Professional Documents

Culture Documents

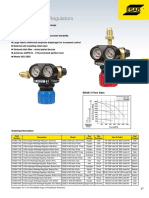

R73G, R73R: Technical Data

Uploaded by

Enrique Arellano HidalgoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R73G, R73R: Technical Data

Uploaded by

Enrique Arellano HidalgoCopyright:

Available Formats

Back to Selector Page

R73G, R73R

EXCELON® 73

Pressure Regulator

1/4" 3/8", 1/2" Port Sizes

● EXCELON design allows in-line or modular

installation

● Full flow gauge ports

● Balanced valve design minimizes effect of variation

in the inlet pressure on the outlet pressure

● Standard relieving models allow reduction of

downstream pressure when the system is

dead-ended

● Optional reverse flow models available for use

downstream of directional control valves

● Modular installations with EXCELON 72, 73, and 74

series can be made to suit particular applications

Technical Data Ordering Information

Fluid: Compressed air See Ordering Information on the following

Maximum pressure: 20 bar (300 psig) pages.

Operating temperature*: -20° to +80°C (0° to +175°F)

*Air supply must be dry enough to avoid ice formation at temperatures below +2°C

(+35°F).

Typical flow with 10 bar (150 psig) inlet pressure, 6,3 bar (90 psig)

set pressure and 1 bar (15 psig) droop from from set: 60 dm3/s

(127 scfm)

Gauge ports: ISO Symbols

1⁄4 PTF with PTF main ports

Rc1/4 with ISO Rc main ports

Rc1/8 with ISO G main ports

Materials:

Body: Aluminum

Bonnet : Aluminum

Valve: Brass

Relieving Non relieving

Elastomers: Nitrile

Bottom plug: Acetal

Our policy is one of continuous research and development.

4/98 We reserve the right to amend, without notice, the specifications given in this document.

N/AL.8.180.200.01

R73G, R73R

Typical Performance Characteristics

FLOW CHARACTERISTICS FLOW CHARACTERISTICS

psig

bar

bar

PORT SIZE: 3/8"

psig

PORT SIZE: 3/8"

INLET PRESSURE: 10 bar (150 psig) INLET PRESSURE: 7 bar (100 psig)

RANGE: 0,3 to 10 bar (5 to 150 psig) RANGE: 0,3 to 10 bar (5 to 150 psig)

100 100

OUTLET PRESSURE

OUTLET PRESSURE

6 6

80 80

60 60 4

4

40 40

2 2

20 20

0 0 0 0

0 20 40 60 80 100 dm3/s 0 10 20 30 40 50 dm3/s

0 40 80 120 160 200 scfm 0 20 40 60 80 100 scfm

AIR FLOW AIR FLOW

Ordering Information. Models listed include uni-directional flow, ISO G parallel threads, knob adjustment, relieving

diaphragm, and 0,3 to 10 bar (5 to 150 psig) outlet pressure adjustment range*.

Port Size Model Flow† dm3/s (scfm) Weight kg (lb)

G1/4 R73G-2GK-RMN Waiting on lab test 0,48 (1.1)

G3/8 R73G-3GK-RMN 60 (127) 0,48 (1.1)

G1/2 R73G-4GK-RMN 60 (127) 0,48 (1.1)

† Typical flow with 10 bar (150 psig) inlet pressure, 6,3 bar (90 psig) set pressure and 1 bar (15 psig) droop from set.

Alternative Models R 7 3 ★ - ★ ★ ★ - ★★ ★

Flow Type Substitute Gauge Substitute

Uni-directional G With G

Reverse R Without N

Port Size Substitute Outlet Pressure Adjustment Range* Substitute

1/4" 2 0,3 to 4 bar (5 to 60 psig) F

3/8" 3 0,3 to 10 bar (5 to 150 psig) M

1/2" 4 0,7 to 17 bar (10 to 250 psig) S

Threads Substitute Diaphragm Substitute

PTF A Relieving R

ISO Rc taper B Non relieving N

ISO G parallel G

Adjustment Substitute

Knob K

T-bar T

* Outlet pressure can be adjusted to pressures in excess of, and less

than, those specified. Do not use these units to control

pressures outside of the specified ranges.

Accessories

Neck Mounting Bracket Tamper Resistant Cover R1/4 R1/8 1/4 PTF

Wall Mounting Bracket With Zinc Panel Nut and Seal Wire†† Pressure Gauge Connection Connection Connection

4424-50 Bracket and nut: 5203-06 Cover and wire: 4455-51 4 bar (60 psig): 18-013-266 18-013-011 18-013-208

Nut: 5191-88 Replacement seal wire: 2117-01 10 bar (150 psig): 18-013-260 18-013-013 18-013-209

20 bar (300 psig): 18-013-267 18-013-014 18-013-210

†† Use padlock with shackle up to 8 mm (0.3" ) in diameter.

Our policy is one of continuous research and development. 4/98

N/AL.8.180.200.02 We reserve the right to amend, without notice, the specifications given in this document.

R73G, R73R

Dimensions mm (inches) 68 (2.68)

31 (1.22)

Panel mounting hole diameter: 48 mm (1.89" )

Panel thickness: 2 to 6 mm (0.06" to 0.25" )

62 (2.45)

56 (2.20)

50 (2.00)

39 (1.54)

(1.22)

31

96 (3.80)

103 (4.04)

Bracket Mounting 12 (0.45)

Bracket Kit Reference

Universal Wall Bracket for 73 Series Products Model Part No.

Use 6mm (1/4" ) screws to mount bracket to wall. All 73 Series products 4424-50

R73, B73 neck mounting bracket with zinc panel nut 5203-06

60 (2.37)

38 (1.50)

67 (2.64)

Port CL

28

(1.10) 18

(0.71)

4 (0.16)

6 (0.24)

48 (1.89)

61 (2.40)

7 (0.28)

Port CL

19 (0.74)

Neck Mounting Bracket for R73 and B73

Includes zinc panel nut. Use 6mm (1/4" ) screws to mount bracket to wall.

64 (2.5)

38 (1.5)

70 (2.75)

38

(1.5)

17 (0.66)

38 (1.5)

(1.0)

7 (0.27)

25

Service Kits

Item Type Part Number

Service kit Relieving 4381-600

Non-relieving 4381-601

Service kit includes diaphragm assembly, valve assembly, valve

spring, bottom plug o-ring.

Our policy is one of continuous research and development.

4/98 We reserve the right to amend, without notice, the specifications given in this document.

N/AL.8.180.200.03

R73G, R73R

Warning

These products are intended for use in industrial compressed air

systems only. Do not use these products where pressures and temperatures

can exceed those listed under ‘Technical Data’.

Before using these products with fluids other than those specified, for

non-industrial applications, life-support systems, or other applications not

within published specifications, consult Norgren.

Through misuse, age, or malfunction, components used in fluid power

systems can fail in various modes. The system designer is warned to

consider the failure modes of all component parts used in fluid power

systems and to provide adequate safeguards to prevent personal injury or

damage to equipment in the event of such failure.

System designers must provide a warning to end users in the

system instructional manual if protection against a failure mode cannot

be adequately provided.

System designers and end users are cautioned to review specific

warnings found in instruction sheets packed and shipped with these

products.

Our policy is one of continuous research and development. 4/98

N/AL.8.180.200.04 We reserve the right to amend, without notice, the specifications given in this document.

You might also like

- High Voltage OperatingDocument21 pagesHigh Voltage OperatingOsman AhmedNo ratings yet

- Catalogo Trox PDFDocument500 pagesCatalogo Trox PDFBenjamín AlainNo ratings yet

- B73 G - Air Filter RegulatorDocument4 pagesB73 G - Air Filter RegulatorkamatamoghNo ratings yet

- 850 860 870 SpecDocument2 pages850 860 870 SpecJerNo ratings yet

- Data Sheet 15-63-3-A - eDocument9 pagesData Sheet 15-63-3-A - eMarko PalekaNo ratings yet

- Norgren Excelon® Modular Series Ultraire Oil Vapour Removal 74Document4 pagesNorgren Excelon® Modular Series Ultraire Oil Vapour Removal 74Iswar Rauf Aboo 'AqilahNo ratings yet

- SPUSF73G3AS005Document4 pagesSPUSF73G3AS005Ezequiel 1No ratings yet

- Technical Data: Air Supply Must Be Dry Enough To Avoid Ice Formation at Temperatures Below +2 C (+35 F)Document4 pagesTechnical Data: Air Supply Must Be Dry Enough To Avoid Ice Formation at Temperatures Below +2 C (+35 F)Enrique Arellano HidalgoNo ratings yet

- S20 Metallic Pump: Technical Data SheetDocument3 pagesS20 Metallic Pump: Technical Data SheetDang LucNo ratings yet

- CR-2000 DS-8690Document2 pagesCR-2000 DS-8690Juan JuanNo ratings yet

- Catalog 3900 - F Series Flow Control ValvesDocument3 pagesCatalog 3900 - F Series Flow Control ValvesRogelio ArandaNo ratings yet

- Belgas p39Document4 pagesBelgas p39Syach FirmNo ratings yet

- Sandpiper Standard Duty Metallic Pumps s30 Data SheetDocument3 pagesSandpiper Standard Duty Metallic Pumps s30 Data Sheetjose manuel alvarez rodriguezNo ratings yet

- ODF Catalogue Edition 6 Gear PumpsDocument16 pagesODF Catalogue Edition 6 Gear PumpsMathan Selva Kumar ANo ratings yet

- Technical Specifications: CV / CL Series FiltersDocument2 pagesTechnical Specifications: CV / CL Series FiltersEmanuel MurilloNo ratings yet

- Miniature Series 07 General Purpose RegulatorDocument4 pagesMiniature Series 07 General Purpose RegulatorarunbiswalNo ratings yet

- Light Dripline With Continuous Labyrinth With Inlet Continuous Double FilterDocument2 pagesLight Dripline With Continuous Labyrinth With Inlet Continuous Double FilterDaniel Alejandro GuerreroNo ratings yet

- 400 Series Regulators for High Flow PurgingDocument3 pages400 Series Regulators for High Flow PurgingmiguesobeNo ratings yet

- SPD210GBDocument2 pagesSPD210GBVenustiano MirandaNo ratings yet

- Rollit 15 P Techno Metric PDFDocument2 pagesRollit 15 P Techno Metric PDFWilmerNo ratings yet

- Bermad: High Pressure, Pressure Reducing ValveDocument4 pagesBermad: High Pressure, Pressure Reducing ValveviqibagasNo ratings yet

- ABF SeriesDocument7 pagesABF SeriesKAVITANo ratings yet

- 12 Boosters LBDocument2 pages12 Boosters LBMauricio Andrés MontenegroNo ratings yet

- Type 1227 High Flow Gas Pressure RegulatorDocument4 pagesType 1227 High Flow Gas Pressure RegulatorgffNo ratings yet

- AHLSTAR End-Suction Single-Stage Centrifugal PumpsDocument24 pagesAHLSTAR End-Suction Single-Stage Centrifugal PumpsDoanh VoNo ratings yet

- m9050 Pioneer Pump Surface Pumps BrochureDocument12 pagesm9050 Pioneer Pump Surface Pumps BrochurecaomandanteNo ratings yet

- 3400 Series Accumulator Tank: Genneral Installation InstructionsDocument2 pages3400 Series Accumulator Tank: Genneral Installation InstructionsmusebladeNo ratings yet

- Valves Brochure2019 PDFDocument50 pagesValves Brochure2019 PDFscibduser001No ratings yet

- Check Valves 50 Series (MS-01-98) R4Document2 pagesCheck Valves 50 Series (MS-01-98) R4herysyam1980No ratings yet

- Lubrication Equipment (Protected-2)Document12 pagesLubrication Equipment (Protected-2)Eko MardiyantoNo ratings yet

- Scanjet Datasheet Bio7SBDocument2 pagesScanjet Datasheet Bio7SBGabriel TravassosNo ratings yet

- ITAP SpA's Technical Catalogue for Automatic Air-Vent ValvesDocument14 pagesITAP SpA's Technical Catalogue for Automatic Air-Vent ValvesCarlos EspNo ratings yet

- Liberty Series Progressive Cavity Curve 1LL8Document1 pageLiberty Series Progressive Cavity Curve 1LL8karthikNo ratings yet

- Smart Mag™ Non Rotating String Magnet BlackDocument4 pagesSmart Mag™ Non Rotating String Magnet BlackAjith MohandasNo ratings yet

- Segment Distributor PSG 2 DSK0-003-02 - UsDocument24 pagesSegment Distributor PSG 2 DSK0-003-02 - UsCristianNo ratings yet

- BAP 01 T A pumps for high pressure truck applicationsDocument4 pagesBAP 01 T A pumps for high pressure truck applicationsyoberNo ratings yet

- Fixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsDocument4 pagesFixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsДаниил СторчеусNo ratings yet

- Bap 01 T B PDFDocument4 pagesBap 01 T B PDFyoberNo ratings yet

- BAP 01 T A pumps for high pressure truck applicationsDocument4 pagesBAP 01 T A pumps for high pressure truck applicationsДаниил СторчеусNo ratings yet

- CX SeriesDocument2 pagesCX Seriesaaron mufukNo ratings yet

- Regulador Fisher, 67chDocument4 pagesRegulador Fisher, 67chjrNo ratings yet

- Sandpiper s30nmdl2dsDocument4 pagesSandpiper s30nmdl2dsYongfeng QianNo ratings yet

- ACTAIR 3 To 200 Selection ChartDocument12 pagesACTAIR 3 To 200 Selection Chartedark2009No ratings yet

- Walvoil Fliud PowerDocument112 pagesWalvoil Fliud PowerVipulNo ratings yet

- Thermal Dynamics Cutmaster A-Series Bro - (63-2809) - August2013 PDFDocument6 pagesThermal Dynamics Cutmaster A-Series Bro - (63-2809) - August2013 PDFestfania23No ratings yet

- ESAB ExtractPage25-26cDocument8 pagesESAB ExtractPage25-26cDries VandezandeNo ratings yet

- Sump PumpDocument2 pagesSump PumpRAM SANNo ratings yet

- Aversa DP Cat RO EN PDFDocument16 pagesAversa DP Cat RO EN PDFmatache temelieNo ratings yet

- Aversa DP Cat RO EN PDFDocument16 pagesAversa DP Cat RO EN PDFmatache temelieNo ratings yet

- RF Series: Low Pressure FiltersDocument10 pagesRF Series: Low Pressure FiltersRestu OktapianaNo ratings yet

- Guide To Thread and Connector Working PressuresDocument4 pagesGuide To Thread and Connector Working Pressureskurnia triwijayaNo ratings yet

- Operating Manual for 5/8”-5000psi Double (Single) Ram BOPDocument32 pagesOperating Manual for 5/8”-5000psi Double (Single) Ram BOPKurniadi WibowoNo ratings yet

- TETPOR%20AIR-Rev%203ADocument4 pagesTETPOR%20AIR-Rev%203AbuattugasmetlitNo ratings yet

- S - F, - r250d: DescriptionDocument2 pagesS - F, - r250d: DescriptionEdward Chan AcostaNo ratings yet

- REGO 1784A Specification SheetDocument1 pageREGO 1784A Specification SheetJesús Alejandro Chavez zuazuaNo ratings yet

- Electric Proportional Control for Hydraulic SystemsDocument28 pagesElectric Proportional Control for Hydraulic SystemsIvailo ZapryanovNo ratings yet

- Flow Control Valves Technical Specs and Performance CurvesDocument3 pagesFlow Control Valves Technical Specs and Performance CurvesAlejandraNo ratings yet

- CBF VLP40-38 Prima ValvolaDocument1 pageCBF VLP40-38 Prima ValvolalucaNo ratings yet

- S30 Non-Metallic Containment Duty Pump: Technical Data SheetDocument2 pagesS30 Non-Metallic Containment Duty Pump: Technical Data SheetMuhamad nurul aminNo ratings yet

- Parker 7321B/ 7322B Series Water ValvesDocument24 pagesParker 7321B/ 7322B Series Water ValvesKambiz ZahedNo ratings yet

- 5 09a e Adcamat Apst Automatic Pump Trap dn50 80Document6 pages5 09a e Adcamat Apst Automatic Pump Trap dn50 80Ian B. YtomNo ratings yet

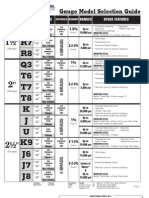

- S R7 R8 Q3 T6 T7 T8 K: Gauge Model Selection GuideDocument4 pagesS R7 R8 Q3 T6 T7 T8 K: Gauge Model Selection GuidetugordoNo ratings yet

- High Flow Hydraulic Controller: Design FeaturesDocument2 pagesHigh Flow Hydraulic Controller: Design FeaturesEnrique Arellano HidalgoNo ratings yet

- Technical Data: Air Supply Must Be Dry Enough To Avoid Ice Formation at Temperatures Below +2 C (+35 F)Document4 pagesTechnical Data: Air Supply Must Be Dry Enough To Avoid Ice Formation at Temperatures Below +2 C (+35 F)Enrique Arellano HidalgoNo ratings yet

- HLR 7965A: Hydraulic Interface ValveDocument2 pagesHLR 7965A: Hydraulic Interface ValveEnrique Arellano HidalgoNo ratings yet

- HLR 7955A: Hydraulic Interface ValveDocument2 pagesHLR 7955A: Hydraulic Interface ValveEnrique Arellano HidalgoNo ratings yet

- .33 HP (.25 KW) M Series Pump Models: Key FeaturesDocument1 page.33 HP (.25 KW) M Series Pump Models: Key FeaturesEnrique Arellano HidalgoNo ratings yet

- HarshEnvironment SeriesA R1 EF8320A512Document2 pagesHarshEnvironment SeriesA R1 EF8320A512Enrique Arellano HidalgoNo ratings yet

- 4in3 - Page 063Document1 page4in3 - Page 063Enrique Arellano HidalgoNo ratings yet

- MC DanielDocument6 pagesMC DanieltugordoNo ratings yet

- Ecd Breather Drain PDFDocument1 pageEcd Breather Drain PDFEnrique Arellano HidalgoNo ratings yet

- 2080 Um002 - en e PDFDocument270 pages2080 Um002 - en e PDFΔημητρηςΣαρακυρουNo ratings yet

- SFP DeltrolDocument1 pageSFP DeltrolRicardo NapitupuluNo ratings yet

- LED Compact System Light - SZ 4140.820: Date: Feb 22, 2019Document4 pagesLED Compact System Light - SZ 4140.820: Date: Feb 22, 2019Enrique Arellano HidalgoNo ratings yet

- DK Lok Tube Fitting June 2015 PDFDocument82 pagesDK Lok Tube Fitting June 2015 PDFLester GuerraNo ratings yet

- HF Charger ManualDocument4 pagesHF Charger ManualEnrique Arellano HidalgoNo ratings yet

- 200 kS/s 16-Bit 16-Channel USB Data Acquisition ModuleDocument1 page200 kS/s 16-Bit 16-Channel USB Data Acquisition ModuleEnrique Arellano HidalgoNo ratings yet

- PCCCV001Document31 pagesPCCCV001Enrique Arellano HidalgoNo ratings yet

- Manual Bomba JockeyDocument36 pagesManual Bomba JockeyEnrique Arellano HidalgoNo ratings yet

- AcculoadDocument47 pagesAcculoadEnrique Arellano HidalgoNo ratings yet

- ISA Applying ISA101 To Existing HMIs - MikeHawrylo PDFDocument34 pagesISA Applying ISA101 To Existing HMIs - MikeHawrylo PDFRubén VélezNo ratings yet

- USB 4716 ManualDocument30 pagesUSB 4716 ManualEnrique Arellano HidalgoNo ratings yet

- Catalogo Eaton - 2015Document20 pagesCatalogo Eaton - 2015Enrique Arellano HidalgoNo ratings yet

- Process Industry Practices Process ControlDocument10 pagesProcess Industry Practices Process ControlEnrique Arellano HidalgoNo ratings yet

- Thesis Proposal TemplateDocument4 pagesThesis Proposal TemplateJane MuliNo ratings yet

- Bre Digest 437Document1 pageBre Digest 437hassan amiriNo ratings yet

- Multi-Technology (3G, 4G) Multi-Carrier Base Station With Integrated Flexible BackhaulDocument2 pagesMulti-Technology (3G, 4G) Multi-Carrier Base Station With Integrated Flexible BackhaulTero TaipaleNo ratings yet

- Div2779 Hyundai 6x4 Rear TipperDocument7 pagesDiv2779 Hyundai 6x4 Rear Tipperedwin ortega medinaNo ratings yet

- SportGrain Plus SpecsDocument3 pagesSportGrain Plus SpecsSamuelVilbrunNo ratings yet

- Donaldson Manual CPVDocument24 pagesDonaldson Manual CPVALFMAN54No ratings yet

- iDirectGov ProdSht 11000 0619Document1 pageiDirectGov ProdSht 11000 0619hasanmuskaanNo ratings yet

- IBOP MaintenanceDocument3 pagesIBOP MaintenanceSasan AbbasiNo ratings yet

- 4th Assignment For Semester 1Document5 pages4th Assignment For Semester 1api-272852708No ratings yet

- Preview NECA+410 2013Document8 pagesPreview NECA+410 2013GILBERTO ALTUNARNo ratings yet

- Fortinet Knowledge Base - How To Install and Configure FortiClient SSLVPN in Linux PDFDocument2 pagesFortinet Knowledge Base - How To Install and Configure FortiClient SSLVPN in Linux PDFRiment AvadiNo ratings yet

- B BNG Cg52xasr9kDocument382 pagesB BNG Cg52xasr9kNb A DungNo ratings yet

- MidTerm CSNB534 Exam Sep10Document2 pagesMidTerm CSNB534 Exam Sep10hzulcefliNo ratings yet

- AlcatelDocument53 pagesAlcatellonesomerider100% (2)

- VMVS2A150GP-RD70 LuminariaDocument8 pagesVMVS2A150GP-RD70 LuminariaivanNo ratings yet

- Maritime QMSDocument0 pagesMaritime QMSdrthuhanNo ratings yet

- Quality ToolDocument7 pagesQuality ToolAhmed M. HashimNo ratings yet

- Et200sp Cpu1510sp 1 PN Manual en-US en-USDocument42 pagesEt200sp Cpu1510sp 1 PN Manual en-US en-USEdin MesinovicNo ratings yet

- Electrical SafetyDocument45 pagesElectrical SafetyAnsarMahmoodNo ratings yet

- Lesson AB27 - Java Lists and IteratorsDocument7 pagesLesson AB27 - Java Lists and IteratorsMatt WashNo ratings yet

- A2LA Policy On Measurement TraceabilityDocument9 pagesA2LA Policy On Measurement Traceabilityjrlr65No ratings yet

- PCNSE6 Exam QuestionsDocument40 pagesPCNSE6 Exam QuestionsEn Red100% (1)

- Error Undefined Offending Command Stack PDFDocument2 pagesError Undefined Offending Command Stack PDFJoel0% (1)

- Isoquant - Meaning and Properties ExplainedDocument12 pagesIsoquant - Meaning and Properties ExplainedrajapatnaNo ratings yet

- TypesDocument6 pagesTypesChudhary JunaidNo ratings yet

- Mike Nelson Resume 2008Document2 pagesMike Nelson Resume 2008api-12184182No ratings yet

- How Do We Get BetterDocument1 pageHow Do We Get BetterHanafi SoesenoNo ratings yet