Professional Documents

Culture Documents

Ijett V22P237 PDF

Uploaded by

avnishchauhan8_46499Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijett V22P237 PDF

Uploaded by

avnishchauhan8_46499Copyright:

Available Formats

International Journal of Engineering Trends and Technology (IJETT) – Volume22 Number 4- April2015

Effects of Improved Gating System by Using

Standard Gating Ratio

Shashank V. Gulhane#1, A. D. Shirbhate*2

#1

Asst. Professor, Department of Mechanical Engineering

GWCET, Nagpur, India

#2

Professor, Department of Mechanical Engineering

PRMIT&R, Badnera, Amravati, India

ABSTRACT: One of the key elements to make a metal casting of The gating system is made up of the following parts: - a)

high quality is the design of a good gating system. The gating Pouring basin b) Sprue c) Runner bar d) In gates e) Riser

system refers to those channels through which the metal flows

from the ladle to the mold cavity. The use of a good gating system

is even more important if a casting is produced by a gravity

process. If poor gating techniques are used, invariably, lower

casting quality is achieved, because of damage on the molten

metal received during the flow through the gating system. It could

be even worse, if the molten material is a sensitive metal for

receiving damage during the filling, because of dross and slag

formation. The purpose of this study is to identify the problem

associated with gating system for the manufacturing of ginning

dead weight which is used for their machineries at Jadhao Steel

Fig. 1. Gating system 3D

Alloys, Amravati . The typical casting defects were identified at

M/s Jadhao Steel Alloys, Amravati in which the shrinkage defect

,blow holes, pin holes, gas holes, sand inclusion and misrun The design of gating system is important and the main

defects etc. are prominent. The total percentage of defect is requisites of gating system are: The gating should be so

around 25-30 % of the total casting produced. It means total % of designed that it avoids the mould or core erosion by reducing

rejection is around 25-30% which is very high and not acceptable. metal velocity within the cavity and avoiding direct

After careful investigation of the casting process, it was found impingement on mould walls or cores. The flow of metal to the

that all the above defects can be considerably reduced by using a mould cavity should occur with as minimum as possible

proper gating system. Hence optimization of gating system is turbulence, because if turbulence is excessive, the aspiration of

considered as a main topic of investigation. According to deep

mould gases will occur which will oxidize the mould metal.

study and analysis of existing gating system used by industry, it

was found that old gating ratio was incorrect and after gating

system calculations it was found that the total of weight of gating The flow of molten metal must be laminar so as to

system is very high that has to reduce considerably. After careful reduce the casting defects like shrinkage, porosity, blow holes,

observation and analysis of existing gating system used by gas holes, misrun, sand inclusion etc.

industry, it was decided to make necessary changes in the design

and dimension of gating system. By using proposed gating system IMPORTANCE OF GATING SYSTEM

the experiment has been carried out at Jadhao Steel Alloys,

Amravati. The result found after experimentation are very sound

and productive. By using standard gating ratio as per ISO, it was The design of gating system is as important as rise

found that the total percentage of productivity improved from ring of a steel casting. It is well known that improper gating

42% to 74% by reducing total weight of gating system from 4.68 practice can result in defects like , ceroxide, inclusions, cold

kg to 2.39 kg with reducing total percentage of rejection from shuts, misruns, hot tears, local shrinkages, and gas cavities in a

25% - 30% to 7.5% - 10%, With % of yield increases from 86% steel casting. A gating system should be pre-designed and

to 92%, with keeping flow laminar through all sections of gating incorporated in method drawing as is the case of rise ring and

system which is most essential to reduce casting defects. not left to the discretion of the molder.

CONSTITUENTS OF GATING SYSTEM

Keywords – Gating Ratio, Gating System, Jadhav Steel Alloys,

A gating system for steel castings can be broadly

Casting Defects, Productivity.

divided into: - The entry section – consisting of the pouring

basin, sprue and sprue base. The distribution section

INTRODUCTION consists of the runners and in gates.

GATING SYSTEM FUNCTIONS OF A GATING SYSTEM

The term gating system includes all the passage ways

through which molten metal enters in to the mould cavity. The entry section of a gating has two functions:-

ISSN: 2231-5381 http://www.ijettjournal.org Page 176

International Journal of Engineering Trends and Technology (IJETT) – Volume22 Number 4- April2015

a) To supply liquid metal free of entrapped gases, slag and study and analysis of existing Gating System used by

eroded sand. industry.

b) To establish a hydraulic pressure head, this will force the

metal through the rest of the gating system and into the STUDY AND ANALYSIS OF EXISTING GATING

casting. SYSTEM

The distribution section has three functions:-

The study and analysis of existing Gating System

and Proposed Gating System for the manufacturing of

a) To decrease the velocity of the metal stream, to Ginning Dead Weight at Jadhao Steel Alloys Amravati. The

minimize turbulence, both in the gating system as well as in main objective of this study is to follow standard casting

the mold cavity. procedure in relation with standard gating system as per

b) To avoid mold and core erosion, to establish the best researcher’s research in the field of casting technology. As per

possible thermal gradient in the casting. the discussions with Mr. G. M. (PROD.) at Jadhao Steel

c) To regulate the rate of flow of metal into the mold cavity. Alloys Amravati regarding with casting defects and

percentage of rejection for the manufacturing of ginning dead

In addition to these, the gating system should be of weight, it was observed that all the above defects can be

such simple design as to facilitate molding, particularly considerably reduced by using a proper gating system. Hence

with mechanical methods, at the same time involving optimization of gating system is considered as a main topic of

minimum fettling cost and affording maximum casting investigation.

yield. Many of these requirements and functions are

conflicting with each other. Effort should be to harmonize GINNING DEAD WEIGHT

these so as to create conditions conducive to the production

of a defect free casting.

Ginning dead weight used as a dead weight for

ginning machine which is agro based machine. To provide

PROBLEM IDENTIFICATION extra load on machine during vibration of ginning machine in

During our industrial visit at M/s Jadhao Steel order to remove cotton seeds from cotton fiber

Alloys, Amravati it was found that so many types of steel

casting jobs are produced. The typical casting defects

observed like Shrinkage, Blow Holes, Pin Holes, Gas

Holes, Sand Inclusion, Misrun etc. are prominent. It was

found that industry was facing the problem of rejection

particularly for ginning weight steel casting used as dead

weight for their machineries.

Following table shows the inspection report for Fig. 2. Ginning Weight

ginning weight at quality desk. DIMESIONAL DRAWING OF GINING WEIGHT

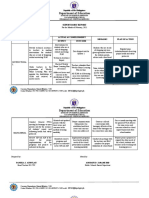

TABLE I: Inspection report for GW. By using existing gating system

Blow

Job shrink holes Sand % of

Misrun Total

Qty age & gas inclusion rejection

holes

20 3 2 1 6 30%

20 1 1 1 2 5 25%

20 1 1 1 1 4 20%

20 2 2 1 - 5 25%

20 2 1 - 2 5 25%

20 1 3 1 - 5 25%

Average percentage of rejection is around 25% to 30%

After observation of inspection report and discussion

had with GM production Jadhao Steel Alloys, Amravati

regarding with the percentage of rejection and various casting

defects observed for the manufacturing of Ginning weight

Fig. 3. Dimensional Drawing of Ginning Weight

which is use as a dead weight for ginning machine it was

decided to follow actual procedure of casting manufacturing

in relation with the gating system used. In order to reduce

percentage of rejection and casting defects. It was decided to

ISSN: 2231-5381 http://www.ijettjournal.org Page 177

International Journal of Engineering Trends and Technology (IJETT) – Volume22 Number 4- April2015

DESIGN & DIMENSION OF EXISTING GATING Gating ratio becomes 1:1.87:2.13

SYSTEM

But as per standard gating ratio suggested by many

As per the discussion had with G. M. (PROD.) at researchers (i.e. 1:2:1, 1:2:0.5, 1:4:1, 2:7:1) for grey cast iron.

Jadhao Steel Alloys Amravati regarding with casting defects Hence obtained gating ratio is not matched with standard

and percentage of rejection for the manufacturing of ginning gating ratio as per researchers in foundry technology.

dead weight, it was observed that all the above defects can be

considerably reduced by using a proper gating system. Hence PROPOSED GATING SYSTEM

optimization of gating system is considered as a main topic of

investigation. In order to reduce casting defects it was According to deep study and analysis of existing

decided to follow deep study and analysis of existing gating gating system it was found that industry has used improper

system. gating system. The result found after calculation and analysis

of existing gating system are very typical in which, gating

ratio 1:1.87:2.13 which is not matched with standard gating

ratio as per researcher’s research in foundry technology. The

further result after calculation of existing gating system are,

the weight of gating system is around 4.7 Kg. which is very

high it has to reduce considerably. Along with this

calculation it was found that the flow pattern for existing

gating system is laminar. On the basis of above results found

for existing gating system it was decided to made necessary

changes in the dimensions of runner and in gates with riser in

order to maintain standard gating ratio as per researchers

research in foundry technology. Necessary changes in the

dimensions of runner and in gates with riser proposed in

Fig. 4. Design and Dimension of Existing Gating System order to maintain standard gating ratio as per researchers in

- foundry technology and to reduce total weight of gating

Total volume of gating = 6.51 × 10 4 m3 system in order to improve total productivity.

Total weight of gating = Total volume of gating × density

4 3

= 6.51×10 ×7.2×10

= 4.68 kg

TABLE III: Gating area with Dimension for existing & proposed gating

system

GATING RATIO AND ITS CALCULATIONS FOR

EXISTING GATING SYSTEM Existing Existing Proposed

Proposed

gating gating gating

Section gating in

The typical gating system made by industry found volume in weight in weight in

typical casting defects which has increased percentage of (m3)

(m3) (kg) (kg)

rejection and which has affected productivity. In order to

-5 -3 -5 -3

reduce percentage of rejection it was decided to follow Sprue 4.19 X10 301.68X10 4.19 X10 301.68X10

standard gating ratio as per ISO in foundry technology. -

-5

483.264 7.2956X10

Runner 6.712 X10 -3 0.5252

Gating ratio: - The rate of flow of molten metal X10

5

through the sprue is a function of the cross sectional areas of -6 -3 -6 -3

the sprue, runners and in gates. Gating ratios recommended In gates 72 X10 518.4X10 14.4X10 103.68X10

by various theoreticians in the literature vary over a wide -4 -4

Riser 5 X10 3.6 2.034 X10 1.4646

range. The Dimensional characteristics of any gating system

can be generally expressed in terms of gating ratio.

TABLE II: Gating area with Dimension for existing gating system. TOTAL 4.68 kg 2.398 kg

Existing Gating

Existing Gating

System

Sr. No. Part Area2

Dimensions (mm )

(mm) GATING RATIO AND CALCULATION FOR PROPOSED

GATING SYSTEM

D1= 20

1 Sprue 491

D2= 25

According to changes in the dimensions of existing

L= 60, H= 65,

2 Runner

T= 23

920 gating system, the followings calculations are made in order

to maintain standard gating ratio. With these calculations for

L=30, H=15, proposed gating system gating ratio will changes to

3 In gates w=40, L=30, 1050

H=5,W=40

Cross sectional area of sprue = 491mm2

ISSN: 2231-5381 http://www.ijettjournal.org Page 178

International Journal of Engineering Trends and Technology (IJETT) – Volume22 Number 4- April2015

Cross sectional area of runner = 1000 mm2 produced flow pattern is laminar through all typical section of

Cross sectional area of in gates = 505 mm2 existing and proposed gating system with typical variation in

Therefore 491: 1000: 505 = 1:2.03: 1.02 mean velocity because of changes in the dimension of existing

gating system. In order to reduce various casting defects by

TABLE IV: Gating area for existing & proposed gating system using existing gating system this flow pattern analysis plays an

important role during manufacturing of Ginning Dead Weight.

Existing Proposed Existing Proposed

Gating Gating Gating Gating EXPERIMENTAL RESULTS, ANALYSIS AND

Sr.

Part System System Area Area

No

Dimension Dimensions

DISCUSSION

2 2

s (mm) (mm) (mm ) (mm )

D1= 20 D1= 20, By using proposed gating system the experiments has

1 Sprue 491 491

, D2= 25 D2= 25 been carried out at Jadhao Steel Alloys, Amravati. The result

L= 60, H= L= 60, H=

2 Runner 65, 65, 920 1000 found after experimentation are very sound and productive. By

T= 23 T= 25 using standard gating ratio as per ISO, it was found that the total

L=30 weight of gating system reduced from 4.68 kg to 2.39 kg with

H=15,w=4 L=20, reducing total percentage of rejection from 25% - 30% to 7.5% -

0, H=12,w=30 10%, With % of yield increases from 86% to 92%, with

3 In gates 1050 505

L=30, ,L=5,

H=5, W=20,H=5 productivity increases from 42% to 74%, with keeping flow

W=40 laminar through all sections of gating system which is most

Gating ratio becomes (1:1.87:2.13)(1:2.03:1.03) essential to reduce casting defects.

Hence It was found that proposed gating ratio, becomes INSPECTION REPORT

(1:2.03:1.02) is matched with std. gating ratio i.e. 1:2:1 as per

researchers research in foundry technology. TABLE VI: Inspection Report by using proposed gating system

Job Blo shrinka Gas Sand Misru Tot % of

FLOW PATTERN ANALYSIS IN BETWEEN PROPOSED Qty w ge holes inclusio n al defects

& EXISTING GATING SYSTEM hole & pin n

s holes

According to necessary changes in the design &

20 - - - 1 1 2 10%

dimension of existing gating system it was found that the

proposed gating ratio matched with standard gating ratio & 20 - - - - - - -

the total weight of gating system reduced from 4.7 kg to 2.4 20 - - 1 - - 1 5%

kg. In order to reduced casting defects and percentage of

rejection it was decided to check flow pattern for the 20 - - - 1 1 2 10%

proposed gating system. Following are the calculations made 20 1 - 1 2 10%

to check molten metal flow pattern for the individual section

20 - - - 2 - 2 10%

of proposed gating system.

Average percentage of rejection is around 5% to 10%

TABLE V: Comparative analysis of flow pattern in between proposed and

existing gating system

ACTUAL WEIGHT OF EXISTING & PROPOSED

For Existing Gating For Proposed GATING SYSTEM

System Gating System

TABLE VII: Comparison for Actual weight of existing & proposed

Flow gating system

Section

Mean Mean pattern

Reynolds Reynolds

Velocity Velocit

Number Number Sectio Existing Existing gating Proposed Proposed gating

in m/s y in m/s

n gating weight in (kg) gating in weight in (kg)

volume in (m3)

(m3)

Sprue 580 4.214 580 4.214 Laminar Sprue -5 -3 -5 -3

4.19 X10 301.68X10 4.19 X10 301.68X10

-5 -3 -5

Runner 108 1.3756 103 1.3040 Laminar Runne 0.5252

6.712 X10 483.264 X10 7.2956X10

r

In gates 141 3.5877 265 6.7270 Laminar

-6 -3 -6 -3

In

72 X10 518.4X10 14.4X10 103.68X10

gates

Riser 96 0.6966 246 1.7845 Laminar -4 -4

Riser 3.6 1.4646

5 X10 2.034 X10

TOT 4.68 kg 2.398 kg

The above comparative analysis for flow pattern and

AL

mean velocity in between existing and proposed gating system

ISSN: 2231-5381 http://www.ijettjournal.org Page 179

International Journal of Engineering Trends and Technology (IJETT) – Volume22 Number 4- April2015

weight of existing gating system 2.4 kg.

According to necessary changes in the design &

dimension of existing gating system it was found that the TABLE IX: Bunch Weight Analysis for existing gating system

proposed gating ratio matched with standard gating ratio &

the total weight of gating system reduced from 4.7 kg to 2.4 Bunch Casting Gating

kg. This is most economical for every manufacturing Sr.

Batch No. weight in weight weight

%

industry in mass production. No yield

Kg in Kg in Kg

1 GW/2011/10 34.650 29.800 4.85 86.00

The above comparative analysis for flow pattern and 2 GW/2011/10 34.720 29.920 4.8 86.17

mean velocity in between existing and proposed gating

3 GW/2011/10 34.710 30.100 4.61 86.71

system produced flow pattern is laminar through all typical

section of existing and proposed gating system with typical 4 GW/2011/10 34.590 29.920 4.67 86.49

variation in mean velocity because of changes in the 5 GW/2011/10 34.690 29.880 4.81 86.13

dimension of existing gating system.

6 GW/2011/10 34.750 29.930 4.82 86.12

BUNCH WEIGHT ANALYSIS

7 GW/2011/10 34.670 29.900 4.77 86.24

TABLE VIII: Bunch Weight analysis after experimentation by using

34.850

proposed gating system 8 GW/2011/10 30.180 4.67 86.59

Bunch Casting Gating 9 GW/2011/10 34.580 29.980 4.6 86.69

Sr. %

Batch No. weight in weight weight in

No yield 10 GW/2011/10 34.660 30.100 4.56 86.84

Kg in Kg Kg

1 GW/2012/04 32.800 30.600 2.200 93.29 Average 34.687 29.971 4.716 86%

2 GW/2012/04 32.440 29.800 2.64 91.86

3 GW/2012/04 32.100 29.900 2.2 93.14 The average weight of casting found 29.971 kg with

4 GW/2012/04 32.480 30.180 2.3 92.91 average bunch weight of casting found 34.687 which

produced average percentage of yield 86% with average

5 GW/2012/04 32.550 30.100 2.45 92.47 weight of existing gating system 4.716 kg. The typical bunch

6 GW/2012/04 32.620 30.190 2.43 92.55 weight analysis in between existing and proposed gating

system produced percentage of yield increases from 86% to

7 GW/2012/04 32.380 29.900 2.48 92.34 92% which is most economical for manufacturing industry.

8 GW/2012/04 32.620 30.180 2.44 92.51

COST ANALYSIS IN BETWEEN EXISTING AND

9 GW/2012/04 32.460 29.980 2.48 92.35 PROPOSED GATING SYSTEM TO MEASURE TOTAL

PRODUCTIVITY

10 GW/2012/04 32.510 29.940 2.57 92.09

Average 32.40 30 2.4 92 This cost analysis in between existing and proposed gating

system produced percentage of productivity increases from

The bunch weight analysis by using proposed gating 42% to 74% which is most essential for every manufacturing

system produced the average weight of casting found 30 kg industry.

with average bunch weight of casting found 32.40 which

produced average percentage of yield 92% with average

TABLE X:-Cost Analysis by using existing gating system

ISSN: 2231-5381 http://www.ijettjournal.org Page 180

International Journal of Engineering Trends and Technology (IJETT) – Volume22 Number 4- April2015

TABLE XI:-Cost Analysis by using proposed gating system

DISSCUSSION has to considerably reduce. After careful observation and

analysis it was decided to make necessary changes in the

design and dimension of gating system.

The purpose of this study is to identify the problem

associated with gating system for the manufacturing of

ginning dead weight which is used for their machineries at By using proposed gating system the experiments

Jadhao Steel Alloys Amravati. After observation, inspection has been carried out at Jadhao Steel Industry, Amravati. The

and analysis of every factor of gating system it has found that, result found after experimentation are very sound and

the small change in the dimension of gating system results productive. By using standard gating ratio as per ISO, it was

large effects on the production cost. The average total found that the total percentage of productivity improved from

percentage of rejection for existing gating system is around 42% to 74% by reducing total weight of gating system from

25% to 30% of total casting produced. The average total 4.68 kg to 2.39 kg with reducing total percentage of rejection

percentage of rejection for proposed gating system is around from 25% - 30% to 7.5% - 10%, With % of yield increases

7.5% to 10% of total casting produced. This major change in from 86% to 92%, with keeping flow laminar through all

the average percentage of rejection plays an effective role on sections of gating system which is most essential to reduce

casting defects.

production cost. After careful investigation of the casting

process, it was found that all the above defects can be

considerably reduced by using a proper gating system. Hence CONCLUSION

optimization of gating system is considered as a main topic of

investigation. The typical changes in design and dimension of

gating system play a crucial role during manufacturing of

casting product. After observation, inspection and analysis of

The number of factors influencing the gating design

every factor of gating system it has found that, the small

is numerous. But out of all these factors can be considered as

change in the dimension of gating system results large effects

a important one. According to deep study and analysis It was

on the production cost. The target or motto of project is to

decided to follow standard gating ratio as per ISO suggested

reduce casting Defects, to reduce % of rejection and to reduce

by many researchers in the field of casting .In order to

weight of gating system in order to achieve maximum

maintain standard gating ratio It was found that old gating

productivity which is most essential for every manufacturing

ratio was incorrect. After gating system calculation it was

industry

found that the total weight of gating system is very high, that

ISSN: 2231-5381 http://www.ijettjournal.org Page 176

International Journal of Engineering Trends and Technology (IJETT) – Volume22 Number 4- April2015

The result found after experimentation are very sound

and productive .By using standard gating ratio as per

researcher’s research in foundry technology, it was found that

the total percentage of productivity improved from 42% to

74% by reducing weight of gating system from 4.68kg to 2.39

kg with reducing total percentage of rejection from 25% - 30%

to 7.5% - 10% , with increasing % of yield from 86% to 92%

with keeping flow laminar through all sections of gating

system which is most essential to reduce casting defects.

To design a gating system for steel casting standard

gating ratio plays a crucial role during manufacturing. In

ordered to reduce casting defects & percentage of rejections,

typical optimization technique must be follow. Design of

typical elements of gating system must be produced optimum

weight of gating system. Flow pattern analysis is very

important in order to check molten metal flow pattern is

laminar or turbulent during casting with optimum velocity of

molten metal in order to reduce various casting defects. To

optimize the gating system for steel casting percentage of yield

and percentage of productivity must be improve.

REFERENCES

[1] Shamsuddin Sulalman and Tham Chee Keen, department of mechanical

and systems engineering university pertanian malaysia, serdang,

Selangor, Malaysia. Flow analysis along the runner and gating system

of a casting process. Journal of material processing technology. Vol. 63

(1997) 690-695.

[2] B. Senthilkumar, S.G. Ponnambalam, N. Jawahar. Process factor

optimization for controlling pull-down defects in iron castings

Published by Elsevier B.V., 2008.

[3] Zhizhong Sun, Henry Hu, Xiang Chen, casting with multiple

performance characteristics Numerical optimization of gating system

parameters for a magnesium alloy Published by Elsevier B.V., 2007.

[4] Chinmay Das, Manufacturing Science-I, Casting defects, NPTEL

website 2004.

[5] Carlos E. Esparza NEMAK S.A. de C.V. Libramiento Arco Vial,

Optimal Design of Gating Systems by Gradient Search Methods, Km.

3.8 García, NL 66000, México December 2004 Revised April 2005.

[6] P. R Beeley P.R, 'Foundry Technology', The Butteworth Group

(London Butterworths), (1972).

[7] P. N. Rao, Manufacturing Technology, TMH Publication, page 195 -

198.

[8] A. Ghosh and A. K. Mallik, Manufacturing Science, East-West Press

Private Limited, page 90-92.

[9] Kalpakjian and Schmid, Pearson Education, Manufacturing Engineering

and Technology, page 253-254.

[10] E. P. Deganno, Y. T. Black and R. A. Kohser, 'Materials and Processes

in Manufacturing', Mac Millan Publishing Co. 7th Edition (1990).

[11] T. R. Vijayaram, S. Sulaiman, A. M. S. Hamouda, M. H. M. Ahmad,

2006. Foundry quality control aspects and prospects to reduce scrap

rework and rejection in metal casting manufacturing industries. J.

Mater. Process. Technol. 178, 1–3.

[12] R. E. Swift, J. H. Jackson, L. W. Eastwood, 1949. A study of principles

of gating. AFS Trans. 57, 76–88.

ISSN: 2231-5381 http://www.ijettjournal.org Page 176

International Journal of Engineering Trends and Technology (IJETT) – Volume X Issue Y- Month 2013

Appendix

Photo copies for types of defects observed by using

existing gating system

Experimentation Images

ISSN: 2231-5381 http://www.ijettjournal.org Page 177

International Journal of Engineering Trends and Technology (IJETT) – Volume22 Number 4- April2015

ISSN: 2231-5381 http://www.ijettjournal.org Page 178

You might also like

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Effects of Improved Gating System by Using Standard Gating RatioDocument9 pagesEffects of Improved Gating System by Using Standard Gating Ratioavnishchauhan8_46499No ratings yet

- SC Book 2017-014Document18 pagesSC Book 2017-014tabibkarimNo ratings yet

- Cold Metal Transfer: A Revolution in Mechanised Root Pass Pipeline WeldingDocument3 pagesCold Metal Transfer: A Revolution in Mechanised Root Pass Pipeline Weldingargentino_ar01No ratings yet

- Ax2014 08Document7 pagesAx2014 08Paresh PatelNo ratings yet

- Gating System Design and Optimization in Sand MoldDocument19 pagesGating System Design and Optimization in Sand MoldĐinh Nguyễn Thành TrungNo ratings yet

- Minimizing Shrinkage Porosity by Optimizing Some Parameters of Al Alloy (6061T6) Using DOEDocument11 pagesMinimizing Shrinkage Porosity by Optimizing Some Parameters of Al Alloy (6061T6) Using DOEIJRASETPublicationsNo ratings yet

- PTC 2009 1.2 FokensDocument7 pagesPTC 2009 1.2 Fokenskaliappan45490No ratings yet

- Optimization of Process Parameters Affecting Gas Tungsten Arc Welding of AA6082Document5 pagesOptimization of Process Parameters Affecting Gas Tungsten Arc Welding of AA6082erpublicationNo ratings yet

- RoboticDocument3 pagesRoboticmahotkatNo ratings yet

- 894-Article Text-13257-1-10-20210622Document13 pages894-Article Text-13257-1-10-20210622Discord YtNo ratings yet

- Robotic Stud Welding Process Optimization With Designed ExperimentDocument8 pagesRobotic Stud Welding Process Optimization With Designed ExperimentSam KashNo ratings yet

- Nozzle Design and Material in Abrasive Jet Machining Process - A ReviewDocument9 pagesNozzle Design and Material in Abrasive Jet Machining Process - A ReviewRajiv RanjanNo ratings yet

- 1 s2.0 S1350630716303624 MainDocument12 pages1 s2.0 S1350630716303624 MainRafaella SilvaNo ratings yet

- Numerical Simulation For Casting Defect PredictionDocument5 pagesNumerical Simulation For Casting Defect PredictionRajkot NPDNo ratings yet

- CMT Spot WeldingDocument11 pagesCMT Spot Weldingkarthick32mechNo ratings yet

- Repeated Weld Repair and Its Influence On Welded Carbon SteelDocument9 pagesRepeated Weld Repair and Its Influence On Welded Carbon SteelRabah BrikaNo ratings yet

- AME-26 RevDocument42 pagesAME-26 RevGyanr BNo ratings yet

- Casting Simulation For Sand Casting of Flywheel: Naveen Hebsur, Sunil MangshettyDocument5 pagesCasting Simulation For Sand Casting of Flywheel: Naveen Hebsur, Sunil MangshettyAkshayNo ratings yet

- JMMFDocument25 pagesJMMFDr-Dasharath MabrukarNo ratings yet

- Voestalpine Stahl GMBH - CC8 Caster For High-Quality Grades and Exposed Automotive Steel Using Danieli TechnologyDocument10 pagesVoestalpine Stahl GMBH - CC8 Caster For High-Quality Grades and Exposed Automotive Steel Using Danieli TechnologyJJNo ratings yet

- A Study of Porosity Formation in Pressure Die Casting Using The Taguchi ApproachDocument11 pagesA Study of Porosity Formation in Pressure Die Casting Using The Taguchi ApproachNourchene BoussaaNo ratings yet

- Gating Aluminum Permanent Castings PDFDocument2 pagesGating Aluminum Permanent Castings PDFdidoNo ratings yet

- Gating SystemDocument7 pagesGating SystemKiwil CtrNo ratings yet

- Jorunal - Not MineDocument4 pagesJorunal - Not Minehaiqal3No ratings yet

- Qin 2015Document7 pagesQin 2015alvian GaspolllNo ratings yet

- Reducing Grinding Energy and Cost - Magnetite Iron Ore Design Case StudyDocument8 pagesReducing Grinding Energy and Cost - Magnetite Iron Ore Design Case StudyElwathig BakhietNo ratings yet

- Design and Fabrication of Pneumatic Sand Molding MachineDocument4 pagesDesign and Fabrication of Pneumatic Sand Molding MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Manuscript (REVIEW PAPER1) - NewDocument4 pagesManuscript (REVIEW PAPER1) - NewAnand PathakNo ratings yet

- S K Bagchi - Weld Failure in Oil & Gas IndustriesDocument6 pagesS K Bagchi - Weld Failure in Oil & Gas IndustriesathulpcucekNo ratings yet

- Quality Index For Friction Stir Welds in 7050 Aluminum PlatesDocument10 pagesQuality Index For Friction Stir Welds in 7050 Aluminum PlatesGabriel AguirreNo ratings yet

- Optimization of Pulsed TIG Welding Process Parameters On Mechanical Properties of AA 5456 Aluminum Alloy WeldmentsDocument10 pagesOptimization of Pulsed TIG Welding Process Parameters On Mechanical Properties of AA 5456 Aluminum Alloy Weldmentsnofrian akbarNo ratings yet

- WeldOverlayofContinuousDigestersTAPPI2002 PDFDocument32 pagesWeldOverlayofContinuousDigestersTAPPI2002 PDFดิฐคุณ ผดุงมาศ100% (1)

- 10 1016@j Jmapro 2020 01 053Document10 pages10 1016@j Jmapro 2020 01 053Uttam AnimireddyNo ratings yet

- Agishev 2017Document10 pagesAgishev 2017GERARDO TORRES RUIZNo ratings yet

- Casting Process Design GuidelinesDocument8 pagesCasting Process Design GuidelinestejassidhpuraNo ratings yet

- Manual For Fusion Welding of Rails by The Alumino-Thermic ProcessDocument49 pagesManual For Fusion Welding of Rails by The Alumino-Thermic ProcesskrischaeverNo ratings yet

- Machine Design, Vol.5 (2013) No.1, ISSN 1821-1259 Pp. 1-10Document10 pagesMachine Design, Vol.5 (2013) No.1, ISSN 1821-1259 Pp. 1-10Sirajuddin ANo ratings yet

- Squeezed Casting Process For AL Alloys PDFDocument156 pagesSqueezed Casting Process For AL Alloys PDFP S Lakshmi KanthanNo ratings yet

- Casting Blemishes and Supply Chain Relationship in Cast Iron FoundryDocument8 pagesCasting Blemishes and Supply Chain Relationship in Cast Iron FoundryVittal SBNo ratings yet

- Minimization of Casting Defects: Achamyeleh A. Kassie, Samuel B. AssfawDocument8 pagesMinimization of Casting Defects: Achamyeleh A. Kassie, Samuel B. AssfawIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- 5 Welding Processes 1Document62 pages5 Welding Processes 1adelNo ratings yet

- Metal Casting Final ReviewDocument21 pagesMetal Casting Final ReviewHarsh guptaNo ratings yet

- Study of Process Parameters of Gravity Die Casting DefectsDocument4 pagesStudy of Process Parameters of Gravity Die Casting DefectsIAEME PublicationNo ratings yet

- Effects of Some Process Parameters On Weld Bead: A Brief InvestigationDocument8 pagesEffects of Some Process Parameters On Weld Bead: A Brief InvestigationkunjNo ratings yet

- Gating Design Criteria For Sound Casting: Research PaperDocument20 pagesGating Design Criteria For Sound Casting: Research PaperFlop ShowNo ratings yet

- Scaling Up Ultrasonic Vibration Assisted Additive Man - 2022 - Journal of ManufaDocument8 pagesScaling Up Ultrasonic Vibration Assisted Additive Man - 2022 - Journal of ManufaDiego BarreraNo ratings yet

- A Review Paper On A-Tig Welding ProcessDocument4 pagesA Review Paper On A-Tig Welding ProcessIJSTENo ratings yet

- Bayesian Inference-Based Investment-Casting Defect Analysis System For Industrial ApplicationDocument2 pagesBayesian Inference-Based Investment-Casting Defect Analysis System For Industrial ApplicationLos_80No ratings yet

- Standards For High Integrity and Structural Die CastingDocument204 pagesStandards For High Integrity and Structural Die CastingThomas S R100% (1)

- Importante b31.gDocument10 pagesImportante b31.gJennifer Julieth Triana ForeroNo ratings yet

- Design and Development of Special Purpose Machine Used For Circular Metal Inert Gas WeldingDocument8 pagesDesign and Development of Special Purpose Machine Used For Circular Metal Inert Gas Weldingwood_ksd3251No ratings yet

- Irjet V6i9115Document8 pagesIrjet V6i9115JaskiratSinghNo ratings yet

- 2831 PDFDocument9 pages2831 PDFAlpha Test HouseNo ratings yet

- 229-01 Dross Inclusions in An Iron FoundryDocument4 pages229-01 Dross Inclusions in An Iron Foundryjlplazaola100% (1)

- Narrow Gap Gas Metal Arc (GMA) Welding Technologies: AbstractDocument7 pagesNarrow Gap Gas Metal Arc (GMA) Welding Technologies: Abstracttiepnh.ameccNo ratings yet

- An Investigation On Cut Quality of Aluminum Matrix Composites Cut by Abrasive WaterjetDocument11 pagesAn Investigation On Cut Quality of Aluminum Matrix Composites Cut by Abrasive WaterjetIJRASETPublicationsNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Topic 4: Classification, Properties and Applications of S.G. and C.G.Iron S.G.IRONDocument11 pagesTopic 4: Classification, Properties and Applications of S.G. and C.G.Iron S.G.IRONsandeep kumarNo ratings yet

- Casting Simulation Niyama Criterion Procedure QualificationDocument7 pagesCasting Simulation Niyama Criterion Procedure Qualificationavnishchauhan8_46499No ratings yet

- Characterization of SG Iron: A Thesis Submitted in Partial Fulfillment of The Requirements For The Degree ofDocument58 pagesCharacterization of SG Iron: A Thesis Submitted in Partial Fulfillment of The Requirements For The Degree ofavnishchauhan8_46499No ratings yet

- Amount of Free Carbon at End of Solidification in Spheroidal Graphite Iron CastingsDocument10 pagesAmount of Free Carbon at End of Solidification in Spheroidal Graphite Iron Castingsavnishchauhan8_46499No ratings yet

- Mechanical Properties of SG-iron With Different Matrix StructureDocument9 pagesMechanical Properties of SG-iron With Different Matrix StructureMaaz AdeelNo ratings yet

- Niyama Based Taper Optimizations in Steel Alloy CastingsDocument102 pagesNiyama Based Taper Optimizations in Steel Alloy Castingsavnishchauhan8_46499No ratings yet

- Internship Report On Foundry TechnologyDocument27 pagesInternship Report On Foundry TechnologyPavan Kalyan80% (5)

- SG Iron Casting Grades and StandardsDocument4 pagesSG Iron Casting Grades and Standardsavnishchauhan8_46499No ratings yet

- Research Paper Optimization To Improve The Quality of Centrifugal Casting by Grey Fuzzy MethodDocument3 pagesResearch Paper Optimization To Improve The Quality of Centrifugal Casting by Grey Fuzzy Methodavnishchauhan8_46499No ratings yet

- Aluminium CastingDocument11 pagesAluminium CastingArjun SharmaNo ratings yet

- Metals: Solidification Pattern of Si-Alloyed, Inoculated Ductile Cast Irons, Evaluated by Thermal AnalysisDocument16 pagesMetals: Solidification Pattern of Si-Alloyed, Inoculated Ductile Cast Irons, Evaluated by Thermal Analysisavnishchauhan8_46499No ratings yet

- Presenting The PlanDocument29 pagesPresenting The Planगौरव जैनNo ratings yet

- Modern High Pressure Die-Casting Processes For Aluminium CastingsDocument7 pagesModern High Pressure Die-Casting Processes For Aluminium Castingswawawa1No ratings yet

- Aluminium Castings PDFDocument4 pagesAluminium Castings PDFpalsettyNo ratings yet

- Metal Casting Processes - 1 PDFDocument136 pagesMetal Casting Processes - 1 PDFRamkrishna SonavaneNo ratings yet

- Aliphatic PDFDocument19 pagesAliphatic PDFK &WNo ratings yet

- Solution of Assignment 4Document5 pagesSolution of Assignment 4venkatachalapathy.thNo ratings yet

- LD2668T41978A67Document55 pagesLD2668T41978A67Fattihi EkhmalNo ratings yet

- Cricket TutorialDocument26 pagesCricket TutorialAsad ZahidiNo ratings yet

- Alcohol-Jeemain Guru PDFDocument31 pagesAlcohol-Jeemain Guru PDFgiriraj shankarNo ratings yet

- Study of Sand Casting Gating System: Nandagopal M, Sivakumar K, Senthilkumar G, Sengottuvelan MDocument8 pagesStudy of Sand Casting Gating System: Nandagopal M, Sivakumar K, Senthilkumar G, Sengottuvelan Mavnishchauhan8_46499No ratings yet

- Elements of Gating SystemDocument44 pagesElements of Gating SystemNemani RaghuNo ratings yet

- Pattern Allowances in Metal CastingDocument15 pagesPattern Allowances in Metal Castingavnishchauhan8_46499No ratings yet

- 2007 Office Suites RoadmapDocument1 page2007 Office Suites Roadmapzohaibmaher07No ratings yet

- Windows 8 - Notice PDFDocument1 pageWindows 8 - Notice PDFSanthosh KumarNo ratings yet

- 1-5-6 SprueDocument45 pages1-5-6 Sprueuday kiran thagirchiNo ratings yet

- Gating-Risering Sec2Document35 pagesGating-Risering Sec2jagan_4u100% (1)

- 2007 Office Suites RoadmapDocument1 page2007 Office Suites Roadmapzohaibmaher07No ratings yet

- Department of Education: Supervisory Report School/District: Cacawan High SchoolDocument17 pagesDepartment of Education: Supervisory Report School/District: Cacawan High SchoolMaze JasminNo ratings yet

- Sci ReportDocument8 pagesSci ReportAna LuisaNo ratings yet

- Bruzon's PortfolioDocument67 pagesBruzon's PortfolioAnna Bruzon-RafalloNo ratings yet

- Lesson 5 - 8ae AbsorptionDocument12 pagesLesson 5 - 8ae AbsorptionarnavprajeetNo ratings yet

- Polytechnic University of The Philippines Basketball Athletes' Superstitious Rituals and Its Effects in Their Game PerformanceDocument25 pagesPolytechnic University of The Philippines Basketball Athletes' Superstitious Rituals and Its Effects in Their Game PerformanceJewo CanterasNo ratings yet

- Can Amitriptyline Makes You Feel More Awake Instead of DrowsyDocument3 pagesCan Amitriptyline Makes You Feel More Awake Instead of Drowsyteddypol100% (1)

- Loan-Level Price Adjustment (LLPA) MatrixDocument8 pagesLoan-Level Price Adjustment (LLPA) MatrixLashon SpearsNo ratings yet

- Gesc 112Document10 pagesGesc 112Kalpavriksha1974No ratings yet

- The New Version of This Sheet Is Available. Item Name Slots FruitDocument6 pagesThe New Version of This Sheet Is Available. Item Name Slots FruitAlex VrankenNo ratings yet

- A Room of One's Own EssayDocument3 pagesA Room of One's Own EssayPeter Hadley MahotiereNo ratings yet

- Creative Writers and Daydreaming by Sigmund Freud To Print.Document7 pagesCreative Writers and Daydreaming by Sigmund Freud To Print.Robinhood Pandey82% (11)

- Cons elecCI 20220 0022Document166 pagesCons elecCI 20220 0022HEREDIA MATA SHARBEL NICOLÁSNo ratings yet

- Answers To Workbook Exercises: Cambridge University Press 2014Document3 pagesAnswers To Workbook Exercises: Cambridge University Press 2014M BNo ratings yet

- Summary Prof EdDocument19 pagesSummary Prof EdFloravie Onate100% (2)

- Ganendra Art House: 8 Lorong 16/7B, 46350 Petaling Jaya, Selangor, MalaysiaDocument25 pagesGanendra Art House: 8 Lorong 16/7B, 46350 Petaling Jaya, Selangor, MalaysiaFiorela Estrella VentocillaNo ratings yet

- Accomplishment and Narrative Report OctDocument4 pagesAccomplishment and Narrative Report OctGillian Bollozos-CabuguasNo ratings yet

- OET SOP For Australia (Statement of Purpose)Document7 pagesOET SOP For Australia (Statement of Purpose)SOP By Preet100% (1)

- Polaris Ranger 500 ManualDocument105 pagesPolaris Ranger 500 ManualDennis aNo ratings yet

- Forrester Hybrid Integration PlatformDocument17 pagesForrester Hybrid Integration PlatformrtNo ratings yet

- Art of CharacterizationDocument4 pagesArt of CharacterizationAli RazaNo ratings yet

- PDF - The Irresistible Kisser 2024 - WatermarkDocument31 pagesPDF - The Irresistible Kisser 2024 - WatermarkRazi100% (1)

- Hindi Cinema 3rd Sem Notes PDF (2) - 1 PDFDocument37 pagesHindi Cinema 3rd Sem Notes PDF (2) - 1 PDFLateef ah malik100% (1)

- ASVAB Core ReviewDocument208 pagesASVAB Core Reviewstanley100% (1)

- Make An Acknowledgment Receipt Showing A Full Payment of A Loan (Extinguishment by Payment)Document5 pagesMake An Acknowledgment Receipt Showing A Full Payment of A Loan (Extinguishment by Payment)Kim Cyrah Amor GerianNo ratings yet

- Camping Checklist: Essentials / Survival Sleep GearDocument2 pagesCamping Checklist: Essentials / Survival Sleep GearRomi Roberto100% (1)

- The Economic Report of The PresidentDocument35 pagesThe Economic Report of The PresidentScribd Government DocsNo ratings yet

- 6 - Cash Flow StatementDocument42 pages6 - Cash Flow StatementBhagaban DasNo ratings yet

- Wheelandaxleupload 113020Document15 pagesWheelandaxleupload 113020api-278325436No ratings yet

- Question 1Document8 pagesQuestion 1daniela222No ratings yet

- Ultimate India Bucket ListDocument5 pagesUltimate India Bucket Listgacawe6143No ratings yet