pagesPCM Operation Basic TrainingYamenNo ratings yet

- Rovan Sports Price List Under 40 CharactersDocument2 pagesRovan Sports Price List Under 40 Charactersmohamed sidkyNo ratings yet

- VALEO - Silencio 2010 PDFDocument58 pagesVALEO - Silencio 2010 PDFgeorge_scala100% (1)

- Audi Option CodesDocument255 pagesAudi Option CodesOMARNo ratings yet

- SGCO 2000: Parts Manual Parts Manual Parts ManualDocument109 pagesSGCO 2000: Parts Manual Parts Manual Parts ManualYonathan W. Castillo RuizNo ratings yet

- Inlet Manifold Optimisation For Gdi Engine Using VortexDocument11 pagesInlet Manifold Optimisation For Gdi Engine Using Vortexnaveeen chackoNo ratings yet

- Briggs and Stratton 500EDocument116 pagesBriggs and Stratton 500EFunnypoumNo ratings yet

- Storz ManualDocument7 pagesStorz Manualhijodebudas100% (1)

- D 631 Compact en LowresDocument4 pagesD 631 Compact en LowresMarly Salas GonzalezNo ratings yet

- Robot Actuator TypesDocument3 pagesRobot Actuator TypesDivanker SaxenaNo ratings yet

- Text 2Document2 pagesText 2MeghaNo ratings yet

- Slush Machine Exploded DiagramDocument4 pagesSlush Machine Exploded DiagramLINANo ratings yet

- A182 F53Document32 pagesA182 F53Leandro SilvaNo ratings yet

- Assembly Instructions For 1999-2004 WJ Jeep Front Bumper Non-Winch KitDocument6 pagesAssembly Instructions For 1999-2004 WJ Jeep Front Bumper Non-Winch Kitslawek benekNo ratings yet

- GENII - Toyota Hilux - D4D Turbo Diesel 4 Speed - Lock Up Instructions New LoomDocument14 pagesGENII - Toyota Hilux - D4D Turbo Diesel 4 Speed - Lock Up Instructions New LoomAaron BantonNo ratings yet

- Vasant Square Hub Charger Details - Ph-3Document3 pagesVasant Square Hub Charger Details - Ph-3Prince RanaNo ratings yet