Professional Documents

Culture Documents

SEW Drive Error List PDF

SEW Drive Error List PDF

Uploaded by

karangoyals03Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEW Drive Error List PDF

SEW Drive Error List PDF

Uploaded by

karangoyals03Copyright:

Available Formats

Service

Error messages and list of errors

7

7.2.3 Error list

The factory set error response is listed in the "Response P" column. (P) indicates that

the response is programmable (via P83_error response or with IPOSplus®). In the event

of error 108, (P) indicates that the response can be programmed via P555 DCS error

response In the event of error 109, (P) indicates that the response can be programmed

via P556 DCS alarm response

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

00 No error

0 Output stage • Short circuit at output • Rectify the short circuit

1 VCE monitoring or under- • Motor too large • Connect a smaller motor

voltage monitoring of the • Defective output stage • Contact SEW Service for

gate driver • Power supply advice if the output stage

Current converters is defective.

5 Inverter remains in hard- • Ramp limit is deactivated • Activate P138 and/or

ware current limit and set ramp time is too increase ramp time

6 VCE monitoring or under- short

voltage monitoring of the • Defective phase module

gate driver or overcurrent • Supply voltage 24 V or 24V

of the current converter. generated from it is instable

Immediate ..Phase U • Interruption or short circuit

01 Overcurrent disconnec- on the signal lines from the

7 ..Phase V phase modules

tion

8 ..Phase W

9 ..Phase U and V

10 ..Phase U and W

11 ..Phase V and W

12 ..Phase U and V and W

13 Voltage supply

Current converter in sta-

tus mains operation

14 MFE signal lines

Ground fault • Eliminate ground fault

Immediate • Consult SEW Service

03 Ground fault disconnec- 0 Ground fault • in the motor lead

tion • in the inverter

• in the motor

0 DC link voltage too high in • Too much regenerative • Extend deceleration ramps

1 4Q operation power • Check supply cable to

• Braking resistor circuit braking resistor

Immediate

Brake chop- interrupted • Check technical data of

04 disconnec-

per • Short circuit in the braking braking resistor

tion

resistor circuit • Replace MOVIDRIVE® if

• Brake resistance too high the brake chopper is

• Brake chopper is defective defective

06 Mains phase Immediate 0 DC link voltage periodi- • Phase failure • Check the line cable

failure disconnec- cally too low • Inadequate line voltage • Check configuration of the

tion quality supply system.

• Check supply (fuses,

contactor)

3 Line frequency fault

4 -

0 DC link voltage too high in DC link voltage too high • Extend deceleration ramps

1 2Q operation • Check supply cable to the

braking resistor

Immediate 2 DC link voltage too high in • Check technical data of

DC link over- 4Q operation ..

07 disconnec- braking resistor

voltage

tion .. Phase U

3 .. Phase V

4 .. Phase W

Operating Instructions – MOVIDRIVE® MDX60B/61B 153

Service

7 Error messages and list of errors

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

0 Inverter in current limit or • Speed controller or current • Reduce load

in slip limit controller (in VFC operating • Increase deceleration time

3 "Actual speed" system mode without encoder) (P501 or P503).

limit exceeded. operating at setting limit due • Check encoder

to mechanical overload or connection, swap A/A and

Speed difference between

phase failure in the power B/B pairs if necessary

ramp setpoint and actual

supply or motor. • Check encoder voltage

Immediate value for 2×ramp time

Speed moni- • Encoder not connected supply

08 disconnec- higher than expected slip.

toring correctly or incorrect • Check current limitation

tion (P) 4 Maximum rotating field direction of rotation. • Extend ramps if necessary

speed exceeded. • nmax is exceeded during • Check motor cable and

Maximum rotating field fre- torque control. motor

quency (with VFC max • In operating mode VFC: • Check mains phases

150 Hz and V/f max 600 Output frequency ≥ 150 Hz

Hz) exceeded. • In operating mode V/f:

Output frequency ≥ 600 Hz

0 Startup missing

Immediate 1 Wrong operating mode

Inverter has not been started up Perform startup for the

09 Startup disconnec- selected

for the selected operating mode. required operating mode.

tion 2 Wrong encoder type or

defective encoder card

• Incorrect command • Check the content of the

detected during IPOSplus® program memory and, if

program execution. necessary, correct.

Emergency

10 IPOS-ILLOP 0 Invalid IPOS command • Incorrect conditions during • Load the correct program

stop

command execution. into the program memory.

• Check program sequence

(→ IPOSplus® manual)

0 Heat sink temperature too • Thermal overload of inverter • Reduce load and/or

high or temperature sen- • Temperature sensor of a ensure adequate cooling.

sor defective phase module faulty. • Check fan.

3 Overtemperature (size 7) • If F-11 is issued even

switched-mode power though the temperatures is

supply obviously not too high, this

Overtempera- Emergency indicates a faulty tempera-

11 6 Heat sink temperature too ture sensor of the phase

ture stop (P) high or temperature sen- module.

sor defective. Replace the phase module

..Phase U (Size 7)

7 ..Phase V

8 ..Phase W

(size 7)

Control signal source not

Immediate

Control sig- available, e.g. control sig- Control signal source not Set correct control signal

13 disconnec- 0

nal source nal source fieldbus without defined or defined incorrectly. source (P101).

tion

fieldbus card

154 Operating Instructions – MOVIDRIVE® MDX60B/61B

Service

Error messages and list of errors

7

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

0 Encoder not connected, • Encoder cable or shield not

defective encoder, defec- connected correctly

tive encoder cable • Short circuit/broken encoder

25 Encoder error X15 - Speed wire

range exceeded. • Encoder defective

Encoder at X15 turns

faster than 6542 rpm.

26 Encoder error X15 - Card

is defective.

Error in the quadrant eval-

uation.

27 Encoder error – encoder

connection or encoder is

defective

28 Encoder error X15 - Com-

munication error RS485

channel.

29 Encoder error X14 - Com-

Immediate munication error RS485 Check encoder cable and

14 Encoder disconnec- channel. shield for correct connection,

tion short circuit and broken wire.

30 Unknown encoder type at

X14/X15

31 Plausibility check fault

X14/X15

Increments have been

lost.

32 Encoder error X15

Hiperface®.

Hiperface® encoder at X15

reports error.

33 Encoder error X14

Hiperface®.

Hiperface® encoder at X14

reports error.

34 Encoder error X15

resolver.

Encoder connection or

encoder is defective.

17 0 "Stack overflow" error • Check grounding and

18 0 "Stack underflow" error shielding and improve, if

necessary.

19 0 Fault "External NMI" • Consult SEW service if the

20 0 Fault "Undefined opcode" error reoccurs.

21 Immediate 0 "Protection fault" error

System mal- Inverter electronics disrupted,

disconnec-

22 function 0 "Illegal word operand possibly due to effect of EMC.

tion

access" error

23 0 "Illegal instruction access"

error

24 0 "Illegal external bus

access" error

Read or write error on • Activate factory settings,

0

EEPROM power section perform reset and reset

11 NV memory read error parameters.

• Contact SEW service if the

NV-RAM inside the unit

error occurs again.

13 NV memory chip card Access to the EEPROM of the • Replace memory card.

25 EEPROM Rapid stop

System module defective memory card has failed

14 NV memory chip card

Memory card defective

16 NV memory initialization

error

Eliminate respective cause;

External ter- Emergency Read in external error signal via

26 0 External terminal reprogram terminal if neces-

minal stop (P) programmable input.

sary.

Operating Instructions – MOVIDRIVE® MDX60B/61B 155

Service

7 Error messages and list of errors

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

0 Both limit switches missing • Open circuit/both limit • Check wiring of limit

or open circuit switches missing. switches.

No limit Emergency • Limit switches are swapped • Swap over limit switch

27 2 Limit switch reversed

switches stop over in relation to direction connections.

3 Both limit switches are of rotation of motor • Reprogram terminals

active simultaneously

0 Fault "Fieldbus timeout" • Check communications

Fieldbus 2 Fieldbus card does not No communication between routine of the master

Rapid stop

28 boot master and slave within the pro- • Extend fieldbus timeout

Timeout (P)

jected response monitoring. time (P819) or deactivate

monitoring

Limit switch Emergency 0 Hardware limit switch A limit switch was reached in • Check travel range.

29

contacted stop approached IPOSplus® operating mode. • Correct user program.

Emergency Immediate 0 Time violation stop emer- • Drive overloaded • Check configuration

30 stop disconnec- gency stop rate • Emergency stop ramp too • Extend emergency stop

Timeout tion short. ramp

• Motor too hot, TF/TH has • Let motor cool off and

triggered reset error

• TF/TH of the motor not • Check connections/link

connected or connected between MOVIDRIVE®

TF/TH sen- No Thermal motor protection incorrectly and TF/TH.

31 0

sor tripped response (P) error • MOVIDRIVE® connection • If a TF/TH is not

and TF/TH connection on connected: Jumper X10:1

motor interrupted with X10:2.

• Set P835 to "No

response".

Programming principles vio- Check and correct the

IPOS index Emergency

32 0 IPOS program defective lated leading to system internal IPOSplus® user program (see

overflow stop

stack overflow IPOSplus® manual).

0 Setpoint source not avail-

Immediate

Setpoint able, e.g. control signal Setpoint source not defined or Set correct setpoint source

33 disconnec-

source source fieldbus without defined incorrectly. (P100).

tion

fieldbus card

Ramp Immediate 0 Time violation rapid stop • Extend the downwards

Time of downward ramps

34 disconnec- ramp ramps

Timeout exceeded, e.g. due to overload.

tion • Eliminate overload

0 Operating mode not avail- • Operating mode not defined • Use P700 or P701 to set

able or defined incorrectly correct operating mode.

1 Wrong assignment operat- • P916 was used to set a • Use MOVIDRIVE® in

ing mode - hardware ramp function that is needed technology version (..OT).

by a MOVIDRIVE® unit in • From the "Startup →

2 Wrong assignment operat- technology version. Select technology

Immediate ing mode - technology • P916 was used to set a function..." menu, select

Operating function

35 disconnec- ramp type that does not the technology function

mode

tion match the selected that matches P916.

technology function. • Check the settings of P916

• P916 was used to set a and P888

ramp type that does not

match the selected

synchronization time

(P888).

0 Hardware is missing or not • Type of option card not • Use correct option card

permitted. allowed • Set correct setpoint source

2 Encoder slot error. • Setpoint source, control (P100)

Immediate signal source or operating • Set correct control signal

Option miss- 3 Fieldbus slot error.

36 disconnec- mode not permitted for this source (P101)

ing

tion 4 Expansion slot error. option card • Set correct operating

• Incorrect encoder type set mode (P700 or P701)

for DIP11B. • Set the correct encoder

type

Immediate 0 Error "watchdog overflow

System Error while executing system

37 disconnec- system" Consult SEW Service.

watchdog software

tion

Immediate 0 "System software" error

System soft-

38 disconnec- System malfunction Consult SEW Service.

ware

tion

156 Operating Instructions – MOVIDRIVE® MDX60B/61B

Service

Error messages and list of errors

7

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

• The reference cam is • Check reference cam

missing or does not switch • Check limit switch

Immediate • Limit switches are connection

Reference

39 disconnec- 0 "Reference travel" error connected incorrectly • Check reference travel

travel

tion (P) • Reference travel type was type setting and required

changed during reference parameters.

travel

• Error during boot

Immediate synchronization between

Boot synchro- Timeout at boot synchroni- Install a new option card if this

40 disconnec- 0 inverter and option.

nization zation with option. error reoccurs.

tion • Synchronization ID not/

incorrectly transmitted

0 Error – Watchdog timer • Error in communication • Consult SEW Service.

from/to option. between system software • Check IPOS program

17 Watchdog IPOS error. and option software

• Watchdog in the IPOSplus®

program

• Check whether the unit

Immediate

Watchdog has been activated for the

41 disconnec- • An application module

option application version (P079)

tion without the application • Check the selected

version has been loaded in technology function (P078)

®

a MOVIDRIVE B unit

• The wrong technology

function has been set if an

application module is used

• Encoder connected • Check encoder connection

incorrectly • Extend ramps

• Acceleration ramps too • Set P component to higher

short value

• P component of positioning • Reset speed controller

controller too small parameters

Immediate

• Incorrectly set speed • Increase lag error

42 Lag error disconnec- 0 Positioning lag error

controller parameters tolerance

tion (P)

• Value of lag error tolerance • Check wiring of encoder,

too small motor and mains phase.

• Check whether

mechanical system

components can move

freely or if they are blocked

Check RS485 connection (e.g.

RS485- Rapid stop Communication timeout at Error during communication via inverter - PC, inverter -

43 0

Timeout (P) RS485 interface. interface RS485 DBG60B). If necessary, con-

tact SEW Service.

0 Unit utilization error • Unit utilization (IxT value) • Decrease power output

8 UL monitoring error > 125% • Extend ramps

Immediate • If suggested actions not

44 Unit utilization disconnec- possible, use larger

tion inverter.

• Reduce load

0 General error during initial- • No parameters set for • Restore factory settings

ization EEPROM in power section, Consult SEW Service if the

3 Data bus error during RAM or parameters set error still cannot be reset.

check incorrectly. • Insert the option card

• Option card not in contact correctly.

6 CPU clock error. with backplane bus.

7 Error in the current evalua-

Immediate tion.

45 Initialization disconnec- 10 Error setting the flash pro-

tion tection

11 Data bus error during RAM

check

12 Parameter setting error

synchronous operation

(internal synchronous

operation)

Operating Instructions – MOVIDRIVE® MDX60B/61B 157

Service

7 Error messages and list of errors

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

System bus 2 Rapid stop 0 Timeout system bus CAN2 Error during communication via

46 Check system bus connection.

timeout (P) system bus 2.

System bus 1 Rapid stop 0 Timeout system bus CAN1 Error during communication via

47 Check system bus connection.

timeout (P) system bus 1.

Only with DRS11B: • Check encoder signals of

• Encoder signal from master/ master/synchronous

Immediate encoder.

Hardware Hardware synchronous synchronous encoder faulty.

48 disconnec- 0 • Check encoder wiring.

DRS operation • Hardware required for

tion • Replace synchronous

synchronous operation is

faulty. operation card.

Only in IPOSplus® operating • Check serial connection to

mode: external control.

IPOS control No • Check write values of

77 0 Invalid control word IPOS • An attempt was made to set external control.

word response (P) an invalid automatic mode

(via external controller). • Set correct value for P016.

• P916 = BUS RAMP is set.

Only in IPOSplus® operating • Check the user program

mode: • Check position of the

IPOS SW limit No response Software limit switch software limit switches

78 0 Programmed target position is

switch (P) reached

outside travel range delimited by

software limit switches.

The following items do not

match anymore after having

replaced the memory card:

Immediate Deviating hardware config- • Power Ensure identical hardware or

Hardware

79 disconnec- 0 uration when replacing the • Rated voltage restore factory setting (param-

configuration • Variant identification

tion memory card eter = factory setting).

• Unit series

• Application or standard

version

• Option cards

Immediate 0 "RAM test" error

Internal unit fault, RAM defec-

80 RAM test disconnec- Consult SEW Service.

tive.

tion

• Check startup data and

Only in "VFC hoist" operating perform new startup, if

mode: necessary.

The motor could not be supplied • Check connection

with the correct amount of cur- between inverter and

rent during the pre-magnetizing motor.

time: • Check cross section of

• Rated motor power too motor cable and increase if

small in relation to rated necessary.

inverter power.

Immediate • Motor cable cross section

Start condition error with too small.

81 Start condition disconnec- 0

VFC hoist

tion Only for operation with a lin-

ear motor (as of firmware 18):

• The drive has been set to

"Enable" although the • Perform commutation

commutation offset between travel in the "No enable"

linear motor and linear state and then switch to

encoder is not known. This "Enable" once the inverter

means that the inverter has acknowledged in

cannot set the current status word bit 25 that

indicator correctly. commutation was

successful.

Only in "VFC hoist" operating • Check connection

mode: between inverter and

Immediate • Two or all output phases motor.

Output open with VFC • Check startup data and

82 Open output disconnec- 0 interrupted.

hoist perform new startup, if

tion • Rated motor power too

small in relation to rated necessary.

inverter power.

158 Operating Instructions – MOVIDRIVE® MDX60B/61B

Service

Error messages and list of errors

7

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

0 "Motor temperature simu- • Motor utilization too high. • Reduce load.

lation" error • IN-UL monitoring 1 triggered • Extend ramps.

2 Short circuit or open circuit • P530 set later to "KTY" • Observe longer pause

Motor protec- Emergency in the temperature sensor times.

84

tion stop (P) • Check P345/346

3 No thermal motor model • Select a larger motor

available

4 UL monitoring error

0 Error in connection with • No memory card • Tighten knurled screw

Immediate memory module • Memory card defective • Insert and secure memory

Memory mod-

86 disconnec- card

ule 2 Hardware card detection

tion • Replace memory card

wrong memory card

Immediate 0 Technology function

Technology A technology function was acti-

87 disconnec- selected with standard unit Disable technology function

function vated in a standard version.

tion

0 "Flying start" error Only in VFC n-CTRL operating

Immediate Inverter not enabled before

mode:

88 Flying start disconnec- actual speed is

tion Actual speed > 6000 rpm with

≤ 6000 rpm.

the inverter enabled.

DIP encoder Error display Possible cause: Encoder is

92 1 Stahl WCS3 dirt problem Encoder signals an error

problem (P) dirty → clean encoder

The encoder signals an error, • Check absolute encoder

e.g. power failure. connection.

• Connection cable between • Check connection cables.

the encoder and DIP11B • Set correct cycle

does not meet the frequency.

requirements (twisted pair, • Reduce maximum

DIP encoder Emergency traveling velocity or ramp.

93 0 Fault "Absolute encoder" shielded).

error stop (P) • Replace absolute encoder.

• Cycle frequency for cable

length too high.

• Permitted max. speed/

acceleration of encoder

exceeded.

• Encoder defective.

0 Power section parameters

5 Control unit data Inverter electronics disrupted,

EEPROM Immediate

94 6 Power section data possibly due to effect of EMC or Send unit in for repair.

checksum shut-off

a defect.

7 Invalid version of the con-

figuration data set

No plausible position could be • Set the correct encoder

determined. type.

• Check IPOSplus® travel

• Incorrect encoder type set. parameters.

DIP plausibil- Emergency Validity check of absolute • IPOSplus® travel parameter • Check traveling velocity.

95 0 set incorrectly.

ity error stop (P) position • Correct numerator/

• Numerator/denominator denominator factor.

factor set incorrectly. • After zero adjustment

• Zero adjustment performed. reset.

• Encoder defective. • Replace absolute encoder.

0 Parameter set upload is/ • Memory card cannot be • Repeat copying process

was faulty written or read. • Restore default setting

1 Download of parameter • Error during data (P802) and repeat copying

Immediate set to unit cancelled. transmission process

97 Copy error disconnec- 2 Not possible to adopt

tion parameters.

Not possible to adopt

parameters from memory

card.

Immediate Internal unit error

"CRC via internal flash"

98 CRC error disconnec- 0 Send unit in for repair.

error Flash memory defective

tion

Operating Instructions – MOVIDRIVE® MDX60B/61B 159

Service

7 Error messages and list of errors

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

plus®

Only in IPOS operating Rewrite the IPOSplus® program

mode: so that ramp times and travel-

Immediate Positioning ramp is sinusoidal or ing velocities can only be

IPOS ramp altered when the inverter is

99 disconnec- 0 "Ramp calculation" error square and an attempt is made

calculation inhibited.

tion to change ramp times and trav-

eling velocities with enabled

inverter.

Vibration sensor warning (→ Determine cause of vibrations.

Vibration Display error Vibrations diagnostics

100 0 "DUV10A" operating instruc- Continue operation until F101

warning (P) warning

tions). occurs.

SEW-EURODRIVE recom-

Rapid stop mends that you remedy the

101 Vibration error 0 Vibration diagnostics error Vibration sensor reports error.

(P) cause of the vibrations imme-

diately

Oil aging Display error Error message from the oil

102 0 Oil aging warning Schedule oil change.

warning (P) aging sensor

SEW-EURODRIVE recom-

Display error Error message from the oil

103 Oil aging error 0 Oil aging error mends that you change the

(P) aging sensor

gear unit oil immediately.

Oil aging • Let oil cool down

Display error Overtemperature signal from the

104 overtempera- 0 Oil aging overtemperature • Check if the gear unit cools

(P) oil aging sensor

ture properly

• Check voltage supply of oil

aging sensor

Oil aging Display error Oil aging sensor is not ready for

105 0 Oil aging ready signal • Check and, if necessary,

ready signal (P) operation

replace the oil aging

sensor

Replace brake lining (→

Display error

106 Brake wear 0 Brake wear error Brake lining worn "Motors" operating instruc-

(P)

tions).

Immediate • Check main contactor

Line compo- No feedback signal from

107 disconnec- 1 Defective main contactor • Check control cables.

nents main contactor.

tion

160 Operating Instructions – MOVIDRIVE® MDX60B/61B

Service

Error messages and list of errors

7

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

0 DCS error

Error during transfer of Interruption in connection during Send the configuration files

1 configuration data to the program download again

monitoring unit.

2 Configuration data for soft- Subassembly configured with Configure subassembly with

ware version of the subas- incorrect software version of the permitted version of the pro-

sembly is invalid. programming interface. gramming interface. Then

switch subassembly off and on

again.

Unit was programmed with Program or configuration data Check the design of the subas-

incorrect programming was loaded into the unit with an sembly. Configure again with a

3 interface. incorrect programming interface. valid programming interface.

Then switch the unit off and on

again.

4 Faulty reference voltage. • Supply voltage of the • Check supply voltage

5 subassembly is defective. • Switch unit off and on

• Faulty component in the again

6 Faulty system voltage. subassembly

7

8

Faulty test voltage

9

Immediate Faulty DC 24 V voltage

10

108 DCS error stop/mal- supply

function (P) Ambient temperature of Temperature at the place of Check the ambient tempera-

11 the unit is not in the operation is not in the permitted ture.

defined range. range.

• Check ZSC activation

For the position changeover, • Check JSS activation

Plausibility error for posi-

12 ZSC, JSS or DMC is perma- • Check DMC activation

tion changeover

nently activated. (only for monitoring via

position)

Faulty switching of the

13 LOSIDE driver DO02_P /

DO02_M

Faulty switching of the

14 HISIDE driver DO02_P /

DO02_M

Faulty switching of the

15 Short circuit of the output. Check wiring at the output.

LOSIDE driver DO0_M

Faulty switching of the

16

HISIDE driver DO0_P

Faulty switching of the

17

LOSIDE driver DO01_M

Faulty switching of the

18

HISIDE driver DO01_P

Operating Instructions – MOVIDRIVE® MDX60B/61B 161

Service

7 Error messages and list of errors

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

0 DCS alarm

1 Communication error at The DCS21B/31B option does • Check hardware

the CAN interface of the not receive any valid data from connection to the inverter

inverter. the inverter. • Check version of the

inverter

2 Plausibility error digital • Check configuration of the

3 input at pulse P1 DI1 binary input according

to configuration and wiring

diagram

• Check the wiring

4 Plausibility error digital • Check configuration of the

5 input at pulse P2 DI2 binary input according

to configuration and wiring

diagram

• Check the wiring

6 Pulse 1 plausibility error at • Check configuration of the

7 binary input DI3 DI3 binary input according

to configuration and wiring

diagram

• Check the wiring

8 Pulse 1 plausibility error at • Check configuration of the

Rapid stop/ 9 binary input DI4 DI4 binary input according

109 DCS alarm to configuration and wiring

warning (P)

diagram

No pulse1 voltage present at • Check the wiring

10 Pulse 1 plausibility error at binary input DI1 • Check configuration of the

11 binary input DI5 DI5 binary input according

to configuration and wiring

diagram

• Check the wiring

12 Pulse 1 plausibility error at • Check configuration of the

13 binary input DI6 DI6 binary input according

to configuration and wiring

diagram

• Check the wiring

14 Pulse 1 plausibility error at • Check configuration of the

15 binary input DI7 DI7 binary input according

to configuration and wiring

diagram

• Check the wiring

16 Pulse 1 plausibility error at • Check configuration of the

17 binary input DI8 DI8 binary input according

to configuration and wiring

diagram

• Check the wiring

162 Operating Instructions – MOVIDRIVE® MDX60B/61B

Service

Error messages and list of errors

7

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

18 Pulse 2 plausibility error at • Check configuration of the

19 binary input DI1 DI1 binary input according

to configuration and wiring

diagram

• Check the wiring

20 Pulse 2 plausibility error at • Check configuration of the

21 binary input DI2 DI2 binary input according

to configuration and wiring

diagram

• Check the wiring

22 Pulse 2 plausibility error at • Check configuration of the

23 binary input DI3 DI3 binary input according

to configuration and wiring

diagram

• Check the wiring

24 Pulse 2 plausibility error at • Check configuration of the

25 binary input DI4 DI4 binary input according

to configuration and wiring

diagram

No pulse 2 voltage present at • Check the wiring

26 Pulse 2 plausibility error at binary input DI1. • Check configuration of the

27 binary input DI5 DI5 binary input according

to configuration and wiring

diagram

• Check the wiring

28 Pulse 2 plausibility error at • Check configuration of the

29 binary input DI6 DI6 binary input according

to configuration and wiring

diagram

• Check the wiring

30 Pulse 2 plausibility error at • Check configuration of the

Rapid stop/

109 DCS alarm 31 binary input DI7 DI7 binary input according

warning (P)

to configuration and wiring

diagram

• Check the wiring

32 Pulse 2 plausibility error at • Check configuration of the

33 binary input DI8 DI8 binary input according

to configuration and wiring

diagram

• Check the wiring

34 Plausibility error in the The difference between the two • Check track again with the

35 speed recording velocity sensors is higher than data of the encoder

the configured speed cut-off configuration.

threshold. • Check the velocity sensor

• Use the SCOPE function

to set speed signals so

that they are congruent

36 Plausibility error in the The difference between the two • Check track with the

37 position acquisition position sensors is higher than configured data of the

the configured value. encoder setting

• Check position signal

• Are all signals connected

correctly to the 9-pin

encoder connector?

• Check the encoder

connector for correct

wiring. Is the jumper

between pin 1 and pin 2 on

the 9-pin encoder

connector closed (SSI

absolute encoder)?

• Use the SCOPE function

to set positions signals so

that they are congruent

Operating Instructions – MOVIDRIVE® MDX60B/61B 163

Service

7 Error messages and list of errors

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

38 Plausibility error incorrect The current position is outside • Check track with the

39 position range the configured range. configured data of the

encoder setting

• Check position signal,

correct offset if necessary

• Use the SCOPE function

to read off the position and

set in ratio to the

configured values

40 Plausibility error incorrect The current velocity exceeds the • The drive moves outside

41 speed. configured maximum velocity. the permitted and

configured velocity range

• Check configuration (set

max. velocity)

• Analyze the velocity

development using the

SCOPE function

42 Configuration error: Accel- The current acceleration is out- • Check encoder type and

43 eration side the configured acceleration configuration (SSI/

range. incremental)

• Check the encoder

connection/wiring

• Check polarity of the

encoder data

• Check function of the

encoder

44 Plausibility error in The wiring of the encoder does • Check encoder type and

45 encoder interface (A3401 not correspond to the configured configuration (SSI/

= encoder 1 and A3402 = data. incremental)

encoder 2). • Check the encoder

Rapid stop/ connection/wiring

109 DCS alarm

warning (P) • Check polarity of the

encoder data

• Check function of the

encoder

46 Encoder supply voltage Encoder voltage supply is out- • Overload in the supply

47 error (A3403 = encoder 1 side the defined range (min. DC voltage of the encoder;

and A3404 = encoder 2) 20 V / max. DC 29 V). internal fuse has triggered

• Check supply voltage of

the DCS21B/31B option

48 The reference voltage input of Check reference voltage input

49 Reference voltage error the encoder system is outside of the encoder system.

the defined range.

50 Difference level RS485

51 driver 1 (error INC_B or

SSI_CLK) faulty

52 Difference level RS485 No encoder connection, incor- Check the encoder connec-

53 driver 2 (error INC_A or rect encoder type. tion.

SSI_DATA) faulty.

54 Incremental counter devia-

55 tion

56 Plausibility error in The wiring of the encoder does • Check encoder type and

57 encoder interface (A3401 not correspond to the configured configuration (SSI/

= encoder 1 and A3402 = data. incremental)

encoder 2) • Check the encoder

connection/wiring

• Check polarity of the

encoder data

• Check function of the

encoder

164 Operating Instructions – MOVIDRIVE® MDX60B/61B

Service

Error messages and list of errors

7

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

58 Plausibility error SIN/COS Incorrect encoder type con- • Check the encoder

59 encoder connection. nected. connection

• Check the encoder

60 connection (jumper

61 between pin 1 and pin2)

62 Plausibility error incremen- Phase error of the incremental • Check the encoder

tal encoder connection or sin/cos encoder. connection

63

• Replace the defective

encoder

64 Plausibility error - SSI Connected encoder type does • Check the encoder

65 encoder connection. not correspond to the configura- connection

tion. • Check connected encoder

66 Plausibility error - SSI lis-

67 tener encoder connection

68 Faulty switching of the

LOSIDE driver DO2_M

69 Faulty switching of the

HISIDE driver DO2_P

70 Faulty switching of the

LOSIDE driver DO0_M DC 0 V short circuit at the out-

Check wiring at the output.

71 Faulty switching of the put.

HISIDE driver DO0_P

72 Faulty switching of the

LOSIDE driver DO1_M

Rapid stop/ 73 Faulty switching of the

109 DCS alarm HISIDE driver DO1_P

warning (P)

74 Undervoltage test watch- DC 0 V short circuit at on of the

dog for LOSIDE driver DC 0 V outputs.

Check wiring at the outputs.

75 Undervoltage test watch- DC 24 V short circuit at on of the

dog for HISIDE driver DC 24 V outputs.

76 CCW and CW monitoring

77 (in DMC module) activated

simultaneously

78 CCW and CW monitoring Only one direction of rotation

79 range of the OLC activated Multiple activation. can be activated in the DMC

simultaneously module.

80 CCW and CW monitoring

81 (in JSS module) was acti-

vated simultaneously

82 Timeout error MET. Input element with time monitor- • Check wiring of input

83 Time monitoring start sig- ing is faulty. element

nal for confirmation button. • Input element is faulty

84 Timeout error MEZ. Two-hand operation with time

85 Time monitoring for two- monitoring is faulty.

hand button.

86 EMU1 monitoring error • Check hardware

87 connections

Faulty monitoring of the external

• Pick-up or release time to

88 EMU2 monitoring error disconnection channel

short

89 • Check switching contacts

• Check configuration

"Ex-e protec- Emergency Duration of operation Duration of operation below 5

110 0 • Shorten duration of

tion" error stop below 5 Hz exceeded Hz exceeded

operation below 5 Hz

Analog input No response AI1 analog input open cir-

113 0 AI1 analog input open circuit Check wiring

open circuit (P) cuit

"Timeout • Check startup

Rapid stop/ MOVI-PLC® communica-

116 MOVI-PLC" 0 • Check wiring

warning tion timeout

error

123 Positioning Emergency 0 Error "Positioning/Posi- Target monitoring when inter- Perform positioning process

interruption stop (P) tioning interruption" rupted positioning is resumed. without interruption until it is

Target would be overrun. complete.

Operating Instructions – MOVIDRIVE® MDX60B/61B 165

Service

7 Error messages and list of errors

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

124 Ambient con- Emergency 1 Permitted ambient temper- Ambient temperature > 60°C • Improve ventilation and

ditions stop (P) ature exceeded cooling conditions

• Improve air supply to the

control cabinet; check filter

mats.

1 Discharge resistor Discharge resistor overload Observe waiting time for power

on/off

2 Hardware ID precharge/ Incorrect precharge/discharge • Consult SEW Service

discharge control control variant • Replace precharge/dis-

charge control

3 Inverter coupling PLD Live Defective inverter coupling • Consult SEW Service

• Replace inverter coupling

4 Inverter coupling reference Defective inverter coupling • Consult SEW Service

voltage • Replace inverter coupling

5 Power section configura- Different phase modules • Inform SEW service.

tion installed in the unit • Check and replace phase

modules

6 Control unit configuration Control unit line inverter or Replace or correctly assign the

motor inverter incorrect control unit of line and motor

inverter.

7 Communication power No communication Check control unit installation.

section control unit

8 Communication pre- No communication • Check wiring

charge/discharge control • Consult SEW Service

inverter coupling

Immediate

196 Power section disconnec- 10 Communication power The inverter coupling does not Replace inverter coupling

tion section control unit support protocol

11 Communication power Faulty communication with Replace inverter coupling

section control unit inverter coupling at power-up

(CRC error).

12 Communication power Inverter coupling uses protocol Replace inverter coupling

section control unit that does not match control unit

13 Communication power Faulty communication with Replace inverter coupling

section control unit inverter coupling during opera-

tion: More than once per second

a CRC error.

14 Control unit configuration Missing PLD functionality for Replace control unit

EEPROM data set size 7.

15 Inverter coupling error Inverter coupling processor has • Consult SEW service if the

signaled internal error. error reoccurs

• Replace inverter coupling

16 Inverter coupling error: Replace inverter coupling

PLD version incompatible

17 Precharge/discharge con- Precharge/discharge control • Consult SEW service if the

trol error processor has signaled internal error reoccurs

error • Replace precharge/dis-

charge control

18 Defective DC link fan The DC link fan is faulty. • Consult SEW Service

• Check whether DC link

choke fan is connected or

faulty

19 Communication power Faulty communication with • Consult SEW service if the

section control unit inverter coupling during opera- error reoccurs.

tion: More than once per second • Replace inverter coupling

an internal error.

20 Communication power The control unit has not sent • Consult SEW service if the

section control unit any messages to the inverter error reoccurs.

coupling for a while. • Replace inverter coupling

21 Uz measurement implausi- Defective phase module Consult SEW service if the

ble phase R error reoccurs

22 Uz measurement implausi-

ble phase S

23 Uz measurement implausi-

ble phase T

166 Operating Instructions – MOVIDRIVE® MDX60B/61B

Service

Error messages and list of errors

7

Error Suberror

Response

Code Designation Code Designation Possible cause Measure

(P)

197 Supply sys- Immediate 1 Line overvoltage (motor Inadequate line voltage quality. • Check supply (fuses, con-

tem disconnec- inverter only at start of pre- tactor)

tion charging process) • Check configuration of the

2 Line undervoltage (only supply system

with line inverter)

199 DC link charg- Immediate 4 Precharging was aborted Unable to charge DC link. • Precontrol overload

ing disconnec- • Connected DC link capac-

tion ity too high

• Short circuit in the DC link;

check DC link connection

in case of several units.

Operating Instructions – MOVIDRIVE® MDX60B/61B 167

You might also like

- VFD-M Service ManualDocument107 pagesVFD-M Service ManualThinh Truong Vu100% (6)

- Fuling Inverter User ManualDocument54 pagesFuling Inverter User ManualFayzan Hannan100% (7)

- SD700 Service Manual PDFDocument139 pagesSD700 Service Manual PDFphysicudo100% (3)

- Delexi Cdi. eDocument266 pagesDelexi Cdi. eNouman Mughal100% (1)

- Kemron KV 2000Document60 pagesKemron KV 2000Jose Ramón Oses Delgado80% (5)

- SAJ 8000-M Manual PDFDocument71 pagesSAJ 8000-M Manual PDFrichardNo ratings yet

- PLC Lab ExercisesDocument33 pagesPLC Lab ExercisesShaheerLatif100% (5)

- Free PLC Programming Tutorial PDFDocument2 pagesFree PLC Programming Tutorial PDFJavierNo ratings yet

- 04 - KMM01U - Manual ENGLISHDocument4 pages04 - KMM01U - Manual ENGLISHPanagiotis CharisopoulosNo ratings yet

- Manual YaskawaDocument28 pagesManual YaskawaEva SuárezNo ratings yet

- GA500 Technical Manual PDFDocument771 pagesGA500 Technical Manual PDFValentin MaricaNo ratings yet

- s7-300 MMC Card Memory ResetDocument3 pagess7-300 MMC Card Memory Resetrigo_sk100% (1)

- v65d v6 0 Instruction ManualDocument57 pagesv65d v6 0 Instruction ManualMr.K ch100% (1)

- Beginner's Guide To PLC Programming: How To Program A PLC (Programmable Logic Controller)Document40 pagesBeginner's Guide To PLC Programming: How To Program A PLC (Programmable Logic Controller)Trung Nguyen ThanhNo ratings yet

- CX Programmer 21 ManualDocument134 pagesCX Programmer 21 ManualbullapNo ratings yet

- Quick Guide of PI8100 Operation6-7Document24 pagesQuick Guide of PI8100 Operation6-7Luis Jaramillo100% (1)

- Modulo Analogo DVP06XA-E2 - ManualDocument19 pagesModulo Analogo DVP06XA-E2 - ManualCarina VallejoNo ratings yet

- 17 Ig5a General Io (20070507)Document2 pages17 Ig5a General Io (20070507)cocodrilo360No ratings yet

- FATEK - Win Pro Ladder Simulator ManualDocument10 pagesFATEK - Win Pro Ladder Simulator Manualjomisefer100% (2)

- Nikki Ac Servo Controller : Manual No. TIE-12400BDocument154 pagesNikki Ac Servo Controller : Manual No. TIE-12400BArmando Aristimuno100% (1)

- Kinco HMIware User ManualDocument536 pagesKinco HMIware User ManualRichard AvilezNo ratings yet

- Atv312 Programming Manual en Bbv46385 02Document126 pagesAtv312 Programming Manual en Bbv46385 02abinildo100% (1)

- Firmware Manual ACS850 Standard Control ProgramDocument296 pagesFirmware Manual ACS850 Standard Control Programen_deepak100% (1)

- Efden-001-002 FD Controller MaintenanceDocument70 pagesEfden-001-002 FD Controller MaintenanceChris HendersonNo ratings yet

- Power Factor Controllers PFR-X R / PFR-M T: Because Excellent Capacitors Are Not EnoughDocument3 pagesPower Factor Controllers PFR-X R / PFR-M T: Because Excellent Capacitors Are Not EnoughMarvin RaxónNo ratings yet

- ATS Dwgs & PLC Manuals 1Document15 pagesATS Dwgs & PLC Manuals 1gigo_dreamNo ratings yet

- Delixi 9200 Inverter ManualDocument114 pagesDelixi 9200 Inverter Manualmushtaq246100% (1)

- S1100 Series General Purpose Inverter: User ManualDocument65 pagesS1100 Series General Purpose Inverter: User Manualyohannes tsegaye100% (1)

- T LinkDocument83 pagesT LinkNgọc Nguyễn ThanhNo ratings yet

- Vinco - DatashetDocument2 pagesVinco - DatashetAntonio Carlos CardosoNo ratings yet

- Shihlin PLC Programming Manual PDF EbookDocument3 pagesShihlin PLC Programming Manual PDF Ebookrguzmanabundis50% (2)

- PLC Programming Guide For Dse ControllersDocument30 pagesPLC Programming Guide For Dse ControllersAimi Mizuki Murtic100% (4)

- LTMR TesysDocument40 pagesLTMR TesysMizi KoNo ratings yet

- IMS MD20 ES English ManualDocument21 pagesIMS MD20 ES English ManualinfoNo ratings yet

- GA700 Technical ManualDocument936 pagesGA700 Technical ManualTuanson Pham0% (1)

- PLC Training Kit Omron CPM1ADocument1 pagePLC Training Kit Omron CPM1Alaihingkok9071No ratings yet

- FX3S, FX3G (C), FX3U (C) - User's Manual (Modbus Serial Communication Edition) JY997D26201-G (04.15)Document128 pagesFX3S, FX3G (C), FX3U (C) - User's Manual (Modbus Serial Communication Edition) JY997D26201-G (04.15)Sampath Weerakkodi67% (3)

- Invent CHE 100Document135 pagesInvent CHE 100williamtroya50% (2)

- OMRON PLC TrainingDocument169 pagesOMRON PLC TrainingBehnam Rezaei100% (10)

- Ac500 PLCDocument22 pagesAc500 PLCAnoop Kumar Panday100% (1)

- Wonderware InduSoft Web Studio 8.0 TrainDocument289 pagesWonderware InduSoft Web Studio 8.0 TrainDefinal ChaniagoNo ratings yet

- 5500213X - 1 - ENG - 2001-06 - Woywod - Motor Control Board - PC90 - OEMDocument12 pages5500213X - 1 - ENG - 2001-06 - Woywod - Motor Control Board - PC90 - OEMzineb100% (2)

- ABB VFD Fault CodesDocument10 pagesABB VFD Fault Codesnitin hadkeNo ratings yet

- G2P2 CN en 0Document110 pagesG2P2 CN en 0kasper kasperNo ratings yet

- Parametros SimovertDocument196 pagesParametros SimovertFrancisco TorresNo ratings yet

- KGLWin Manual (Unlockplc - Com)Document98 pagesKGLWin Manual (Unlockplc - Com)Unlock PLC67% (3)

- Delta Ia-Plc DVP-20PM PM en 20140212Document580 pagesDelta Ia-Plc DVP-20PM PM en 20140212Nguyen Quang DoanNo ratings yet

- Siemens Tutorial Manuals On PLCDocument17 pagesSiemens Tutorial Manuals On PLCKT MENON100% (1)

- Fault Messages and List of FaultsDocument5 pagesFault Messages and List of FaultsAhmadNo ratings yet

- LED Display Description Cause Possible Solutions OV Over VoltageDocument1 pageLED Display Description Cause Possible Solutions OV Over VoltageJr BasalNo ratings yet

- Vector Drive Troubleshooting GuideDocument9 pagesVector Drive Troubleshooting GuideIsrael Martinez AlonsoNo ratings yet

- Alarm List ME Alarm Codes: Page 15 of 52 Version 01.00 (G4)Document1 pageAlarm List ME Alarm Codes: Page 15 of 52 Version 01.00 (G4)Rafik MessaNo ratings yet

- 1-1cvjgdf Ys840di Errorcode of Alarm 380500-DeuDocument14 pages1-1cvjgdf Ys840di Errorcode of Alarm 380500-DeuNazar AbbasNo ratings yet

- Alarm Codes For Solis 1P - 3PDocument5 pagesAlarm Codes For Solis 1P - 3Pmadantiwari200No ratings yet

- SPS-1500 SPS-1501 TroubleshootingDocument12 pagesSPS-1500 SPS-1501 TroubleshootingJuan Pablo AtenciaNo ratings yet

- ITEM No.: Bay No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument7 pagesITEM No.: Bay No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NosaiNo ratings yet

- Bảng mã lỗi module Fanuc - Cung cấp giải pháp tự động hóaDocument1 pageBảng mã lỗi module Fanuc - Cung cấp giải pháp tự động hóaQuang Nguyễn đứcNo ratings yet

- Troubleshooting-Inverter User ManualDocument4 pagesTroubleshooting-Inverter User Manualqison.yanNo ratings yet

- 15 Power Converter Technologies for Photovoltaic Systems and Energy Storage - คุณณัฐนันท์Document24 pages15 Power Converter Technologies for Photovoltaic Systems and Energy Storage - คุณณัฐนันท์chock channel 19No ratings yet

- Digital Stepper Drive CW250: DescriptionsDocument7 pagesDigital Stepper Drive CW250: DescriptionsDavid MartinezNo ratings yet

- Wiring Table: FAQ ID: 9992646Document1 pageWiring Table: FAQ ID: 9992646karangoyals03No ratings yet

- Teach-In Operation Starts, Green Led Flashes (Approx. 1 HZ) - The Teach-In Operation Is Completed After Approx. 60 S, and The State Led Goes OutDocument1 pageTeach-In Operation Starts, Green Led Flashes (Approx. 1 HZ) - The Teach-In Operation Is Completed After Approx. 60 S, and The State Led Goes Outkarangoyals03No ratings yet

- B03S211 / B03E211 Instrunction Sheet: High Color User-Friendly HMI ProductsDocument1 pageB03S211 / B03E211 Instrunction Sheet: High Color User-Friendly HMI Productskarangoyals030% (1)

- Radix X96P-MANDocument26 pagesRadix X96P-MANkarangoyals0375% (4)

- CAT 126R24-IsoscanDocument4 pagesCAT 126R24-Isoscankarangoyals03No ratings yet

- Atari ST InternalsDocument472 pagesAtari ST InternalsKarlson2009No ratings yet

- Operation Manual UFM V5.04Document166 pagesOperation Manual UFM V5.04Prunel BogdanNo ratings yet

- Ionic 4 SuccinctlyDocument101 pagesIonic 4 SuccinctlyRurik Nicolau JaniszewskiNo ratings yet

- BabbletypeDocument12 pagesBabbletypeZf ZafNo ratings yet

- Fortigate Lab Setup Guide1Document39 pagesFortigate Lab Setup Guide1Net RunnerNo ratings yet

- DoD Instruction 5000.88, Engineering of Defense SystemsDocument31 pagesDoD Instruction 5000.88, Engineering of Defense SystemsAwadh AlharbiNo ratings yet

- Harmonic MediaGrid Linux FSD 4.0.1.2 Release NotesDocument18 pagesHarmonic MediaGrid Linux FSD 4.0.1.2 Release NotesRobertNo ratings yet

- Introducing Otbi Metadata Independent Mode: Oracle Business Intelligence Cloud Connector Release 13.19CDocument8 pagesIntroducing Otbi Metadata Independent Mode: Oracle Business Intelligence Cloud Connector Release 13.19CAmarnath RamarajNo ratings yet

- Bahria University,: Karachi CampusDocument7 pagesBahria University,: Karachi CampusZain RizviNo ratings yet

- Human Computer Interaction Prelim Quizzes Exam and Midterm QuizzesDocument12 pagesHuman Computer Interaction Prelim Quizzes Exam and Midterm QuizzesMark De Guzman100% (1)

- PROG102 Assigment1Document30 pagesPROG102 Assigment1Như PhạmNo ratings yet

- Weigh Feeder Manual (Keh)Document54 pagesWeigh Feeder Manual (Keh)Vaibhav ShrivastavNo ratings yet

- MongoDB DatatypesDocument14 pagesMongoDB DatatypesAshutosh TrivediNo ratings yet

- ACP 2.G Dissasembly and Asembly PICO Pad GGT3 Series Version 1Document17 pagesACP 2.G Dissasembly and Asembly PICO Pad GGT3 Series Version 1darmin azayNo ratings yet

- PHP Coding Sample QuestionDocument63 pagesPHP Coding Sample QuestionAbhinav Raj EJAqXCJLYLNo ratings yet

- Genigraphics Poster Template 48x36Document1 pageGenigraphics Poster Template 48x36Hew LetNo ratings yet

- ABCs of ZOS System Programming Vol 3 RBDocument180 pagesABCs of ZOS System Programming Vol 3 RBGerardo SavinoNo ratings yet

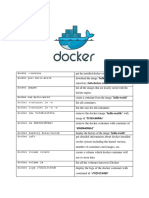

- Basic Docker CommandsDocument3 pagesBasic Docker CommandsManjunath.RNo ratings yet

- Vowifi Activation Steps 260722Document10 pagesVowifi Activation Steps 260722NazriNo ratings yet

- Revisions and Version Control in TRIMDocument3 pagesRevisions and Version Control in TRIMel97639No ratings yet

- Getting Started With Alliedware Plus: Feature Overview and Configuration GuideDocument50 pagesGetting Started With Alliedware Plus: Feature Overview and Configuration GuideSalkovićElvisNo ratings yet

- Table PartitionDocument3 pagesTable Partitionspider14No ratings yet

- Digital Assignment 3: TopicDocument18 pagesDigital Assignment 3: Topicprajari ghoshNo ratings yet

- Unit 4: Microcontrollers (Arduino) Overview Digital I/ODocument60 pagesUnit 4: Microcontrollers (Arduino) Overview Digital I/OAriNetoNo ratings yet

- Guidelines For Applied Machine Learning in Construction Industry-A Case of Profit Estimation PDFDocument17 pagesGuidelines For Applied Machine Learning in Construction Industry-A Case of Profit Estimation PDFDebasish DeyNo ratings yet

- Lockdown Browser and Respondus Monitor: Installation GuideDocument1 pageLockdown Browser and Respondus Monitor: Installation GuideSherwin LingatingNo ratings yet

- OHB SBC DashboardDocument9 pagesOHB SBC DashboardAbdulmejid Abdureuf100% (1)

- Lego Mindstorm ProgrammingDocument7 pagesLego Mindstorm ProgrammingKlare MontefalcoNo ratings yet

- What Is AgileDocument7 pagesWhat Is AgileAhmad meharNo ratings yet

- F08AD-1 Modulo de 8 Entradas Analogicas de CorrienteDocument18 pagesF08AD-1 Modulo de 8 Entradas Analogicas de CorrienteGermán SuchanNo ratings yet