Professional Documents

Culture Documents

B03S211 / B03E211 Instrunction Sheet: High Color User-Friendly HMI Products

Uploaded by

karangoyals03Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B03S211 / B03E211 Instrunction Sheet: High Color User-Friendly HMI Products

Uploaded by

karangoyals03Copyright:

Available Formats

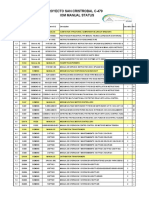

(3) Pin Definition of Serial Communication (5) Dimensions

DOP-B03S211 / DOP-B03E211 COM1 and COM2 Ports DOP-B03S211 / DOP-B03E211

MODE1 MODE2 MODE3 Note:

118.8+1.0 +0.04"

0 (4.68" 0 ) T=1.6mm(0.063")~6mm(0.24")

COM Port PIN COM1 COM2 COM1 COM2 COM1 COM2

DOP-B03

29.5(1.16")

RS-232 RS-485 RS-485 RS-485 RS-232 RS-422

)

High Color T

+0.04"

1 D+ TXD+

0 (3.65" 0

129(5.08")

User-Friendly HMI Products PIN1

2

3

RXD

TXD

RXD

TXD

92.8+1.0

4 D+ D+ RXD+

B03S211 / B03E211 5

6

GND

D-

GND GND

TXD-

91(3.58")

7 RTS

Instrunction Sheet

103(4.06")

8 CTS

9 D- D- RXD-

(1) Preface Note1: Blank = No Connection.

Thank you for purchasing DELTA’s DOP-B series. This instruction sheet will be helpful in the installation, wiring and

inspection of Delta HMI. Before using the product, please read this instruction sheet to ensure correct use. You should (4) Parts Names

thoroughly understand all safety precautions before proceeding with the installation, wiring and operation. Place this

instruction sheet in a safe location for future reference. Please observe the following precautions: DOP-B03S211 / DOP-B03E211 (Front View)

Install the product in a clean and dry location free from corrosive and inflammable gases or liquids.

(6) Specifications

Ensure that all wiring instructions and recommendations are followed. MODEL DOP-B03S211 DOP-B03E211

Ensure that HMI is correctly connected to a ground. The grounding method must comply with the electrical

standard of the country (Please refer to NFPA 70: National Electrical Code, 2005 Ed.). Display Type 4.3" TFT LCD (65536 colors )

LCD MODULE

Do not disassemble HMI, modify or remove wiring when power is applied to HMI. Resolution 480 x 272 pixels

Do not touch the power supply during operation. Otherwise, it may cause electric shock.

o (Note 1)

If you have any questions during operation, please contact our local distributors or Delta sales representatives. Backlight LED Back Light (less than 20,000 hours half-life at 25 C)

The content of this instruction sheet may be revised without prior notice. Please consult our distributors or download the

Display Size 95.04 x 53.856mm

most updated version at http://www.delta.com.tw/ia.

B Operation System Delta Real Time OS

(2) Safety Precautions

A MCU 32-bit RISC Micro-controller

Carefully note and observe the following safety precautions when receiving, inspecting, installing, operating, maintaining

and troubleshooting. The following words, DANGER, WARNING and STOP are used to mark safety precautions when Flash ROM 128 MB

NOR Flash ROM

using the Delta’s HMI product. Failure to observe these precautions may void the warranty! (OS System: 30MB / Backup: 16MB / User Application: 82MB)

Installation SDRAM 64Mbytes

Comply with quick start for installation. Otherwise it may cause equipment damage.

Backup Memory 32Kbytes

Do not install the product in a location that is outside the stated specification for the HMI. Failure to

observe this caution may result in electric shock, fire, or explosion.

Do not install the product in a location where temperatures will exceed specification for the HMI. Buzzer Multi-Tone Frequency (2K ~ 4K Hz) / 85dB

A Touch Screen / Display

Failure to observe this caution may result in abnormal operation or damage the product.

Please note that this equipment has obtained EMC registration for commercial use. In the event that it 1 USB Slave Ver 2.0

B Power LED Indicator ( ) Note: Lights in green when HMI works normally. USB

has been mistakenly sold or purchased, please exchange it for equipment certified for home use. 1 USB Host Ver 1.1

Do not use this product as an alarm device for disaster early warning that may result in personal injury,

equipment damage, or system emergency stop. Serial COM1 RS-232(supports hardware flow control) / RS-485

DOP-B03S211 (Rear View)

Wiring COM

Port COM2 RS-422/RS-485

Connect the ground terminals to a class-3 ground (Ground resistance should not exceed 100

Improper grounding may result in communication error, electric shock or fire. Ethernet Interface N/A 10M/100M

Operation Perpetual Calendar Built-in

The users should use Delta Screen Editor software to perform editing in Delta's HMI product. To D Cooling Method Natural air circulation

perform editing and confirming HMI programs without using Delta Screen Editor software in Delta's

HMI product may result in abnormal operation. Safety Approval CE / UL (Note 3)

To prevent the personal injury and equipment damage, when designing HMI programs, please ensure

that a communication error occurred between Delta’s HMI product and the connecting controller or A Waterproof Degree IP65 / NEMA4 (Note 3)

equipment will not result in system failure or malfunction.

Operation Voltage

Please be sure to backup the screen data and HMI programs in case they are lost, accidentally (Note2) DC +24V (-10% ~ +15%) (please use isolated power supply)

deleted or worse.

E AC500V for 1 minute (between charging (DC24V terminal)

B Voltage Endurance

Do not modify wiring during operation. Otherwise it may result in electric shock or personal injury. and FG terminals)

Never use a hard or pointed object to hit or strike the screen as doing this may damage the screen and Power

(Note 2) 4.8W 7.2W

let the screen has not respond at all, and then cause HMI to work abnormally. Consumption

C

Maintenance and Inspection Backup Battery 3V lithium battery CR2032 x 1

Do not touch any internal or exposed parts of the HMI as electrical shock may result. It depends on the temperature used and the conditions of usage,

A System Key B USB Host C USB Slave Backup Battery Life o

Do not remove operation panel while power is on. Otherwise electrical shock may result. about 3 years or more at 25 C.

Wait at least 10 minutes after power has been removed before touching any HMI terminals or Operation o o

performing any wiring and/or inspection as an electrical charge may still remain in the HMI with D Power Input Terminal E COM1 0 C ~ 50 C

Temperature

hazardous voltages even after power has been removed.

Storage o o

Turn the power off before changing backup battery and check system settings after finishing change. DOP-B03E211 (Rear View) -20 C ~ +60 C

Temperature

(all data will be cleared after changing battery).

o o

Be sure the ventilation holes are not obstructed during operation. Otherwise malfunction may result Ambient Humidity 10% ~ 90% RH [0 ~ 40 C], 10% ~ 55% RH [41 ~ 50 C], Pollution Degree 2

due to bad ventilation or overheating troubles.

IEC 61131-2 compliant 5Hz f 8.3Hz = Continuous: 3.5mm, 8.3Hz f 150Hz = Continuous:

Wiring Method Vibration

1.0g

Do not use a voltage that will exceed specification for the HMI. Failure to observe this caution may

result in electric shock or fire. E Shock IEC 60068-2-27 compliant 15g peak for 11 ms duration, X, Y, Z directions for 6 times

Remove the terminal block from the HMI before wiring. A Dimensions

Insert only one wire into one terminal on the terminal block. 129 x103 x 39

(W) x (H) x (D) mm

If the wiring is in error, perform the wiring again with proper tools. Never use force to remove the

terminals or wires. Otherwise, it may result in malfunction or damage. Panel Cutout

118.8 x 92.8

For the power line that forced to take out, ensure to check wiring again and restart. (W) x (H) mm

B

Communication Wiring Weight Approx. 230g Approx. 264g

Comply with communication wiring specification for wiring. F

Wiring length should comply with the stated specification for the HMI. C

Proper grounding to avoid bad communication quality. NOTE

To avoid noise and interference, the communication cable, all power cables, and motor power cable

1) The half-life of backlight is defined as original luminance being reduced by 50% when the maximum driving current is supplied

should be placed in separate conduits. o

D to HMI. The life of LED backlight shown here is an estimated value under 25 C normal temperature and humidity conditions.

2) The value of the power consumption indicates the electrical power consumed by HMI only without connecting to any

peripheral devices. In order to ensure the normal operation, it is recommended to use a power supply which the capacity is 1.5

A Ethernet Interface (LAN) B System Key C USB Host ~2 times the value of the power consumption.

3) Some models are in the process of application to certification. For more information, please consult our distributors.

D USB Slave E Power Input Terminal F COM 1 4) The content of this instruction sheet may be revised without prior notice. Please consult our distributors or download the most

updated version at http://www.delta.com.tw/ia/.

You might also like

- Kuper ManualDocument335 pagesKuper Manualdonkey slap100% (1)

- VisioChrom UK 2 90my 037Document132 pagesVisioChrom UK 2 90my 037clizas100% (1)

- Arburg Allrounder 375v TD 680185 en GBDocument10 pagesArburg Allrounder 375v TD 680185 en GBAleksandar MarkovicNo ratings yet

- Bruxism Hypnosis Script No. 2Document12 pagesBruxism Hypnosis Script No. 2Eva Jacinto100% (2)

- NURS 366 Exam 1 Study Guide and RubricDocument7 pagesNURS 366 Exam 1 Study Guide and RubriccmpNo ratings yet

- Mixer Matrix m4 - EnglishDocument4 pagesMixer Matrix m4 - EnglishCengiz Bay100% (2)

- Traction Die Cutting BG 07Document41 pagesTraction Die Cutting BG 07DeniMestiWidiantoNo ratings yet

- Compression Molding Machine PriceDocument13 pagesCompression Molding Machine PriceSalma FarooqNo ratings yet

- Coating Supply Machine PDFDocument26 pagesCoating Supply Machine PDFDeniMestiWidianto100% (1)

- Feedback Linearization, Sliding Mode and Swing Up Control For The Inverted Pendulum On A CartDocument71 pagesFeedback Linearization, Sliding Mode and Swing Up Control For The Inverted Pendulum On A CartAmba James AsukNo ratings yet

- Smigroup enDocument30 pagesSmigroup enSNNo ratings yet

- Drymax E60 EN V1 6Document53 pagesDrymax E60 EN V1 6PedroGomes2No ratings yet

- Class 11 Class Biology Syllabus 2011-12Document5 pagesClass 11 Class Biology Syllabus 2011-12Sunaina RawatNo ratings yet

- نافخهDocument136 pagesنافخهmohamedNo ratings yet

- Information On The Safe Operation of Starlinger MachinesDocument29 pagesInformation On The Safe Operation of Starlinger MachinesThaigroup CementNo ratings yet

- Technical Description: 4XP1640.00-K01/K02 & 4XP0000.00-K01Document30 pagesTechnical Description: 4XP1640.00-K01/K02 & 4XP0000.00-K01Justo Alberto Guerra Inca100% (1)

- Tai Mex by Tederic D SeriesDocument13 pagesTai Mex by Tederic D SeriesPHYONEGRIPNo ratings yet

- A02-Injection Machine Robot Control System Operation Manual V1.14Document133 pagesA02-Injection Machine Robot Control System Operation Manual V1.14jagoklurukNo ratings yet

- DBE-04499Deng - DisplayDocument163 pagesDBE-04499Deng - DisplayThaigroup CementNo ratings yet

- Operating Instructions: MCD 3000 Soft StarterDocument44 pagesOperating Instructions: MCD 3000 Soft StarterDragoslav DzolicNo ratings yet

- Dbe 04567aengDocument111 pagesDbe 04567aengElectronic RampolytexNo ratings yet

- Contoh User ManualDocument74 pagesContoh User Manualaziz abdulNo ratings yet

- Sheet Refurbishment Command Shaft UPM UDocument5 pagesSheet Refurbishment Command Shaft UPM UЛюбить ЕннеттNo ratings yet

- Manual Secador Mdcw50Document115 pagesManual Secador Mdcw50daniel menaNo ratings yet

- SIDEL02Document80 pagesSIDEL02Anthony JohanNo ratings yet

- Drymax E Battery en V1 4Document59 pagesDrymax E Battery en V1 4bschmaltzy1No ratings yet

- Manual SewDocument168 pagesManual SewKaik Marques100% (1)

- Linea - Rev 1.0 2014039-40-41-42 LIDERSAN - ENDocument366 pagesLinea - Rev 1.0 2014039-40-41-42 LIDERSAN - ENasgeemNo ratings yet

- Battenfeld - Blown Film 2003Document12 pagesBattenfeld - Blown Film 2003J Díaz SalaverríaNo ratings yet

- Master04eng P5802P0010Document360 pagesMaster04eng P5802P0010Ком. ОтделNo ratings yet

- Operating Manual: Farragtech GMBHDocument57 pagesOperating Manual: Farragtech GMBHzakariiNo ratings yet

- Fundamentals of Electric CircuitsDocument7 pagesFundamentals of Electric CircuitsHiếu DươngNo ratings yet

- Ai 11Document141 pagesAi 11Juan100% (1)

- Regloplas RT50 Controller Manual PDFDocument28 pagesRegloplas RT50 Controller Manual PDFalso strong and durableNo ratings yet

- NC 5 Prezentare EngDocument33 pagesNC 5 Prezentare EngSolomon Bogdan-DanielNo ratings yet

- Castflex EngDocument12 pagesCastflex EngJuanNo ratings yet

- Engineering Data Sheet: Total Air System (TAS)Document2 pagesEngineering Data Sheet: Total Air System (TAS)Marco ChablaNo ratings yet

- Iq Weight Control en PDFDocument31 pagesIq Weight Control en PDFMarius VaidaNo ratings yet

- VIVA Software For Flying Probe Systems MA-VI-VIVASWEN-02Document198 pagesVIVA Software For Flying Probe Systems MA-VI-VIVASWEN-02Army AnguianoNo ratings yet

- Sacmi - Beverage Plastic Cap Market TrendsDocument64 pagesSacmi - Beverage Plastic Cap Market TrendsVarun CNo ratings yet

- Micro Injection Molding Machine-ANN TONG INDUSTRIAL CODocument4 pagesMicro Injection Molding Machine-ANN TONG INDUSTRIAL COAndreas AlvaroNo ratings yet

- Dbe 04568bengDocument74 pagesDbe 04568bengElectronic RampolytexNo ratings yet

- Universal-XR60CX: The All in One ControlDocument2 pagesUniversal-XR60CX: The All in One ControlMostafa ShannaNo ratings yet

- Chapter 2 Material Selection ProcessDocument38 pagesChapter 2 Material Selection ProcessYousab CreatorNo ratings yet

- Krauss Maffei 200tonDocument1 pageKrauss Maffei 200tonLarbi BelazizNo ratings yet

- Angle Valve and Tap Assembly and Leak Test MachineDocument7 pagesAngle Valve and Tap Assembly and Leak Test MachineJimmy KingNo ratings yet

- Granulator KnivesDocument10 pagesGranulator Knivesmgk80No ratings yet

- Cy 600 800gii PDFDocument92 pagesCy 600 800gii PDFArmando Rivera100% (1)

- Haitian Plastics Machinery Group CO., LTD.: Spare PartsDocument529 pagesHaitian Plastics Machinery Group CO., LTD.: Spare PartshaisamnagyNo ratings yet

- 5092@feedmax BS6@ENDocument40 pages5092@feedmax BS6@ENALFONSO TORRESNo ratings yet

- Toni Expert Operating Instructions Structural Shape 6215: Building Materials TestingDocument42 pagesToni Expert Operating Instructions Structural Shape 6215: Building Materials TestingDC2 KCSNo ratings yet

- InkDocument2 pagesInkghani ibnuNo ratings yet

- Catalogo Valvulas YukenDocument124 pagesCatalogo Valvulas YukenLuis Alberto RamosNo ratings yet

- Sidel Matriz Parte 2Document250 pagesSidel Matriz Parte 2Fernando RosaNo ratings yet

- SomatecDocument123 pagesSomatecAdi kurniantoNo ratings yet

- TSTA User ManualDocument218 pagesTSTA User ManualHieu NguyenNo ratings yet

- VJA 3330 3130 Lesson 2 System OverviewDocument72 pagesVJA 3330 3130 Lesson 2 System Overviewjohn smith100% (1)

- Fundamentals of The Ultrasonic Plastics Welding-KlinsteinDocument196 pagesFundamentals of The Ultrasonic Plastics Welding-KlinsteinAlba R.No ratings yet

- Pxa255 q7 EngDocument106 pagesPxa255 q7 Engqweeerty123100% (1)

- Dop B03Document1 pageDop B03eduardo mata gamezNo ratings yet

- Rapter & Conc. Box Gutter Detail: Proposed Fence and Extension PlanDocument1 pageRapter & Conc. Box Gutter Detail: Proposed Fence and Extension PlanCresdenn FuentesNo ratings yet

- Mainboard 694asDocument20 pagesMainboard 694asHo Thanh BinhNo ratings yet

- Wiring Table: FAQ ID: 9992646Document1 pageWiring Table: FAQ ID: 9992646karangoyals03No ratings yet

- RS 485 Repeater ManualDocument46 pagesRS 485 Repeater ManualViveha AnandhanNo ratings yet

- Teach-In Operation Starts, Green Led Flashes (Approx. 1 HZ) - The Teach-In Operation Is Completed After Approx. 60 S, and The State Led Goes OutDocument1 pageTeach-In Operation Starts, Green Led Flashes (Approx. 1 HZ) - The Teach-In Operation Is Completed After Approx. 60 S, and The State Led Goes Outkarangoyals03No ratings yet

- CP342 eDocument72 pagesCP342 eaxefecNo ratings yet

- ATV31 Programming Manual en 1624589 04Document84 pagesATV31 Programming Manual en 1624589 04dj_nerminNo ratings yet

- SEW Drive Error List PDFDocument15 pagesSEW Drive Error List PDFkarangoyals03100% (3)

- SEW Drive Error List PDFDocument15 pagesSEW Drive Error List PDFkarangoyals03100% (3)

- E5CC E5EC Users Manual PDFDocument336 pagesE5CC E5EC Users Manual PDFJorgeErnestoCartagenaNo ratings yet

- SEW Drive Error List PDFDocument15 pagesSEW Drive Error List PDFkarangoyals03100% (3)

- Radix X96P-MANDocument26 pagesRadix X96P-MANkarangoyals0375% (4)

- d1040 HoneywellDocument32 pagesd1040 Honeywellduybac-spkhcmNo ratings yet

- CAT 126R24-IsoscanDocument4 pagesCAT 126R24-Isoscankarangoyals03No ratings yet

- Delta B Drive Short Manual PDFDocument32 pagesDelta B Drive Short Manual PDFAshok SahuNo ratings yet

- The Nation State and Global Order A Historical Introduction To ContemporaryDocument195 pagesThe Nation State and Global Order A Historical Introduction To Contemporaryrizwan.mughal1997100% (1)

- Network Monitoring & Forensics: Jim IrvingDocument102 pagesNetwork Monitoring & Forensics: Jim IrvingKarel GoldmannNo ratings yet

- Introduction To Communication Systems: James Flynn Sharlene KatzDocument15 pagesIntroduction To Communication Systems: James Flynn Sharlene KatzAnisari MeiNo ratings yet

- MTE Radionuclear THYROID FK UnandDocument44 pagesMTE Radionuclear THYROID FK UnandAmriyani OFFICIALNo ratings yet

- Jeoparty Fraud Week 2022 EditableDocument65 pagesJeoparty Fraud Week 2022 EditableRhea SimoneNo ratings yet

- Proyecto San Cristrobal C-479 Iom Manual StatusDocument18 pagesProyecto San Cristrobal C-479 Iom Manual StatusAllen Marcelo Ballesteros LópezNo ratings yet

- Post Employee Benefit Psak 24 (Guide)Document21 pagesPost Employee Benefit Psak 24 (Guide)AlvianNo ratings yet

- Independence of Costa RicaDocument2 pagesIndependence of Costa Ricaangelica ruizNo ratings yet

- CHP 11: Setting Goals and Managing The Sales Force's PerformanceDocument2 pagesCHP 11: Setting Goals and Managing The Sales Force's PerformanceHEM BANSALNo ratings yet

- R. K. NarayanDocument9 pagesR. K. NarayanCutypie Dipali SinghNo ratings yet

- Franieboy Ponce, BSIT-1, - DAY 2 ACTIVITYDocument2 pagesFranieboy Ponce, BSIT-1, - DAY 2 ACTIVITYFrancisco PonceNo ratings yet

- Ficha Álvaro y Jesús 3Document8 pagesFicha Álvaro y Jesús 3Alex8mRNo ratings yet

- Jao Vs Court of Appeals G.R. No. 128314 May 29, 2002Document3 pagesJao Vs Court of Appeals G.R. No. 128314 May 29, 2002Ma Gabriellen Quijada-TabuñagNo ratings yet

- High-Performance Cutting and Grinding Technology For CFRP (Carbon Fiber Reinforced Plastic)Document7 pagesHigh-Performance Cutting and Grinding Technology For CFRP (Carbon Fiber Reinforced Plastic)Dongxi LvNo ratings yet

- Chronology of Events:: Account: North Davao Mining Corp (NDMC)Document2 pagesChronology of Events:: Account: North Davao Mining Corp (NDMC)John Robert BautistaNo ratings yet

- Bekic (Ed) - Submerged Heritage 6 Web Final PDFDocument76 pagesBekic (Ed) - Submerged Heritage 6 Web Final PDFutvrdaNo ratings yet

- Profix SS: Product InformationDocument4 pagesProfix SS: Product InformationRiyanNo ratings yet

- Chapter 8 Supplier Quality ManagementDocument71 pagesChapter 8 Supplier Quality ManagementAnh NguyenNo ratings yet

- How A Type 4 Multiverse WorksDocument4 pagesHow A Type 4 Multiverse WorksIdkNo ratings yet

- AP Online Quiz KEY Chapter 8: Estimating With ConfidenceDocument6 pagesAP Online Quiz KEY Chapter 8: Estimating With ConfidenceSaleha IftikharNo ratings yet

- StrategiesDocument7 pagesStrategiesEdmar PaguiriganNo ratings yet

- Literature StudyDocument20 pagesLiterature StudyAnn NambiaparambilNo ratings yet

- Campos V BPI (Civil Procedure)Document2 pagesCampos V BPI (Civil Procedure)AngeliNo ratings yet

- John Wick 4 HD Free r6hjDocument16 pagesJohn Wick 4 HD Free r6hjafdal mahendraNo ratings yet

- Women in IslamDocument22 pagesWomen in Islamsayed Tamir janNo ratings yet

- Deutz Common RailDocument20 pagesDeutz Common RailAminadav100% (3)

- PFASDocument8 pagesPFAS王子瑜No ratings yet